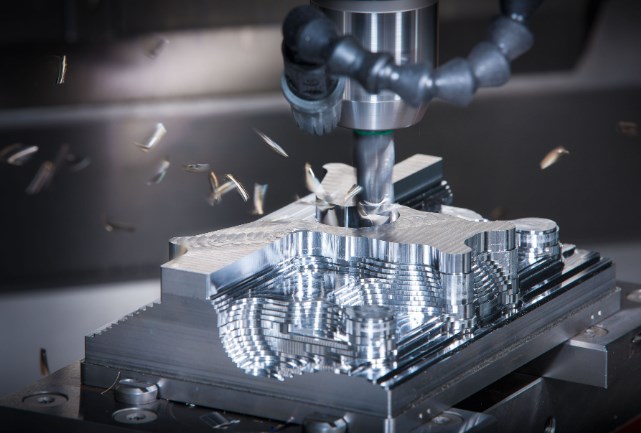

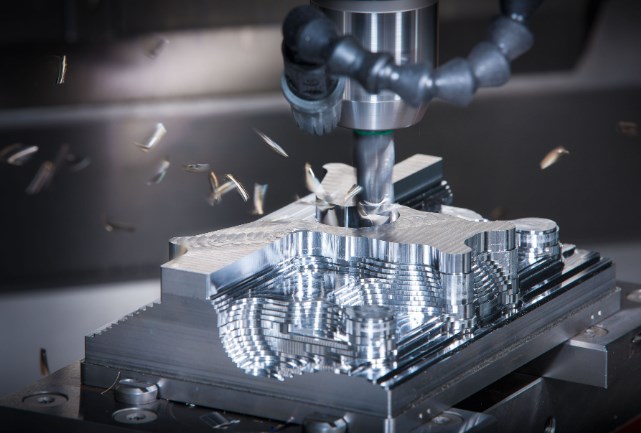

What is CNC Machine Repair? Understanding the Importance of Maintaining and Restoring CNC Equipment

Introduction:

In today's advanced manufacturing landscape, CNC (Computer Numerical Control) machines play a pivotal role in producing intricate and precise components across various industries. These sophisticated machines rely on complex systems and components to operate efficiently. However, like any mechanical or electronic equipment, CNC machines are susceptible to wear, tear, and malfunctions over time. That's where CNC machine repair comes into play. In this article, we will explore what CNC machine repair entails and why it is essential for maintaining the optimal performance of these cutting-edge manufacturing tools.

Definition of CNC Machine Repair:

CNC machine repair refers to the process of identifying, diagnosing, and resolving issues that arise in CNC machines. It involves skilled technicians or specialists who possess in-depth knowledge of CNC systems, programming languages, and mechanical components. The primary goal of CNC machine repair is to restore the equipment to its optimal functioning state, minimizing downtime, and ensuring accurate and reliable production.

Diagnostic Procedures:

When a CNC machine encounters a malfunction or exhibits signs of diminished performance, the repair process typically begins with a thorough diagnostic assessment. Experienced technicians employ a range of tools, software, and testing procedures to identify the root cause of the problem. This may involve examining error logs, conducting visual inspections, testing electronic components, and verifying the accuracy of mechanical parts.

Mechanical Repairs:

CNC machines consist of various mechanical components such as spindles, tool changers, axes, and bearings. Over time, these components may experience wear, misalignment, or damage, leading to diminished performance or complete breakdown. CNC machine repair often involves repairing or replacing these mechanical elements to restore the machine's functionality. Skilled technicians utilize specialized tools and follow precise procedures to ensure proper alignment, lubrication, and calibration of these critical parts.

Electrical and Electronic Repairs:

CNC machines heavily rely on electrical and electronic systems to control their operations. Repairing electrical and electronic components involves troubleshooting and rectifying issues related to wiring, connections, power supplies, motor drives, encoders, and circuit boards. Technicians proficient in understanding the intricate wiring diagrams and electrical schematics of CNC machines can identify faults and repair or replace faulty components to restore proper functionality.

Software and Programming:

CNC machines are operated through computer software that converts digital designs into precise instructions for the machine. Repairing the software or programming aspects of CNC machines involves troubleshooting errors, addressing compatibility issues, and updating or reconfiguring the software to ensure accurate communication between the machine and the control system. Skilled technicians may need to work closely with programmers to rectify software-related problems effectively.

Preventive Maintenance:

In addition to repairs, CNC machine maintenance focuses on preventive measures to minimize the risk of breakdowns and extend the machine's lifespan. This includes routine inspections, cleaning, lubrication, and calibration procedures. Regular preventive maintenance schedules help identify potential issues before they escalate, reducing unplanned downtime and maximizing the productivity and longevity of the CNC equipment.

Conclusion:

CNC machine repair service is a critical aspect of maintaining the efficiency and reliability of CNC machines in modern manufacturing environments. With their complex mechanical, electrical, and software systems, these machines require specialized knowledge and skills to diagnose and resolve issues effectively. By investing in timely repairs, preventive maintenance, and the expertise of skilled technicians, manufacturers can ensure that their CNC machines operate at peak performance, minimizing downtime, maximizing productivity, and ultimately driving the success of their operations.