Milling machines are versatile machine tools designed to shape solid materials by removing excess material. They employ rotary cutters to create precise parts and components. These machines can perform various operations like cutting, drilling, and shaping on metals, plastics, wood, and other materials.

Brief History of Milling Machines

The evolution of milling machines dates back to the early 19th century:

1818: Eli Whitney invented the first milling machine in New Haven, Connecticut.

Before this invention: Workers relied on hand files, a time-consuming and skill-dependent process.

Early applications: Primarily used for government contracts, such as manufacturing rifle parts.

Subsequent developments: Led to increased precision, efficiency, and versatility in manufacturing processes.

Importance of Milling Machines in Manufacturing Industries

Milling machines play a crucial role in modern manufacturing:

Versatility: They can create various shapes, from simple flat surfaces to complex 3D contours.

Precision: Capable of producing parts with tight tolerances, essential for industries like aerospace and automotive.

Efficiency: CNC milling machines automate processes, increasing production rates and reducing human error.

Material flexibility: Can work with a wide range of materials, including metals, plastics, and composites.

Cost-effectiveness: Despite initial investment, they offer long-term savings through improved productivity and reduced waste.

Industries benefiting from milling machines include:

Automotive

Aerospace

Electronics

Medical devices

Tooling and die making

By providing precise, efficient, and versatile material removal capabilities, milling machines have become indispensable in modern manufacturing processes across numerous industries.

Structure and Key Components of Milling Machines

Milling machines consist of several crucial components working in harmony to ensure precise and efficient machining operations.

Base

The base forms the foundation of a milling machine:

Function: Provides stability and absorbs vibrations during operation

Material: Typically cast iron, offering durability and rigidity

Design: Often incorporates a coolant reservoir for efficient heat management

Column

As the backbone of the milling machine, the column:

Supports the entire structure

Houses the spindle and motor

Contains drive systems for controlling spindle motion

Knee

The knee is a critical adjustable component:

Supports both saddle and worktable

Features a vertical feed screw for precise depth control

Enables vertical movement along the column for accurate positioning

Saddle

This component facilitates multi-directional movement:

Slides along the knee in the Y-axis

Allows worktable movement in the X-axis

Enhances overall positioning flexibility

Worktable

The worktable is the primary workpiece support:

Moves along X and Y axes via saddle and knee

Features T-slots for secure workpiece and clamp attachment

Provides a stable platform for various machining operations

Spindle

As the central component, the spindle:

Holds and rotates cutting tools

May be oriented vertically or horizontally based on machine type

Offers adjustable feed rates for different machining requirements

Overarm, Arbor, and Quill

These components vary based on machine type:

Horizontal machines: Use overarm and arbor for cutting tool support

Vertical machines: Employ a quill to guide tool up-and-down movement

Both enhance cutting precision and versatility

Additional Components

Several other parts contribute to milling machine functionality:

Spindle head: Houses the spindle and may swivel for angular movements

Tool holders: Secure various cutting tools to the spindle

Dividing head: Enables precise workpiece rotation for complex operations

Working Principle of Milling Machines

Milling machines operate on a fundamental principle of material removal using rotary cutters. They offer precision and versatility in shaping various materials for manufacturing applications.

Material Removal Process

The core function of milling machines involves:

Rotating multi-point cutters at high speeds

Advancing these cutters into a stationary workpiece

Selectively removing material to achieve desired shapes and dimensions

Key Parameters

Successful milling operations rely on careful adjustment of several parameters:

Pressure: Controls the force applied by the cutter on the workpiece

Cutter head speed: Determines the rate of material removal

Feed direction: Influences the quality of the finished surface

Critical Operational Factors

To ensure optimal machining results, operators must consider:

Spindle speed: Affects cutting efficiency and surface finish quality

Table feed rate: Impacts material removal rate and tool life

Depth of cut: Determines the amount of material removed in each pass

Cutter rotation direction: Influences chip formation and surface quality

Machining Quality and Efficiency

Several factors significantly affect the overall quality and efficiency of milling operations:

Cutting Tool Selection

Material: Should match or exceed workpiece hardness

Geometry: Influences chip formation and evacuation

Coating: Enhances tool life and reduces friction

Cutting Parameters Optimization

| Parameter | Effect on Quality | Effect on Efficiency |

| Speed | Surface finish | Material removal rate |

| Feed | Dimensional accuracy | Tool wear |

| Depth | Part integrity | Processing time |

Cooling and Lubrication

Proper cooling and lubrication systems:

Reduce friction between tool and workpiece

Dissipate heat generated during cutting

Extend tool life and improve surface finish

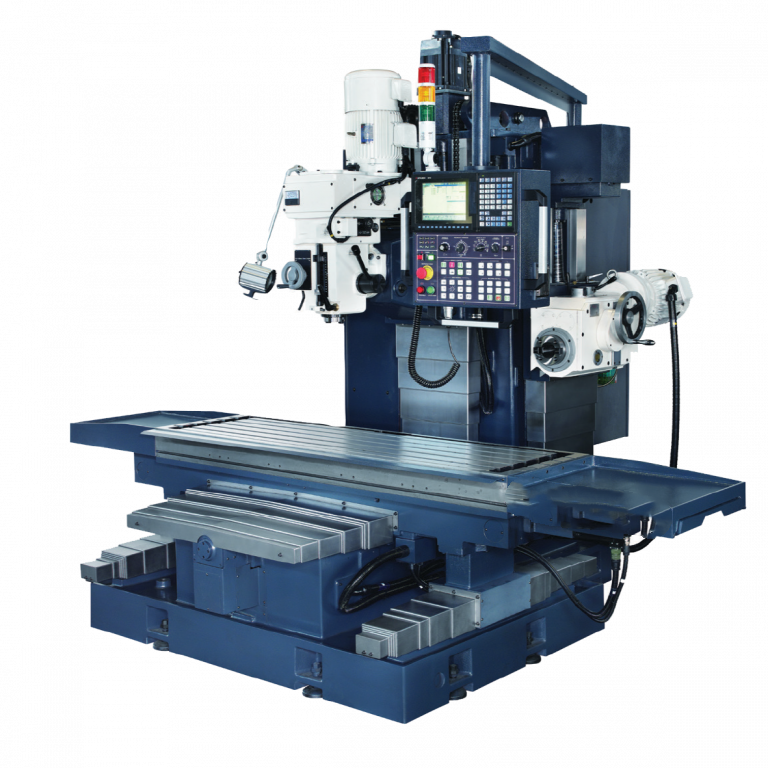

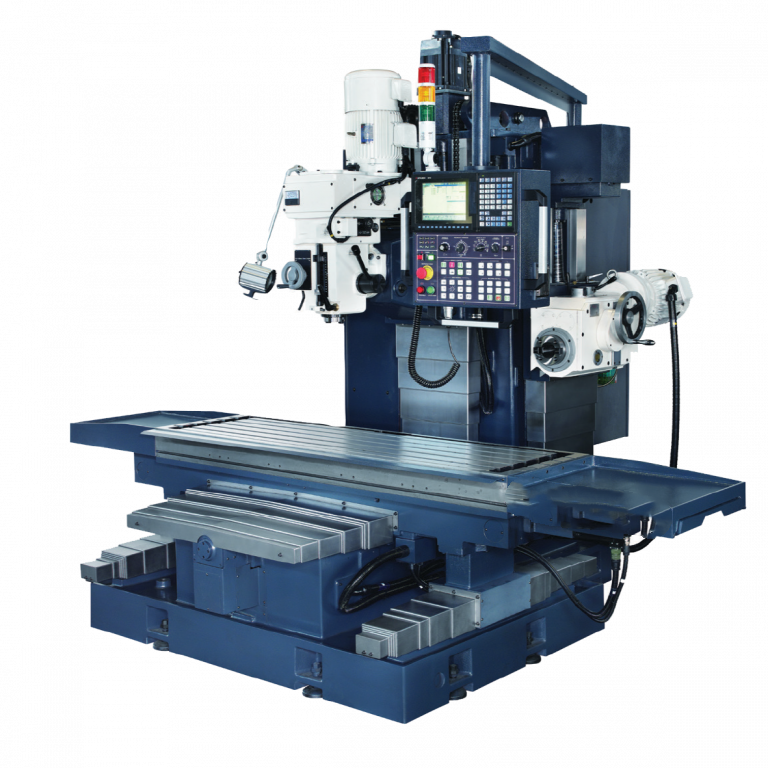

Types of Milling Machines

Vertical Milling Machines

Vertical milling machines have a spindle oriented vertically along the Z-axis. The spindle moves up and down, making these machines ideal for plunge cutting and drilling. They excel in operations that require precision positioning, particularly for creating complex parts. Their versatility allows them to perform shaping, cutting, and drilling tasks with high accuracy, making them popular in industries such as aerospace and automotive.

Key features of vertical milling machines:

Spindle Orientation: Vertically aligned spindle along the Z-axis.

