What are Nuts?

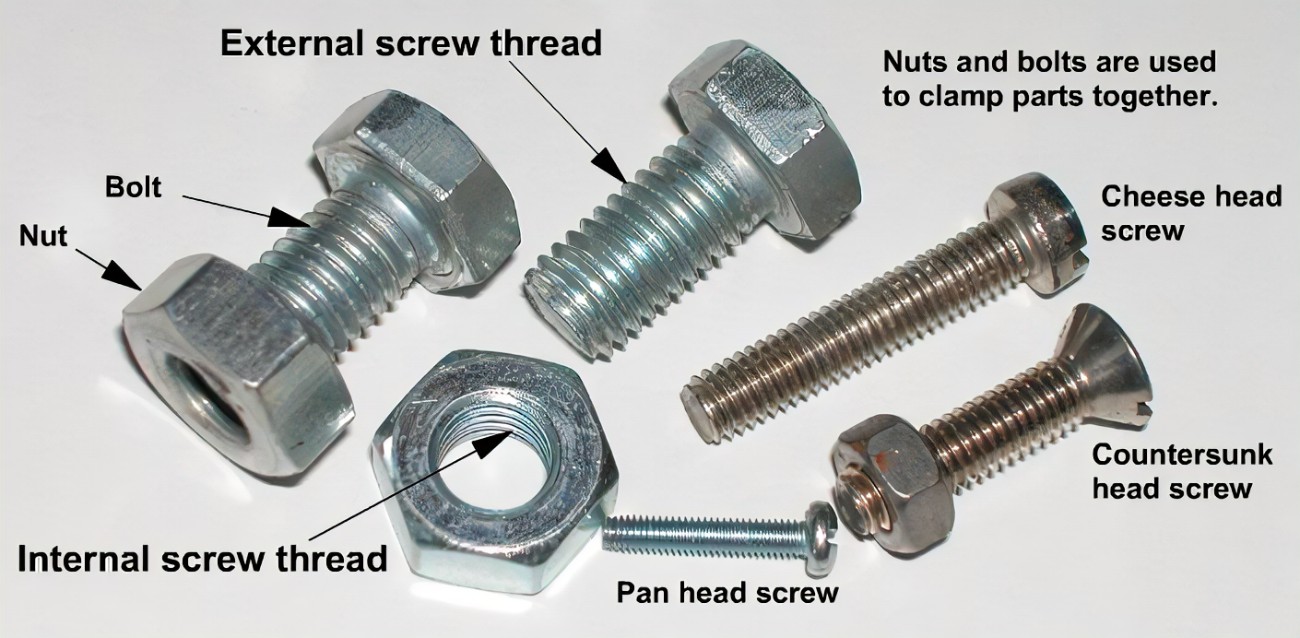

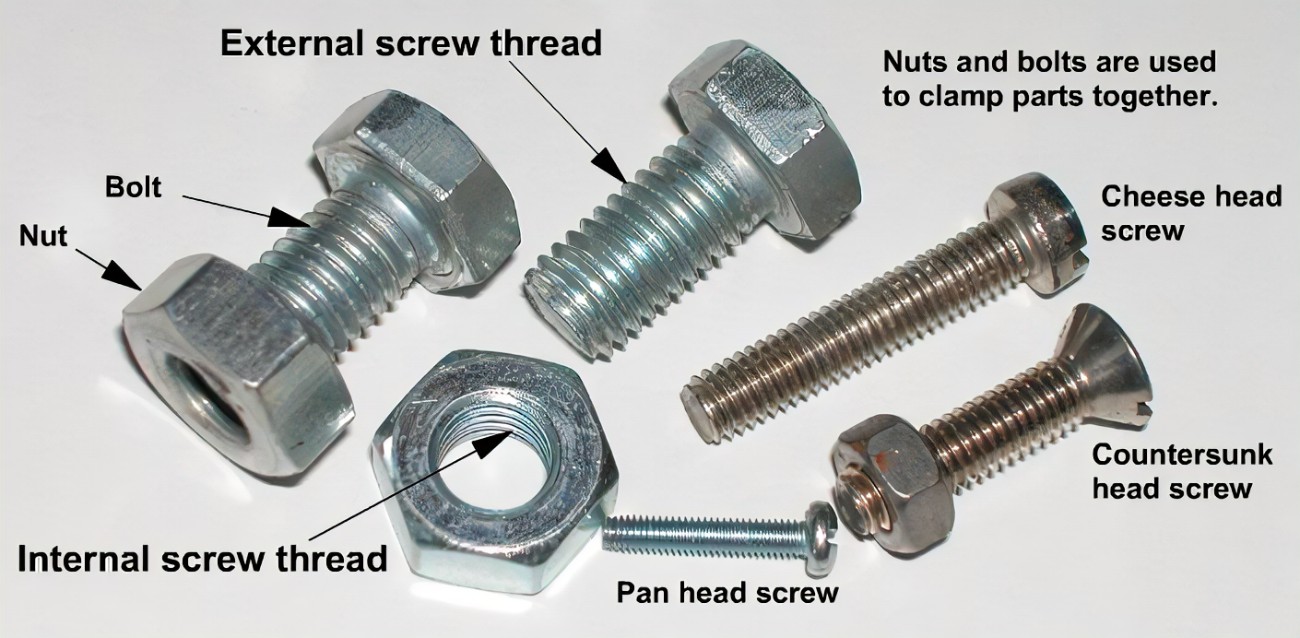

Nuts are essential fastening components that work in tandem with bolts to secure and keep parts intact. At their core, nuts are internally threaded fasteners designed to mate with externally threaded bolts. When I say they are internally threaded, I mean they have grooves on the inside that match the threads on a bolt. This pairing creates a secure threaded connection that can handle both compressive and tensile forces.

The Role of Nuts in Fastening and Applications

Nuts play a crucial responsibility in fastening. They are the counterparts to bolts and screws, providing the necessary grip due to their internal threads. When a nut is twisted over the threaded stem of a bolt or screw, it moves along the grooves, drawing the two components together. This action results in a bolt joint that can withstand vibrations and prevent loosening. Nuts and bolts are everywhere, from furniture to industrial CNC machining machinery.

Types of Nuts

Acorn Nuts

Acorn Nuts, or cap nuts, have a domed top that covers the end of the bolt. This conical top not only protects the bolt from damage but also provides a safer, smoother finish to the bolt joint. They're often used in applications where a decorative or protective finish is beneficial.

Hex Nuts

Hex Nuts are the standard hex-shaped fastening device you'll find in almost any toolkit. They come in various sizes and grades to suit different applications.

● Hex Finish Nuts are typically used for general-purpose fastening. They have a standard size that matches the bolt sizes and thread length.

● Structural Heavy Hex Nuts are larger and thicker, designed to anchor or secure structures to concrete. They can handle more comprehensive stress and are often used in construction.

