Plastic parts are the backbone of modern manufacturing, found in countless products we use every day. Designing these parts requires careful consideration to ensure efficiency and quality. This article provides a detailed guide on the design process of plastic parts, from material selection to final production. In this post, you'll learn how to define requirements, select materials, and optimize designs for manufacturability.

Overview of the Plastic Part Design Process

Importance of Plastic Part Design for Manufacturability

Effective plastic part design is essential for ensuring manufacturability, quality, and cost-efficiency. A well-optimized design minimizes material waste and production time, leading to higher profitability. Manufacturers must carefully consider factors like material selection, dimensional accuracy, and production methods to achieve optimal results.

Emphasis on Injection Molding Processes

Injection molding is the most commonly used process for plastic part production due to its scalability and precision. This method allows for the mass production of complex parts while maintaining tight tolerances and reducing waste. Proper design for injection molding includes attention to wall thickness, draft angles, and rib placement to prevent defects like warping or sink marks.

Key Stages in Design-to-Production Workflow

The plastic part design process involves several interconnected stages:

Requirement Definition

Concept Sketching

Material Selection

Detailed Design

Structural Analysis

Final Material Selection

Modifying the Design for Manufacturing (DFM)

Prototyping

Tooling and Manufacturing

This workflow ensures a systematic approach to plastic part development. It balances functionality, manufacturability, and cost-effectiveness.

Step 1: Defining Requirements

Importance of Quantifying Requirements

Quantifying requirements forms the cornerstone of successful plastic part design. It provides:

Clear, measurable objectives

Reduced misinterpretation risks

Solid foundation for design decisions

Designers should avoid vague terms like "strong" or "transparent". Instead, they must strive for specific, quantifiable metrics.

Factors to Consider

Structural Loading

Structural loading analysis ensures parts withstand intended use and potential misuse:

Types: Static, dynamic, impact

Rate: Slow, moderate, rapid

Frequency: Continuous, intermittent, occasional

Considerations extend beyond end-use:

Assembly stress

Shipping vibrations

Storage conditions

Worst-case scenarios

Environmental Conditions

Environmental factors significantly impact plastic material properties:

| Factor | Considerations |

| Temperature | Operating range, thermal cycling |

| Humidity | Moisture absorption, dimensional stability |

| Chemical exposure | Resistance to solvents, oils, cleaning agents |

| Radiation | UV stability, gamma radiation tolerance |

Worst-case scenario planning helps ensure product reliability under extreme conditions.

Dimensional Requirements and Tolerances

Precise dimensional specifications are crucial:

Balancing tight tolerances with manufacturing costs is essential. Overly strict tolerances can significantly increase production expenses.

Standards and Regulatory Requirements

Adherence to relevant standards ensures product compliance:

Designers must identify applicable standards early in the process. This approach prevents costly redesigns later.

Marketing and Economic Restrictions

Economic considerations shape design decisions:

These factors influence material selection, manufacturing processes, and design complexity.

Step 2: Creating a Preliminary Concept Sketch

Developing Initial Concept Sketches

Concept sketching initiates the visual representation of design ideas. It serves as a crucial bridge between requirements and tangible solutions.

Key aspects of effective concept sketching:

Rapid ideation: Generate multiple design concepts quickly.

Focus on functionality: Prioritize core features over aesthetic details.

Adaptability: Allow for easy modifications as the design evolves.

Highlighting Key Areas of Concern

Designers must emphasize critical regions in their sketches:

This approach facilitates early problem identification and targeted design improvements.

Identifying Fixed vs. Variable Functions

Distinguishing between fixed and variable functions is crucial:

| Fixed Functions | Variable Functions |

| Standard-governed dimensions | Aesthetic elements |

| Critical performance features | Non-essential geometry |

| Safety-related components | Customizable features |

Recognizing these distinctions enables designers to focus their creative efforts on areas with greater design flexibility.

