Injection molding is a widely used manufacturing process that demands high precision. Without it, part defects and costly downtime occur. One crucial component in this process is the guide bushing, which ensures proper mold alignment, preventing damage and ensuring product quality.

In this post, we’ll explore the essential role of guide bushings in injection molding. You'll learn about their function, materials, design, and how they contribute to efficient production. By understanding their importance, you can improve mold performance and avoid common issues in manufacturing.

What is a Guide Bush?

A guide bush, also known as a guide pin bushing or guide sleeve, is a critical component in the injection molding process. It is a cylindrical sleeve that is installed in one half of the injection mold, usually the stationary half or the "A-side" of the mold. The primary purpose of a guide bush is to provide precise alignment and guidance for the moving half or the "B-side" of the mold during the opening and closing of the mold.

Role of Guide Bushes in Injection Molds

Guide bushes serve two primary functions in the injection mold process:

Alignment: They guide the moving mold half (B-side), ensuring it aligns perfectly with the stationary half during mold closing and opening.

Support: By maintaining proper alignment, guide bushes reduce wear on the mold and its components, increasing the overall lifespan of the tooling.

Without precise guide bush function, molds can misalign, leading to issues such as part deformation, flashing, and mold damage, resulting in costly downtime.

Relationship Between Guide Bushes and Guide Pins

Guide bushes and guide pins work as a pair to ensure the smooth operation of injection molds. While the guide bush provides the channel, the guide pin fits into this channel, ensuring that both mold halves close in a perfectly aligned manner. The relationship between the guide bush and guide pin is critical in high-speed molding environments, where even minor misalignments can lead to production inefficiencies.

Benefits of Using Guide Bushes in Injection Molding

Guide bushes play a crucial role in enhancing the efficiency and quality of injection molding processes. Their implementation offers numerous advantages, significantly impacting production outcomes and operational effectiveness.

Improved Part Quality and Consistency

Guide bushes contribute substantially to part quality:

Ensure precise alignment of mold halves

Minimize variations in part dimensions

Reduce the occurrence of defects such as flashing or short shots

Enhance surface finish quality of molded parts

By maintaining consistent alignment throughout the molding cycle, guide bushes help produce parts with superior dimensional accuracy and aesthetic appeal.

Increased Efficiency and Reduced Cycle Times

Properly implemented guide bushes streamline the molding process:

Facilitate smoother mold opening and closing

Minimize downtime due to misalignment issues

Enable faster production speeds without compromising quality

Reduce the need for frequent adjustments during production runs

These factors collectively contribute to shorter cycle times and increased overall productivity.

Minimized Mold Damage and Prolonged Mold Life

Guide bushes act as protective elements within the mold:

Prevent misalignment-induced wear on mold surfaces

Distribute stress evenly across mold components

Reduce the risk of damage during mold closure

Minimize vibration and uneven loading on mold elements

By mitigating these potential sources of damage, guide bushes significantly extend mold lifespan and reduce maintenance requirements.

Enhanced Operator Safety

The implementation of guide bushes improves workplace safety:

Reduce the risk of mold misalignment during operation

Minimize the potential for sudden mold movements or shifts

Decrease the likelihood of part ejection issues

Lower the frequency of manual interventions required

These safety enhancements not only protect operators but also contribute to a more stable and predictable production environment.

Design and Manufacturing of Guide Bushings

The design and manufacturing process of guide bushings is crucial for ensuring precision and reliability in injection molding. This section explores the key aspects involved in creating high-quality guide bushings.

Material Selection

Choosing the right material is essential for guide bushing performance:

Hardened steel: Offers excellent durability and wear resistance

Tool steels (D2, M2): Provide high hardness and dimensional stability

Stainless steel: Resists corrosion in demanding environments

Bronze alloys: Offer good lubrication properties and wear resistance

Material selection depends on factors like molding process, expected loads, and temperature conditions. The chosen material must withstand repeated use while maintaining dimensional accuracy.

