POM, or polyoxymethylene, is a high-performance thermoplastic that's revolutionizing industries. It was first synthesized in the 1920s but only commercialized in the 1950s.

This remarkable material boasts exceptional strength, low friction, and dimensional stability. From automotive parts to medical devices, POM is transforming product design and manufacturing.

In this post, we'll explore POM's types, properties, applications, advantages, disadvantages, modifications and how it process.

What is POM Plastic?

Polyoxymethylene (POM), also called acetal, polyacetal, or polyformaldehyde, is a high-performance engineering thermoplastic.

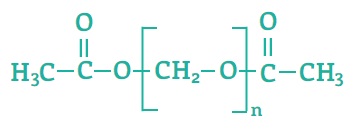

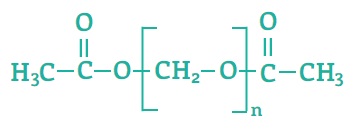

Molecular Structure of Polyoxymethylene (POM)

The molecular structure of Polyoxymethylene (POM) is based on repeating units of formaldehyde monomers. These monomers consist of carbon atoms bonded to two -OR groups. The structure of POM can be simplified to the formula (CH₂O)n, which forms long polymer chains.

This simple yet effective structure results in a semi-crystalline thermoplastic. Its high crystallinity gives POM its notable strength and rigidity. The polymer chains tightly pack together, leading to impressive dimensional stability and low moisture absorption.

Key Points of POM's Molecular Structure:

Repeating units of CH₂O (formaldehyde).

Semi-crystalline nature enhances mechanical properties.

Tight polymer packing improves wear resistance and strength.

This structure allows POM to maintain high performance in environments where precision and resilience are essential.

Types of POM Plastic

There are two main types of POM plastic: POM Homopolymer (POM-H) and POM Copolymer (POM-C). Both offer unique advantages depending on the application, but they differ in structure and performance.

POM Homopolymer (POM-H)

POM-H is made from a single monomer, giving it a more regular crystalline structure. This higher crystallinity leads to superior mechanical properties. It's stiffer, stronger, and can handle higher tensile and compressive loads. If your application requires high strength and low creep, POM-H is a solid choice.

Key Features of POM-H:

Higher tensile strength: Better for load-bearing parts.

Improved hardness: Stands up to wear and tear.

Better dimensional stability: Retains shape in demanding environments.

POM Copolymer (POM-C)

On the other hand, POM-C is created by polymerizing two different monomers. This makes it more chemically resistant and gives it better thermal stability than POM-H. It’s less prone to centerline porosity, which improves durability, especially in wet environments. POM-C also performs better in alkaline conditions.

Key Features of POM-C:

Better chemical resistance: Ideal for exposure to solvents, fuels, and chemicals.

Improved resistance to hydrolysis: Performs well in moisture-heavy environments.

Higher thermal stability: Withstands higher operating temperatures.

Here’s a quick comparison:

| Property | POM-H | POM-C |

| Tensile Strength | Higher | Lower |

| Chemical Resistance | Moderate | Higher |

| Thermal Stability | Moderate | Higher |

| Processing Ease | Good | Easier |

Each type of POM has its strengths, depending on the environment and performance needs.

Properties of POM Plastic

POM Mechanical Properties

| Property | POM-C (Copolymer) | POM-H (Homopolymer) |

| Tensile Strength | 66 MPa | 78 MPa |

| Tensile Strain at Yield | 15% | - |

| Tensile Strain at Break | 40% | 24% |

| Tensile Modulus of Elasticity | 3,000 MPa | 3,700 MPa |

| Flexural Strength | 91 MPa | 106 MPa |

| Flexural Modulus of Elasticity | 2,660 MPa | 3,450 MPa |

| Rockwell Hardness (M Scale) | 84 (ISO), 88 (ASTM) | 88 (ISO), 89 (ASTM) |

| Charpy Impact (Notched) | 8 kJ/m² | 10 kJ/m² |

| Izod Impact (Notched) | 1 ft.lb./in | 1 ft.lb./in |

| Density | 1.41 g/cm³ | 1.43 g/cm³ |

| Wear Rate (ISO 7148-2) | 45 µm/km | 45 µm/km |

| Coefficient of Friction | 0.3 - 0.45 | 0.3 - 0.45 |

POM Thermal Properties

| Thermal Property | POM-C | POM-H |

| Melting Point | 165°C | 180°C |

| Heat Deflection Temperature (HDT) (1.9 MPa) | 100°C (ISO), 220°F (ASTM) | 110°C (ISO), 250°F (ASTM) |

