It is appropriate to say that laser cutting and wire EDM cutting are two fully coherent cutting technologies, even though one may consider them to be two opposites. Knowing their distinctions is necessary for engineers and manufacturers in order to pick the right methodology for the given project.

This blog aims to compare laser cutting and wire EDM in every aspect, including but not limited to their principles, capabilities and technologies, their pros and cons, and their uses. Understanding the fundamental difference of these cutting processes allows the respective manufacturers to optimize their selection of technology for a given project, such that quality, lead-time and cost are all satisfactory.

Differences Between Laser Cutting and Wire EDM

What is laser cutting?

Laser cutting refers to the high precision and accuracy thermal cutting process of devising shapes and sizes of various materials by the use of a powerful laser beam. In this case, a laser beam is directed onto a target image, and the intense light beam is absorbed by the image which softens or vaporizes the image and subsequently cuts through it.

What is the process of laser cutting?

A laser cutting machine is a computer-controlled cutting tool (CNC) that employs a powerful laser beam of high energy, notably the carbon dioxide, fiber laser, or any other type of laser beam. A series of mirrors and focusing lenses direct the laser beam to the curve of the workpiece. While directing the laser on the surface of the material, the material absorbs the radiant energy and within seconds gets heated up to such a degree that it melts, turns to vapor, or chemically dissolves, thus getting cut off. Conversely, the gas that is typically nitrogen or oxygen is blown perpendicular to the cutting direction through the nozzle to the cutting edge to help in removing the molten material, preventing oxidation of the material, and cooling the cutting tip.

CNC LPG cutting with sparks close up

Advantages of laser cutting

Laser cutting technology offers numerous significant benefits that make it a preferred choice in modern manufacturing. These advantages span across precision, efficiency, quality, and versatility dimensions:

High precision: The precision of laser cutting can reach ±0.05mm, and the cutting width can be as low as 0.1mm, which meets the requirements of high-precision processing.

Fast speed: The speed of laser cutting can reach several meters per minute, which greatly improves production efficiency.

Small heat-affected zone: The heat-affected zone of laser cutting is usually less than 0.5mm, which has little effect on the thermal deformation of the workpiece.

Good incision quality: The incision of laser cutting is smooth and burr-free, reducing the need for subsequent processing.

Wide range of applicable materials: Laser cutting is suitable for a variety of materials, including metals and non-metals.

High flexibility: Laser cutting can flexibly cut complex patterns and shapes to meet personalized customization needs.

What is Wire EDM?

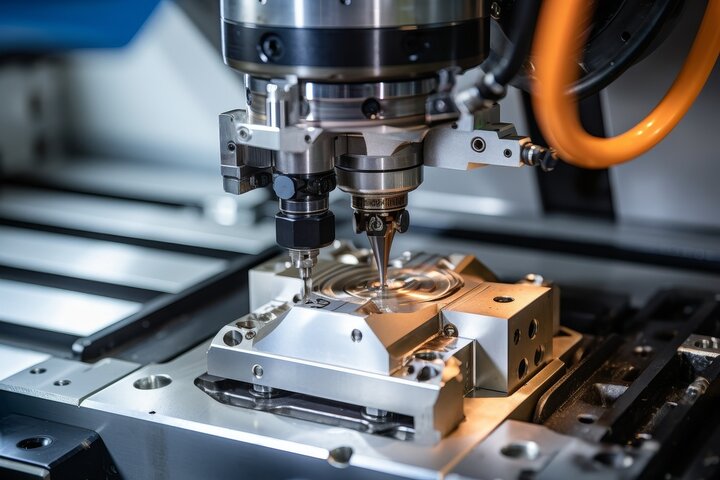

Wire EDM, known as Wire EDM, is an advanced machining process in which continuous electrical sparks are generated to erode conductive materials with great precision. The process involves second to none machining techniques in which the workpiece is submerged in deionized water and a very thin wire is pushed at high speed around the workpiece because of two guide wheels. When a high voltage frequency is applied between the wire and the workpiece, it produces continuous arcs between the two, resulting in a very large amount of heat in a certain area. After that, the area of the workpiece’s surface starts to melt, evaporate and spall off thus causing the material to be fabricated and the piece to be severed.

Close-up View of a Precision Wire EDM Head in an Industrial Setting

Differences between WEDM and traditional EDM

Compared with traditional EDM, WEDM has the following characteristics:

Fine Strand Cutter: WEDM employs a 0.01-0.2mm-sized metallic thread to accomplish features of these kind.

Contactless processing: There is no point at which the work- piece is touched by the wire, as this is done at totally no-contact distance in WEDM that results in mechanical manipulation of the work piece.

