How do you ensure machine parts fit perfectly and function smoothly? Choosing the right fit is critical in engineering. A precise fit impacts the performance, durability, and safety of products.

Understanding different types of fits is essential for designing components that move, rotate, or slide.

In this post, you'll learn about clearance, transition, and interference fits. We'll guide you through selecting the best fit for your project based on function, precision, and budget.

Understanding Engineering Fits: The Fundamentals

Engineering fits play a crucial role in modern manufacturing. Understanding these fundamentals helps engineers create precise, reliable mechanical assemblies.

What is an Engineering Fit?

An engineering fit defines the dimensional relationship between two mating components. It determines how parts interact when assembled together. Engineering fits ensure:

Precise mechanical connections between components through controlled dimensional relationships

Optimal performance through specific clearance or interference between mating parts

Reliable assembly processes based on standardized dimensional specifications

Enhanced product longevity through proper component interaction and wear control

Key Terminology in Engineering Fits

Understanding essential terminology helps engineers communicate effectively about fits:

Base Components:

Hole: The internal feature of a component (cylindrical or non-cylindrical)

Shaft: The external feature designed to mate with a hole

Nominal Size: The theoretical perfect dimension used as a reference

Dimensional Terms:

Tolerance: Acceptable variation from specified dimensions

Clearance: Space between mating components

Interference: Overlap between component dimensions

Deviation: Difference from nominal size

Role of Fits in Mechanical Assemblies

Engineering fits serve multiple purposes in mechanical systems:

Movement Control

Load Transfer

Ensure proper force transmission

Maintain structural integrity

Prevent component failure

Assembly Management

Guide manufacturing processes

Standardize component relationships

Facilitate maintenance procedures

Basic Principles of Dimensional Relationships

The foundation of engineering fits relies on several key principles:

| Principle | Description | Application |

| Hole Basis System | Fixed hole dimensions, variable shaft size | Most common manufacturing approach |

| Shaft Basis System | Fixed shaft dimensions, variable hole size | Specialized applications |

| Tolerance Zones | Defined acceptable dimensional variations | Quality control standard |

Critical Relationships:

Component Interaction

Mating surfaces must align within specified tolerances

Surface finish affects fit performance significantly

Material properties influence fit characteristics

Manufacturing Considerations

Production capabilities determine achievable tolerances

Cost increases with tighter tolerances

Assembly methods affect fit selection

Performance Requirements

Operating conditions influence fit selection

Load requirements determine appropriate fit type

Environmental factors affect long-term fit stability

This fundamental understanding helps engineers select appropriate fits for specific applications. They can optimize component relationships while considering manufacturing capabilities and cost constraints.

Understanding the Hole and Shaft Basis System

Explanation of the Hole and Shaft Basis System

The hole and shaft basis system is the foundation for defining engineering fits. It establishes which part of the assembly—either the hole or the shaft—will have a constant dimension. The other component's dimension is then adjusted to achieve the desired fit. This system is crucial in determining how tightly or loosely the parts will join.

Hole-Basis System: Constant Hole Size, Shaft Dimensions Vary

In the hole-basis system, the hole’s dimension is fixed while the shaft’s size is altered to achieve the required fit. This approach simplifies the manufacturing process because the hole’s size is easier to control through common processes like drilling. The shaft's dimensions can then be fine-tuned to meet precise fitting requirements.

Key characteristics of the hole-basis system:

Shaft-Basis System: Constant Shaft Size, Hole Dimensions Vary

In the shaft-basis system, the shaft’s dimension remains constant, and the hole’s size is modified to achieve the fit. This method is often used when altering the shaft size is difficult, such as in high-speed rotating shafts where mass balancing is critical. Adjusting the hole size offers greater flexibility when the shaft cannot be changed.

Key characteristics of the shaft-basis system:

Advantages of Using the Hole-Basis System

The hole-basis system is the more widely used option in engineering. Its advantages include:

Ease of manufacturing: Holes are simpler to control in mass production.

Cost efficiency: Reduces the need for specialized machining of holes.

Versatility: Allows for easier adjustments by modifying the shaft dimensions.

| System Type | Fixed Component | Variable Component | Common Applications |

| Hole-Basis System | Hole | Shaft | Gears, bushings, machine parts |

| Shaft-Basis System | Shaft | Hole | High-speed rotating components |

Tolerances and Their Role in Engineering Fits

Tolerances define the allowable variation in a part's dimension from its nominal size. They set the limits within which parts can be manufactured without affecting their function. In engineering fits, tolerances determine how much deviation is acceptable when mating parts are assembled.