● Small Pattern Hex Nuts are smaller in size, suitable for tight spaces where a regular hex nut won't fit.

Lock Nuts

Lock Nuts are designed to resist loosening under vibrations and torque. There are different types of hex nuts with unique locking mechanisms.

● Prevailing Torque Lock Nuts maintain their hold through friction between the mating threads.

● Serrated Flange Lock Nut has a serrated flange at one end that bites into the material being fastened, acting as a locking mechanism.

● Castle Lock Nut features notches at one end that can be secured with a pin or wire for added safety.

● Nylon Insert Lock Nut uses a nylon collar that grips the thread of the bolt, providing a resilient locking action.

Specialty Nuts

Then we have Specialty Nuts, which include a variety of shapes and designs for specific applications.

● Coupling Nuts are long, cylindrical nuts used to connect two pieces of threaded rod.

● Speed Nuts, also known as clip nuts, are pressed into place and do not require threading.

● Square Nuts have a larger surface area in contact with the part being fastened, offering more resistance to loosening.

● T-Nuts are designed to embed into wood, providing a threaded connection.

● U-Nuts clip onto the edge of a panel, offering a secure fastening point.

● Wing Nuts can be tightened and loosened by hand, thanks to their wing-like projections.

Choosing the Right Nut

When selecting the right nut for a job, consider the material (steel, zinc, high-grade steel, nickel, and chrome), size (matching bolt sizes and thread length), and application (whether it needs to stretch under tension or withstand vibration). The correct nut, matched with the appropriate bolt, ensures a threaded connection that will secure components reliably under various stresses.

