Plastic products are everywhere, but designing them isn’t simple. How do engineers balance strength, cost, and production efficiency? This article will uncover the complexities behind the structural design of plastic products. You'll learn key factors, like wall thickness, reinforcing ribs, and more, that make durable, cost-effective plastic parts.

Characteristics and Procedures of Plastic Part Structural Design

Plastic materials offer unique properties and versatile shaping options, setting them apart from conventional engineering materials like steel, copper, aluminum, and wood. This distinctive combination of material composition and formability grants plastics a higher degree of design flexibility compared to their counterparts.

Unique Material Composition and Versatile Shapes

The diverse range of plastic materials, each with its specific properties, allows designers to tailor their choice according to the product's requirements. This variety, coupled with the ability to mold plastics into intricate shapes, enables the creation of complex geometries and functional features that would be challenging or impractical with other materials.

General Procedure for Plastic Part Design

To leverage the advantages of plastics and ensure optimal structural design, it is essential to follow a systematic approach. The general procedure for plastic part design involves several key stages:

Determine functional requirements and appearance of the product:

Draw preliminary design drawings:

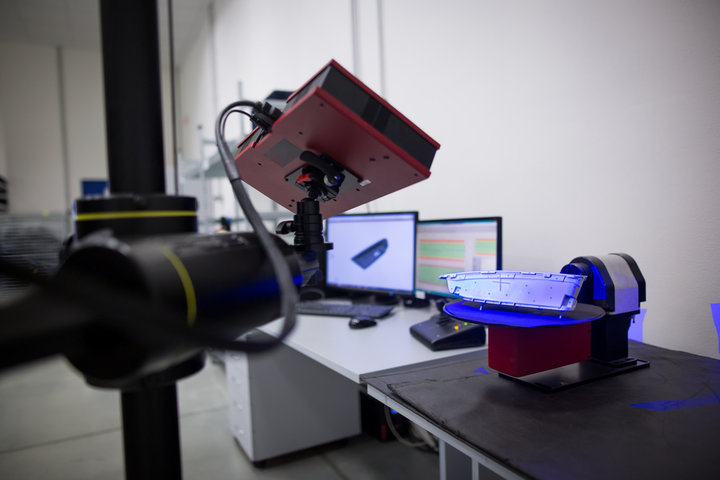

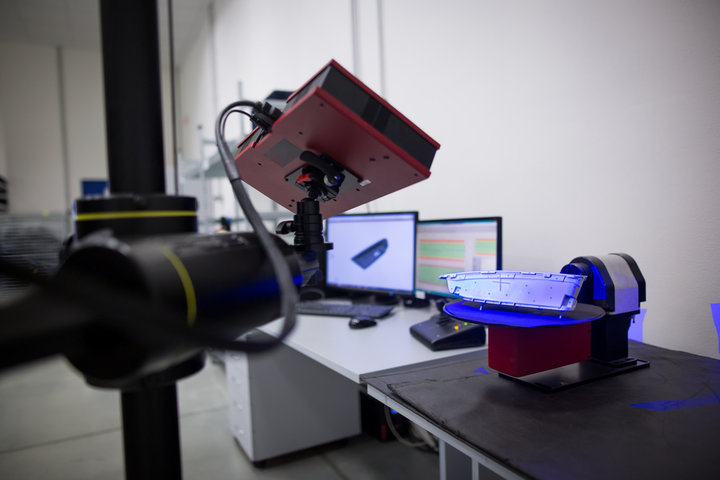

Prototyping:

Produce physical prototypes using methods like 3D printing or CNC machining

Evaluate the prototype's functionality, ergonomics, and overall design

Product testing:

Design recalibration and revision:

Analyze test results and identify areas for improvement

Make necessary design adjustments to enhance performance, reliability, or manufacturability

Develop important specifications:

Create detailed specifications for the final product, including dimensions, tolerances, and material grade

Ensure the specifications align with the manufacturing process and quality control standards

Open mold production:

Design and fabricate the injection mold based on the finalized product specifications

Optimize the mold design for efficient material flow, cooling, and ejection

Quality control:

Fundamental Factors in Plastic Product Structural Design

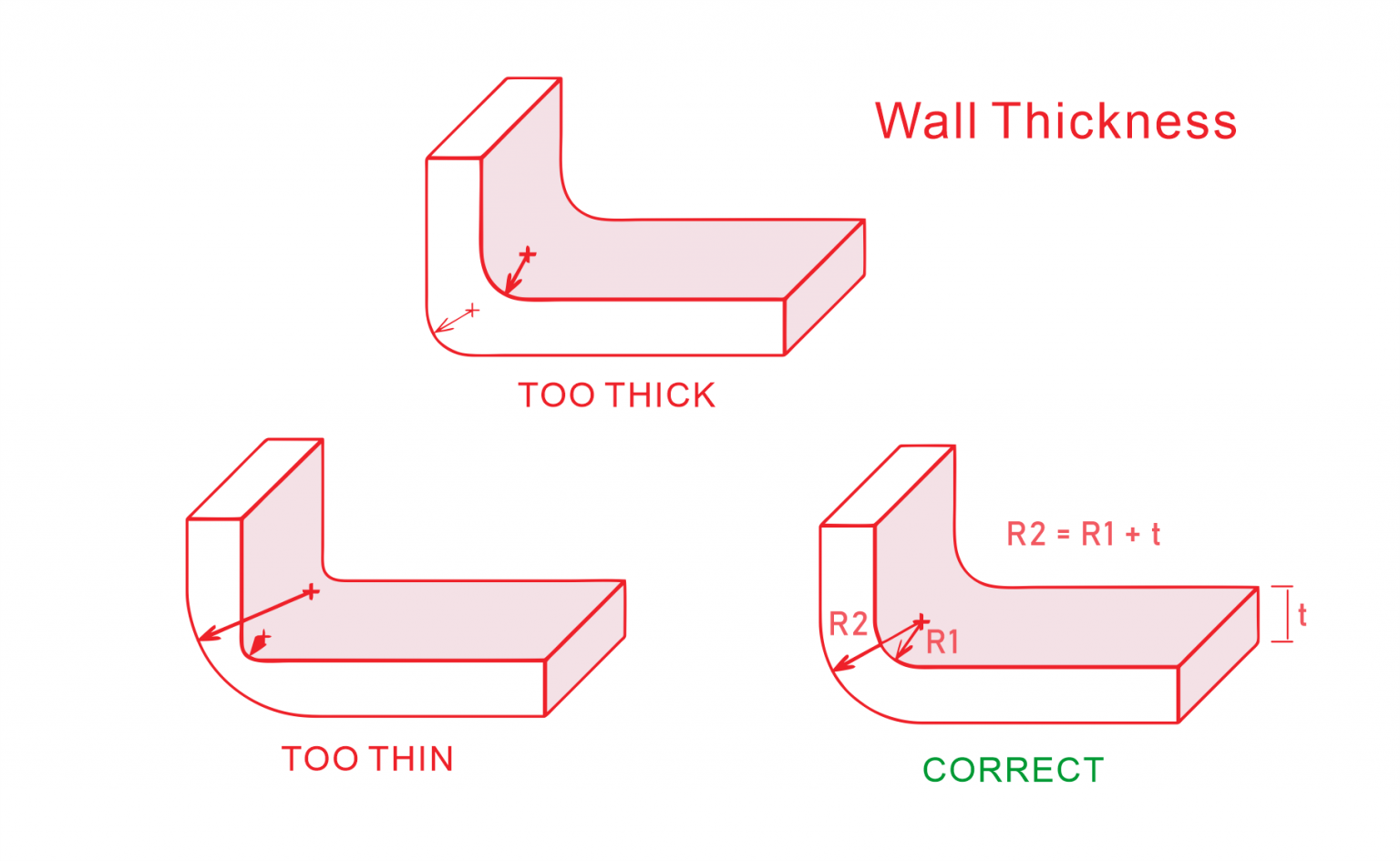

Wall Thickness

Wall thickness plays a crucial role in plastic product design. Proper thickness ensures optimal performance, manufacturability, and cost-effectiveness.

