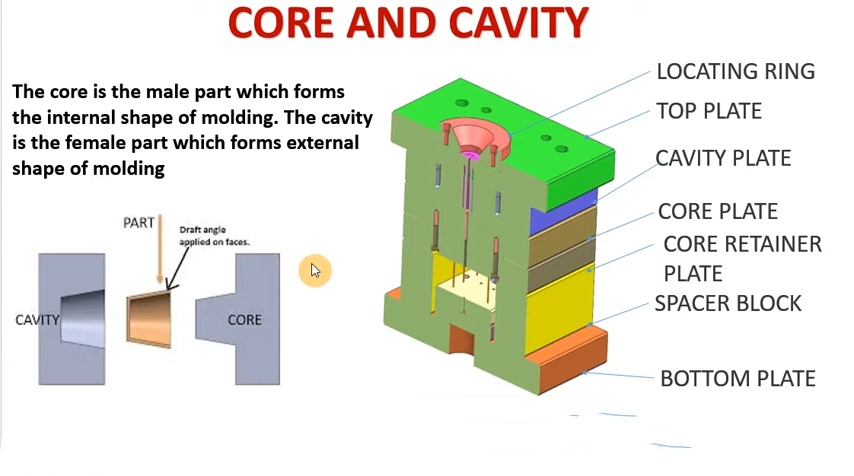

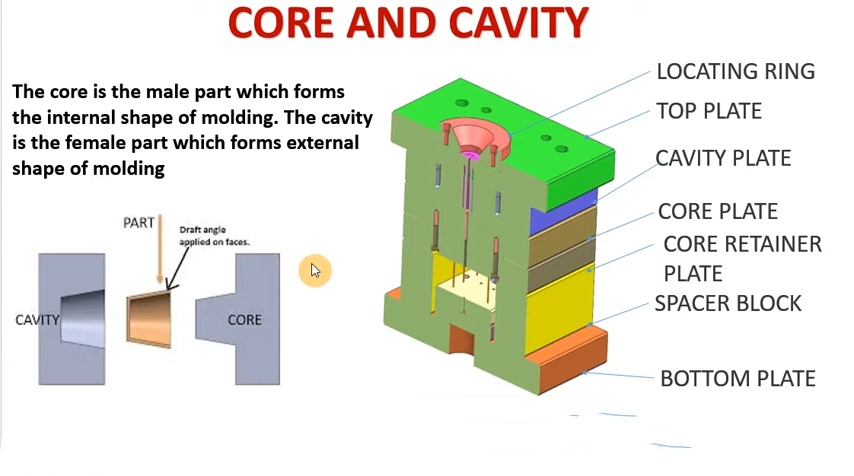

Plastic injection molding is a key method for creating precision parts. But what drives its success? The mold core and cavity. These components form the internal and external features of molded products.

In this post, you'll learn how the core and cavity work together, why they're essential, and their critical differences.