| Service Temperature Range | -50°C to 100°C | -50°C to 110°C |

| Thermal Conductivity | 0.31 W/(K·m) | 0.31 W/(K·m) |

| Coefficient of Linear Thermal Expansion (CLTE) | 110 µm/(m·K) (23-60°C) | 95 µm/(m·K) (23-60°C) |

| Maximum Continuous Service Temperature | 100°C | 110°C |

POM Chemical Properties

| Chemical Property | POM-C | POM-H |

| Chemical Resistance (pH Range) | pH 4 - 13 | pH 4 - 9 |

| Resistance to Organic Solvents | Good | Moderate |

| Resistance to Hydrolysis | Excellent (up to 85°C) | Moderate (up to 60°C) |

| Resistance to Acids | Good resistance to weak acids | Moderate resistance |

| Resistance to Bases | Good resistance to weak bases | Moderate resistance |

| Resistance to Strong Acids/Bases | Poor | Poor |

| Resistance to Phenols and Cresols | Poor | Poor |

| Resistance to Oxidizing Agents | Poor | Poor |

| Water Absorption | Low (0.2% per day) | Low (0.2% per day) |

POM Electrical Properties

| Electrical Property | Details |

| Relative Permittivity (at 1 MHz) | 3.8 |

| Electrical Resistivity | 10^15 Ω·cm |

| Dielectric Strength | 200 kV/cm |

| Dielectric Constant | 3.7 - 4.0 |

| Dissipation Factor | 0.005 - 0.008 |

| Volume Resistivity | 10^14 - 10^16 Ω·cm |

Advantages of Polyoxymethylene (POM)

Polyoxymethylene (POM) is prized for its unique set of advantages, making it a go-to material in many industries. Below are some key benefits that highlight why POM is so versatile.

High Strength-to-Weight Ratio

POM is known for its exceptional strength while remaining lightweight. This balance makes it ideal for applications where both strength and weight reduction are critical, such as automotive parts and industrial machinery.

Low Friction and Wear Resistance

One standout feature of POM is its low coefficient of friction. This property significantly reduces wear and tear in applications involving sliding or rotating parts, like gears and bearings. It’s a self-lubricating material, which enhances its longevity in demanding environments.

Dimensional Stability

POM maintains excellent dimensional stability even under fluctuating temperatures and humidity levels. This characteristic makes it perfect for precision parts, ensuring the material holds its shape and size over time, which is crucial in high-performance applications.

Chemical and Moisture Resistance

POM shows outstanding resistance to chemicals and moisture, particularly in alkaline environments. It absorbs very little water, making it a reliable choice for applications involving wet or chemical-heavy conditions such as pumps and valves.

Ease of Machinability

One of the reasons POM is favored by manufacturers is its ease of machining. It can be drilled, milled, and turned with high precision, making it an excellent choice for creating intricate parts in large quantities.

Excellent Electrical Insulation

POM offers strong electrical insulation, making it a preferred material for electrical components. Its dielectric properties help protect electronic systems from electrical interference, making it useful for switches, relays, and connectors.

Self-lubricating Properties

Thanks to its self-lubricating nature, POM reduces the need for external lubricants in mechanical systems. This property, combined with its low friction, helps extend the life of components such as bushings and rollers.

Aesthetically Pleasing Surface Finish

Beyond functionality, POM provides an aesthetic surface finish. Its glossy and smooth appearance makes it suitable for exposed parts, especially in consumer goods and industrial designs that require a polished look.

FDA Compliant Grades Available

For industries like food processing and healthcare, POM offers FDA-compliant grades. These grades are safe for direct contact with food and medical devices, ensuring compliance with stringent safety standards.

| POM Advantage | Benefit |

| High Strength-to-Weight Ratio | Ideal for lightweight yet durable applications |

| Low Friction and Wear Resistance | Reduces maintenance and extends part life |

| Dimensional Stability | Maintains precision over time and under stress |

| Chemical and Moisture Resistance | Performs well in wet and chemical environments |

| Ease of Machinability | Enables precise, efficient manufacturing |

| Excellent Electrical Insulation | Protects electronic components from interference |

| Self-lubricating Properties | Lowers maintenance costs in moving parts |

| Aesthetic Surface Finish | Suitable for exposed, polished components |

| FDA Compliant Grades Available | Safe for food and medical device applications |

Disadvantages of Polyoxymethylene (POM)

While POM plastic offers many benefits, it does come with several disadvantages that need to be considered for specific applications.