Importance of Tolerances in Achieving Proper Fits

Tolerances are essential for ensuring the proper fit of components. Without precise tolerances, parts may be too loose or too tight, leading to performance issues or even failure. Properly specified tolerances allow engineers to control the quality of the fit and ensure reliability across various applications.

Relationship Between Tolerances and Fit Types

Different fit types require specific tolerance ranges:

| Fit Type | Typical Tolerance Range | Application Example |

| Clearance | +0.025mm to +0.089mm | Rotating assemblies |

| Transition | +0.023mm to -0.018mm | Location-critical components |

| Interference | -0.001mm to -0.042mm | Permanent assemblies |

How Tolerances are Specified in Engineering Drawings

In engineering drawings, tolerances are often indicated using Geometric Dimensioning and Tolerancing (GD&T) symbols. These symbols help define the acceptable range for part dimensions, ensuring consistency in manufacturing. The tolerances are presented in both linear and angular measurements, helping manufacturers achieve the correct fit.

Key elements in specifying tolerances include:

Nominal Dimension: The ideal size of the part

Upper and Lower Limits: The maximum and minimum allowable dimensions

GD&T Symbols: Standard symbols to specify tolerance zones and geometric constraints

| Fit Type | Tolerance Requirement | Example Use |

| Clearance Fit | Loose tolerances for free movement | Pivots, sliding joints |

| Interference Fit | Tight tolerances for press-fit assemblies | Gears, bushings, fixed bearings |

| Transition Fit | Moderate tolerances for precise alignment | Motor shafts, pulley assemblies |

Properly defined tolerances ensure the desired fit is achieved, leading to better performance and longer part life.

Three Main Types of Engineering Fits

In engineering, choosing the correct fit ensures the proper functioning of mechanical assemblies. There are three main types of fits: clearance fits, interference fits, and transition fits. Each type serves different purposes and is chosen based on the application's requirements.

1. Clearance Fits

Clearance fits establish a positive dimensional difference between mating components, ensuring free movement.

Core Characteristics:

The shaft diameter consistently remains smaller than the hole diameter

The designed gap enables specific movement patterns between components

Assembly processes require minimal force or specialized tools

Common Types:

Loose Running Fit (H11/c11)

Designed for applications requiring maximum movement freedom while maintaining basic positional relationships between mechanical components

Optimal for environments experiencing significant contamination, thermal variations, or irregular maintenance schedules

Free Running Fit (H9/d9)

Provides balanced clearance enabling smooth operation in high-speed applications while maintaining acceptable alignment between rotating components

Ideal for systems requiring consistent lubrication films and moderate precision in industrial machinery settings

Close Running Fit (H8/f7)

Maintains precise clearance relationships between components while enabling controlled movement patterns in precision machinery applications

Suitable for machine tool spindles and precision sliding mechanisms requiring accurate positional control during operation

Sliding Fit (H7/g6)

Enables smooth linear or rotational movement while maintaining strict dimensional control between mating surfaces in precision assemblies

Common in hydraulic systems, precision guide mechanisms, and specialized machinery requiring controlled motion characteristics

Locational Clearance Fit (H7/h6)

Establishes exact component positioning while allowing necessary movement for assembly and operation in precision engineering applications

Essential for guide systems and positioning equipment requiring repeatable alignment during assembly and maintenance procedures

Applications Matrix:

| Fit Type | Primary Use | Environmental Conditions | Assembly Requirements |

| Loose Running | Heavy Equipment | Contaminated/Variable | Minimal Force |

| Free Running | Rotating Systems | Clean/Controlled | Basic Alignment |

| Close Running | Precision Tools | Clean/Stable | Careful Handling |

| Sliding | Linear Motion | Clean/Lubricated | Precise Setup |

| Locational | Positioning | Controlled | Exact Alignment |

2. Transition Fits

Transition fits represent intermediate dimensional relationships between clearance and interference conditions.

Primary Classifications:

Similar Fit (H7/k6)

Creates balanced dimensional relationships allowing either minimal clearance or slight interference depending on manufacturing variations

Enables reliable positioning while maintaining assembly flexibility in precision mechanical systems requiring moderate hold strength

Fixed Fit (H7/n6)

Establishes more definitive interference conditions while remaining manageable for assembly and potential future maintenance requirements

Provides enhanced positional stability compared to similar fits while maintaining reasonable assembly force requirements

Key Advantages:

Optimal balance between positioning accuracy and assembly practicality

Suitable for diverse environmental conditions

Adaptable to varying load requirements

3. Interference Fits

Interference fits create strong mechanical bonds through controlled dimensional overlap between components.