Core and Cavity: Definition and Roles

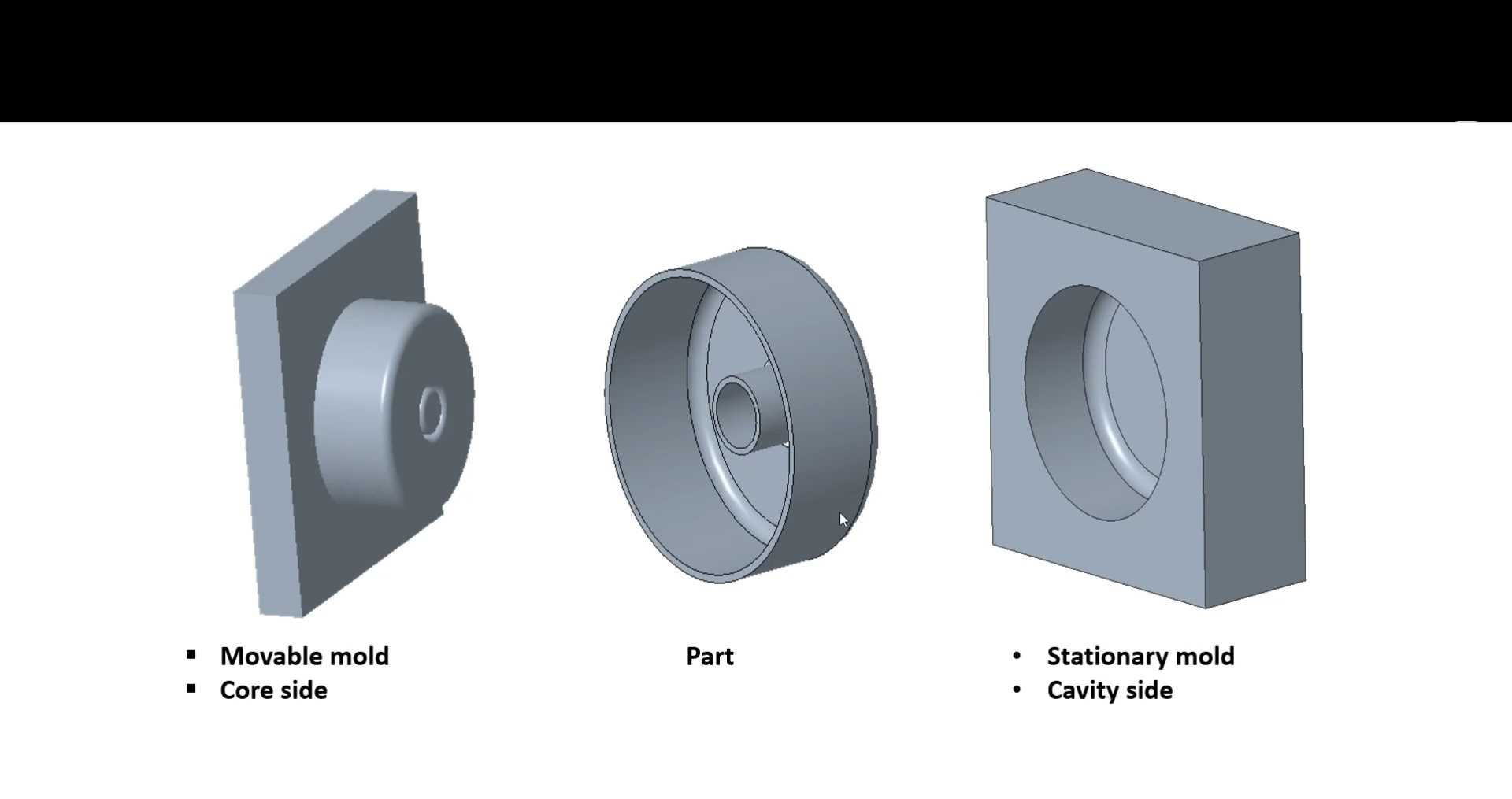

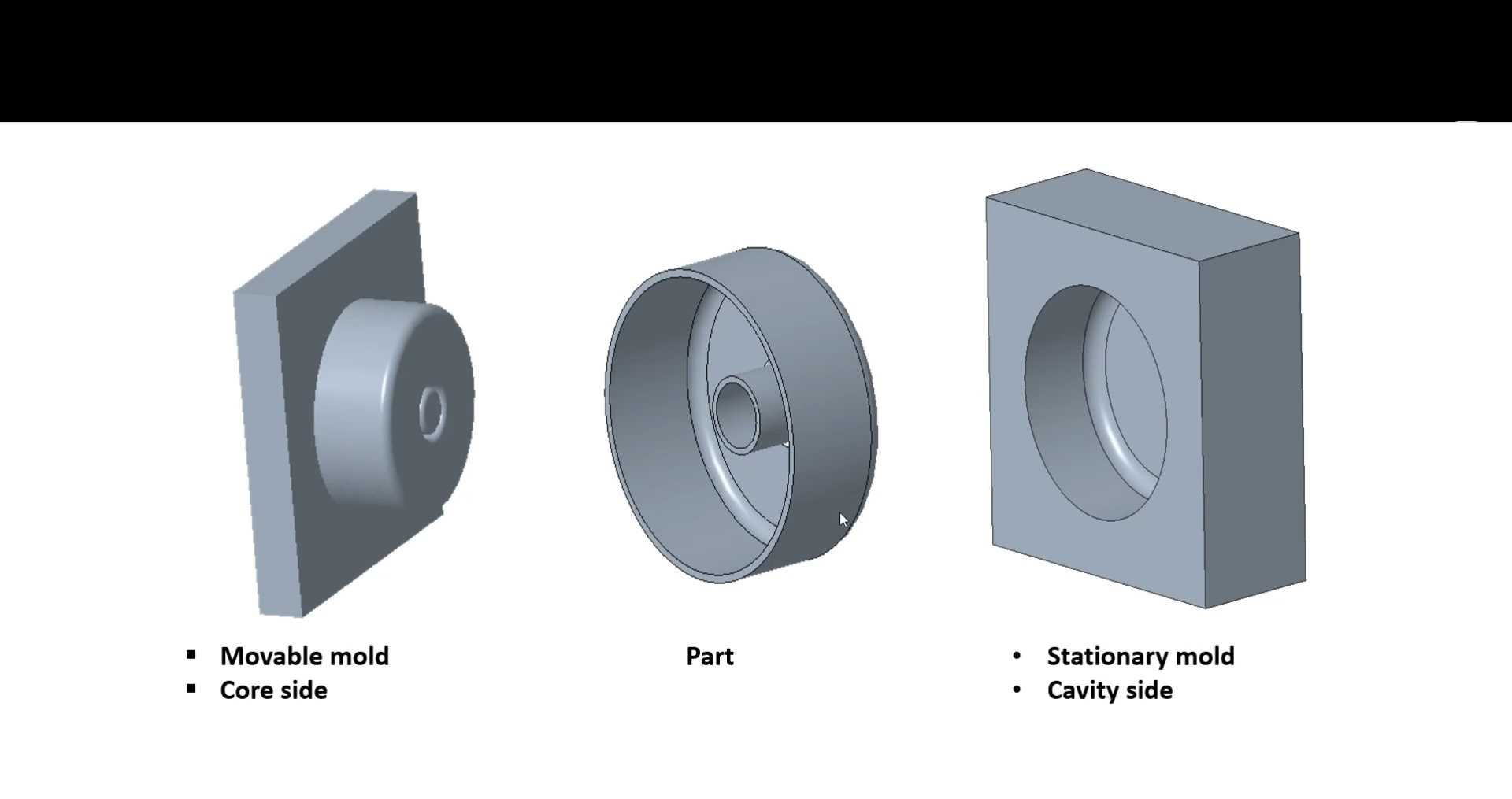

The Mold Core

The mold core shapes internal features of injection molded parts. It's crucial for creating hollow sections and complex internal structures. During the injection process, the core sits in the B-side of the mold. It moves with the ejector system, ensuring parts release properly after cooling.

Key points about mold cores:

Form inner cavities and details

Usually made from hardened steel

Require precise machining for accuracy

Often include cooling channels for faster production

The Mold Cavity

