Welding plays a crucial role in industries like automotive, aerospace, and construction. But when it comes to choosing the right method, the debate between MIG and TIG welding often arises. Each technique offers distinct advantages and serves different purposes.

In this post, we’ll compare MIG and TIG welding, two of the most widely used welding processes. You'll learn about their principles, pros and cons, and when to use each method. Whether you're a beginner or an experienced welder, this guide will help you make the right choice for your project.

What is MIG Welding?

MIG (Metal Inert Gas) welding represents an advanced arc welding technology. It creates strong metal bonds through a semi-automatic or automatic process. Professional welders often refer to it as Gas Metal Arc Welding (GMAW) in industrial applications.

The MIG Welding Process

The process relies on three key components working in harmony:

Continuous Wire Electrode: A motorized system feeds wire automatically through the welding gun. This wire serves both as electrode and filler material, melting to form the weld bond.

Shielding Gas: A mixture of 75% argon and 25% CO2 flows through the gun nozzle. The gas shield protects the molten metal from atmospheric contamination while promoting optimal weld penetration.

Electrical Current: Direct current (DC) passes through the wire electrode, generating an arc. The intense heat melts both the wire and base metals, creating a solid fusion joint.

Why Choose MIG Welding?

MIG welding offers significant advantages across various applications:

Speed and Efficiency

Creates continuous welds without frequent stops

Achieves higher deposition rates compared to traditional methods

Reduces production time through automated wire feeding

User-Friendly Operation

| Feature | Benefit |

| Single-handed operation | Better control and positioning |

| Semi-automatic feed | Reduced operator fatigue |

| Simple setup | Shorter learning curve |

Material Versatility

MIG welding excels in joining:

Aluminum sheets from 26-gauge to heavy plate

Stainless steel components

Structural steel assemblies

Dissimilar metals requiring strong bonds

Its adaptability extends to multiple welding positions - flat, horizontal, vertical, and overhead. This flexibility makes it invaluable for automotive, construction, and manufacturing industries.

What is TIG Welding?

TIG (Tungsten Inert Gas) welding, also known as GTAW (Gas Tungsten Arc Welding), delivers precise, high-quality welds. This sophisticated process creates exceptional joints, particularly on thin materials requiring superior finish quality.

The TIG Welding Process

The process integrates four essential components:

Non-consumable Tungsten Electrode: A specialized tungsten rod generates the arc without melting. Its durability enables consistent arc characteristics throughout extended welding operations.

Pure Inert Gas Shield: Argon gas flows through the torch, protecting the weld pool from atmospheric contamination. Some applications utilize helium or argon-helium mixtures for enhanced performance.

