Ever wondered about the plastic in your water bottle? It's likely PET, a material that's revolutionized packaging. Since the 1940s, this versatile material has transformed industries and everyday life.

In this post, you'll learn about PET plastic, its properties, types, applications, and how it's processed etc.

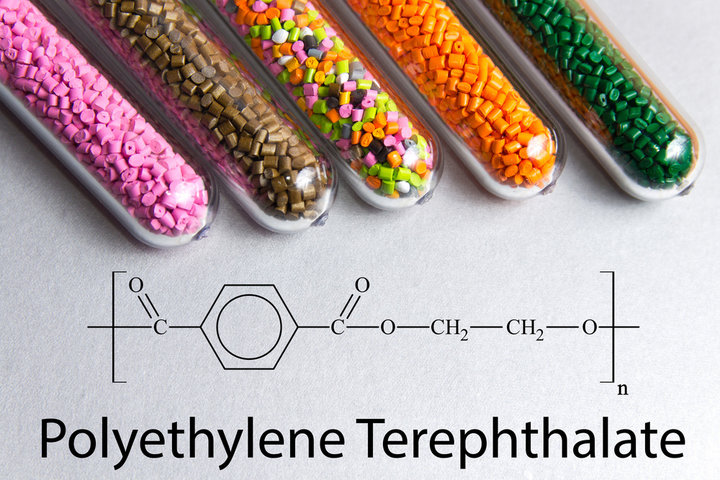

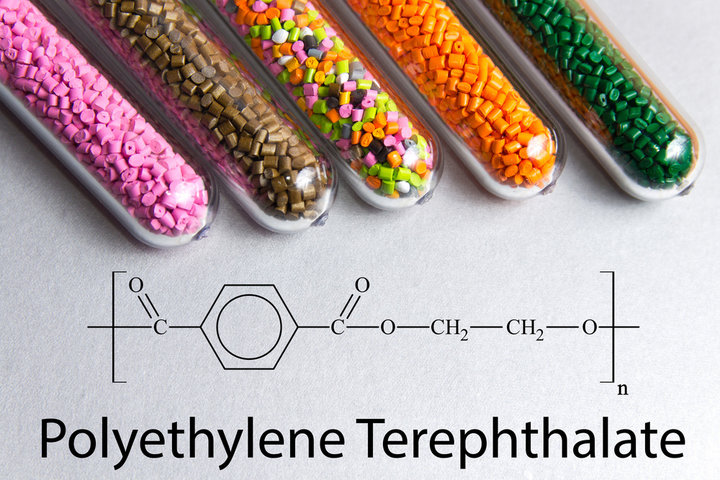

What is PET Plastic?

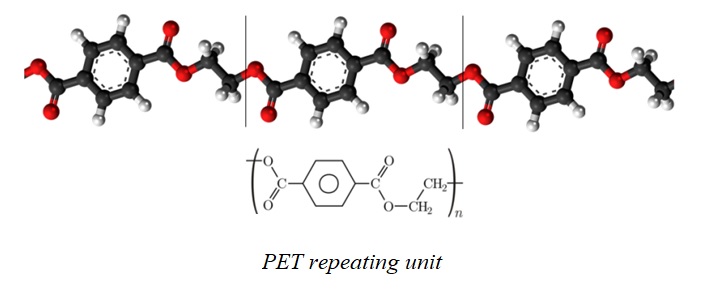

PET, short for Polyethylene Terephthalate, is a widely used thermoplastic polymer. It belongs to the polyester family of materials.

Polyethylene terephthalate (PET), also known by its chemical formula (C10H8O4)n, is a polyester polymer made from two key components:

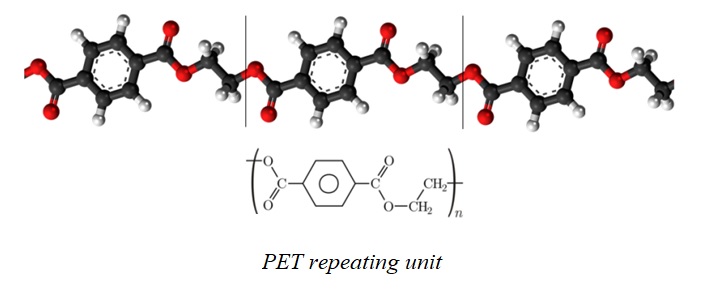

Molecular Structure of Polyethylene Terephthalate

These molecules combine to form long, repeating chains that give PET its strength and flexibility.