Poor UV Stability

One major limitation of POM is its poor resistance to UV light. When exposed to direct sunlight for extended periods, it can degrade, leading to discoloration, embrittlement, and loss of strength. If UV exposure is expected, UV stabilizers are needed.

Limited Chemical Resistance

Although POM resists many chemicals, it is vulnerable to strong acids and bases. Prolonged exposure to aggressive chemicals can cause degradation, making POM less suitable for harsh chemical environments without extra precautions.

Thermal Limitations

POM can degrade at high temperatures without suitable stabilizers. Continuous exposure to heat beyond its limits may lead to structural breakdown and reduced mechanical performance. It's critical to account for temperature constraints in demanding applications.

Bonding Challenges

POM has low surface energy, which makes bonding or gluing difficult without surface treatment. Special adhesives and preparation methods are required to create a strong bond between POM and other materials, which can complicate manufacturing processes.

High Shrinkage in Molding

During the molding process, POM exhibits high shrinkage, which may affect dimensional accuracy. Manufacturers need to carefully control mold design and cooling processes to compensate for this issue, especially in precision applications.

Cost Considerations

POM is relatively more expensive than many commodity plastics. This higher cost can be a factor in choosing materials for large-scale production, especially when cost efficiency is critical.

Highly Flammable Without Flame Retardants

POM is highly flammable in its natural form. Without flame retardants, it can burn easily, and the combustion releases toxic gases. In applications with strict fire safety requirements, additional treatments are necessary.

| Disadvantage | Impact |

| Poor UV Stability | Degrades in sunlight without UV stabilizers |

| Limited Chemical Resistance | Vulnerable to strong acids and bases |

| Thermal Limitations | Breaks down at high temperatures without stabilizers |

| Bonding Challenges | Difficult to bond without surface treatment |

| High Shrinkage in Molding | Affects dimensional accuracy during manufacturing |

| Cost Considerations | Higher cost compared to commodity plastics |

| Highly Flammable | Burns easily without flame retardants |

Applications of Polyoxymethylene (POM)

Polyoxymethylene (POM) is a versatile engineering plastic used in a wide range of industries due to its strength, dimensional stability, and low friction. Below are the key applications where POM excels.

Automotive Industry

POM keeps your car running smoothly. It's used in:

Fuel system components

Gears and bushings

Valves and door handles

Interior trim pieces

These parts benefit from POM's strength, low friction, and chemical resistance.

Electrical and Electronics

In the world of electronics, POM plays a crucial role. You'll find it in:

Connectors and switches

Relay housings

Insulating components

Circuit breakers

POM's electrical insulation properties make it perfect for these applications.

Consumer Goods

POM is all around you in everyday items:

Zippers and buckles

Knobs and handles

Fasteners and toys

Luggage components

Its durability and attractive finish make it ideal for consumer products.

Medical Devices

In healthcare, POM ensures reliability and safety:

Surgical instruments

Drug delivery systems

Dental components

Orthopedic implants

POM's biocompatibility and chemical resistance are crucial in medical applications.

Industrial Machinery

POM keeps industry moving:

Conveyor system parts

Gears and bearings

Valve components

Rollers and sprockets

Its wear resistance and strength make it perfect for heavy-duty applications.

Fluid Handling Systems

When it comes to managing fluids, POM shines:

Pumps and valves

Impellers and fittings

Couplings

Plumbing components

POM's chemical resistance and low moisture absorption are key here.

Food Processing

POM ensures safe food handling:

Food-grade POM meets strict safety standards for these applications.

Sports and Recreation

POM adds performance to your playtime:

Ski bindings

Archery equipment

Bicycle components

Fishing reels

Its impact resistance and low friction properties enhance sporting goods.

Aerospace

Even in the sky, POM has a place:

Structural components

Gears and bearings

Interior fittings

Fuel system parts

POM's lightweight strength is valuable in aerospace applications.

Miscellaneous Applications

POM's versatility extends to many other areas:

| Industry | Common POM Applications |

| Automotive | Fuel system components, gears, bushings, valves |

| Electrical/Electronics | Connectors, switches, relay housings, insulators |

| Consumer Goods | Zippers, buckles, knobs, fasteners, toys |

| Medical Devices | Surgical instruments, drug delivery systems, dental components |

| Industrial Machinery | Conveyor components, gears, bearings, valve parts |

| Fluid Handling | Pumps, valves, impellers, fittings |

| Food Processing | Packaging machinery, FDA-compliant components |

| Sports/Recreation | Ski bindings, archery equipment, bicycle parts |

| Aerospace | Structural components, gears, bearings |

| Miscellaneous | Textile machinery, musical instruments, construction hardware |

POM Plastic Modifications

Polyoxymethylene (POM) can be modified to enhance its performance in specific applications. These modifications tailor POM’s properties, making it even more versatile across industries.