Recommended Wall Thickness Values

| Plastic Material | Minimum (mm) | Small Parts (mm) | Medium Parts (mm) | Large Parts (mm) |

| Nylon | 0.45 | 0.76 | 1.5 | 2.4-3.2 |

| PE | 0.6 | 1.25 | 1.6 | 2.4-3.2 |

| PS | 0.75 | 1.25 | 1.6 | 3.2-5.4 |

| PMMA | 0.8 | 1.5 | 2.2 | 4-6.5 |

| PVC | 1.2 | 1.6 | 1.8 | 3.2-5.8 |

| PP | 0.85 | 1.54 | 1.75 | 2.4-3.2 |

| PC | 0.95 | 1.8 | 2.3 | 3-4.5 |

| POM | 0.8 | 1.4 | 1.6 | 3.2-5.4 |

| ABS | 0.8 | 1 | 2.3 | 3.2-6 |

Factors Affecting Wall Thickness Selection

Plastic material properties

External forces endured

Safety regulations

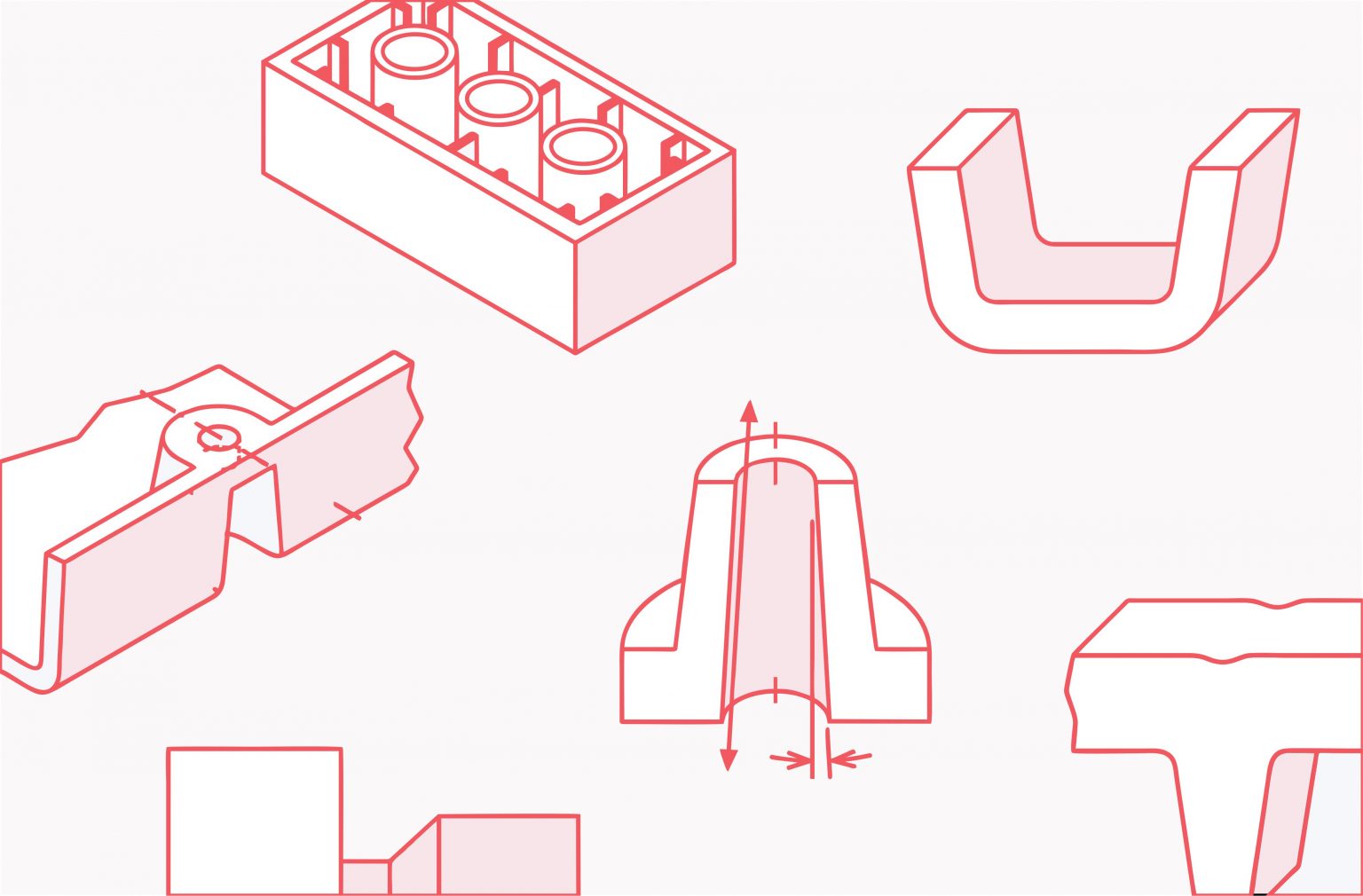

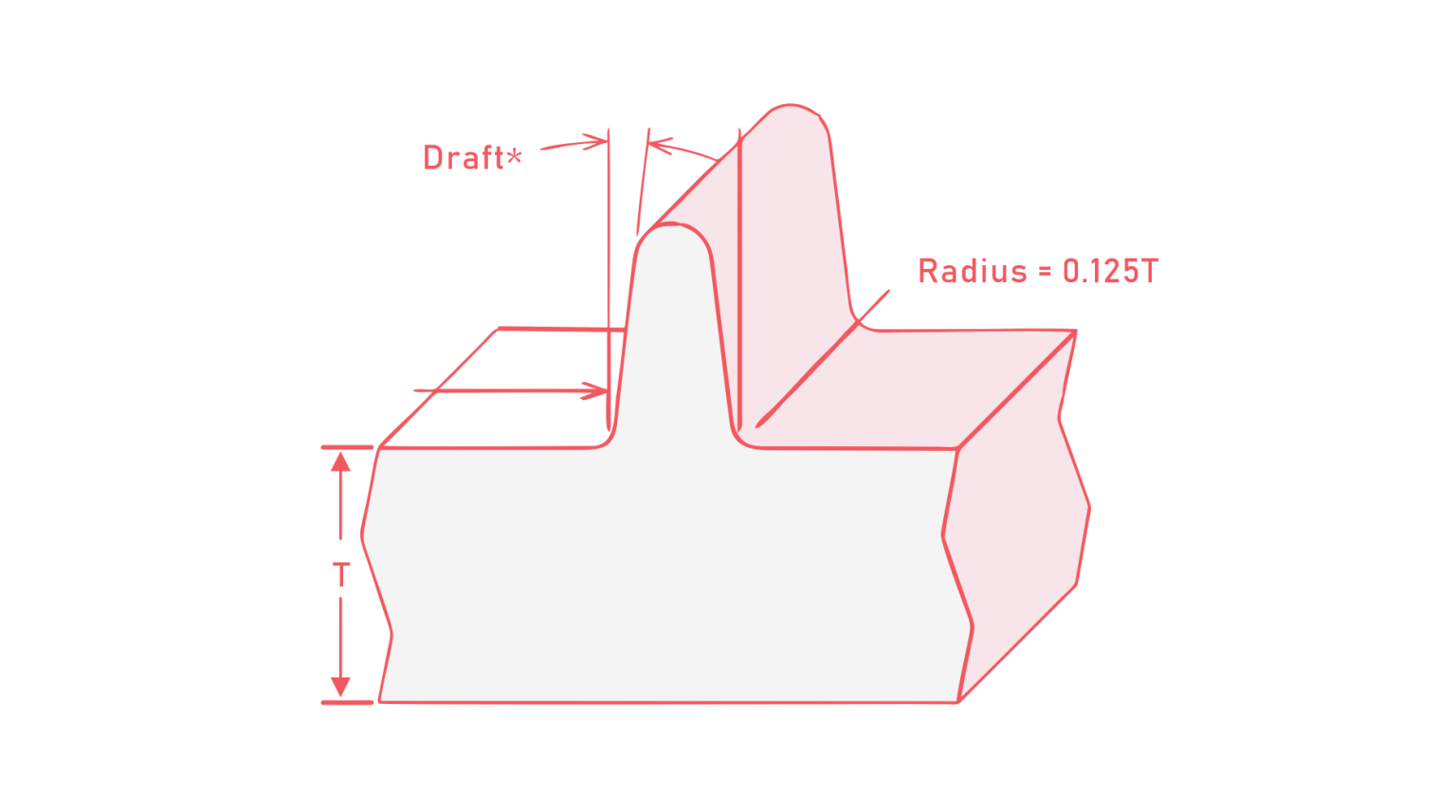

Reinforcing Ribs