How is PET Plastic Made?

The production of PET plastic involves several steps. It starts with the raw materials and ends with various forms of PET products.

Raw Materials

PET is made from two primary raw materials:

Ethylene glycol (EG): It is a colorless, odorless liquid. EG is derived from ethylene, which comes from petroleum or natural gas.

Terephthalic acid (TPA) or dimethyl terephthalate (DMT): These are derived from p-xylene, also obtained from petroleum. TPA is more commonly used due to its lower cost.

Polymerization Process

The raw materials undergo a two-stage polymerization process to form PET:

Esterification or Transesterification: EG reacts with TPA (esterification) or DMT (transesterification) to form bis-hydroxyethyl terephthalate (BHET) monomer. This step removes water or methanol as byproducts.

Polycondensation: BHET monomers react with each other under high temperature (around 280°C) and vacuum. They form long PET polymer chains. The final product is a molten, viscous PET resin.

Properties of PET Plastic

PET plastic exhibits a wide range of properties. These properties make it suitable for various applications. Let's dive into the details of each property category.

| Property Category | Property | Description/Value |

| Physical Properties | Density | 1.3 g/cm³, lightweight yet durable |

| Mechanical Properties | Tensile Strength | 55–75 MPa |

| Impact Resistance | High, resistant to breaking or shattering |

| Flexibility | Good, can be molded into various shapes |

| Dimensional Stability | Excellent, maintains form under heat and pressure |

| Young’s Modulus | 2.0–2.7 GPa, contributes to stiffness |

| Thermal Properties | Melting Point | 250–260°C |

| Glass Transition Temperature (Tg) | 70–80°C, softens above this range |

| Heat Distortion Temperature (HDT) | 65–80°C, maintains shape under moderate heat |

| Electrical Properties | Insulation | Excellent, strong electrical barrier |

| Dielectric Strength | High, suitable for electronics and electrical components |

| Optical Properties | Transparency | High, allows light to pass through without distortion |

| Clarity | High, ideal for clear packaging |

| Chemical Resistance | Resistance to Alcohols, Hydrocarbons, Oils, and Diluted Acids | Strong resistance to various chemicals |

| Barrier Properties | Oxygen Permeability | Low, keeps contents fresh |

| Carbon Dioxide Permeability | Low, prevents gas leakage |

| Moisture Resistance | High, prevents water vapor from passing through |

Physical Properties

Mechanical Properties

Tensile Strength: PET has a high tensile strength of about 80 MPa. It can withstand significant stretching forces before breaking.

Impact Resistance: It has good impact resistance, especially when modified with additives. PET can absorb energy from impacts without shattering.

Flexibility: PET is relatively flexible for a plastic. It can bend without breaking, allowing for various shapes and designs.

Dimensional Stability: It maintains its shape and size under normal conditions. PET has a low shrinkage rate, ensuring consistent dimensions.

Young's Modulus: PET has a Young's modulus of around 2-4 GPa. This indicates its stiffness and resistance to deformation under stress.

Thermal Properties

Melting Point: PET has a melting point of 260°C. It can withstand high temperatures without deforming or melting.

Glass Transition Temperature (Tg): The Tg of PET is around 70°C. Below this temperature, PET is rigid and brittle. Above Tg, it becomes more flexible.

Heat Distortion Temperature (HDT): PET has an HDT of 75°C under a load of 0.45 MPa. It can maintain its shape under elevated temperatures.

Electrical Properties

Insulation: PET is an excellent electrical insulator. It has a high resistance to electric current flow.

Dielectric Strength: It can withstand high voltage gradients without conducting electricity. PET has a dielectric strength of about 17 kV/mm.

Optical Properties

Transparency: PET can be produced in clear, transparent forms. It allows for good visibility of contents in packaging.

Clarity: PET has excellent clarity, allowing for detailed visual inspection. It is often used for clear bottles and containers.

Chemical Resistance

Resistance to Alcohols, Hydrocarbons, Oils, and Diluted Acids: PET is resistant to many common chemicals. It can withstand exposure to alcohols, oils, and diluted acids without degradation.