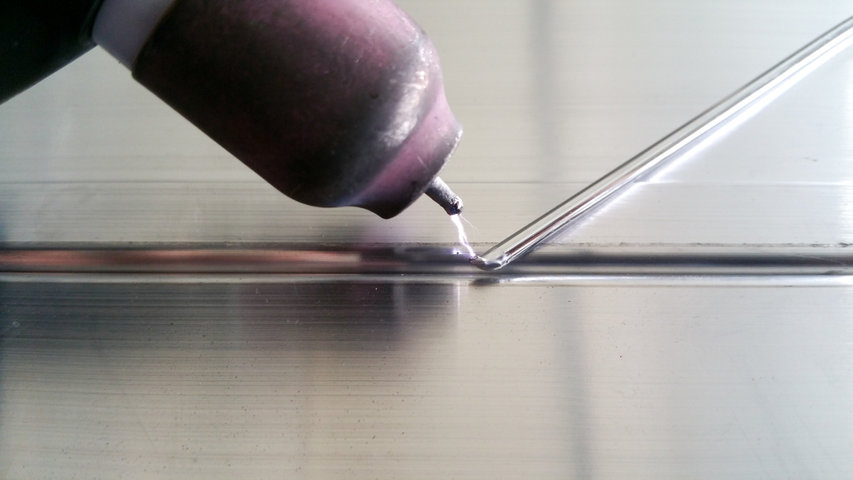

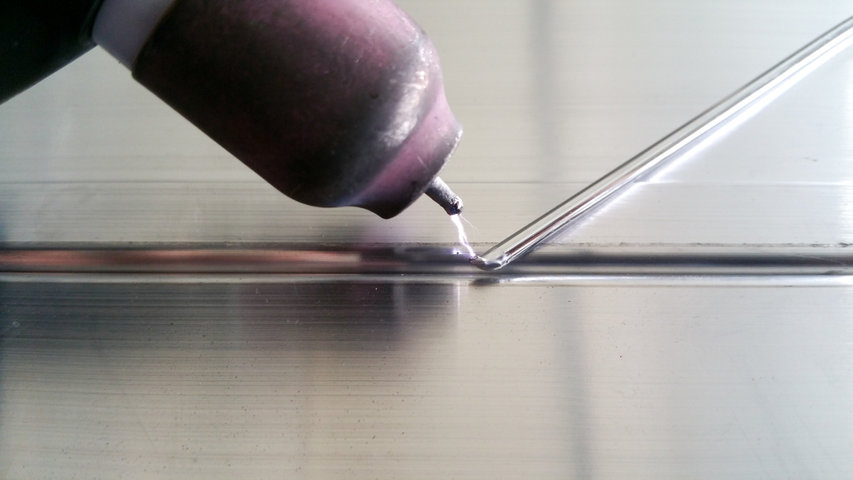

Optional Filler Metal: Welders manually feed separate filler rods into the weld pool. This technique allows precise control over material addition and joint characteristics.

Power Source Flexibility: TIG systems operate on both AC and DC power. AC excels for aluminum, while DC provides superior results on steel and stainless materials.

Advantages of TIG Welding

TIG welding offers several advantages, making it the preferred method for tasks requiring high precision:

Precision and Control: TIG welding provides unmatched control over the welding process, making it ideal for detailed work. Operators can finely tune the heat and filler for precise, clean welds.

High-Quality Welds: The welds produced by TIG welding are clean, strong, and aesthetically pleasing, with minimal spatter. This makes TIG suitable for projects requiring visually perfect welds.

Versatility in Materials: TIG is effective across a wide range of metals, including stainless steel, aluminum, and titanium. Its ability to handle thin sections without warping is one of its biggest strengths.

Key Differences Between MIG and TIG Welding

Understanding the distinct characteristics between MIG and TIG welding helps professionals select the optimal process for specific applications. Let's explore their fundamental differences across key aspects.

Process and Technique Comparison

| Aspect | MIG Welding | TIG Welding |

| Operation | Semi/Automatic | Manual |

| Wire Feed | Continuous | Hand-fed |

| Control Method | One-handed | Two-handed + foot |

| Learning Curve | Moderate | Steep |

Equipment Requirements

MIG Welding Setup

Wire feed welding gun integrating electrode delivery and gas flow

Automatic wire feeding system maintaining consistent material supply

Argon-CO2 mixture (75/25) shielding gas system

DC power source providing stable arc characteristics

TIG Welding Setup

Specialized torch housing tungsten electrode

Precision foot pedal controlling amperage

Pure argon shielding gas delivery system

AC/DC power source offering versatile operation modes

Performance Metrics

Speed and Efficiency

MIG welding excels in production environments:

Achieves 35-50 cubic feet per hour gas flow rates

Maintains continuous operation for extended periods

Enables rapid completion of long weld runs

TIG welding prioritizes precision:

Operates at 15-25 cubic feet per hour gas flow

Requires careful attention to detail

Produces superior results on critical joints

Quality Characteristics

| Feature | MIG Result | TIG Result |

| Weld Appearance | Good, uniform | Excellent, aesthetic |

| Spatter Level | Minimal to moderate | Nearly zero |

| Post-weld Cleanup | Sometimes needed | Rarely required |

| Joint Strength | Strong | Superior |

Cost Analysis

Initial Investment

MIG systems provide cost-effective entry into welding

TIG equipment requires higher capital investment

Both systems need proper safety equipment

Operating Expenses

MIG consumables remain economical for high-volume work

TIG operations incur higher per-foot costs

Material preparation impacts overall expenses

Materials Suitable for MIG and TIG Welding

Each welding process demonstrates specific strengths when joining different materials. Understanding these capabilities helps optimize welding outcomes across various applications.

Materials Suitable for MIG Welding

MIG welding is versatile, handling a wide range of materials, including:

Carbon Steel: Widely used in construction and automotive industries, MIG welding easily handles thicker sections.

Stainless Steel: Suitable for various structural applications, offering durability and corrosion resistance.

Aluminum: Ideal for larger, thicker sections, commonly used in the transportation and aerospace industries.

MIG welding performs best when working with materials thicker than 1.2mm. Its high heat and wire-fed system make it perfect for fast-paced production on sturdy, thick metals.

Materials Suitable for TIG Welding

TIG welding excels in precision, especially for delicate or thin materials, making it a preferred choice for metals like:

Carbon Steel: Provides clean, strong welds, even in thin sheets, making it perfect for fine, detailed work.

Stainless Steel: Known for its smooth finish and minimal distortion, TIG is ideal for corrosion-resistant applications.

Aluminum: Best for thin aluminum sections, it offers precise control and beautiful welds.

Magnesium, Titanium, Copper: TIG handles these exotic metals effectively, offering weld strength and superior aesthetics.

TIG welding shines on materials between 0.5mm and 3mm. Its fine control and non-consumable electrode make it perfect for delicate projects requiring high precision.

Comparison Table: MIG vs TIG Material Compatibility

| Material | Suitable for MIG | Suitable for TIG |

| Carbon Steel | Yes | Yes |

| Stainless Steel | Yes | Yes |

| Aluminum | Yes | Yes |

| Magnesium | No | Yes |

| Titanium | No | Yes |

| Copper | No | Yes |

| Material Thickness | 1.2mm and above | 0.5mm - 3mm |

This table illustrates which materials work best with each welding method, highlighting the thickness each process handles most effectively.

Weld Quality Comparison

Characteristics of MIG Welds

MIG welding produces strong and reliable welds, making it ideal for structural applications. Some key characteristics include:

Strength and Fullness: MIG welds are known for being robust, with deep penetration. This makes them suitable for thicker materials and heavy-duty projects.

Spatter: One downside is the occurrence of spatter. While it doesn’t affect the weld's strength, the weld area may require cleaning or grinding to improve appearance.

Aesthetics: MIG welds are functional but typically lack the refined appearance of TIG welds. Projects requiring visual appeal may need secondary processing, such as sanding or polishing.

Characteristics of TIG Welds

TIG welding is highly regarded for producing clean, precise welds, especially when aesthetics matter. Key characteristics include:

Smooth and Aesthetic Finish: TIG welds are smooth, with a neat "stacked dime" appearance, making them suitable for decorative or visible welds. This process creates welds that often require no secondary finishing.

No Spatter: TIG welds create virtually no spatter, reducing the need for post-weld cleanup and contributing to the overall neatness of the final product.

Porosity: One potential issue is porosity at the weld root. Proper cleaning of both the material and the filler is essential to avoid gas pockets that can weaken the weld.