Reinforcing ribs enhance strength without increasing overall wall thickness, prevent product deformation, and improve structural integrity.

Design Guidelines for Reinforcing Ribs

Thickness: 0.5-0.75 times overall wall thickness (recommended: <0.6 times)

Height: Less than 3 times wall thickness

Spacing: Greater than 4 times wall thickness

Aspects of Reinforcement Design Needing Attention

Avoid material accumulation at rib intersections

Maintain perpendicularity to outer walls

Minimize reinforcing ribs on steep slopes

Consider appearance impact of sink marks

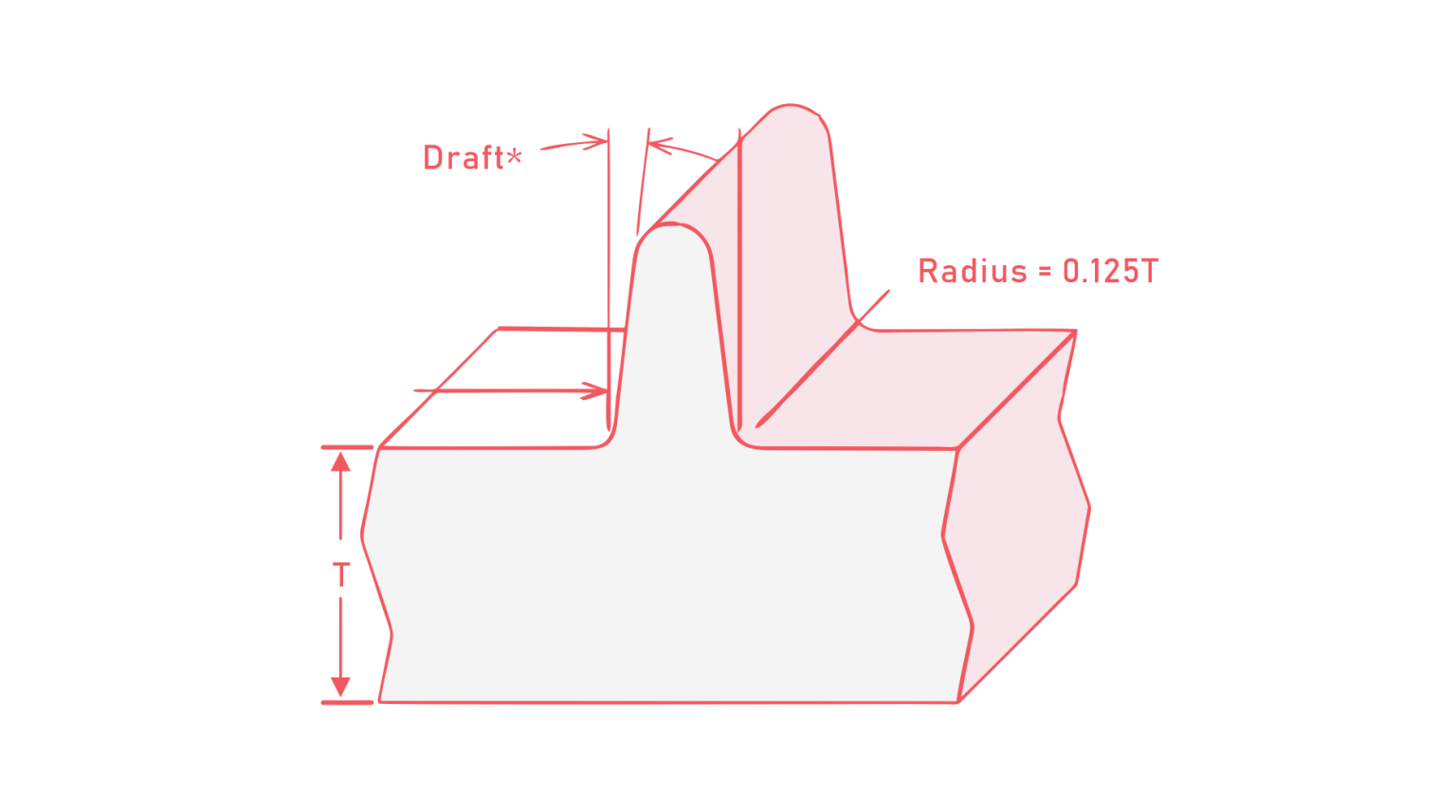

Draft Angles

Draft angles facilitate easy part removal from molds, ensuring smooth production and high-quality parts.