Mold cavities define external features of molded parts. They're responsible for the outer aesthetics and dimensions. Cavities remain stationary in the A-side of the mold during production. They create the visible surfaces customers interact with.

Important aspects of mold cavities:

Shape outer surfaces and textures

Often polished for desired finish

Must account for material shrinkage

Include gating systems for plastic flow

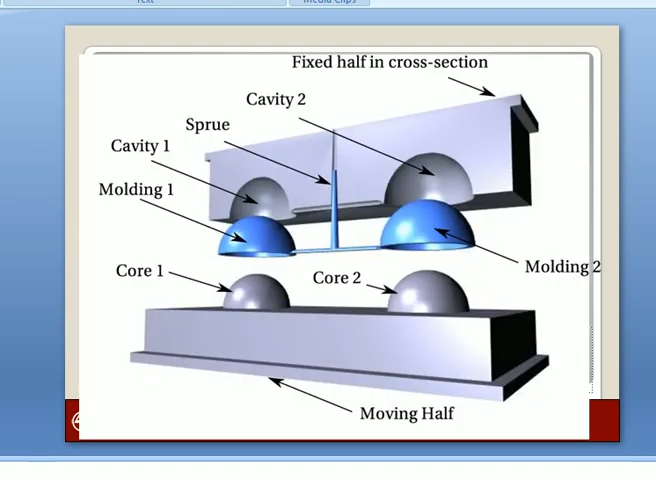

How Core and Cavity Work Together

Cores and cavities combine to form complete molded parts. When the mold closes, they create a void in the shape of the final product. Molten plastic fills this space, taking on the features of both components.