Shape and Dimensions

Guide bushings feature a cylindrical design with precise internal and external diameters. Key considerations include:

Smooth internal bore for minimal friction with guide pins

External surface designed for secure fitting within the mold

Minimal clearance between bushing and pin ensures accurate alignment

Dimensions carefully calculated to accommodate corresponding guide pins or posts

Lubrication Features

Proper lubrication is critical for reducing friction and wear:

Oil grooves: Machined into the inner surface to hold lubricant

Lubricant pockets: Designed to facilitate even distribution during operation

Efficient lubrication: Minimizes heat generation and extends bushing lifespan

Reduced friction: Ensures smooth mold operation and prevents premature wear

Surface Treatment

Surface treatments enhance wear resistance and minimize friction:

Heat treatments:

Carburizing: Increases surface hardness while maintaining core toughness

Nitriding: Improves wear resistance and reduces friction

Induction hardening: Provides localized hardening for specific areas

Surface coatings:

Accuracy and Tolerance

Precision is paramount in guide bushing manufacturing:

Tight tolerances: Ensure proper fit with guide pins and within the mold

High dimensional accuracy: Critical for achieving precise mold alignment

Concentricity and straightness: Key factors in maintaining overall mold precision

Consistent tolerances: Vital for interchangeability and long-term performance

Machining and Finishing

Advanced machining techniques ensure dimensional accuracy and surface quality:

Primary machining processes:

Turning: Establishes basic cylindrical shape

Drilling: Creates precise internal bore

Grinding: Achieves tight tolerances and smooth surfaces

Finishing operations:

Inspection and Quality Control

Rigorous quality control measures ensure guide bushing reliability:

Dimensional measurements: Verify adherence to specified tolerances

Surface quality checks: Ensure proper finish for optimal performance

Hardness testing: Confirms material properties and heat treatment effectiveness

Visual inspections: Identify any surface defects or imperfections

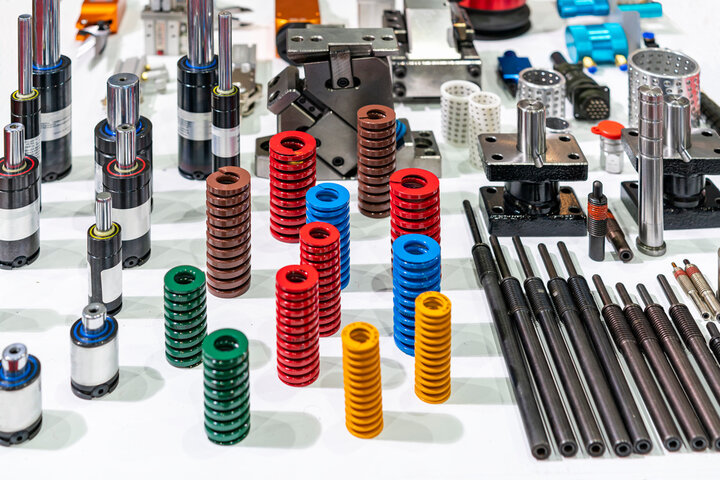

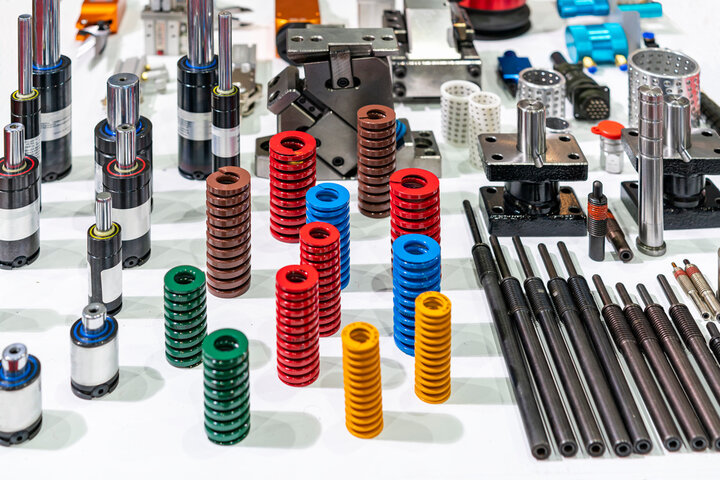

different kinds of guide bushing, Photo Resource Prototool

Issues with Poorly Manufactured Guide Bushings

Poorly manufactured guide bushings can lead to significant problems in the injection molding process. These issues affect not only part quality but also overall production efficiency. Below are the common problems associated with substandard guide bushings.

Misalignment of Mold Halves

When guide bushings are not manufactured with precision, mold halves can misalign. This misalignment causes:

Uneven Material Distribution: Leading to defects like flashes, short shots, and incomplete cavity filling.

Excessive Wear: Misalignment increases wear on the mold, potentially causing long-term damage.

Increased Friction and Wear

A poorly made guide bushing creates additional friction between mold components. This friction results in:

Reduced Lifespan: Increased wear reduces the durability of both the guide bushing and surrounding parts.

Dimensional Inaccuracies: Over time, friction causes deviations in part dimensions, leading to inconsistent production.