Recommended Draft Angles for Different Materials

| Material | Mold Core | Mold Cavity |

| ABS | 35'-1° | 40'-1°20' |

| PS | 30'-1° | 35'-1°30' |

| PC | 30'-50' | 35'-1° |

| PP | 25'-50' | 30'-1° |

| PE | 20'-45' | 25'-45' |

| PMMA | 30'-1° | 35'-1°30' |

| POM | 30'-1° | 35'-1°30' |

| PA | 20'-40' | 25'-40' |

| HPVC | 50'-1°45' | 50'-2° |

| SPV | 25'-50' | 30'-1° |

| CP | 20'-45' | 25'-45' |

Aspects of Draft Angle Selection Needing Attention

Choose smaller angles for glossy surfaces and high-precision parts

Use larger angles for parts with high shrinkage rates

Increase draft for transparent parts to prevent scratches

Adjust angle based on texture depth for textured surfaces

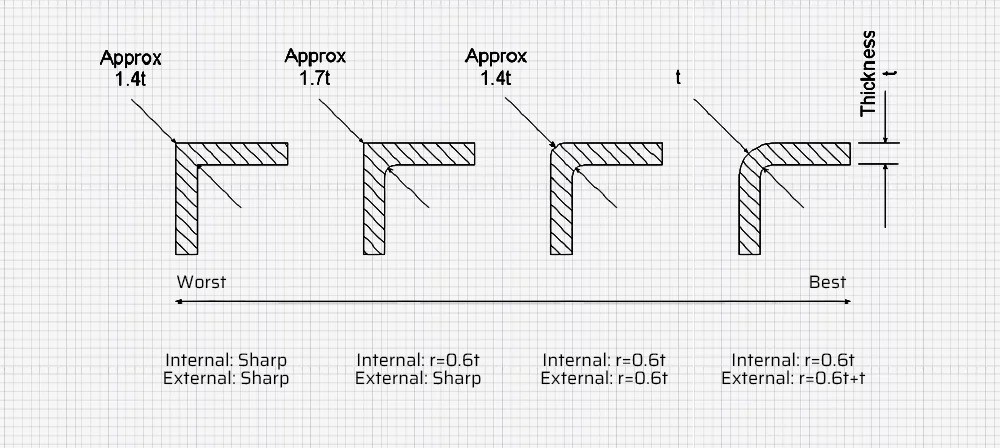

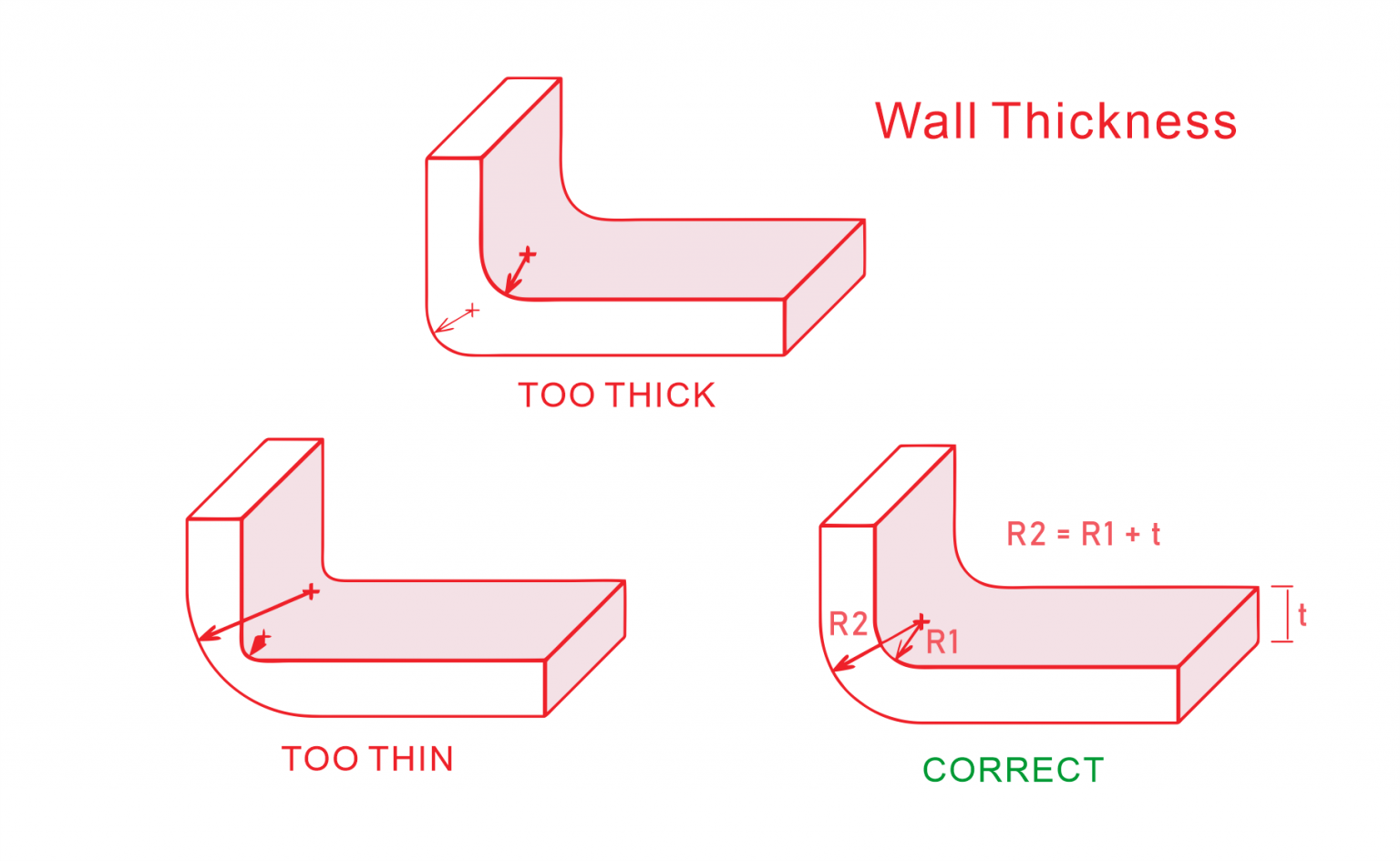

R Corners (Rounded Corners)

Rounded corners reduce stress concentration, facilitate plastic flow, and ease demolding.