Collaboration with Industrial Designers

Partnering with industrial designers enhances the concept sketching phase:

Brings aesthetic expertise to functional designs

Ensures manufacturability of visually appealing concepts

Facilitates holistic product development

Creation of 3D Sketches or Renderings

Modern concept sketching often involves 3D visualization:

Digital sketching tools enable rapid 3D concept creation.

3D renderings provide stakeholders with clearer design vision.

Early 3D models facilitate smoother transition to CAD development.

Step 3: Initial Material Selection

Comparing Material Properties with Requirements

Initial material selection involves a systematic comparison of material properties against defined requirements. This process ensures optimal material choices for specific applications.

Key steps in this comparison:

Identify critical performance parameters

Evaluate material datasheets

Rank materials based on requirement fulfillment

Eliminating Unsuitable Material Families

Efficient material selection often begins with elimination:

Identify deal-breaker properties

Remove entire material families failing to meet critical requirements

Narrow focus to promising candidates

This approach streamlines the selection process, saving time and resources.

Non-Designable Material Properties

Certain material properties cannot be enhanced through design modifications:

| Property | Importance |

| Coefficient of thermal expansion | Affects dimensional stability |

| Transparency | Critical for optical applications |

| Chemical resistance | Determines compatibility with environment |

| Softening temperature | Limits operating conditions |

| Agency approval | Ensures regulatory compliance |

These properties serve as primary screening criteria in material selection.

Impact of Additives and Technologies

Material selection complexity increases with:

Coatings: Enhance surface properties

Additives: Modify bulk material characteristics

Co-injection technology: Combines multiple materials

These factors expand design possibilities but require careful consideration of their effects on overall part performance.

Role of Compounding and Melt Blending

Compounding and melt blending offer opportunities for property enhancement:

Tailoring mechanical properties

Improving thermal characteristics

Enhancing chemical resistance

Optimizing processability

These techniques allow designers to fine-tune material properties, potentially creating custom solutions for specific applications.

Step 4: Designing the Part According to Selected Materials

Designing Part Geometry According to Material Characteristics

Material properties significantly influence part geometry. Designers must adapt their approach based on the chosen material's unique attributes.

Key considerations:

Modulus of elasticity

Yield strength

Creep resistance

Chemical compatibility

Adjusting Geometry for Various Conditions

Different materials require specific geometric adaptations:

Static loads: Reinforce high-stress areas

Solvent exposure: Increase wall thickness in vulnerable regions

Thermal expansion: Design appropriate clearances and tolerances

Material-Specific Design Examples

| Material | Design Considerations |

| High-density polyethylene | Large draft angles, thick sections for rigidity |

| Polypropylene | Uniform wall thickness, generous radii |

| Nylon 6/6 | Ribbing for stiffness, moisture absorption allowances |

Step 5: Structural Analysis

Utilizing CAE Software for Analysis

Computer-Aided Engineering (CAE) software plays a crucial role in modern plastic part design. It enables designers to:

Simulate real-world conditions

Predict part behavior under various loads

Identify potential failure modes

Popular CAE tools include ANSYS, Solidworks Simulation, and Abaqus.

Testing Under Worst-Case Scenarios

Rigorous analysis involves subjecting virtual models to extreme conditions:

Maximum load cases

Temperature extremes

Impact and fatigue scenarios

Chemical exposure simulations

These tests help uncover potential weaknesses before physical prototyping begins.

Design Optimization Based on Analysis Results

Analysis results guide iterative design improvements:

| Analysis Outcome | Design Response |

| High stress concentrations | Add fillets or gussets |

| Excessive deflection | Increase wall thickness or add ribs |

| Thermal hotspots | Modify geometry for better heat dissipation |

This process continues until the design meets all performance criteria while minimizing material usage and complexity.

Ensuring Modified Design Meets Requirements

After optimization, designers must verify:

End-use performance standards are still met

Manufacturing feasibility remains intact

Cost targets are achieved

A balance between these factors often requires trade-offs and creative problem-solving.