Barrier Properties

Oxygen and Carbon Dioxide Permeability: PET has good barrier properties against oxygen and carbon dioxide. It helps preserve the freshness of packaged products.

Moisture Resistance: PET is resistant to moisture and humidity. It maintains its properties and performance in wet environments.

Manufacturing Processes for PET

PET plastic offers versatility in manufacturing. Let's explore the key processes that shape this material into everyday products.

Injection Molding

Injection molding transforms PET into precise shapes. Here's how it works:

Melt PET resin (240-280°C)

Inject into mold cavity under high pressure

Cool and solidify

Eject finished part

Temperature control is crucial. It affects part quality and cycle time.

Common applications include:

Automotive components

Packaging containers

Electronic housings

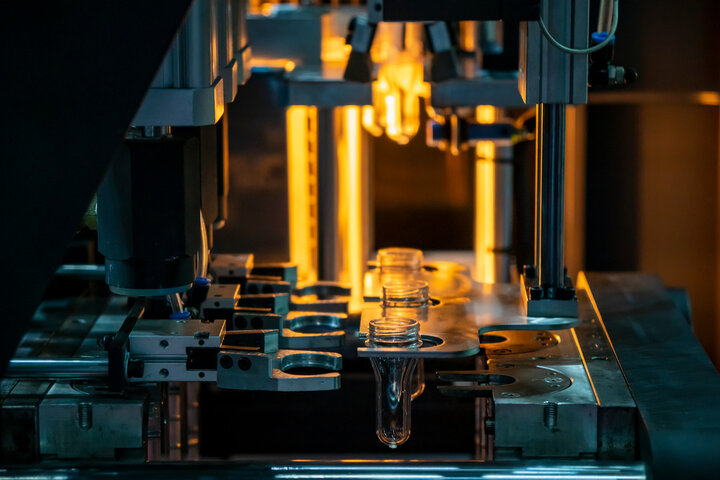

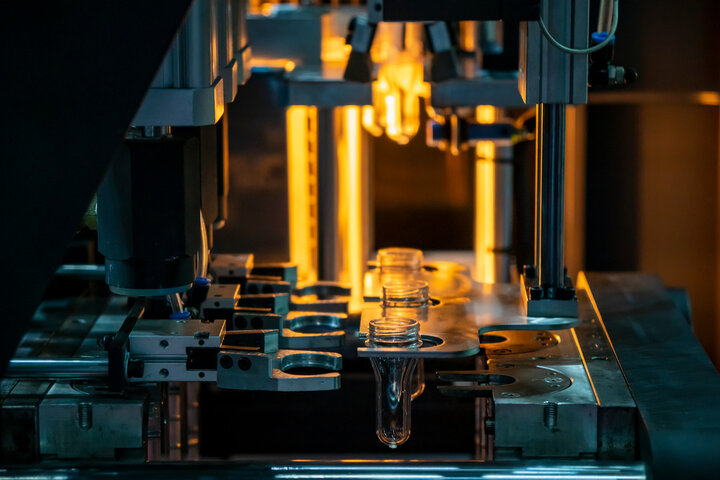

Blow Molding

Stretch blow molding is vital for PET bottle production. The process involves:

Create PET preform via injection molding

Heat preform

Stretch and inflate with compressed air

Cool in mold

This method produces bottles with uniform wall thickness. It's ideal for:

Extrusion

Extrusion creates PET sheets and films. The process:

Melt PET (270-290°C)

Force through a die

Cool and solidify

Extruded PET is used in:

Food packaging trays

Protective coatings

Thermoformed products

3D Printing

PET and PETG filaments are gaining popularity in additive manufacturing. Advantages include:

3D printed PET is used for:

Prototypes

Custom parts

Intricate designs

Melt Spinning

Melt spinning produces PET fibers for textiles. The steps:

Melt PET resin

Extrude through spinnerets

Cool and solidify filaments

Stretch to align polymer chains

These fibers are used in:

Clothing

Upholstery

Carpets

Industrial textiles

Each manufacturing process offers unique benefits. They allow PET to meet diverse product needs across industries.

Types of PET

There are several types of PET plastic, each with unique properties that make them suitable for different applications.