Design Guidelines for R Corners

Internal corner radius: 0.50 to 1.50 times material thickness

Minimum radius: 0.30mm

Maintain uniform wall thickness when designing rounded corners

Avoid rounded corners on mold parting surfaces

Use minimum 0.30mm radius for edges to prevent scratching

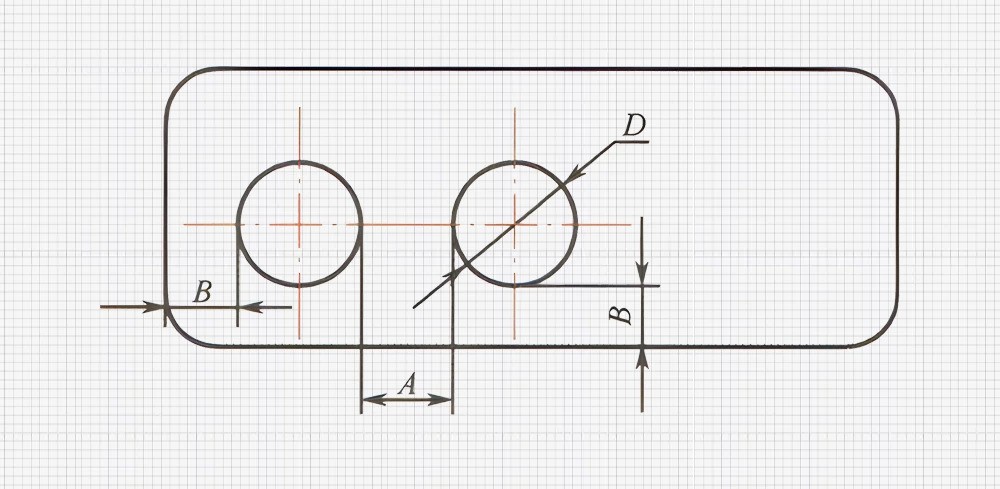

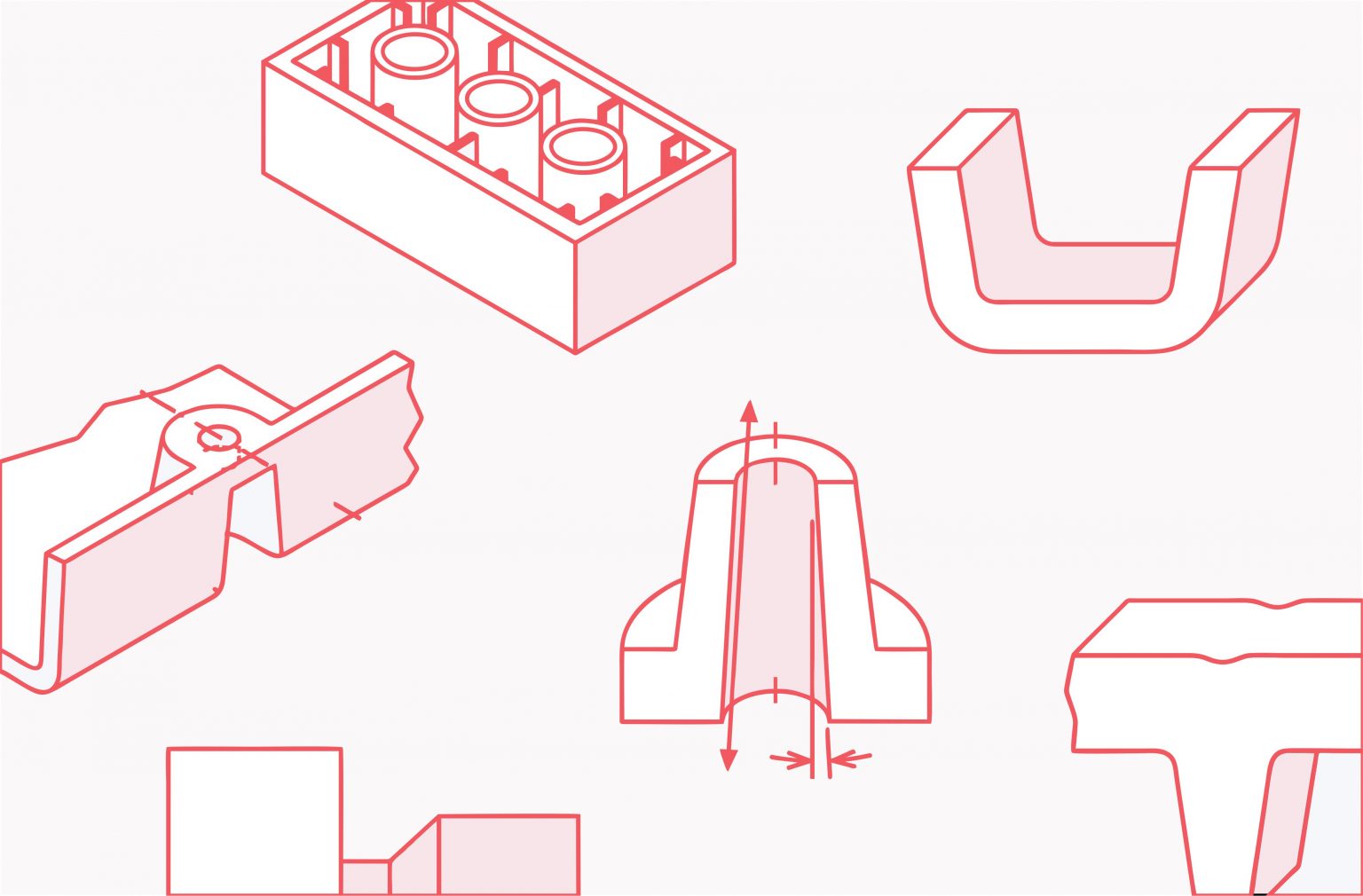

Holes

Holes serve various functions in plastic products and require careful design consideration.

Design Requirements for Holes

Relationship Between Hole Diameter and Depth

Design Considerations for Special Hole Types

Step holes: Use multiple coaxially connected holes of different diameters

Angled holes: Align axis with mold opening direction when possible

Side holes and indentations: Consider core pulling structures or design improvements

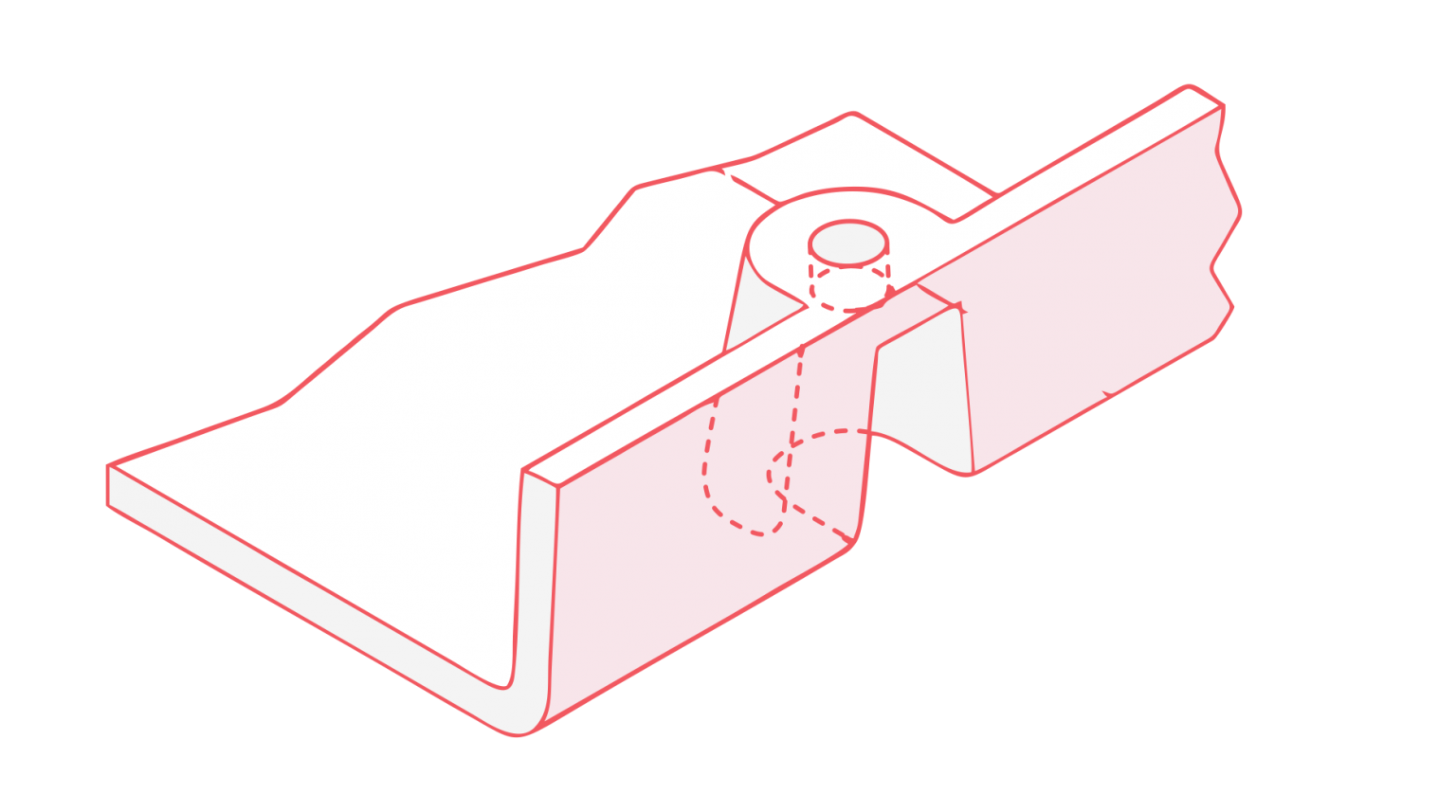

Bosses

Bosses provide assembly points, support other parts, and enhance structural integrity.