Understanding the different types of nuts and their specific applications is key to ensuring a strong and reliable fastening solution. Whether it's a simple hex nut or a specialized lock nut, each plays a vital role in the world of nuts and bolts.

What are Bolts?

Bolts are a type of fastening hardware, essential for creating a bolt joint between two or more parts. They consist of a cylindrical threaded rod with a head at one end. When we talk about nuts and bolts, bolts are the externally threaded fasteners that go through the parts to be joined. A nut, which has internal threads, is then screwed onto the bolt to secure the connection.

The role of bolts in fastening and applications

Bolts play a vital role in fastening by providing a strong, secure hold that can withstand tensile and compressive forces. They are used in a wide range of applications, from building bridges to assembling furniture. The bolt sizes and thread length must match the nuts they are paired with to ensure a tight fit.

Types of Bolts

Carriage Bolts

Carriage bolts have a smooth, circular head with a square section underneath. This design allows them to lock into place when tightened, making them ideal for wood-to-wood connections. You'll often find carriage bolts in deck building and other carpentry projects.

Anchor Bolts

Used primarily in construction, anchor bolts are a heavy-duty fastener designed to anchor or secure structures to concrete. They come in various shapes, but all serve the same purpose of providing a strong hold in a threaded hole in the center of their anchor point.

Hex Bolts

Hex bolts are named for their hexagonal nut shape. They are a standard hex-shaped fastening device used in a multitude of projects. Their six-sided design makes them easy to grip with tools, allowing for tight fastening. Common uses include construction and machinery assembly.

Specialty Bolts

● Flange Bolts: These bolts have a flange under the head that acts like a washer to distribute pressure. They are often used in vehicle frames.

● U-Bolts: Shaped like the letter U, these bolts are used to support pipework.

● J-Bolts: Resembling the letter J, they are used to hook into concrete or wood.

● Lag Bolts: These are large wood screws with a bolt head and are used for heavy-duty wood applications.

● Eye Bolts: With a loop at one end, they are used for attaching ropes or cables.

Innovative Bolts

● Blind Bolts: These are used where you can't access the back of the item being bolted, like in aerospace applications.

● Double-end Bolts: These have threads on both ends and are used in situations where a bolt needs to be secured at both ends.

● Machine Bolts: These are used to fasten metal to metal or metal to wood.

Selecting the Appropriate Bolt

When choosing the right bolt, consider the length, thread, and material. The length must be sufficient to go through the materials being joined with enough thread exposed to secure the nut. The thread must match the types of nuts you're using. Material choice is based on the environment the bolt will be in; for instance, zinc, high-grade steel, or nickel and chrome coatings can protect against corrosion.

Bolts are essential fastening components that keep parts intact. Whether you're using a carriage bolt for woodworking or an anchor bolt for construction, selecting the right bolt is crucial for the integrity of the structure. Remember, bolts come in various sizes and styles, from the common hex bolt to the specialty bolts designed for specific applications.

Differences Between Nuts and Bolts

When we talk about Nuts vs. Bolts, we're looking at two essential fastening components that work together to secure parts and keep parts intact. Here's a simple comparative analysis:

● Nuts are internally threaded fasteners that fit onto bolts or screws. They are typically smaller in size and have a circular cross-section.

● Bolts are externally threaded fasteners with a cylindrical threaded rod and a head. They are comparatively bigger and designed to be used with a matching nut.

Aspect | Nuts | Bolts |

Threads | Internal threads | External threads |

Function | Secure by applying compressive force | Secure by applying tensile force |

Shape | Circular with a flat or conical top | Cylindrical with various bolt head styles |

Pairing | Typically paired with a bolt or screw | Often paired with a nut to create a bolt joint |

Size | Generally smaller in size | Larger than nuts, with varying bolt sizes |

Locking Mechanism | Can have features to prevent loosening | May have features like a locking mechanism to resist vibration |

How Nuts and Bolts Work Together

When we talk about nuts and bolts, we're discussing a team. They're like a dynamic duo of fasteners, each with its own role. Let's break down how they work together.

The Basics of Nuts and Bolts

Bolts are a type of fastening hardware with external threads that fit into nuts, which have internal threads. When you turn a nut onto a bolt, the threads interlock. This creates a threaded connection that holds materials together.