Amorphous PET (APET)

Amorphous PET (APET) is known for its excellent transparency and elasticity. Because it lacks a crystalline structure, APET remains clear and flexible, which makes it ideal for films and packaging applications. Its clarity ensures that products are easily visible through the packaging, while its elasticity allows for easy molding into various shapes.

| Property | APET |

| Transparency | High |

| Elasticity | Flexible and moldable |

| Applications | Films, packaging materials |

PETG (Glycol-modified PET)

PETG is a modified version of PET with glycol added during the polymerization process. This gives it enhanced toughness and processability, making it easier to mold and shape compared to standard PET. PETG is often used in technical parts and robust packaging applications due to its ability to withstand impact while remaining flexible.

| Feature | PETG |

| Toughness | High, withstands impact |

| Processability | Easier to mold and form |

| Applications | Technical parts, robust packaging |

For more information for PETG, you can check the guide on what is PETG.

Recycled PET (rPET)

Recycled PET (rPET) is made from post-consumer PET products like bottles and packaging. This recycling process offers significant environmental benefits, reducing the need for virgin plastic production. rPET retains many of the properties of virgin PET and is widely used in textiles, new bottles, and other products. Using rPET lowers energy consumption and helps minimize plastic waste.

| Benefit | Recycled PET (rPET) |

| Environmental Impact | Reduced energy use, less plastic waste |

| Applications | Textiles, bottles, packaging, carpets |

PET Fibers

PET fibers are created through the melt spinning process and are extensively used in textiles and industrial applications. These fibers are durable, wrinkle-resistant, and easy to care for, making them popular in clothing, upholstery, and carpets. Additionally, PET fibers offer strength and flexibility for use in industrial fabrics.

| Property | PET Fibers |

| Durability | High, long-lasting in textiles |

| Applications | Clothing, upholstery, industrial fabrics |

Applications of PET Plastic

PET plastic is versatile, finding use in numerous industries thanks to its strength, clarity, and recyclability. Let’s explore some of its key applications.

Packaging

PET is the go-to choice for various packaging solutions due to its transparency, durability, and barrier properties.

Food and Beverage Containers: PET bottles and jars keep beverages fresh by preventing oxygen from entering.

Cosmetic and Personal Care Packaging: PET’s clarity showcases product colors and textures, making it ideal for lotions and creams.

Pharmaceutical Packaging: PET is used for blister packs and containers, ensuring safety and maintaining product integrity.

Sourcing from Unuo's Wholesales 60ml 100ml Square Plastic PETG Serum Bottle

| Application | Description |

| Food & Beverage Containers | Used for water bottles, soda bottles, and jars |

| Cosmetic Packaging | Creams, lotions, and other personal care items |

| Pharmaceutical Packaging | Blister packs, pill bottles, and more |

Textiles

PET fibers are durable and widely used in the textile industry.

Clothing and Apparel: PET fibers are transformed into polyester fabrics, making clothes more durable and wrinkle-resistant.

Home Furnishings: PET fibers are used in carpets, curtains, and upholstery, offering both durability and ease of maintenance.

Industrial Fabrics: Industrial uses include conveyor belts, filters, and safety gear due to PET’s high strength.

Engineering Plastics

PET is used for manufacturing durable and reliable engineering components.

Automotive Parts: PET is molded into parts like seat belts, dashboard components, and airbag housings.

Electrical and Electronic Components: Its insulating properties make PET ideal for circuit boards and connectors.

Machinery and Equipment: PET is often used in gears, bearings, and housings for its resistance to wear.

Medical Devices

PET plays a crucial role in the healthcare industry, particularly in sterile environments.

Surgical Sutures: PET fibers are used for absorbable and non-absorbable sutures, ensuring strength and flexibility.

Implantable Devices: PET is biocompatible, making it ideal for implantable devices.

Medical Packaging: PET ensures sterile packaging for medical instruments and supplies.

Films and Sheets

PET is extensively used in film production due to its clarity and strength.

Packaging Films: These films provide an excellent barrier for food packaging, protecting against moisture and gases.

Lamination Films: PET films are used in laminating documents and packaging to protect from wear and tear.

Graphic Arts and Printing: PET films provide the durability needed for high-quality graphics, ensuring color retention and sharpness.

3D Printing

PET and PETG are popular materials in 3D printing due to their ease of use and durability.