Basic Design Guidelines for Bosses

Height: ≤ 2.5 times boss diameter

Use reinforcement ribs or attach to outer walls when possible

Design for smooth plastic flow and easy demolding

Design Points for Different Materials

ABS: Outer diameter ≈ 2x inner diameter; use beveled ribs for strengthening

PBT: Base design on rib concept; connect to sidewalls when possible

PC: Interlock side bosses with ribs; use for assembly and support

PS: Add ribs for strengthening; connect to sidewalls when nearby

PSU: Outer diameter ≈ 2x inner diameter; height ≤ 2x outer diameter

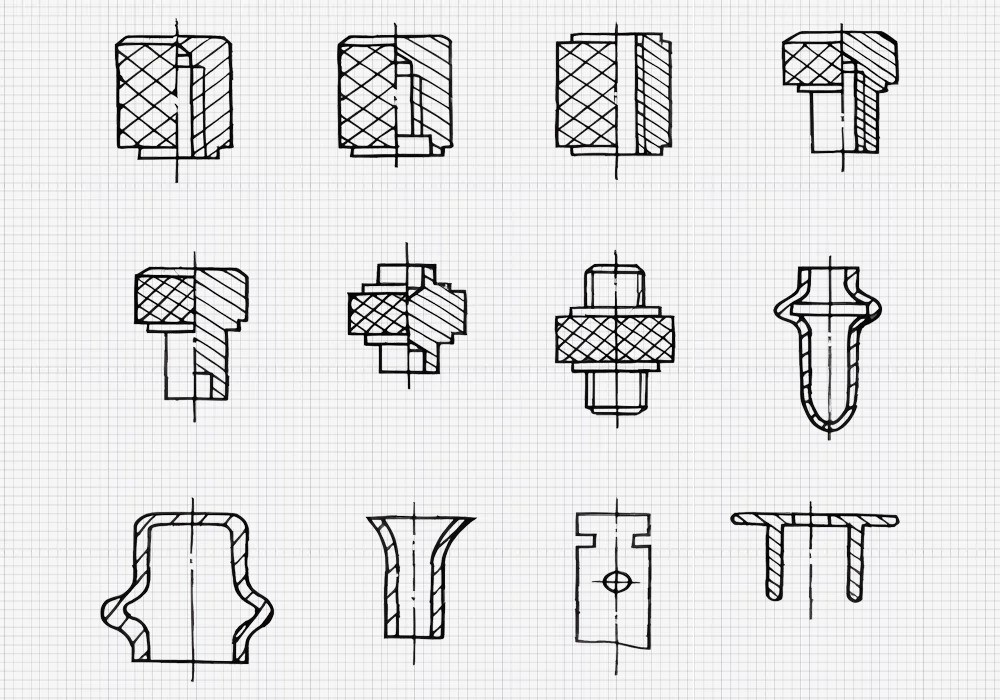

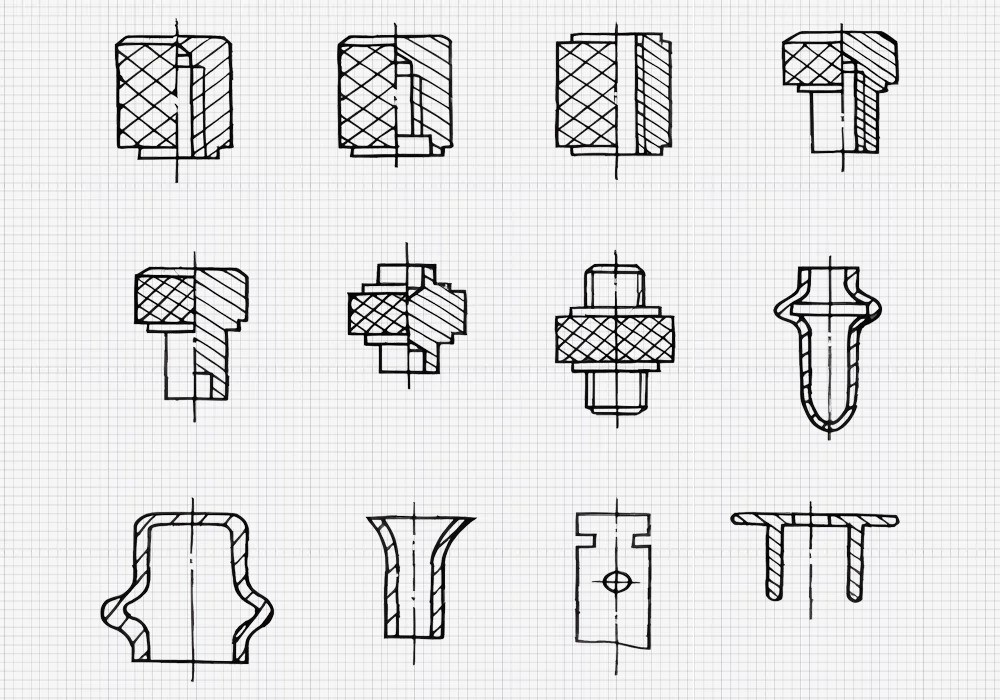

Inserts

Inserts enhance functionality, provide decorative elements, and improve assembly options in plastic parts.

Shape and Structural Requirements for Inserts

Manufacturability: Compatible with cutting or stamping processes

Mechanical strength: Sufficient material and dimensions

Bonding strength: Adequate surface features for secure attachment

Positioning: Cylindrical extending portions for easy mold placement

Flash prevention: Include sealing boss structures

Post-processing: Design for secondary operations (threading, cutting, flanging)

Design Considerations When Using Inserts

Ensure precise positioning within molds

Create strong connections with molded parts

Prevent plastic leakage around inserts

Consider thermal expansion differences between insert and plastic material

Product Surface Texture and Text/Pattern Design

Surface Textures for Plastic Products

Plastic product surfaces can be designed with various textures to enhance aesthetics, functionality, and user experience. Common surface textures include:

Smooth

Spark-etched

Patterned etched

Engraved

Smooth Surfaces

Smooth surfaces result from polished mold surfaces. They offer:

Spark-Etched Surfaces

Created through copper EDM processing of the mold cavity, spark-etched surfaces provide:

Patterned Etched Surfaces

These surfaces feature various patterns etched into the mold cavity, offering:

Engraved Surfaces

Engraved surfaces are created by directly machining patterns into the mold, allowing for:

Draft Angle Considerations for Textured Surfaces

When designing textured surfaces, consider increasing draft angles to facilitate part ejection:

| Texture Depth | Recommended Additional Draft Angle |

| 0.025 mm | 1° |

| 0.050 mm | 2° |

| 0.075 mm | 3° |

| > 0.100 mm | 4-5° |

Text and Pattern Design

Plastic products often incorporate text and patterns for branding, instructions, or decorative purposes. These elements can be either raised or recessed.

Raised vs. Recessed Surfaces

Recommendation: Use raised surfaces for text and patterns when possible.

Benefits of raised surfaces:

For designs requiring flush or recessed features:

Create a recessed area

Raise text or pattern within the recess

Maintain overall flush appearance while simplifying mold design

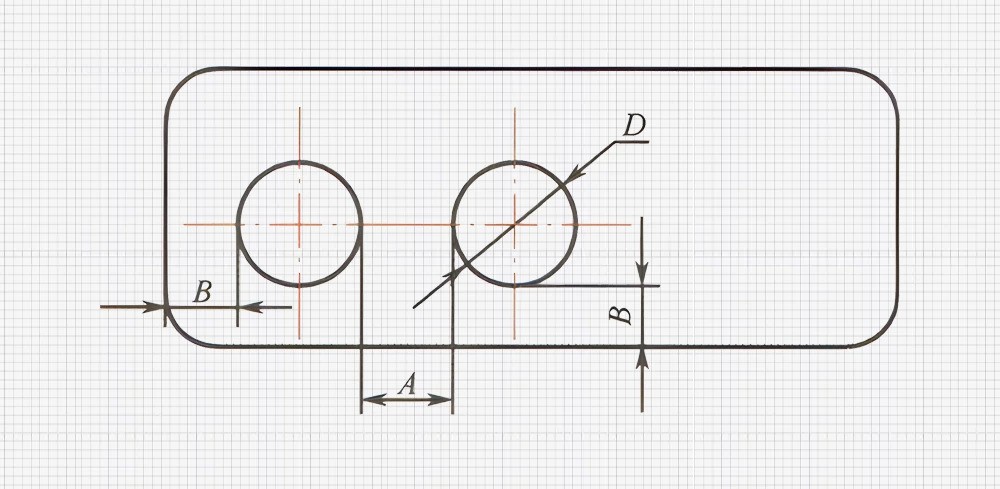

Text and Pattern Dimensions

| Feature | Recommended Dimension |

| Height/Depth | 0.15 - 0.30 mm (raised) |

| 0.15 - 0.25 mm (recessed) |

Text Size Specifications

Follow these guidelines for optimal text design:

Stroke width (A): ≥ 0.25 mm

Spacing between characters (B): ≥ 0.40 mm

Distance from characters to edge (C, D): ≥ 0.60 mm

Additional Text/Pattern Design Considerations

Avoid sharp angles in text or patterns

Ensure size is conducive to molding process

Consider the impact of text/pattern on overall part strength

Evaluate the effect of text/pattern on material flow during molding

Additional Structural Design Considerations

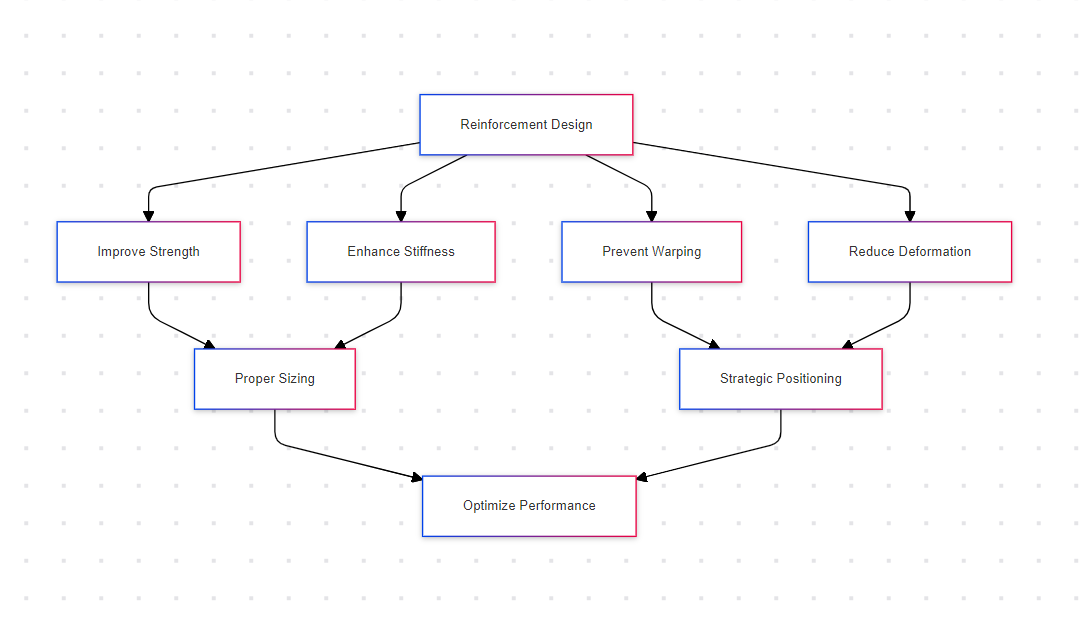

Reinforcement Structure Design Principles

Reinforcement structures play a crucial role in enhancing the overall performance of plastic products. They significantly improve strength, stiffness, and dimensional stability.

Key Objectives of Reinforcement Design:

Strength enhancement

Stiffness improvement

Warping prevention

Deformation reduction

Proper Positioning and Sizing of Reinforcements:

Wall thickness: 0.4-0.6 times main body thickness

Spacing: > 4 times main body thickness

Height: < 3 times main body thickness

Screw column reinforcement: At least 1.0mm below column surface

General reinforcement: Minimum 1.0mm below part surface or parting line

Advanced Reinforcement Techniques:

Misaligned reinforcement bars to prevent material buildup

Hollow structures at reinforcement intersections

Tension-based designs for slender reinforcements

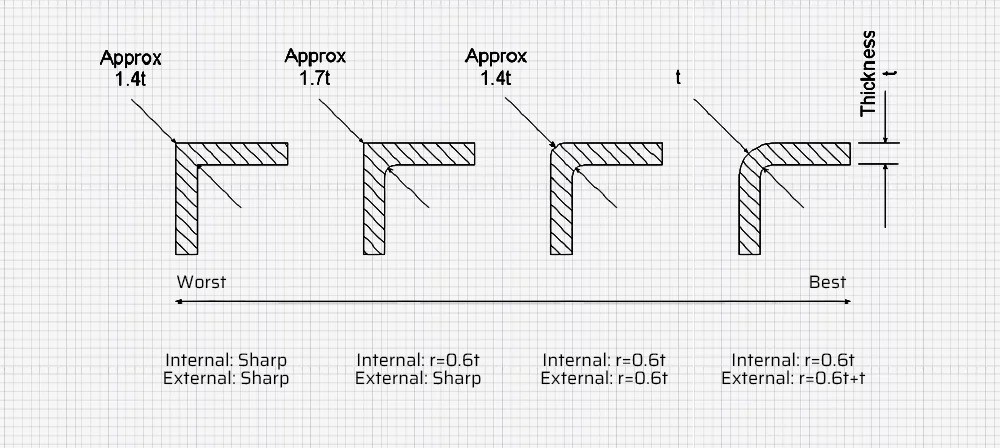

Avoiding Stress Concentration

Stress concentration can significantly impact the structural integrity and longevity of plastic products. Proper design techniques can mitigate these issues.

Importance of Avoiding Sharp Corners:

Measures to Reduce Stress Concentration:

Chamfers

Rounded corners

Gentle slopes for transitions

Inward hollowing at sharp corners

| Technique | Description | Benefit |

| Chamfers | Beveled edges | Gradual stress distribution |

| Rounded corners | Curved transitions | Eliminates sharp stress points |

| Gentle slopes | Gradual thickness changes | Even stress distribution |

| Inward hollowing | Material removal at corners | Localized stress reduction |

Designing Suitable Draft Angles

Draft angles are essential for successful part ejection from molds. They significantly impact part quality and production efficiency.

Principles for Determining Draft Angles:

Use whole number angles (e.g., 0.5°, 1°, 1.5°)

Exterior angles > interior angles

Maximize angles without compromising appearance

Factors Influencing Draft Angle Size:

Part depth

Surface finish

Material shrinkage rate

Texture depth

Draft Angle Design Points for Different Materials:

| Material | Recommended Draft Angle Range |

| ABS | 0.5° - 1° |

| PC | 1° - 1.5° |

| PP | 0.5° - 1° |

| PS | 0.5° - 1° |

| PET | 1° - 1.5° |

Structural Design from Mold Structure Perspective

Efficient mold design is crucial for successful plastic part production. Consider these aspects to optimize both part and mold design.