Key considerations:

Functional requirements

Aesthetic standards

Regulatory compliance

Production efficiency

Step 6: Final Material Selection

Committing to a Primary Material

At this stage, designers must choose a primary material for the plastic part. This decision should be based on:

The selected material becomes the focus for subsequent design refinements and production planning.

Maintaining Backup Options

While committing to a primary material, it's prudent to keep alternative materials in reserve. These backups serve as:

Contingency plans for unforeseen issues

Options for future product iterations

Potential cost-saving alternatives

Designers should maintain detailed information on these alternatives throughout the development process.

Economic and Performance Considerations

Final material selection balances economic factors with end-use performance:

| Economic Factors | Performance Properties |

| Raw material cost | Mechanical strength |

| Processing expenses | Chemical resistance |

| Production volume | Thermal stability |

| Lifecycle costs | Aesthetic qualities |

Designers must weigh these factors against each other to find the optimal material solution.

Semi-Quantitative Scoring Method

To objectively evaluate materials, a semi-quantitative scoring system proves invaluable:

Identify key selection criteria

Assign weightings to each criterion

Rate materials on a numerical scale for each criterion

Calculate weighted scores

Compare total scores to determine the best overall performer

This method provides a data-driven approach to material selection, minimizing subjective bias.

Example scoring criteria:

Tensile strength: 0-10 points

Cost per unit: 0-10 points

Processing ease: 0-10 points

Environmental impact: 0-10 points

Step 7: Modifying the Design for Manufacturing (DFM)

Injection Molding Considerations

Injection molding involves five critical stages:

Mold filling

Packing

Holding

Cooling

Ejection

Each stage requires specific design modifications to ensure moldability:

Draft angles: Facilitate part removal

Radii: Improve material flow and reduce stress concentrations

Surface texture: Enhance appearance and mask imperfections

Key Design Elements for Injection Molding

Wall Thickness

Uniform wall thickness is crucial for preventing defects:

Avoid thick sections: They can lead to sink marks and warpage

Maintain consistency: Typically within 10% of nominal thickness

Follow resin-specific guidelines: Usually ranging from 0.04" to 0.150"

Rib Reinforcement

Ribs strengthen parts without increasing overall thickness:

| Guideline | Recommendation |

| Height | ≤ 3x wall thickness |

| Thickness | ≤ 0.5-0.75x wall thickness |

| Placement | Perpendicular to main stress direction |

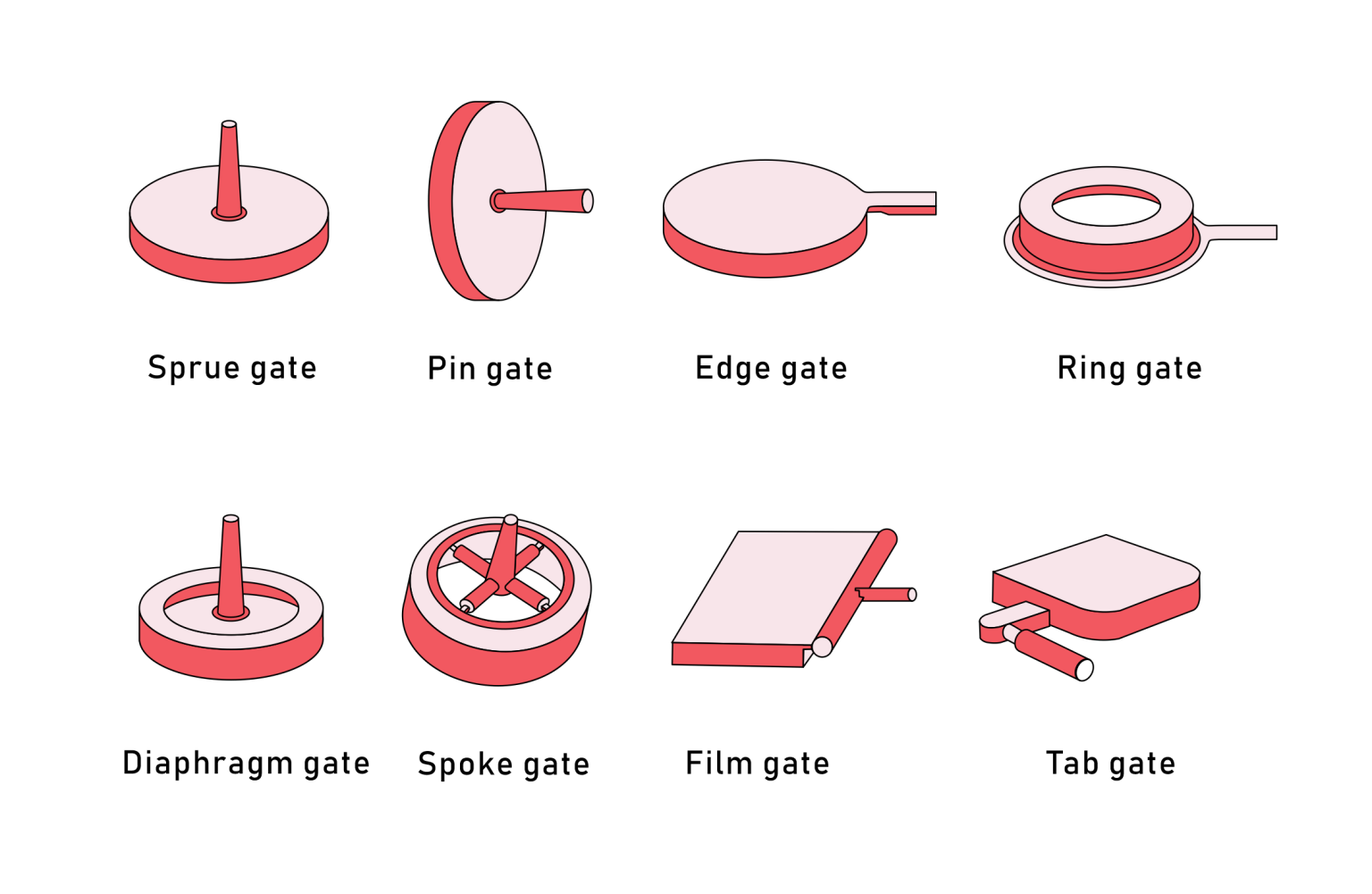

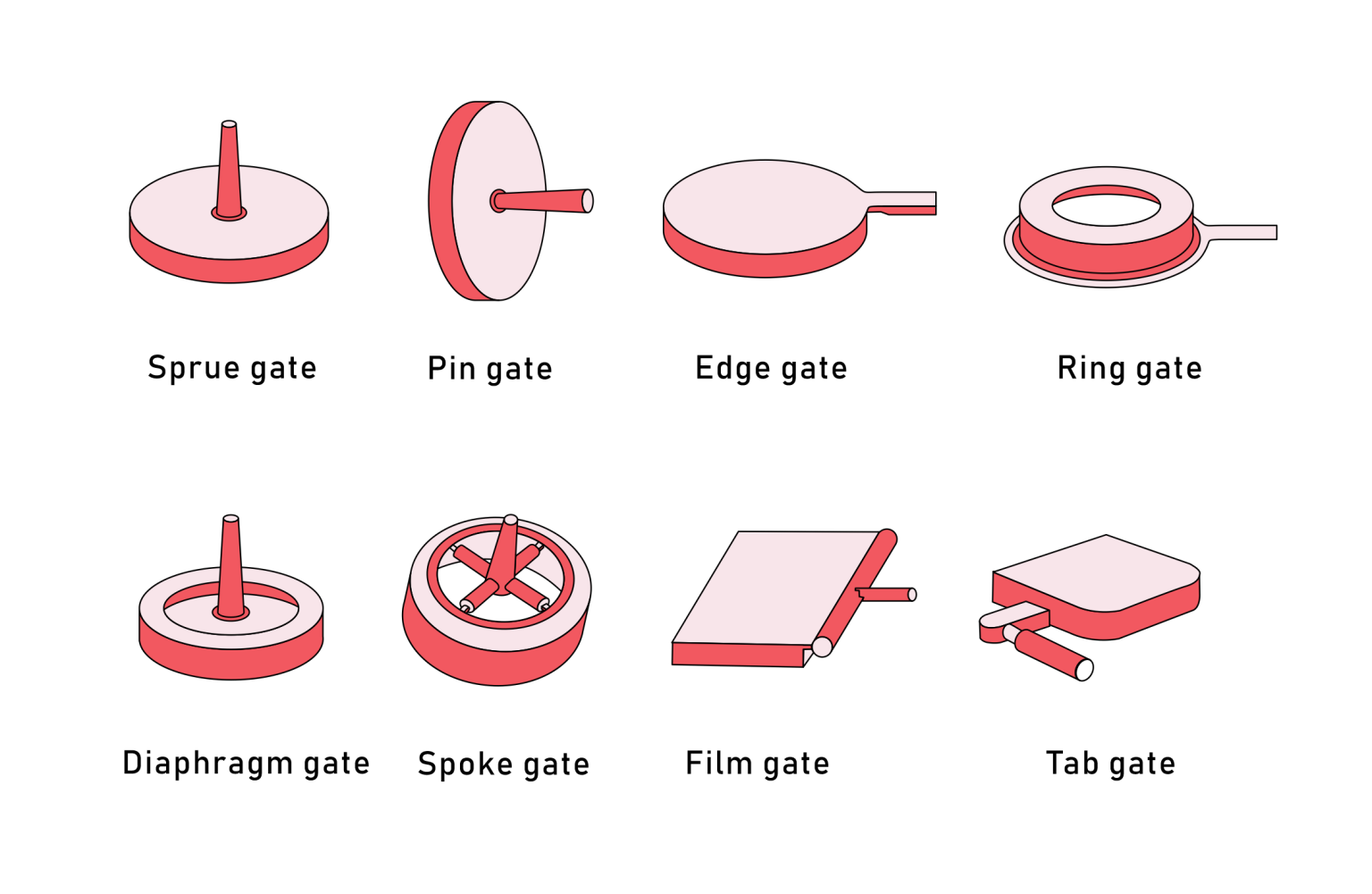

Gate Placement

Proper gate location ensures optimal material flow and minimizes shrinkage:

Ejector Pin Placement

Early planning of ejector pin locations is essential:

Sink Marks

Addressing sink marks involves:

Optimizing cooling channel design

Adjusting packing pressure and time

Implementing gas-assist or foam injection techniques

Parting Lines

Collaborate with molders to optimize parting line placement:

Special Features

Design considerations for complex features:

Undercuts: Use collapsible cores or side actions

Holes: Incorporate proper aspect ratios and locations

Side actions: Balance complexity with cost implications

Step 8: Prototyping

Importance of Prototyping for Design Verification

Prototyping plays a crucial role in verifying the design before full-scale production. It allows designers and manufacturers to identify potential issues that may arise during the manufacturing process or in the product’s performance. By creating a prototype, teams can visualize the product and assess its functionality in real-world conditions.

Identifying Manufacturing and Performance Issues

Prototyping helps uncover defects such as dimensional inaccuracies, poor material flow, or areas prone to failure. Early identification of these problems ensures they can be corrected before expensive tooling is created. Some common issues prototypes help identify include:

Weld lines

Warpage

Sink marks

Structural weaknesses

Methods of Prototyping

There are two main methods for prototyping plastic parts:

3D Printing

This method provides a quick, cost-effective way to produce prototypes. It’s ideal for visualizing the design and testing basic functionality.