PET and PETG Filaments: These filaments are strong and flexible, commonly used in prototyping and functional parts.

Prototyping and Functional Parts: PETG’s durability and resistance make it ideal for creating custom parts with real-world applications.

Blending PET with Other Polymers

Blending PET with other polymers enhances its performance, making it suitable for more demanding applications. Let’s explore how PET blends with thermoplastics, thermosets, and rubbers to improve toughness, flexibility, and durability.

Thermoplastic Blends

Blending PET with thermoplastics like Polyethylene (PE), Polycarbonate (PC), Polypropylene (PP), and Acrylonitrile Butadiene Styrene (ABS) improves its toughness and flexibility. These blends are ideal for applications requiring strength, durability, and impact resistance.

PET/PE Blends: Enhance flexibility and toughness, often used in packaging and industrial parts.

PET/PC Blends: Combine heat resistance with mechanical strength, making them suitable for automotive components.

PET/PP Blends: Increase impact resistance, common in automotive and household goods.

PET/ABS Blends: Improve toughness and flexibility, ideal for consumer electronics.

| Thermoplastic Blend | Key Property | Applications |

| PET/PE | Improved flexibility, toughness | Packaging, industrial parts |

| PET/PC | Heat resistance, strength | Automotive components, electronics |

| PET/PP | Impact resistance | Automotive, household goods |

| PET/ABS | Toughness, flexibility | Consumer electronics, casings |

Thermoset Blends

When blended with thermosetting resins like epoxy, polyester, and phenolic resins, PET gains enhanced thermal and mechanical properties. These blends are perfect for high-temperature environments and applications that demand long-term durability.

PET/Epoxy Blends: Provide excellent thermal stability, often used in coatings and electrical insulation.

PET/Polyester Blends: Improve impact strength and chemical resistance, useful in automotive and aerospace industries.

PET/Phenolic Resin Blends: Enhance flame retardancy and mechanical strength, making them ideal for electrical components and high-stress environments.

| Thermoset Blend | Key Property | Applications |

| PET/Epoxy | Thermal stability, insulation | Coatings, electrical insulation |

| PET/Polyester | Impact strength, chemical resistance | Automotive, aerospace |

| PET/Phenolic Resins | Flame retardancy, mechanical strength | Electrical components, high-stress environments |

Rubber Blends

Blending PET with rubbers like Nitrile Butadiene Rubber (NBR) and Styrene Butadiene Rubber (SBR) increases its durability and resistance to wear and tear. These blends are particularly useful in applications requiring flexibility and high resistance to oils and chemicals.

PET/NBR Blends: Enhance oil resistance and flexibility, commonly used in seals and gaskets.

PET/SBR Blends: Provide excellent durability and impact resistance, used in automotive tires and industrial hoses.

| Rubber Blend | Key Property | Applications |

| PET/NBR | Oil resistance, flexibility | Seals, gaskets, hoses |

| PET/SBR | Durability, impact resistance | Automotive tires, industrial applications |

Comparison of PET with Other Polymers

PET offers a unique combination of properties, but how does it stack up against other commonly used plastics? Let's compare PET with other popular polymers in terms of strength, flexibility, environmental impact, and more.

PET vs Polypropylene (PP)

PET has greater strength and transparency compared to Polypropylene (PP). While PET is widely used in clear packaging, PP is typically more flexible and used in applications like textiles and automotive parts. PET's better barrier properties make it the preferred choice for bottles and food packaging where visibility and freshness are important.

| Property | PET | PP |

| Strength | Higher | Moderate |

| Transparency | High | Moderate |

| Applications | Bottles, clear packaging | Textiles, automotive components |

PET vs Polyvinyl Chloride (PVC)

PET offers better chemical resistance and transparency compared to Polyvinyl Chloride (PVC), which is more flexible but less environmentally friendly. PVC has excellent durability in construction materials like pipes and window frames, while PET is favored for food-grade packaging and medical applications due to its inert nature. PVC's chlorine content raises environmental concerns during production and disposal.

| Property | PET | PVC |

| Chemical Resistance | Excellent | Moderate |

| Flexibility | Semi-rigid | High when plasticized |

| Environmental Impact | Lower | Higher, due to chlorine content |

| Applications | Packaging, medical devices | Pipes, cables, window frames |

PET vs High-Density Polyethylene (HDPE)