Avoiding Complex Structures:

Simplify part geometry

Reduce undercuts

Minimize side actions

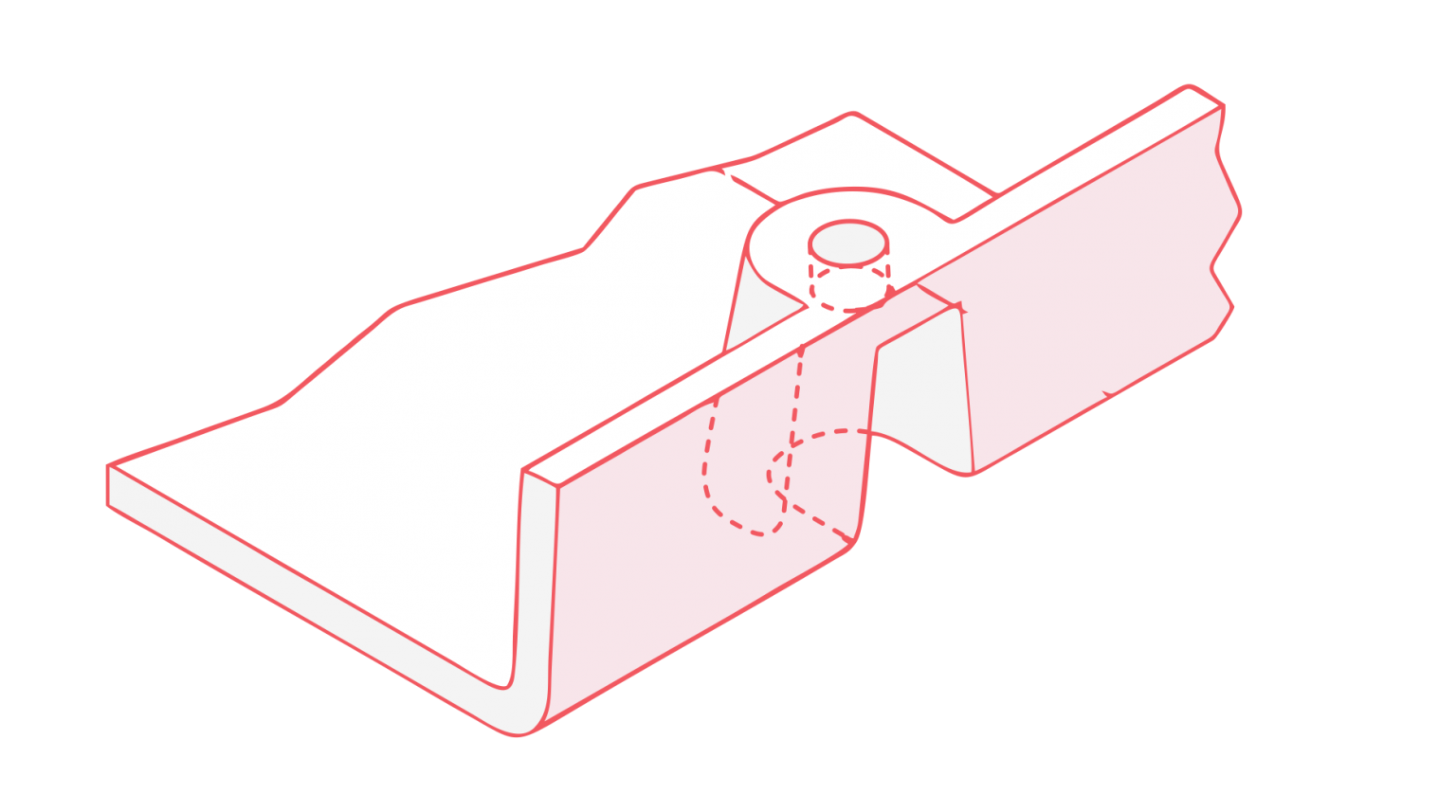

Avoiding Internal Cutting Structures:

Considering Lateral Release Requirements:

Allow sufficient space for slider movement

Design appropriate shut-off surfaces

Optimize part orientation in the mold

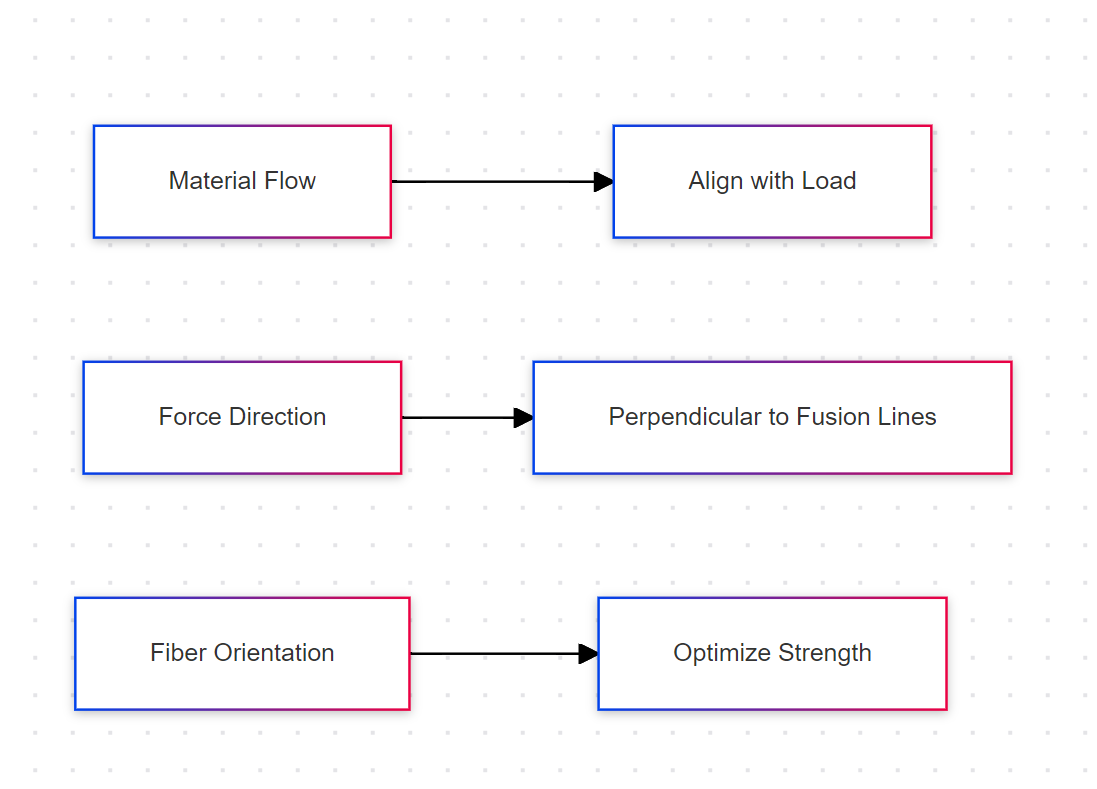

Designing for Non-Isotropic Characteristics of Plastics

Many plastics exhibit non-isotropic properties, requiring special design considerations to maximize performance.

Aligning Material Flow Direction with Load-Bearing Direction:

Force Direction Relative to Fusion Lines:

Structural Design from Assembly Perspective

Effective assembly design ensures product functionality, longevity, and ease of manufacture.

Avoiding Large Sizes with Small Tolerances:

Bonding Interface Design:

Prioritize shear force over tearing tension

Increase bonding surface area

Consider chemical compatibility of adhesives

Bolt Connection Considerations for Plastic Parts:

Use inserts for high-stress connections

Design appropriate boss structures

Consider thermal expansion differences

Summary

In plastic product design, key structural factors like wall thickness, reinforcing ribs, and draft angles are essential for durability and performance. It's crucial to consider material properties, mold structure, and assembly needs throughout the process. Proper structural design not only enhances product functionality but also reduces defects and manufacturing costs. By focusing on these design elements, manufacturers can ensure high-quality, cost-effective plastic parts that meet both functional and aesthetic requirements.