Low-Volume Injection Molding

This method closely simulates the final production process. It’s used to validate the design’s manufacturability and performance in actual conditions.

Testing Prototypes for Common Defects

Prototypes must be tested for various issues to ensure the design is ready for production. Testing helps identify:

Weld Lines – Points where different flows of plastic meet during molding, potentially weakening the structure.

Warpage – Uneven cooling that causes distortion.

Sink Marks – Depressions formed in thicker areas due to inconsistent cooling.

Strength and Durability – Ensuring the part meets performance requirements under load.

Early Detection of Issues to Minimize Tooling Rework

By identifying and resolving issues during the prototyping phase, teams can significantly reduce the need for expensive tooling rework. Catching problems early helps streamline production and ensures the final product meets all design and performance specifications.

Step 9: Tooling and Manufacturing

Building Pre-Production and Production Tools

The transition from design to manufacturing hinges on creating high-quality injection molds. This process involves:

Tool design: Translating part geometry into mold components

Material selection: Choosing appropriate tool steels for durability

Fabrication: Precision machining of mold cavities and cores

Assembly: Integrating cooling channels, ejector systems, and gates

Mold makers often begin basic work on production tools early to save time.

Debugging Tooling

Rigorous testing and refinement of molds ensure optimal performance:

Trial runs: Identify and address issues in part formation

Dimensional analysis: Verify adherence to design specifications

Surface finish evaluation: Assess and improve part aesthetics

Iterative adjustments may include:

| Issue | Potential Solution |

| Flash | Adjust parting line or increase clamp force |

| Short shots | Optimize gate design or increase injection pressure |

| Warpage | Refine cooling system layout |

Initiating Manufacturing Process

Once tools are debugged, production can commence:

Process parameter optimization

Quality control procedures establishment

Production ramp-up planning

Key considerations during initial production:

Best Practices for Plastic Part Design

Collaborative Approach

Engaging injection molders and engineers early in the design process yields significant benefits:

Improved manufacturability

Reduced design iterations

Enhanced cost-effectiveness

Leveraging Technology

Utilize advanced software tools to optimize designs:

CAD software: Create precise 3D models

Mold flow analysis: Simulate injection molding process

FEA tools: Evaluate structural performance

These technologies enable designers to identify and address issues before physical prototyping.

End-Use Consideration

Prioritize the product's intended application throughout the design process:

| Aspect | Consideration |

| Environmental conditions | Temperature, chemical exposure, UV radiation |

| Loading scenarios | Static, dynamic, impact forces |

| Regulatory requirements | Industry-specific standards, safety regulations |

Designing with end-use in mind ensures optimal performance and longevity.

Balancing Key Factors

Successful plastic part design requires a delicate balance:

Cost: Material selection, tooling complexity

Performance: Mechanical properties, durability

Manufacturability: Ease of production, cycle time

Strive for the optimal intersection of these factors to create viable products.

Early Prototyping

Implement prototyping early in the design cycle:

Validates design concepts

Identifies potential issues

Reduces costly late-stage modifications

Rapid Prototyping Techniques

Leverage advanced prototyping methods to accelerate development:

3D printing: Quick turnaround for complex geometries

CNC machining: Accurate representation of final materials

Silicone molding: Cost-effective for small batch production

These techniques enable faster design iterations and market validation.

Conclusion

The plastic part design process involves several crucial steps. From defining requirements to final manufacturing, each stage is vital.

A systematic approach ensures optimal results. It balances performance, cost, and manufacturability effectively.

Well-designed plastic parts offer numerous benefits:

Improved product quality

Reduced production costs

Enhanced functionality

Increased durability

Prototype validation and small-batch trials are essential. They help detect issues early, saving time and resources.

We encourage readers to apply this knowledge in their projects. By following these steps, you can create successful plastic parts.