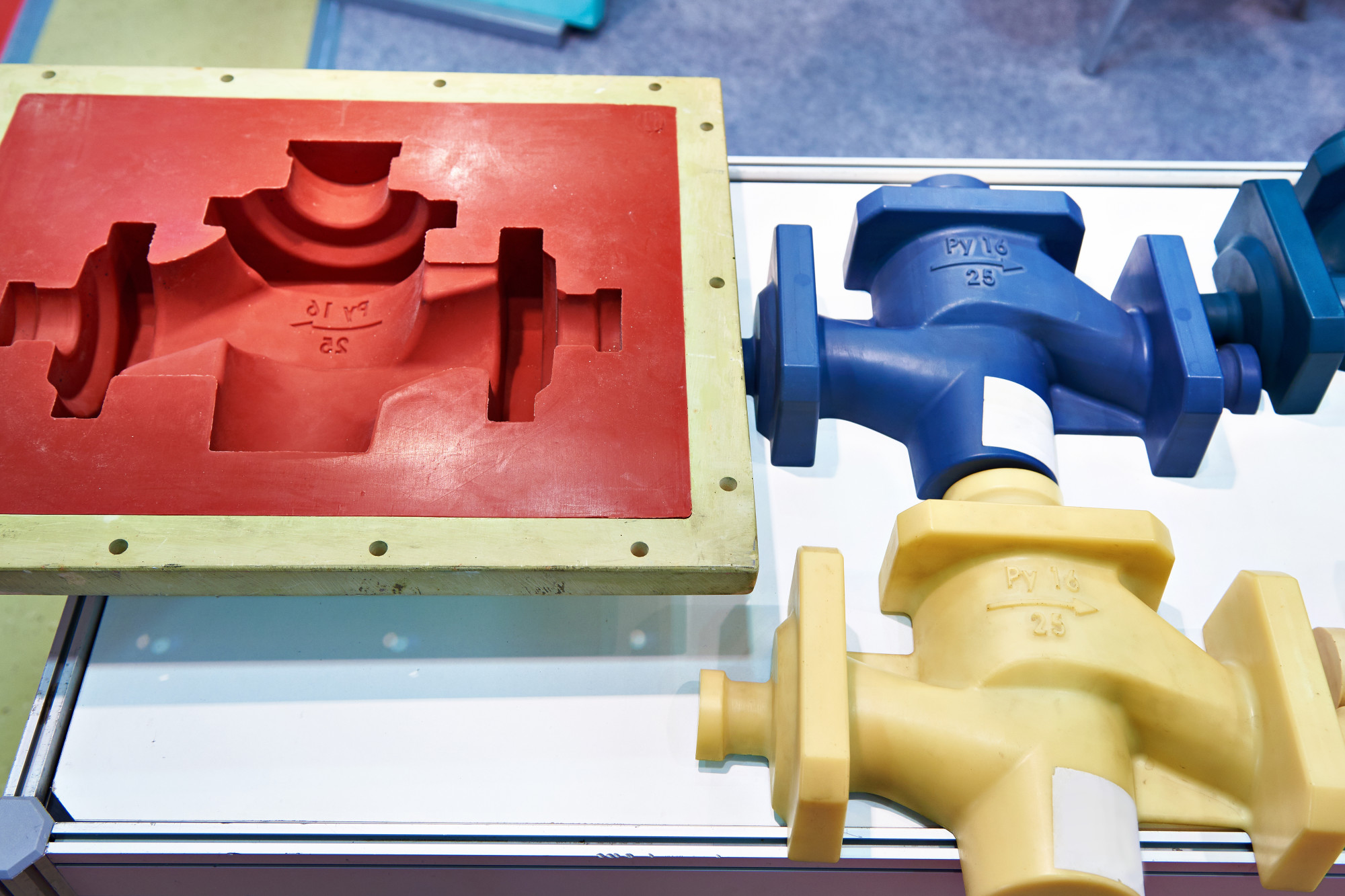

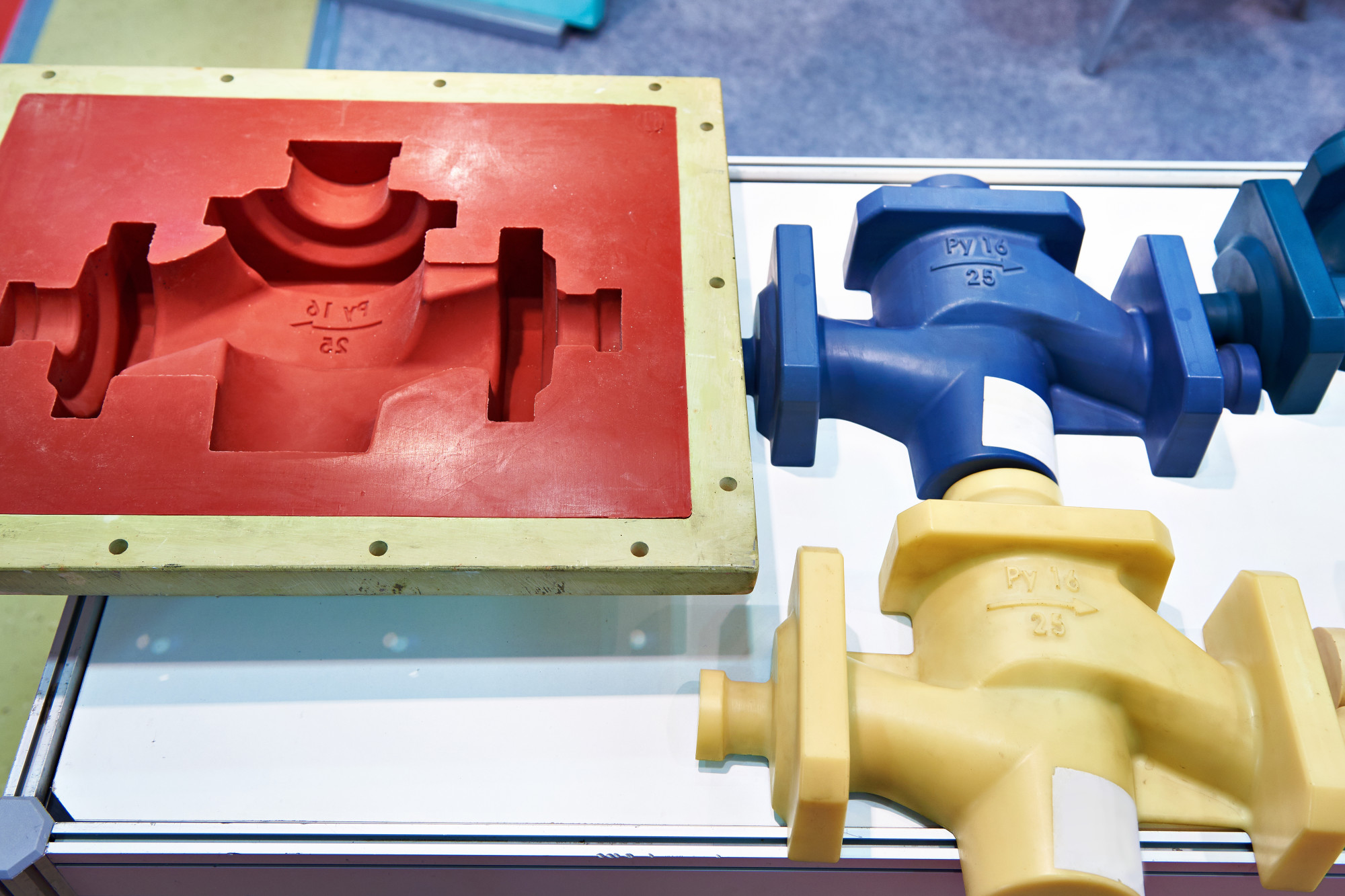

Plastic injection molding is a widely used manufacturing process for producing plastic parts, components, and products. This process involves injecting molten plastic into a mold cavity and allowing it to cool and solidify. The finished product is then removed from the mold and is ready for use.

Plastic injection molding is used in a variety of industries, including automotive, medical, consumer goods, aerospace, and electronics. The process has become an integral part of the manufacturing industry due to its efficiency, versatility, and cost-effectiveness.

One of the main benefits of plastic injection molding is the ability to produce large quantities of parts quickly and at a low cost. This makes it an attractive option for manufacturers who need to produce high volumes of parts while keeping costs down. Additionally, the process allows for complex shapes and intricate details to be produced with precision and accuracy, which is difficult to achieve with other manufacturing processes.

The automotive industry is one of the biggest users of plastic injection molding. Plastic parts are used extensively in the interior and exterior of cars, including dashboard components, door handles, and bumpers. Plastic injection molding is also used to produce parts for medical devices, such as syringes, inhalers, and IV components. These parts must meet stringent quality and safety standards, and plastic injection molding is a reliable method of achieving these standards.

Consumer goods is another industry where plastic injection molding is heavily utilized. Products such as toys, household appliances, and packaging materials are all produced using plastic injection molding. This process allows for the production of consistent, high-quality parts that are essential for these types of products.

In the aerospace industry, plastic injection molding is used to produce lightweight components for airplanes and spacecraft. These components must be durable and able to withstand the extreme conditions of space travel. Plastic injection molding is a reliable method of producing these components to meet the industry's exacting standards.

Finally, the electronics industry also relies heavily on plastic injection molding to produce a variety of components, including computer keyboards, phone cases, and remote controls. The process allows for the production of high-quality, precise parts that are essential for these types of products.

In conclusion, plastic injection molding is a versatile and efficient manufacturing process that is used in a variety of industries to produce a wide range of plastic parts and products. The ability to produce high volumes of parts quickly and at a low cost makes it an attractive option for manufacturers. The process allows for the production of complex shapes and intricate details with precision and accuracy, making it an essential tool for the manufacturing industry.