The interaction process:

Mold closes, aligning core and cavity

Plastic injected into the formed space

Material cools and solidifies

Mold opens, core moves with ejector system

Part releases, retaining shapes from both core and cavity

Types of Mold Cores and Cavities

Fixed Cores and Cavities

Fixed cores and cavities are the foundation of injection molding. They remain stationary throughout the production process.

Standard Cores and Cavities

These are basic components machined from hardened steel. They're designed for long production runs and consistent part quality.

Simple Core/Cavity

Used for parts with straightforward shapes. They're ideal for products without complex internal features.

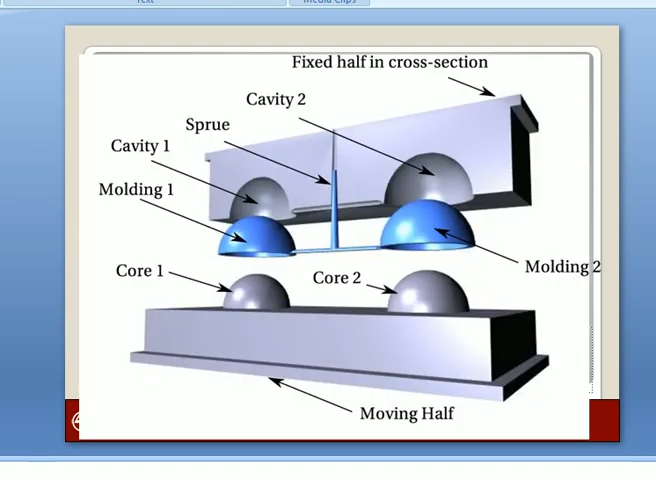

Multi-Core/Cavity

These molds produce multiple parts in one cycle. They increase production efficiency but require careful design for balanced filling.

Interchangeable Cores and Cavities

Interchangeable components offer flexibility in production. They allow for quick changeovers and product variations.

Replaceable Cores and Cavities

These can be swapped out to produce different part designs. They reduce tooling costs for product families.

Sliding Cores and Cavities

They move within the mold to create complex features. Sliding components are essential for parts with undercuts or side details.

Insert Cores and Cavities

These are used to create specific features or incorporate pre-formed components. They're often used for threaded inserts or special materials.

Collapsible Cores

Collapsible cores are crucial for parts with internal threads or complex hollow sections. They contract to allow part ejection, then expand for the next cycle.

Key benefits:

Unscrewing Cores and Cavities

These components rotate to release parts with threaded features. They're essential for molding screw caps, fittings, and similar products.

Advantages:

Produce fully-formed threads in one step

Eliminate secondary operations

Increase production efficiency for threaded parts

Designing Mold Cores and Cavities

Key Design Factors

Designing effective mold cores and cavities requires careful consideration of several factors:

Part Geometry: Complex shapes demand precise core and cavity designs.

Material Selection: Different plastics require specific mold materials and finishes.

Shrinkage: Account for material shrinkage to ensure dimensional accuracy.

Draft Angles: Proper angles facilitate easy part release.

Ejection System: Plan for efficient part removal without damage.

Cooling System: Optimize cooling channels for consistent part quality.

Design Guidelines

Follow these guidelines for successful mold core and cavity design:

Uniform Wall Thickness

Maintain consistent thickness throughout the part.

Prevents warping, sink marks, and uneven cooling.

Proper Draft Angles

Radii and Fillets

Venting and Gating

Common Challenges and Solutions

| Challenge | Solution |

| Undercuts | Use sliding cores or collapsible inserts |

| Thin walls | Implement cascade or sequential gating |

| Weld lines | Optimize gate locations and melt temperatures |

| Sink marks | Adjust cooling system and wall thickness |

Material Selection for Core and Cavity

Importance of Material Choice

Selecting the right materials for mold cores and cavities is crucial. It directly impacts mold life and overall production costs. Proper selection ensures durability, precision, and cost-effectiveness.

Commonly Used Materials

Several materials are popular for mold cores and cavities:

P20: Versatile steel with good machinability

738: Improved properties over P20

NAK80: Excellent for high-polish applications

2316: Ideal for corrosive plastics

2344: Suited for high-volume production

Production Volume Considerations

Material choice varies based on production volume:

High-volume production justifies investing in premium materials. They extend mold life and reduce long-term costs.