Suitability: Best for plunge cutting, drilling, and precision shaping.

Versatility: Can handle complex parts across various materials.

Horizontal Milling Machines

Horizontal milling machines feature a spindle parallel to the worktable, which enables better handling of larger and thicker materials. They are commonly used for applications such as slotting, grooving, and planning flat surfaces. Horizontal mills provide increased rigidity, making them ideal for roughing processes that require powerful cutting tools.

Advantages of horizontal milling machines:

Spindle Orientation: Parallel to the worktable, increasing stability.

Applications: Used for slotting, grooving, and planning flat surfaces.

Material Handling: Efficient for large, thick workpieces and high-speed operations.

You also can get the knowlage about the comparation between Horizontal and Vertical Milling Machines.

CNC Milling Machines

CNC milling machines integrate computer numerical control (CNC) technology, allowing precise control over machining processes. These machines use pre-programmed computer instructions to automate cutting, drilling, and shaping tasks. CNC mills are known for their high accuracy and ability to produce complex components with consistent results, making them indispensable in industries requiring precision, such as aerospace and medical devices.

Notable aspects of CNC milling machines:

CNC Technology: Automated processes driven by computer programs.

Precision: High accuracy in creating complex and delicate components.

Efficiency: Capable of running 24/7, increasing productivity.

Universal Milling Machines

Universal milling machines combine the capabilities of both vertical and horizontal milling machines. They feature a swiveling worktable that allows angular milling operations, making them highly versatile for various tasks. These machines are often used in toolrooms, repair shops, and workshops where a wide range of operations needs to be performed on a single machine.

Key features of universal milling machines:

Combination of Capabilities: Supports both vertical and horizontal milling.

Swiveling Worktable: Enables angular milling for complex shapes.

Applications: Ideal for toolroom, repair shop, and workshop use.

Bed Milling Machines

Bed milling machines are designed for heavy-duty operations. They have a fixed worktable, and the spindle moves along the Z-axis to perform the cutting. These machines offer great rigidity and strength, making them suitable for working on large, heavy parts, such as those in the automotive, aerospace, and construction industries.

Main characteristics of bed milling machines:

Fixed Table: Provides stability for heavy-duty milling operations.

Spindle Movement: Moves vertically along the Z-axis for deep cuts.

Applications: Widely used in automotive, aerospace, and construction industries.

Special Purpose Milling Machines

Designed for specific milling requirements:

Rotary Table Milling Machines

Circular table rotates on vertical axis

Multiple cutters at different heights

Continuous loading/unloading during operation

Gantry Milling Machines

Large bed supporting a movable gantry

Multiple cutters mounted on gantry frame

Ideal for machining oversized parts

5-Axis Milling Machines

Offers movement in three linear and two rotary axes

Creates complex shapes and contours

Enhances precision and reduces setup time

Mill Machine Operations and Techniques

Face Milling

Face milling creates flat surfaces perpendicular to the tool axis:

Utilizes face milling cutters with multiple cutting edges

Depth of cut adjusted via cross-feed screw on the table

Produces high-quality surface finishes on large areas

Applications: Engine block surfaces, mold bases, structural components

Plain Milling (Slab Milling)

This operation produces smooth, horizontal surfaces:

Cutter axis parallel to the machined surface

Commonly used for reducing workpiece thickness

Generates flat surfaces with good dimensional accuracy

Applications: Keyways, slots, flat baseplate surfaces

Angular Milling

Angular milling generates surfaces at specific angles:

Employs angled cutters or tilted worktables

Creates precise angular features on workpieces

Widely used in V-block manufacturing and chamfering

Applications: Dovetail joints, angled brackets, gear teeth

Form Milling

Form milling produces irregular shapes using specialized cutters:

Utilizes form cutters designed for specific profiles

Slower cutting rates compared to plain milling

Creates complex contours in a single pass

Applications: Architectural moldings, custom machine parts

Straddle Milling

This technique simultaneously mills two parallel surfaces:

Uses two side milling cutters mounted on the same arbor

Spacing between cutters adjustable with collars

Efficient for producing multiple parallel surfaces

Applications: T-slot milling, hexagonal/square surface generation

Gang Milling

Gang milling employs multiple cutters on a single arbor:

| Advantage | Description |

| Productivity | Performs multiple operations in one pass |

| Efficiency | Reduces setup time and improves accuracy |

| Versatility | Combines roughing and finishing operations |

Applications: Automotive components, mass-produced parts

Profile Milling

Profile milling replicates complex shapes onto workpieces:

Uses helical plain cutters or end mill cutters

Follows a template or CNC program for precise replication

Suitable for both 2D and 3D profiling operations

Applications: Die making, aerospace components, custom parts

Additional Milling Techniques

Advanced milling strategies enhance efficiency and quality:

Ramping: Gradual tool engagement for improved tool life

Helical milling: Creates precise holes and threads

Trochoidal milling: Reduces tool wear in hard materials

High-speed machining and optimized chip control strategies further improve productivity and surface quality across various milling operations.