Impact Modification

Want tougher POM? Impact modification is the answer. We blend POM with elastomers or other tough polymers. This process:

Improves impact strength

Enhances toughness

Increases flexibility

Impact-modified POM is perfect for parts that need to withstand shocks and vibrations.

Reinforcement

Need stronger POM? Let's add some muscle. We mix in materials like:

Glass fibers

Carbon fibers

Mineral fillers

These reinforcements boost:

Tensile strength

Stiffness

Dimensional stability

Reinforced POM is ideal for high-load applications and structural parts.

Low-Friction Modification

POM already has low friction, but we can make it even slicker. We add:

PTFE (Teflon)

Silicone

Graphite

Benefits include:

These modifications make POM perfect for bearings and sliding components.

Food-Grade Modification

Safety first! Food-grade POM meets strict regulatory requirements. We achieve this by:

Using FDA-approved additives

Implementing special processing techniques

Rigorous testing and certification

Food-grade POM is essential for food processing equipment and packaging.

UV Resistance Modification

Let's make POM sun-proof. We add UV stabilizers and absorbers to:

UV-resistant POM is crucial for exterior automotive parts and outdoor equipment.

Nanocomposite Modification

Time for some high-tech tweaks. We incorporate nanomaterials like:

These tiny additions can lead to big improvements:

Enhanced mechanical properties

Improved thermal stability

Better barrier properties

Nanocomposite POM pushes the boundaries of performance in demanding applications.

Here's a quick overview of POM modifications:

| Modification | Key Additives | Main Benefits |

| Impact | Elastomers | Toughness, flexibility |

| Reinforcement | Glass/carbon fibers | Strength, stiffness |

| Low-friction | PTFE, silicone | Reduced wear, better lubrication |

| Food-grade | FDA-approved additives | Safe for food contact |

| UV-resistant | UV stabilizers | Outdoor durability |

| Nanocomposite | Nanomaterials | Overall performance boost |

These modifications expand POM's capabilities, making it even more versatile and valuable across industries.

POM Plastic Processing Methods

POM plastic can be processed through various methods, each offering specific benefits for different applications. Below are the most common techniques used to shape and produce POM components.

Injection Molding

Injection molding is the most widely used method for POM. It’s ideal for high-volume production and enables the creation of complex geometries with high precision. This method is highly efficient and is frequently employed in industries like automotive and electronics.

| Advantages of Injection Molding | Details |

| High-volume production | Cost-effective for mass manufacturing |

| Complex geometries | Enables intricate shapes and designs |

| Tight tolerances | Achieves high accuracy for precision components |

Extrusion

The extrusion process is used to produce sheets, rods, and tubes from POM. These parts are often semi-finished and require further machining like cutting, turning, or milling to meet precise specifications.

| Advantages of Extrusion | Details |

| Continuous production | Produces long lengths of material |

| Versatile shapes | Suitable for rods, sheets, and tubes |

| Further machining | Often needed for final part shaping |

Machining

POM is highly suitable for machining, which includes processes like turning, milling, and drilling. Due to its dimensional stability, POM is ideal for parts requiring tight tolerances. This method is commonly used when precision is critical, such as in the aerospace and medical device industries.

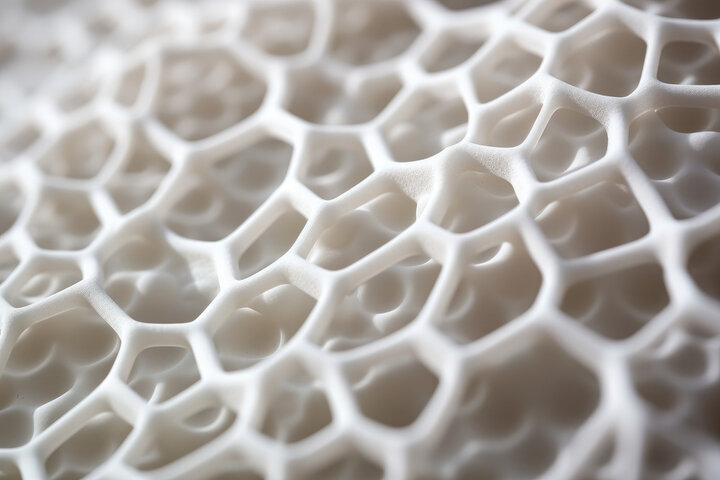

3D Printing

POM can also be processed using 3D printing technologies, particularly Fused Filament Fabrication (FFF) and Selective Laser Sintering (SLS). Although less common, 3D printing allows for the creation of complex prototypes and small-scale production runs. It is especially useful for applications where traditional molding may be too costly or time-consuming.