Key Material Characteristics

When selecting materials, consider these properties:

| Characteristic | Importance |

| Wear Resistance | Prolongs mold life |

| Toughness | Prevents chipping and cracking |

| Polishing Properties | Achieves desired surface finish |

| Hardness | Resists deformation under pressure |

Wear Resistance

Materials with high wear resistance maintain dimensional accuracy over time. They're essential for high-volume production.

Toughness

Tough materials withstand the stresses of repeated molding cycles. They reduce the risk of premature mold failure.

Polishing Properties

Some materials polish better than others. This is crucial for parts requiring high-gloss finishes.

Hardness

Harder materials resist deformation under injection pressure. They maintain part precision but may be more difficult to machine.

Manufacturing Process of Mold Core and Cavity

1. Material Preparation

The process begins with selecting appropriate materials and tools. This step is crucial for ensuring mold quality and longevity.

2. Traditional Milling

Initial shaping involves:

These operations form the foundation of the mold structure.

3. CNC Machining

Rough cutting defines the basic shape of the core and cavity. CNC technology ensures precision and efficiency in this stage.

4. Heat Treatment

This step enhances:

Durability

Wear resistance

Dimensional stability

Heat treatment is essential for prolonging mold life.

5. Grinding and Finishing

Precision grinding achieves:

6. CNC Finishing

High-precision operations include:

Fine detail cutting

Engraving

Text application

These steps add crucial features to the mold components.

7. Wire Cutting

Wire EDM creates complex shapes such as:

Lifter holes

Ejector pin slots

Intricate contours

8. Electrical Discharge Machining (EDM)

EDM excels at producing:

Fine grooves

Narrow slots

Precise cavities

It's ideal for features difficult to machine conventionally.

9. Mold Polishing

Final surface finishing involves:

10. Assembly

This stage includes:

Proper assembly ensures optimal mold function.

11. Trial Molding

Testing the completed mold involves:

This final step confirms the mold is ready for production.

Different Steps of Mold Core and Cavity in the Injection Molding Process

The injection molding process involves a carefully choreographed interaction between the mold core and cavity. Understanding this sequence is crucial for grasping the full scope of injection molding.

Step 1: Injection

Plastic granules enter the closed space formed by the mold cavity. This space, created by the precisely engineered core and cavity, defines the shape of the final product.

Key points:

Step 2: Cooling and Solidification

The mold core fits tightly with the cavity during this phase. As the plastic cools, it takes on the exact shape of the core-cavity combination.

Important aspects:

Step 3: Mold Opening and Ejection

After solidification, the mold core moves away. The product, now solid, is ejected from the core through the ejection system.

Process details:

Mold opens

Core retracts

Ejector pins activate

Part releases from core

Mold Cavity's Role

Throughout these steps, the mold cavity remains stationary. It provides a stable reference point for the part's external features.

Cavity functions:

Maintains outer shape

Supports gating system

Houses cooling channels

This choreographed process ensures consistent, high-quality parts production. The interplay between core and cavity is fundamental to successful injection molding operations.

Pressure Differences Endured by Mold Core and Cavity

The mold core and cavity experience varying pressure levels during injection molding. These differences significantly impact part quality and mold longevity.

Mold Cavity: High-Pressure Zone

The cavity withstands higher pressures for several reasons:

Ensures complete filling of the mold

Maintains integrity of product's internal structure

Compensates for material shrinkage

Key points about cavity pressure:

Can reach thousands of PSI

Varies based on material and part design

Affects surface finish and dimensional accuracy

Mold Core: Lower Pressure Area

In contrast, the core endures lower pressures. Its primary functions include:

Shaping the product's exterior

Ensuring a perfect appearance

Facilitating part release

Core pressure considerations:

Generally lower than cavity pressure

Focused on external features

Impacts surface quality and detail reproduction

Pressure Distribution Table

| Mold Component | Pressure Level | Primary Function |

| Cavity | High | Internal structure integrity |

| Core | Lower | External appearance perfection |

Understanding these pressure differences is crucial for:

Proper mold design

Material selection

Maintenance planning

Usage Cycle and Maintenance Frequency Differences between Mold Core and Cavity

Mold Cavity: Higher Maintenance Needs

The mold cavity experiences greater stress during injection molding:

These factors lead to more frequent maintenance requirements:

Regular inspections

Periodic polishing

More frequent replacements

Manufacturers often schedule cavity maintenance to ensure consistent product quality.