Equal Erosion: It Is Possible To always keep a single cutting height with WEDM in order to produce very accurate shapes.

Straight or Rotated Cuts: WEDM also allows processing of tapering edges, cones, and more complicated geometric surfaces.

Time efficiency: Very fast speeds of cutting have been achieved by this type of machining such that in one minute one can machine several hundred square millimeters which can not be done even by the old unconventional machining processes.

Advantages of using WEDM

There are several distinct advantages of Wire-cut EDM or WEDM that make it crucial in high-quality manufacturing. Some of the advantages that best sums up the WEDM technology are technical in nature:

High accuracy in performing operations: Here it can be stated that the possible dimensional deviation of the WEDM manufacturing can stick within the interval of ±0.001mm, while the Ra value to be obtained on the machined surfaces is 0.1lm or even better.

Large variability of the processed materials: Techniques of spark wire cutting allow processing of a wide array of conductive materials, including those of high hardness like heat-treated steel and ceramics.

Absence of cutting forces: Operations of spark wire cutting involve no contact between the cutting tool or electrode and the workpiece.

Micro kerf size: The cut width in spark erosion can be much smaller in-value and if so this promises to reduce waste of material.

Complex cutting shapes: Technological and demand-induced capabilities of spark erosion are such that neither the respective geometrical enclosures and their elements, nor the other porous parts of the mold including the tapers can be properly machined, which is not true of almost all other practices.

Comparing Laser Cutting and Wire EDM: Critical Differences

Cutting Capabilities: Laser vs EDM

There are a number of advantages which apply to each of the technologies. Laser cutting is usually is better for thin materials or with high production needs since it helps the cutting process at a faster tempo. Fiber lasers have the potential to reach eyeliner speeds when cutting metals thus increasing the amount of cutting done by the manufacturers at a given time.

On the other hand, wire EDM can be described as a faster ultraprecise technique. Although machining thick metal sections eminently involves higher accuracy than the machining thin parts, the latter is explained better by the pace of wire EDM. This technology’s fine detailing characteristics along with the high precision and close tolerances it can achieve make it useful for industries where there is an emphasis on the accuracy requirements.

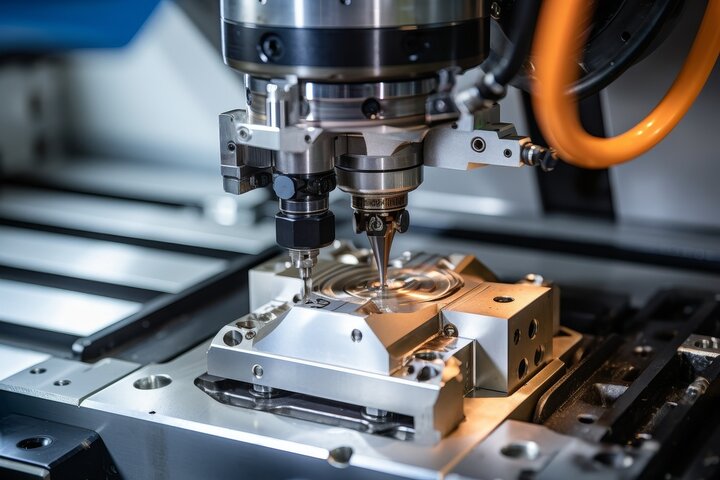

Laser cutting. Metal machining with sparks on CNC laser engraving maching

Material Compatibility and Limitations

The broad range of materials suitable for laser cutting includes the metals, none metals and composites. For an instance, metal like steel or aluminium and none metal like plastics or wood, can be used for laser cutting, marking a scope of materialiocut in laser cutting. In terms of material alone, choice of laser type can be dependent on a certain material being processed in itself, such as CO2 or fiber laser.

In contrast to laser cutting, wire cutting uses a different principle and is strictly limited to metals all qualified in the wire EDM cutting and only electrically conductive ones at that as well. Some of these colectable materials would consist of steel, aluminum, titanium, copper and the likes. However, this method cannot be employed when processing non-conducting materials such as plastics, glass, and ceramics. The difficulty in wire EDM to work on charge metals instead requires this technique in such applications and it works.

Precision and Tolerance Levels

Out of all precision options available today, wire EDM stays ahead of the pack. It is capable of providing the narrowest of tolerancies on a repeatable basis ranging between ±0.001 and ±0.005 inches, including extremely stringent requirements for intricate parts and fancy shapes. No forces are used such as in mechanical cutting to eliminate issues relating to a bending of a cutting tool within the cut hole, ensuring inexpectable accuracy.