| Advantages of 3D Printing | Details |

| Prototype creation | Ideal for producing complex and custom designs |

| Reduced lead times | Faster production for small-scale runs |

| Flexible design modifications | Easy to make changes to design prototypes |

Designing with POM Plastic

When designing components using POM plastic, careful attention to specific design elements can greatly enhance performance and manufacturing efficiency. Here are key considerations to keep in mind.

Wall Thickness Considerations

Getting wall thickness right is crucial. Here's what you need to know:

Aim for uniform thickness

Recommended range: 1.5 to 3.0 mm

Thicker walls increase cooling time and may cause sink marks

Thinner walls might not fill properly

Pro tip: Use ribs or gussets to reinforce thin walls instead of increasing overall thickness.

Draft Angles for Molding

Draft angles are your friend in injection molding. They help parts release from the mold easily.

For POM, consider:

Minimum draft angle: 0.5°

Recommended draft angle: 1° to 2°

Increase draft for textured surfaces

Remember: More draft means easier ejection and fewer marks on your part.

Snap Fits and Living Hinges

POM's flexibility makes it great for snap fits and living hinges. Here's how to design them:

Snap fits:

Living hinges:

These features can reduce part count and assembly time.

Avoiding Sharp Corners

Sharp corners are stress concentrators. They're bad news for POM parts. Instead:

Use generous radii on all corners

Minimum recommended radius: 0.5 mm

Larger radii improve flow and reduce stress

Smooth curves make for stronger, more durable parts.

Accounting for Shrinkage

POM shrinks as it cools. Plan for it in your designs.

Typical shrinkage rates:

Factors affecting shrinkage:

Part geometry

Molding conditions

Material grade

Compensate by slightly oversizing your mold cavity.

Here's a quick design checklist for POM parts:

| Design Element | Recommendation |

| Wall Thickness | 1.5 - 3.0 mm |

| Draft Angle | 1° - 2° |

| Corner Radius | ≥ 0.5 mm |

| Snap Fit Undercut | 1.0 - 1.5 × thickness |

| Living Hinge Thickness | 0.3 - 0.5 mm |

| Shrinkage Allowance | 1.5% - 2.2% |

Comparing POM Plastic to Other Materials

Let's stack POM up against some other popular materials. You'll see why it's often the top choice for many applications.

POM vs. Nylon: Which is better?

POM and Nylon are both versatile thermoplastics. But they've got their own strengths:

POM advantages:

Nylon advantages:

Choose POM for precision parts in wet environments. Go for Nylon when you need toughness and heat resistance.

POM plastic vs. Polybutylene Terephthalate (PBT)

POM and PBT are often neck-and-neck in engineering applications. Let's break it down:

POM strengths:

PBT strengths:

POM shines in mechanical applications. PBT takes the lead in electrical and high-heat scenarios.

How POM compares to other engineering plastics

POM holds its own against many engineering plastics. Here's a quick comparison:

| Property | POM | ABS | PC | PEEK |

| Strength | High | Moderate | High | Very High |

| Stiffness | High | Moderate | High | Very High |

| Wear Resistance | Excellent | Poor | Moderate | Excellent |

| Chemical Resistance | Good | Moderate | Poor | Excellent |

| Cost | Moderate | Low | Moderate | Very High |

POM offers a balanced mix of properties at a reasonable cost. It's often the go-to for:

Parts requiring high precision

Components with moving parts

Applications needing low friction

PEEK might outperform POM in extreme conditions, but at a much higher price. ABS is cheaper but can't match POM's mechanical properties.

Remember, material choice depends on your specific needs. Consider factors like:

Operating environment

Mechanical requirements

Cost constraints

Processing methods

Conclusion

POM plastic, or polyoxymethylene, offers high strength, low friction, and excellent dimensional stability. It’s a key material in industries like automotive, electronics, and medical devices. POM’s role in modern manufacturing continues to grow due to its versatility and durability. Whether you need components with chemical resistance or precision, POM delivers reliable performance across various applications.

Tips: You maybe interested to the all plastics