Implementation Methods:

Press Fit (H7/p6)

Establishes permanent mechanical connections through precisely controlled dimensional interference between mating components in critical assemblies

Requires specialized assembly equipment and careful process control to achieve optimal results without component damage

Shrink Fit

Utilizes thermal expansion and contraction principles to create extremely strong mechanical bonds between precision-engineered components

Demands precise temperature control and specialized handling procedures during both assembly and potential maintenance operations

Selection Considerations:

Operating temperature ranges affecting dimensional stability

Load transmission requirements in assembled systems

Maintenance accessibility requirements for future service

Manufacturing capabilities and cost constraints

Material properties and surface finish specifications

How to Select the Right Type of Fit

Selecting the right type of fit in engineering is crucial to ensure that mechanical components function as intended. The choice depends on several factors, including application needs, precision, and environmental conditions. Understanding these factors helps engineers make informed decisions for optimal performance.

Factors to Consider

When choosing a fit, it's essential to evaluate key factors that impact both the design and functionality of the components:

Application Requirements: Determine if the parts will need to move, rotate, or remain fixed.

Operating Conditions: Consider factors like temperature, humidity, and potential exposure to dust or corrosion.

Assembly and Disassembly Needs: Evaluate how often the components need to be assembled or disassembled, which affects fit tightness.

Cost Considerations: Tighter tolerances and precision fits typically increase manufacturing costs, so balance performance with budget.

Precision Requirements: Some applications require very tight tolerances to ensure functionality, especially in high-stress environments.

Material Properties: The material type affects how parts interact, including their thermal expansion, wear, and durability under load.

Selection Criteria

When finalizing the fit type, engineers should base their decisions on detailed selection criteria:

Load Requirements: Choose a fit that can handle the expected load, especially for components under constant stress.

Movement Requirements: Determine whether the fit allows for free movement, restricted motion, or no movement at all.

Temperature Conditions: Some fits, like interference fits, require consideration of expansion and contraction due to temperature changes.

Maintenance Needs: Components that need regular servicing should use fits that allow easy assembly and disassembly.

Manufacturing Capabilities: Ensure that your manufacturing processes can meet the precision required for the selected fit.

| Fit Type | Ideal For | Common Applications |

| Clearance Fit | Free movement between components | Pivots, sliding joints, low-load parts |

| Interference Fit | Secure, permanent connections | Gears, bushings, bearing mounts |

| Transition Fit | Moderate clearance or interference | Precision alignment, shafts, pulleys |

By assessing these factors and criteria, engineers can select the ideal fit type for their specific project, ensuring efficiency and durability.

Achieving Dimensional Tolerances for Fits

Achieving precise dimensional tolerances is critical in engineering to ensure components fit together accurately and perform as expected. Various manufacturing techniques help engineers meet tight tolerance requirements, enhancing the functionality and longevity of mechanical parts.

Manufacturing Techniques for Achieving Tight Tolerances

Several manufacturing processes are commonly used to achieve high precision in parts, ensuring that the tolerances specified in engineering designs are met.

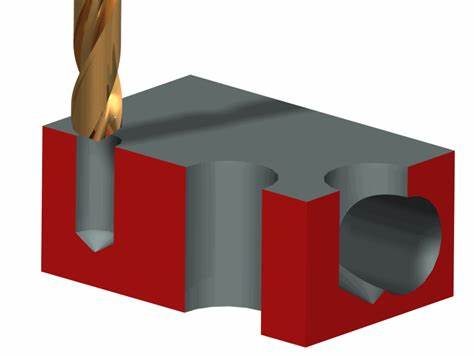

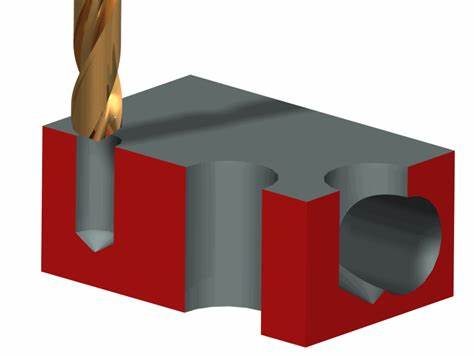

CNC Precision Machining

CNC machines offer exceptional accuracy, often achieving tolerances as tight as +/- 0.001 mm. They are ideal for producing parts that require intricate details or very small deviations in size.

Advantages: High precision, repeatability, ability to produce complex shapes

Applications: Shafts, gears, housings

Grinding

Grinding is a finishing process used to achieve extremely smooth surfaces and very tight tolerances. It is particularly useful for parts where high precision is required, such as interference fits.

Advantages: Achieves high accuracy up to +/- 0.25 microns

Applications: Bearing surfaces, press-fit parts

Reaming

Reaming is a process used to refine the size of holes, improving their roundness and precision. It is often employed after drilling to bring holes to the exact tolerances required for assembly.