Importance of Compatibility and Sizing

For nuts and bolts to work, they must be the right size for each other. A hex nut won't fit a carriage bolt if it's too big or small. It's like trying to fit a square peg in a round hole. Bolt sizes and hex nut dimensions need to match.

● Metric bolt and nut dimensions are standardized, so a 5mm bolt fits a 5mm nut.

● Bolt grade guide helps you choose the right strength for the job.

Types of Nuts and Bolts

There are many types of nuts and types of bolts:

● Hex Nuts and Hex Bolts are common. They have six sides and are easy to tighten.

● Lock Nuts have a special feature to prevent loosening from vibration.

● Carriage Bolts have a smooth, rounded head for a neat finish.

Each type has a specific use. For example, anchor bolts help secure structures to concrete.

The Role of Thread Length and Bolt Head Styles

Thread length and bolt head styles are important too. If a bolt is too short, the nut can't grip enough threads to hold tight. If it's too long, it might poke out too much on the other side.

Bolt head styles, like hex, square, or flush-mount domed, affect how you can tighten them. Some need a wrench, while others can be turned by hand.

Why Threads Matter

Threads are the grooves on nuts and bolts. They come in different shapes and sizes. The threads help distribute the compressive and tensile forces across the bolt joint. This means the nut and bolt can handle more pressure without being damaged.

Fastening and Unfastening

Nuts and bolts are made to fasten and unfasten easily. When you need to hold two pieces together, you fasten them with a nut and bolt. If you need to take them apart, you just unfasten the nut.

The Interplay

Imagine you're building something with steel components. You'd pick a bolt and a nut that fit the material's thickness. You'd also check the bolt grade guide to make sure they can handle the stress.

As you tighten the nut onto the bolt, they compress together. This compression is what holds your materials in place. If the nut and bolt weren't compatible, they wouldn't hold. The pieces could come apart, or the fasteners could break.

The Takeaway

Nuts and bolts might seem small, but they have a big responsibility. They secure parts and keep them intact. Remember, the right types of nuts and types of bolts, with the correct sizing and compatibility, are key to a strong and lasting bolt joint.

Advanced Topics in Nuts and Bolts

In the world of fastening, the details matter. Let's explore some advanced topics in nuts and bolts that can make a big difference in their performance.

Impact of Material Choice on Performance

The material of nuts and bolts affects their strength, durability, and suitability for different environments.

● Carbon Steel: Widely used due to its strength and affordability. Ideal for indoor applications.

● Nickel: Adds corrosion resistance. Great for outdoor or high-moisture environments.

● Chrome: Provides extra hardness and a shiny finish. Often used in automotive applications for both strength and aesthetics.

Different materials can significantly impact the tensile and compressive strength of fasteners.

Understanding Bolt Grades and Standards

Bolt grades determine the strength and application of bolts. Here are some common standards:

● SAE (Society of Automotive Engineers): Grades like 2, 5, and 8, with Grade 8 being the strongest.

● ASTM (American Society for Testing and Materials): Includes a wide range of standards for construction and engineering.

● Metric: Uses classes like 8.8, 10.9, and 12.9, where the higher numbers indicate stronger bolts.

Knowing the right grade is crucial for ensuring that bolts can handle the stress and load they will face.

Nut Grades and Compatibility with Bolts

Just like bolts, nuts also have grades. It's essential to match the nut grade with the bolt grade for optimal performance.

● Compatibility: A high-grade bolt should be matched with an equivalent or higher-grade nut.

● Material Match: The material of the nut should complement the bolt's material to prevent corrosion or wear.

Case Study: Building a Bridge

In bridge construction, engineers carefully select bolt and nut combinations based on bolt grade guide and metric bolt and nut dimensions. This ensures that the structure can withstand vibrations, tensile forces, and environmental stresses.

Quick Facts

● Hex Nuts and Hex Bolts are commonly used together due to their versatility and strength.

● Lock Nuts often accompany Carriage Bolts in applications where vibration is a concern.

● The thread length and bolt sizes must be carefully considered to ensure a secure fit.

Understanding the advanced aspects of nuts and bolts, like material choice and grading standards, is key for professionals in construction, engineering, and manufacturing. This knowledge ensures that the right fasteners are used for the right job, leading to safer and more durable constructions.

Maintenance and Care for Nuts and Bolts

Keeping nuts and bolts in top condition is key to ensuring the longevity and safety of any construction or assembly. Here are some tips and common troubleshooting advice.