Comparison Table: MIG vs TIG Weld Quality

| Weld Quality Aspect | MIG Welds | TIG Welds |

| Strength | Strong, reliable for thick materials | Strong but better for thinner materials |

| Spatter | Common, requires post-weld cleaning | No spatter, minimal cleanup required |

| Aesthetics | Functional, requires finishing | Smooth, polished, ideal for decorative use |

| Potential Issues | Spatter, uneven finish | Prone to porosity, cleanliness is critical |

Skill Requirements for Welders

MIG Welding: Low Skill Requirements

MIG welding is considered one of the easiest welding methods to learn. Its semi-automatic nature makes it ideal for beginners or welders working on high-volume production. Key reasons why MIG is easy to master include:

Simplified Process: The continuous wire feed and self-regulating arc make MIG welding straightforward, requiring less manual intervention.

Minimal Coordination: Welders only need to handle the gun, leaving less room for error compared to more complex techniques.

Quick Learning Curve: With basic training, welders can quickly produce acceptable welds, making it ideal for industries needing fast results.

TIG Welding: Higher Skill Levels Required

In contrast, TIG welding demands more precision and control, making it harder to master. The complexity of the process requires welders to develop a range of specialized skills:

Molten Pool Control: TIG welders must monitor and adjust the molten pool constantly, ensuring smooth, clean welds.

Manual Wire Feeding: The welder needs to manually feed the filler rod into the weld pool while handling the torch, which adds to the challenge.

Foot Pedal Coordination: TIG welding uses a foot pedal to control heat. Welders must carefully balance this while managing the other tools, making it difficult for beginners.

Attention to Detail: TIG welders must maintain clean, precise welds, which often require significant experience to perfect.

Comparison Table: MIG vs TIG Skill Requirements

| Skill Aspect | MIG Welding | TIG Welding |

| Learning Curve | Quick, suitable for beginners | Slow, requires extensive training |

| Process Complexity | Simple, automated wire feed | Complex, requires manual control of all aspects |

| Hand-Eye Coordination | Basic coordination with one hand | High-level coordination, both hands and foot control |

| Suitability for Beginners | Ideal for new welders | Challenging, best for experienced welders |

Application Scenarios Examples

MIG Welding Applications

MIG welding is well-suited for larger, high-production tasks where speed and efficiency are essential. Some key examples include:

Construction Steel Structures: MIG welding handles thick materials efficiently, making it ideal for structural steel in buildings and bridges.

Automotive Manufacturing: Widely used for assembling car frames and body panels, MIG welding’s speed and adaptability make it a go-to for high-volume automotive production.

Heavy Equipment: From agricultural machinery to industrial equipment, MIG welds are robust and durable, suitable for heavy-duty use.

TIG Welding Applications

TIG welding is preferred for tasks requiring precision, cleanliness, and high-quality welds. Some application examples include:

Chemical Pipelines: TIG welding’s ability to create smooth, clean welds makes it perfect for pipelines carrying sensitive materials in chemical plants.

Food Equipment: In the food industry, where hygiene is crucial, TIG’s clean welds are ideal for stainless steel equipment and storage tanks.

Bicycle Frames: TIG’s precision makes it ideal for welding lightweight materials like aluminum and titanium, frequently used in high-performance bicycle frames.

Artworks: For sculptures or decorative metalwork, TIG offers the smooth, aesthetically pleasing finish required for artistic projects.

Comparison Table: MIG vs TIG Application Scenarios

| Application | MIG Welding | TIG Welding |

| Construction | Steel structures, high-volume projects | Precise, clean welds for specialized work |

| Automotive | Car frames, body panels | Specialty parts, high-quality finishes |

| Industrial | Heavy equipment, machinery | Chemical pipelines, food-grade equipment |

| Art and Design | Large metal structures | Sculptures, bicycle frames, fine artwork |

Factors to Consider When Choosing Between MIG and TIG Welding

When deciding between MIG and TIG welding, several key factors must be considered to ensure the best choice for your specific project.

Material Type and Thickness

One of the most important factors is the material and its thickness. MIG welding is better suited for thicker materials, such as steel and aluminum, making it ideal for heavy-duty tasks. In contrast, TIG welding excels at handling thin materials, like stainless steel and titanium, where precision is crucial.