Coming to the accuracy concerns, laser cutting as well has shown improved results: the most recent systems can cover thin materials to accuracies of ±0.002 to ±0.005 inches. However, with even thicker materials being processed, the attainment of finishing precision during laser cutting decreases for the reason of heat generated, as well as heat affected zones, even warping in some cases.

Surface Finish: Laser Cut vs EDM Machined

Typically, wire EDM is known for its ability to deliver high quality and extremely clean finishes that almost never require any additional polishing. This unique sound finish is because the cutting is controlled with laser operations. The typical surface finish that wire EDM can achieve is 16-32 Ra microinches which gives the final product a great uniform polished look.

Laser cutting is effective in getting precise, neat edges especially for shorter materials. However, with the increase in the steel thickness the edges may not be of such a good quality because of the more expansive output. Processing would also become necessary for the relatively thicker material if the surface quality is to be improved by say grinding or polishing.

Cutting Speed of Laser Cutting and Wire EDM

Laser beams provide faster results and are usually the ideal option when it comes to time and production efficiency. In particular, because the energy of a laser typically leads to aggressive vaporization of the material, laser processing typically results in considerably faster operation. This holds especially for thin sections where, instead of wire EDM comes into play, laser cutting produced orders the magnitude of quicker velocities.

Wire EDM uses a lot of time compared to the rest of the processes due to its focus on precision work instead speed. Cutting speeds can vary depending on the kind of material, thickness, and surface finish required in the wire EDM setup. Wire EDM is slower than laser cutting but the ability to cut with high precision speed and accuracy in wire EDM still makes it better for applications that require precision.

Choosing Between Laser Cutting and Wire EDM Services

When determining between laser cutting and wire EDM services suitable for the task many aspects count, which include the type of material, the thickness of the part, the level of accuracy needed, the quantity of the object and prices and many others.

Factors to Consider

Material: Laser cutting is a versatile processing technique which can work with a variety of material types— including metals, plastics, wood, and composites. This is in contrast to wire EDM which can only operate on conductive metals and their alloys.

Thickness: Laser technologies are suitable when one requires processing thin sections. In comparison, wire EDM can be applied when the workpiece is especially thick. Such a selection usually depends on the required thickness of the workpiece and the project.

Precision: In terms of precision, wire EDM edges the competition providing unmatched precision and allowing tolerances as tight as ±0.001 inches or less. Also, as opposed to laser cutting which achieved high precision, this case is limited by using thick materials.

Volume: When a large quantity of items are needed in a single production process, then laser cutting becomes the most preferred method as it has a very high cutting speed and is less expensive. Wire EDM is therefore more geared towards projects that demand high accuracy but need a relatively low volume.

Cost: The cost of laser cutting or wire EDM will be different depending on a number of factors like the material being worked on, time of work and charge rates per hour. One is advised to look at both the fundamental and residual costs when selecting a service.

Typical Laser Cutting Applications

There are many purposes served by laser cutting in different industries. To provide a few distinct uses:

Signage and Displays: Resorts and Parks, big companies such as Google or BMW, who try to show their credentials in their offices or other spaces, working in different areas of USA. They do create different signage elements based on the brand/logo.

Electronics: The niche specialization and the manufacturing of various types and fields of electronic elements, including Hizing and BGA elements, led to the development of laser cutting.

High-Volume Production: Geometric compression is used in large make-u in such cases. Lasers use in the manufacture of items provides for the production of more and more parts within the same time frame and a situation that cause good results from doing many cuts in the same duration.

Common Wire EDM Uses

Wire Electrical Discharge Machining (EDM) has a special place in cases that need the highest possible accuracy for operations, like:

Aerospace: Such types of components as turbine blades, fuel injectors, and landing gear sections that are easy to produce using wire EDM, find extensive use within the aerospace sector.

Medical Devices: In the fabrication of surgical instruments, implants or instruments such as the wire EDM, which can achieve high accuracy with very dense accuracy and very polished surface, this technology is needed.

Tooling: For instance, wire EDM is used in production of such elements as molds of cavities and cores with inserts having intricate design.

Low-Volume Precision: Also for small production batches consisting of several sophisticated parts, wire EDM is in the majority of cases the most competitive solution.

The Future of Laser Cutting and Wire EDM Technology

As manufacturing industries continue to evolve, both laser cutting and wire EDM technologies are undergoing significant advancements to meet the ever-growing demands for precision, efficiency, and sustainability.

Advances in Laser Technology

Laser cutting technology is experiencing a wave of innovations aimed at enhancing its capabilities and performance:

Higher Power: The development of high-power laser sources, such as fiber lasers, enables faster cutting speeds and the ability to process thicker materials with improved edge quality.