Compared to High-Density Polyethylene (HDPE), PET excels in clarity and transparency, making it ideal for clear containers like water bottles. However, HDPE is more resistant to stress cracking and is widely used in outdoor applications like pipes and storage tanks. Both materials are highly recyclable, but PET's recyclability is better suited for food and beverage containers.

| Property | PET | HDPE |

| Clarity | High, ideal for clear packaging | Opaque |

| Stress Cracking | Lower resistance | Higher resistance |

| Recyclability | High, commonly recycled | High, used in various applications |

PET vs Polycarbonate (PC)

Polycarbonate (PC) outperforms PET in terms of impact resistance, making it suitable for bulletproof glass and safety equipment. However, PET has better UV resistance, making it more stable in outdoor applications without additional coatings. PET is also more commonly used in food packaging due to its transparency and inert nature, whereas PC finds more use in optical discs and automotive parts.

| Property | PET | PC |

| Impact Resistance | Moderate | High |

| UV Resistance | Higher | Requires UV stabilizers |

| Applications | Food packaging, beverage bottles | Safety equipment, optical discs |

PET vs Biaxially Oriented Polypropylene (BOPP)

When compared to Biaxially Oriented Polypropylene (BOPP), PET has better barrier properties for oxygen and moisture, making it ideal for longer shelf life products. BOPP, on the other hand, offers greater scuff resistance and is widely used in labels and flexible packaging. PET's tensile strength gives it the edge in applications requiring durability and rigidity.

| Property | PET | BOPP |

| Barrier Properties | Excellent for oxygen and moisture | Moderate |

| Tensile Strength | Higher | Lower |

| Scuff Resistance | Moderate | Higher, ideal for flexible packaging |

Sustainability and Recycling of PET

Environmental Impact

PET outperforms glass and aluminum in energy efficiency. Here's why:

Lightweight: Requires less fuel for transport

Strong: Less material needed for packaging

Low diffusion coefficient: Maintains product quality longer

PET's environmental benefits:

PET Recycling Process

Two main methods recycle PET:

Mechanical Recycling:

Chemical Recycling:

Breaking down PET into monomers

Purifying and re-polymerizing

Creating virgin-quality PET

rPET (recycled PET) finds use in:

New bottles

Clothing fibers

Food packaging

Global Recycling Statistics

PET recycling rates vary globally:

| Region | Recycling Rate |

| U.S. | 31% |

| Europe | 52% |

Room for improvement exists worldwide. Education and infrastructure play key roles.

Sustainability Efforts

Using rPET offers significant benefits:

Corporate initiatives driving PET recycling:

Supplying recycling bins (650,000+ provided)

Upgrading processing equipment

Educating consumers on proper recycling

These efforts aim to increase PET bottle collection. The goal? Remake them into new bottles.

Safety and Regulations of PET Plastic

PET's widespread use demands strict safety standards. Let's explore the regulations ensuring its safe application.

Food Safety Assessment

PET has undergone extensive testing for food contact. Key findings:

Inert material: Doesn't react with food or beverages

Low migration: Minimal transfer of substances to food

No known health risks when used as intended

Global Certifications

Regulatory agencies worldwide have approved PET for food contact:

| Agency | Region |

| FDA | United States |

| EFSA | European Union |

| Health Canada | Canada |

These approvals reflect PET's safety in food packaging applications.

Medical Applications Safety

PET's use in medical devices is well-established. It's valued for:

Biocompatibility: Doesn't cause adverse reactions in the body

Sterilizability: Can be sterilized without degradation

Durability: Maintains integrity in medical environments

Common medical uses include surgical sutures and implantable devices.

Regulatory Compliance

PET meets various global regulations:

REACH (EU): Registered and compliant

RoHS: Doesn't contain restricted substances

Proposition 65 (California): No known risks at normal exposure levels

Important notes:

These regulations ensure PET's safety across different applications and regions.

Wrap Up

PET plastic plays a crucial role in our everyday lives. Its strength, flexibility, and recyclability make it versatile for many applications, from packaging to textiles. By understanding PET’s properties, we can make better choices about how we use and dispose of it. Let’s continue to prioritize recycling and sustainable practices in our daily lives.

Tips: You maybe interested to the all plastics