Advantages and Applications of Milling Machines

Milling machines offer numerous benefits across various industries, making them indispensable in modern manufacturing processes.

Advantages

High Precision and Accuracy

Capable of achieving tight tolerances, often within microns

Consistent results, especially with CNC-controlled machines

Repeatable processes for high-volume production

Versatility

Handles diverse materials: metals, plastics, composites, and wood

Performs various operations: cutting, drilling, boring, and shaping

Adaptable to different part sizes and complexities

Improved Surface Finish

Produces high-quality surface finishes

Reduces need for secondary finishing operations

Enhances product aesthetics and functionality

Increased Efficiency with CNC Technology

Automates complex machining processes

Reduces human error and increases productivity

Enables 24/7 operation for high-volume manufacturing

Applications

Milling machines find extensive use across numerous industries:

Automotive Industry

Manufactures engine blocks, cylinder heads, and transmission components

Produces complex parts with high precision and repeatability

Enables rapid prototyping and tooling for new vehicle models

Aerospace Industry

Machines lightweight yet strong components for aircraft and spacecraft

Creates intricate turbine blades and structural parts

Ensures compliance with stringent industry standards

Electronics Industry

Fabricates circuit boards with precise patterns and holes

Produces housings and heat sinks for electronic devices

Enables miniaturization of components through high-precision milling

Metalworking Industry

Creates molds and dies for various manufacturing processes

Produces custom tooling components and fixtures

Enables rapid prototyping and small-batch production

Medical and Dental Industry

Manufactures implants and prosthetics with biocompatible materials

Produces surgical instruments with complex geometries

Creates custom dental crowns and bridges

Specific Application Examples

| Application | Description | Key Benefits |

| Mold and Die Making | Creates complex molds for injection molding and die-casting | High precision, excellent surface finish |

| Gear Manufacturing | Produces various gear types with precise tooth profiles | Consistent quality, high production rates |

| Complex Surface Machining | Generates intricate 3D surfaces for aerospace and automotive parts | Ability to create unique geometries, tight tolerances |

Selection and Maintenance of Milling Machines

Proper selection and maintenance of milling machines ensure optimal performance, longevity, and cost-effectiveness in manufacturing operations.

Selecting the Right Milling Machine

Choose a milling machine based on specific machining requirements:

Workpiece size and material

Required precision and surface finish

Production volume and flexibility needs

Available floor space and budget constraints

Key Factors for Machine Selection

Consider these crucial aspects when choosing a milling machine:

Spindle Speed Range and Power

Adequate power for intended materials and cutting depths

Sufficient speed range for various operations

Torque characteristics matching typical workloads

Table Size and Travel

| Factor | Importance |

| Table size | Determines maximum workpiece dimensions |

| X-axis travel | Affects longitudinal machining capability |

| Y-axis travel | Influences transverse cutting range |

| Z-axis travel | Determines vertical machining capacity |

Control System and Automation Level

Manual controls for simple operations and low volumes

CNC systems for complex parts and high-volume production

Consideration of operator skill levels and training requirements

Maintenance and Troubleshooting

Proper maintenance ensures reliable operation and extends machine life.

Regular Cleaning and Lubrication

Daily cleaning of chips and coolant residue

Weekly lubrication of moving parts and guide ways

Monthly inspection of coolant quality and filtration systems

Inspection and Replacement of Wear Parts

Check and replace worn cutting tools regularly

Inspect spindle bearings for unusual noise or vibration

Monitor and adjust belt tensions as needed

Common Issues and Solutions

Poor surface finish

Excessive vibration

Inaccurate dimensions

Unusual noises

By carefully selecting the appropriate milling machine and implementing a robust maintenance program, manufacturers can maximize productivity, quality, and equipment longevity in their operations.

Endnotes

Milling machines play a crucial role in modern manufacturing. They provide precision, versatility, and efficiency for various industries.

This article highlighted key aspects of milling machines, including their types, functions, and applications. Understanding vertical, horizontal, CNC, and universal milling machines can help optimize production processes.

We encourage you to explore further and apply this knowledge in your projects.