Advantages: Precise hole-making with tight tolerances

Applications: Bearings, bushings, dowel holes

Importance of GD&T (Geometric Dimensioning and Tolerancing)

GD&T is a system of symbols and annotations used in engineering drawings to define the allowable variation in part dimensions. It helps manufacturers understand which dimensions are critical for achieving the desired fit. GD&T ensures that parts maintain the necessary geometry, even when slight variations occur in the manufacturing process.

Critical Elements

| GD&T Symbol | Application | Tolerance Range |

| Cylindricity | Shaft/Hole Form | 0.01-0.05mm |

| Concentricity | Assembly Alignment | 0.02-0.08mm |

| True Position | Component Location | 0.05-0.10mm |

| Roundness | Circular Features | 0.01-0.03mm |

Role of Quality Control in Ensuring Proper Fits

Quality control plays a vital role in maintaining the precision of fits. Regular inspections and testing ensure that parts meet the required tolerances. Methods like coordinate measuring machines (CMM) and optical comparators are used to verify dimensions.

Dimensional Inspections: Ensure parts conform to the specified tolerances.

Fit Testing: Verifies the assembly of parts and checks for any issues in fit.

Process Control: Monitors manufacturing processes to reduce variations and maintain consistency.

| Manufacturing Technique | Precision Level | Applications |

| CNC Precision Machining | +/- 0.001 mm | Gears, shafts, complex components |

| Grinding | +/- 0.25 microns | Bearings, press-fit components |

| Reaming | Precise hole-making | Bushings, dowel holes |

By utilizing these manufacturing techniques and maintaining rigorous quality control, engineers can achieve the tight tolerances required for proper fits, ensuring the performance and reliability of mechanical assemblies.

Troubleshooting Fit Problems

Common Issues in Fit Assemblies

1. Loose Connections

Excessive clearance between components leads to unwanted movement during operation

Improper tolerance specifications result in reduced assembly stability over time

Misaligned components create uneven wear patterns affecting system performance

Manufacturing variations exceed specified clearance limits for intended applications

2. Wear-Related Problems

Incorrect tolerance specifications accelerate component degradation during operational cycles

Mismatched material hardness properties create uneven wear patterns across mating surfaces

Surface finish irregularities contribute to premature component failure in assemblies

Inadequate lubrication systems compound wear issues in dynamic applications

3. Stress-Related Failures

| Issue | Cause | Solution |

| Component Cracking | Excessive interference | Adjust fit specifications |

| Surface Deformation | High assembly pressure | Modify installation process |

| Material Fatigue | Cyclic stress loading | Review material selection |

| Assembly Damage | Improper installation | Improve assembly procedures |

Methods to Adjust Fits

Manufacturing Refinements

Tolerance Optimization

Implement statistical process control methods to maintain consistent component dimensions

Review machining parameters to achieve more precise dimensional control

Adjust cutting tool selection based on material properties requirements

Surface Treatment

Apply specialized surface finishing techniques to improve component interaction

Enhance material properties through heat treatment or surface hardening

Modify surface texture specifications for optimal performance characteristics

Thermal Solutions

Calculate proper heating temperatures for successful interference fit assemblies

Monitor cooling rates to prevent unwanted material property changes

Control expansion rates through precise temperature management procedures

Lubrication Strategies

Assembly Applications

Select appropriate lubricants based on material compatibility requirements

Apply controlled lubrication layers during component assembly procedures

Monitor lubricant viscosity effects on assembly force requirements

Operational Considerations

Implement regular lubrication maintenance schedules for dynamic assemblies

Monitor lubricant degradation patterns during system operation cycles

Adjust lubrication specifications based on operational feedback data

Prevention Guidelines:

Conduct regular dimensional inspections during manufacturing processes

Document assembly procedures for consistent installation methods

Maintain detailed records of fit-related issues for future reference

Implement preventive maintenance schedules based on operational data

Summary of Fit Selection for Engineering Projects

Choosing the right fit in engineering depends on several factors. Functional requirements, machining precision, and cost constraints all play key roles. Managing tolerances ensures that parts meet design specifications.

To decide between clearance, transition, and interference fits, engineers must consider the intended movement, load, and assembly needs. A decision tree helps guide the process, balancing precision with practicality. Proper fit selection improves performance, reduces wear, and ensures long-term durability. By following these guidelines, engineers can make informed decisions that lead to successful mechanical assemblies.

Reference Sources

Engineering fits

Different types of holes in engineering

CNC Machining Tolerances

High Pressure Die Casting