Binding or Sticking

Guide bushings with incorrect tolerances can bind or stick, leading to:

Operational Difficulties: Mold halves struggle to open and close, which disrupts production flow.

Longer Cycle Times: Sticking increases cycle times, reducing the overall efficiency of the molding process.

Excessive Clearance

Excessive clearance between the guide pin and guide bushing creates instability. This instability causes:

Poor Alignment: Resulting in inconsistent mold closing and potential defects in the final parts.

Mold Noise and Vibrations: Loose components generate unwanted noise and vibrations, further affecting mold precision.

Inconsistent Part Quality

Inaccurate guide bushings lead to variations in part quality. The primary issues include:

Dimension Variations: Parts may deviate from the desired specifications.

Poor Aesthetics: Surface defects, uneven finishes, or visible imperfections can impact the final product's appearance.

Increased Maintenance and Downtime

Guide bushings that wear out too quickly or cause operational issues increase maintenance needs. The consequences include:

Frequent Adjustments and Repairs: Faulty bushings require ongoing adjustments, adding to operational costs.

Unplanned Downtime: Maintenance to fix poorly manufactured bushings disrupts production schedules, lowering productivity.

Causes of Guide Bush Damage

Understanding the factors leading to guide bush damage is crucial for maintaining optimal injection molding operations. This section explores various causes of guide bush deterioration and failure.

Material Quality Issues

Poor material selection significantly impacts guide bush performance:

Substandard raw materials compromise durability

Inconsistent material properties lead to premature wear

Inadequate material strength results in deformation under load

Heat Treatment and Hardness Deficiencies

Improper processing can severely affect guide bush longevity:

Incorrect heat treatment protocols cause inconsistent hardness

Insufficient surface hardness accelerates wear rates

Overheating during treatment may induce brittleness and cracking

Fitment and Lubrication Problems

Improper fitment and inadequate lubrication contribute to rapid deterioration:

Excessive gap between guide bush and pin:

Insufficient lubrication:

Design and Knife Hole Considerations

Flaws in design can compromise guide bush functionality:

Improper knife hole placement reduces support

Inadequate consideration of stress distribution leads to premature failure

Poor design may transform guide bushes into mere positioning mechanisms

Installation and Operation Errors

Incorrect handling during installation and operation causes damage:

Misalignment during installation stresses components

Overtightening fasteners may induce deformation

Improper mold closure speeds can impact guide bush lifespan

Maintenance Negligence

Lack of regular upkeep accelerates guide bush degradation:

Infrequent inspections allow minor issues to escalate

Delayed replacement of worn components affects overall mold performance

Neglecting cleaning and lubrication schedules hastens wear

Best Practices for Guide Bushing Maintenance

Proper maintenance of guide bushings is crucial to extending their lifespan and ensuring the efficiency of injection molding operations. Adopting the following best practices can help prevent wear, reduce downtime, and maintain consistent production quality.

Regular Inspection and Replacement

Conducting regular inspections is key to minimizing wear and detecting potential issues early. By scheduling periodic checks, you can:

Identify Wear Patterns: Look for early signs of wear before they lead to mold damage.

Replace Worn Components: Timely replacement of worn guide bushings prevents operational failures and reduces downtime.

Routine inspections help keep the mold in optimal condition, ensuring uninterrupted production.

Lubrication Management

Proper lubrication significantly reduces friction between the guide bush and guide pin, helping to prevent damage. Best practices for lubrication management include:

Use of Oil Grooves: Ensure the guide bushing features grooves that can retain lubricant, providing consistent coverage during operation.

Regular Lubricant Application: Regularly apply lubricant to the bushings to prevent friction buildup and wear.

Effective lubrication management not only extends the life of the guide bushing but also ensures smoother mold operation.

Dimensional Accuracy Checks

Maintaining dimensional accuracy is essential for proper alignment and mold function. Regular dimensional checks ensure:

Tolerance Adherence: Verifying that the guide bushing remains within specified tolerances to avoid misalignment.

Smooth Mold Movement: Ensuring the mold halves open and close smoothly, preventing issues like binding or sticking.

By performing regular checks on dimensional accuracy, you can avoid production issues caused by misalignment or excessive clearance.

Conclusion

Guide bushings play a vital role in injection molding, ensuring precision and alignment. Proper design and manufacturing significantly impact part quality and extend mold lifespan. Their precision directly affects product consistency and the operational life of the mold.

Regular maintenance and selecting the right materials are essential for smooth production. Keeping guide bushings in good condition minimizes downtime, ensuring efficiency.

In summary, well-designed guide bushings combined with routine care are key to maintaining high-quality production and reducing operational costs.