Mold Core: Lower Maintenance Requirements

In contrast, the mold core enjoys a less demanding role:

This results in:

Fewer maintenance checks

Less frequent replacements

Lower overall maintenance costs

Comparison Table

| Aspect | Mold Cavity | Mold Core |

| Pressure Exposure | High | Lower |

| Wear Rate | Faster | Slower |

| Service Life | Shorter | Longer |

| Maintenance Frequency | Higher | Lower |

| Replacement Needs | More Often | Less Often |

Impact on Production

Understanding these differences helps manufacturers:

Plan maintenance schedules effectively

Budget for replacements accurately

Optimize production efficiency

Regular cavity maintenance ensures product quality remains high. Less frequent core maintenance reduces downtime and costs.

Methods to Differentiate Mold Core and Cavity

Distinguishing between mold cores and cavities is crucial for effective mold design and maintenance. Several key features help identify each component:

Appearance

Mold cavities typically exhibit:

Smoother surfaces

Distinct protrusions

Clear recesses

Mold cores often show:

Rougher textures

Visible holes

Cutting marks

These visual cues provide quick identification in most cases.

Structural Elements

Cavity structures include:

Core components feature:

Parting surfaces

Mold sleeves

Ejector pin holes

Weight and Material Differences

| Aspect | Mold Cavity | Mold Core |

| Weight | Generally lighter | Usually heavier |

| Material | Wear-resistant, high-hardness (e.g., mold steel) | Cast iron, steel, alloys |

Material choice impacts durability and performance of each component.

Markings and Identifiers

Manufacturers often use specific markings:

Cavity:

"F" (Fixed side)

"1" (First half)

Core:

"R" (Removable side)

"2" (Second half)

These markings simplify assembly and maintenance processes.

Quality Inspection Methods for Mold Core

Ensuring mold core quality is crucial for producing precise injection molded parts. Follow these steps for accurate inspections:

Preparing the Depth Micrometer

Before use:

Check flexibility of differential cylinder

Ensure smooth movement of differential screw

Verify reliability of locking device

Selecting Measurement Tools

Calibration Process

Use grade 00 platform for cleaning

Clean datum plane and measuring surface

Verify zero position accuracy

Measurement Techniques

For blind holes and deep grooves:

Large Diameter Measurements

When hole diameter exceeds micrometer base:

Employ auxiliary positioning plate

Ensure plate is clean and flat

Take multiple measurements for accuracy

Inspection Checklist

| Step | Action | Importance |

| 1 | Check micrometer functionality | Ensures accurate readings |

| 2 | Select proper measuring rod | Matches inspection needs |

| 3 | Clean and calibrate | Provides reliable zero point |

| 4 | Use careful technique | Prevents damage to tool and part |

| 5 | Adapt for large diameters | Enables accurate measurement of all features |

Maintenance and Troubleshooting

Regular Maintenance Practices

Proper care of mold cores and cavities ensures longevity and quality production.

Cleaning and Lubrication

Remove residue after each production run

Apply appropriate lubricants to moving parts

Use non-abrasive cleaners for sensitive surfaces

Inspection and Repair

Conduct visual checks for wear or damage

Measure critical dimensions regularly

Address minor issues promptly to prevent major failures

Common Issues and Solutions

| Issue | Cause | Solution |

| Wear | Friction during molding | Polish or resurface affected areas |

| Corrosion | Chemical reactions | Apply protective coatings |

| Erosion | High-pressure material flow | Redesign gating system |

| Damage | Mishandling or accidents | Replace damaged components |

Preventive Measures

Extend mold life with these practices:

Use appropriate mold materials

Optimize cooling systems

Implement proper venting

Train operators in correct handling procedures

Mold Life Extension Tips

Monitor cycle times to prevent overuse

Rotate molds for even wear distribution

Store molds properly when not in use

Conclusion

Mold cores and cavities are vital to injection molding. They shape parts, ensure precision, and affect production efficiency. Designers, engineers, and manufacturers should focus on material selection, accurate design, and maintenance.

Manufacturers benefit from regular inspections and proactive troubleshooting. These practices extend mold life and improve production efficiency.