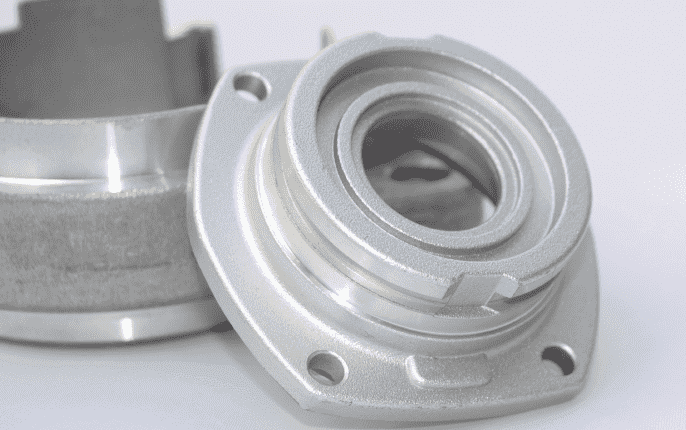

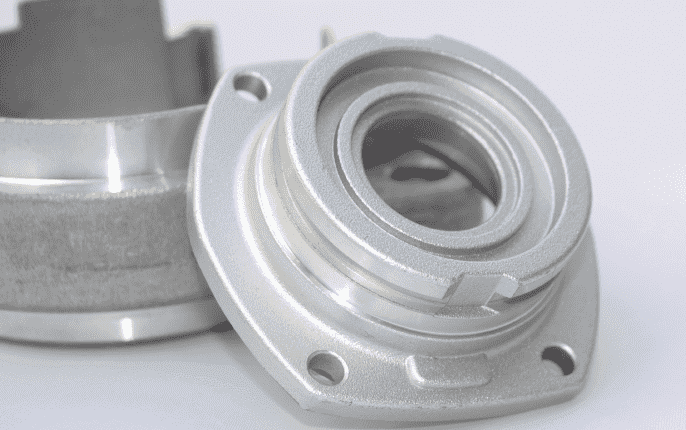

Pressure Die casting is a metal casting process characterized by the use of a mold cavity to apply high pressure to the molten metal. Molds are usually machined from higher strength alloys, some of which are similar to injection molding.

Most pressure die castings are iron-free, such as zinc, copper, aluminum, magnesium, lead, tin, and lead-tin alloys, as well as alloys thereof. Depending on the type of pressure die casting, a cold chamber die casting machine or a hot chamber die casting machine is required.

Casting equipment and injection molds are expensive, so the pressure die casting process is generally only used to mass produce a large number of products. It is relatively easy to manufacture pressure die-cast parts, which generally requires only four major steps, with a single cost increment being low.

Pressure Die casting is particularly suitable for the manufacture of a large number of small and medium-sized castings, so die casting is the most widely used of various casting processes. Compared to other casting techniques, the die-cast surface is flatter and has a higher dimensional consistency.

Based on the traditional die-casting process, several improved processes have been developed, including a non-porous die-casting process that reduces casting defects and eliminates porosity,which can reduce the direct injection process of waste to increase the yield.

TEAM MFG specializes in cold chamber aluminum pressure die casting processes. We have been manufacturing quality products for customers in all industries. Our main services include plastic mold design, casting, secondary precision machining, and various surface treatments services. For more information about our services and solutions, please visit our website https://www.team-mfg.com/.