New Wavelengths: The introduction of new laser wavelengths, like green and ultraviolet lasers, expands the range of materials that can be effectively cut, including reflective metals and heat-sensitive materials.

Better Automation: Advanced automation features, such as automatic nozzle changing, adaptive optics, and real-time process monitoring, optimize the cutting process, reduce downtime, and ensure consistent quality.

Developments in Wire EDM

Wire EDM technology is also witnessing significant advancements focused on improving machine efficiency and expanding its material processing capabilities:

Machine Efficiency: Manufacturers are developing more efficient wire EDM machines with faster cutting speeds, reduced wire consumption, and improved flushing systems to minimize machining time and operational costs.

Expanding Material Options: Research efforts are focusing on enhancing wire EDM's ability to process non-conductive materials through the use of specialized coatings and hybrid machining techniques, opening up new application possibilities.

Sustainability Efforts

Both laser cutting and wire EDM technologies are prioritizing sustainability to reduce their environmental impact:

Energy Efficiency: Manufacturers are developing energy-efficient machines and implementing power-saving features to minimize energy consumption and reduce the carbon footprint of the cutting processes.

Waste Reduction: Efforts are being made to optimize material utilization, minimize waste generation, and promote the use of recyclable and eco-friendly consumables, such as biodegradable dielectric fluids in wire EDM.

Potential for Hybrid Laser/EDM Systems

The future may witness the emergence of hybrid laser/EDM systems that combine the strengths of both technologies:

Complementary Capabilities: Hybrid systems could leverage the speed and versatility of laser cutting for initial shaping and the precision and surface finish of wire EDM for final finishing, offering the best of both worlds.

Expanded Application Range: The integration of laser and EDM technologies in a single machine could enable the processing of a wider range of materials and geometries, catering to diverse industry needs.

Conclusion

To sum up, both laser cutting and wire EDM are different but unique technologies with their own advantages in precision engineering. Knowing the critical disparities between the two systems is a necessity when deciding which one to choose for any given task, in the interest of quality as well as cost.

In place of cutting only, we will employ the high precision wire EDM process for the aforementioned application. Shall there be any needs, please do not hesitate to contact us at any time.

Reference Sources

Laser cutting

Electrical discharge machining (EDM)

FAQs

What distinguishes wire EDM from laser cutting the most?

Laser cutting mostly concentrates on working with thin materials in a high speed production capacity. Wire EDM is of importance when dealing with the cutting of large thickness metallic materials for precision purposes. In respect of material compatibility, Laser cutting wins by a big margin compared to Wire EDM which achieves higher precision and has better surface finish.

Can wire EDM cut non-conductive materials?

NO, wire EDM is specifically designed for electrical conductive metals and all its variations leaving out the non-conductive materials such as plastics, glass and ceramics which are out of the equation when using wire EDM.

Which cutting method has more advantages for a large series production?

In the situation of large series production, laser cutting in consideration of the rate of cutting is the best since it is the fastest and economically the billet which is the modified much and in large quantity. On the other hand, Wire EDM will be preferable with the small quantities because one cannot afford to run it with such high task.

How can wire EDM cutting be accomplished in comparison to laser cutting?

lIKewise, Wire EDM can reach accuracy of ±0.001 to ±0.005 inch even in most of the complex geometries without any issues. A laser on the other hand is accurate approximately in the range of ±0.002 to ± 0.005 inch for points being incised into thin materials whereas the accuracy degrades for thick materials.

Which is faster? Laser or Waterjet cutting especially for thicker metal components?

No, lasers are not always faster than water jets; the speed of the laser is determined by the strength of the liquid. While this is true, however, Wire EDM actually maintains higher accuracy even at high speeds, so it is a perfect solution for processes on thick walled materials that require supreme accuracy.

In what different fields, laser cutting service is usually needed?

From making signs and displays, to working with electronic parts and general countable products, the use of laser cutters broadens with the addition of high speed solution and capability of producing uneconomical complex patterns in a timely customizer.

How do the surface finishes of laser-cut components compare with those produced by wire-EDM?

Wire EDM is known for delivering a high quality finish where the final alternative is a fine work that can be separated into two partings with a typical value of 16 - 32 microns Ra. When it comes to thin materials, laser cutting has the advantage edge quality but for the thicker materials, the edges may require further processing.

Can we expect any new changes in the Laser cutting and laser EDM technology?

In fact, these two technologies continue to be improved, due to for example the introduction of more powerful lasers, new laser wavelengths, the addition of even more automation to a laser cutter and the development of new machines for EDM; resulting in higher productivity, and more choices of materials for EDM machining. In addition, the combination of green strategies and the implementation of hybrid systems also offers tremendous opportunities.