Tips on Prolonging the Life of These Fasteners

1. Regular Inspection: Regularly check for signs of wear, corrosion, or damage. This is crucial for nuts bolts used in critical structures like bridges or machinery.

2. Proper Lubrication: Apply appropriate lubricants to prevent rust and ensure smooth operation, especially for threaded connections and locking mechanisms.

3. Correct Tightening: Use the right tools to avoid over-tightening, which can cause stress and damage. Follow the bolt grade guide for specific torque recommendations.

4. Cleanliness: Keep the fasteners clean. Dirt and grime can cause damage over time, especially in bolt joints and internal threads.

5. Environmentally Suitable Materials: Choose materials like high-grade steel or zinc-coated fasteners for environments prone to moisture or chemicals to prevent corrosion.

6. Storage: Store unused nuts and bolts in a dry, cool place to prevent rust and degradation.

Common Issues and Troubleshooting

● Rust and Corrosion: Regularly inspect for rust. If found, replace the fastener. Stainless steel or coated fasteners like zinc can prevent this.

● Stripped Threads: Occurs when nuts or bolts are over-tightened. Replace the damaged parts and ensure proper torque is applied in the future.

● Seized Nuts and Bolts: Apply penetrating oil and allow it to soak in to loosen them.

● Wear and Tear: Replace any nuts or bolts showing signs of wear, as they can lead to joint failure.

Case Study: Bridge Maintenance

A study on bridge maintenance showed that regular inspection and timely replacement of nuts and bolts, especially carriage bolts and anchor bolts, significantly reduced the risk of structural failures.

Proper maintenance and care of nuts and bolts are crucial for the safety and longevity of any structure or machinery. Regular inspections, appropriate material choice, and correct installation practices are key to avoiding common issues and ensuring that these essential fastening components remain secure and intact.

Conclusion

As we wrap up our exploration of nuts and bolts, it's clear that these small components play a massive role in our daily lives. From the furniture we use to the cars we drive, nuts and bolts hold our world together.

The Importance of Understanding Nuts and Bolts

Understanding the different types of nuts and types of bolts is not just for engineers or mechanics. It's knowledge that can benefit everyone. Whether you're fixing a bike or building a deck, knowing the difference between a hex nut and a lock nut, or a carriage bolt and an anchor bolt, can make your project more successful.

● Nuts and bolts work together to create strong, secure connections.

● Choosing the right fasteners is crucial for both safety and functionality.

● Material choice (like steel or zinc), thread length, and bolt sizes are key factors to consider.

Encouragement to Choose the Right Type for Specific Needs

There's no one-size-fits-all when it comes to fasteners. Each type has its own unique features and benefits:

● Hex Nuts and Hex Bolts are versatile for various applications.

● Lock Nuts are essential where vibration might loosen a connection.

● Carriage Bolts are perfect for wood projects due to their smooth, circular head.

Next time you're working on a project, take a moment to consider the nuts and bolts you're using. Are they the right type for the job? Do they match in terms of material and grade? Your choices can make all the difference in creating something that's secure, durable, and reliable.

In conclusion, nuts and bolts might be small, but their impact is huge. Understanding their types, differences, and applications is a skill that will serve you well in many aspects of life and work. So, choose wisely and build confidently!

FAQ

Q: What Are the Most Commonly Used Nut and Bolt Types?

A: Hex bolts and nuts are most prevalent. Carriage bolts and wing nuts also widely used. Machine screws and locknuts are common in machinery.

Q: How Do I Determine the Right Grade of Bolt and Nut?

A: Check load requirements and material compatibility. Grade markings on bolt heads indicate strength. Consult standards like ASTM or SAE for guidance.

Q: Can Bolts and Nuts of Different Materials Be Used Together?

A: Generally not recommended due to corrosion risks. Galvanic corrosion can occur with dissimilar metals. Always ensure material compatibility for safety.

Q: Maintenance Tips for Prolonging the Life of Nuts and Bolts

A: Regularly clean and inspect for corrosion. Apply anti-seize or lubricants to prevent galling. Tighten to correct torque to avoid stress.

Q: How to Identify the Right Size and Material in Fasteners?

A: Measure diameter, length, and thread pitch. Match materials to application environment. Refer to fastener standards for proper selection.