Required Weld Quality and Appearance

The desired weld quality and appearance also play a significant role. If high-quality, smooth, and visually appealing welds are needed, TIG is the superior option. TIG welds are often used for decorative purposes or projects requiring a clean finish. MIG welds, though strong, may require post-processing to achieve the same level of aesthetic appeal.

Production Speed and Efficiency

For projects requiring high production speed, MIG welding is the clear winner. Its continuous wire feed allows for rapid welding, making it suitable for large-scale industrial applications. TIG welding, on the other hand, is slower due to its manual nature, making it less efficient for large-volume tasks but ideal for precision work.

Skill Level of the Welder

The welder's skill level significantly influences the choice. MIG welding is easier to learn and operate, making it a good option for beginners or production environments with less experienced welders. TIG welding, however, requires more advanced skills, such as molten pool control, wire feeding, and foot pedal coordination, making it better suited for experienced welders.

Budget and Cost Considerations

Budget is another crucial factor. MIG welding generally comes with lower equipment costs and consumables, making it the more cost-effective option for large projects. TIG welding, while offering higher quality welds, tends to have higher equipment and operational costs due to the precision involved.

Summary Table: Factors Influencing MIG vs TIG Choice

| Factor | MIG Welding | TIG Welding |

| Material Type & Thickness | Thick materials (steel, aluminum) | Thin materials (stainless steel, titanium) |

| Weld Quality & Appearance | Strong, may require post-processing | High-quality, clean finish |

| Production Speed | Fast, suitable for large-scale production | Slower, ideal for precise welds |

| Welder Skill Level | Easier to learn, good for beginners | Requires advanced skills |

| Budget & Cost | Lower equipment and operating costs | Higher costs due to precision and complexity |

Safety Precautions for MIG and TIG Welding

Welding, whether MIG or TIG, involves significant safety risks, making it crucial to follow proper precautions. Below are key safety measures to ensure a safe welding environment.

Personal Protective Equipment (PPE)

Proper PPE is essential to protect welders from burns, electric shock, and harmful fumes. Key items include:

Welding Helmet and Face Shield: A helmet protects your eyes and face from the intense light and sparks generated during welding. Face shields add an extra layer of protection.

Fire-Resistant Clothing and Gloves: Welders should wear flame-resistant jackets and gloves to shield against burns. Cotton or leather materials work best to prevent sparks from catching fire.

Safety Boots: Fire-resistant boots with steel toes protect feet from heavy objects, sparks, and molten metal.

Workspace Safety

A safe workspace is just as important as personal protection. The following measures help ensure a hazard-free welding area:

Proper Ventilation: Welding generates toxic fumes. Ensure your workspace is well-ventilated to prevent fume inhalation, which could lead to serious respiratory issues.

Fire Prevention Measures: Keep fire extinguishers nearby and clear the area of flammable materials. Welding sparks can ignite fires quickly if they come into contact with hazardous substances.

Electrical Safety

Both MIG and TIG welding use electrical currents, presenting the risk of electric shock if not properly managed. Follow these guidelines:

Grounding and Insulation: Always ensure that welding machines are grounded properly and that all electrical components are well-insulated to avoid short circuits.

Avoiding Electric Shock Hazards: Never touch the electrode or metal parts of the welding machine while in operation. Additionally, keep your equipment dry and avoid welding in wet conditions to reduce the risk of shock.

Rundown: MIG versus TIG Welding

MIG and TIG welding each have remarkable qualities and impediments. MIG welding is quick, reasonable for thick materials, and more straightforward for amateurs. TIG welding, while more slow, offers unrivaled accuracy and feel for more slender materials.

Understanding the benefits and imperatives of every strategy assists you with picking the right procedure for your undertaking. Think about material kind, wanted weld quality, and creation proficiency while choosing among MIG and TIG.

Reference Sources

MIG welding

Gas tungsten arc welding

China Best CNC Machining Services