Why do some plastic parts have uneven color after injection molding? This defect can be costly for manufacturers. Inconsistent color can reduce product quality and increase waste. In this post, we’ll discuss the importance of color consistency in injection molding, the challenges factories face, and practical solutions to ensure better results.

Understanding Color Defects

In the realm of injection molding, color consistency plays a crucial role in product quality. Let's dive into the world of color defects and explore their impact on manufacturing processes.

Definition of Uneven Color or Color Difference

Uneven color, also known as color difference, refers to:

Inconsistencies in hue, depth, and shade across molded parts

Variations that deviate from the intended color specifications

Non-uniform pigment distribution within the plastic material

These discrepancies can manifest in subtle or stark ways, affecting:

Visual appeal

Product quality

Brand consistency

Common Symptoms

Color defects often reveal themselves through:

Visual Indicators

Mixed colors: Swirls or patches of different shades

Discoloration: Unexpected shifts in hue or intensity

Marbling effects: Streaks or patterns resembling marble

Spotting: Localized areas of darker or lighter coloration

Impact on Manufacturing

Color inconsistencies can lead to:

| Issue | Consequence |

| Increased scrap rates | Higher production costs |

| Difficulty matching parts | Assembly challenges |

| Quality control failures | Delayed shipments |

| Customer dissatisfaction | Potential loss of business |

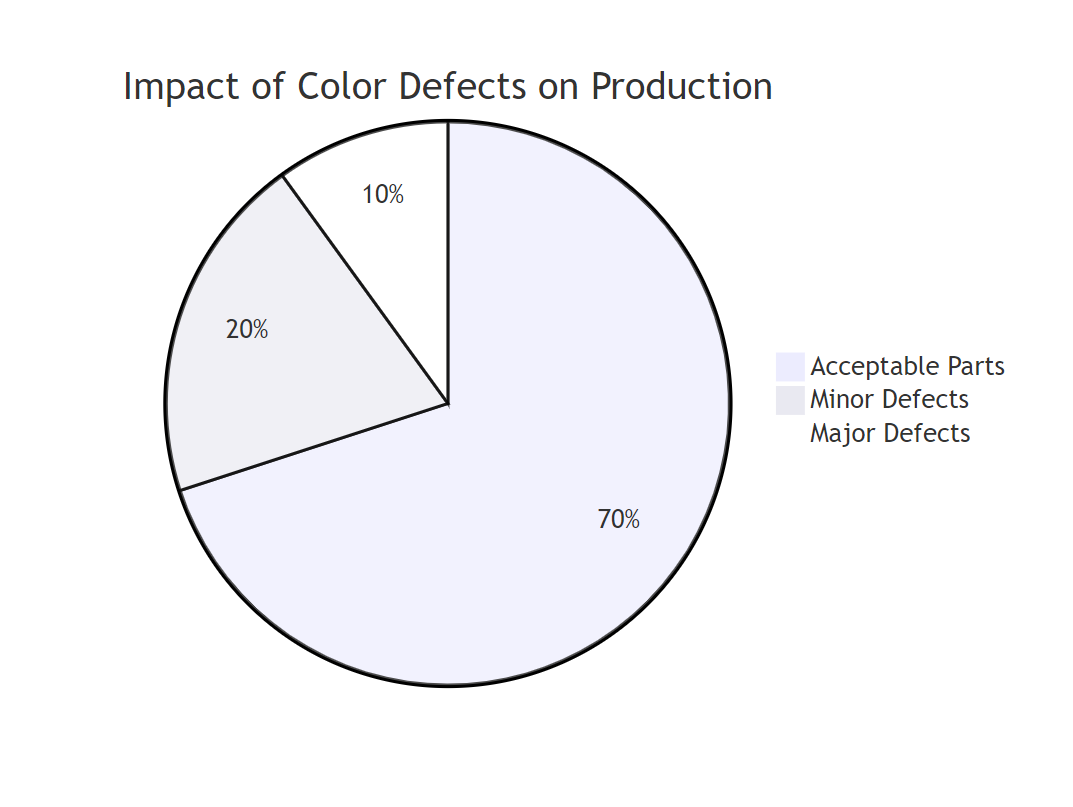

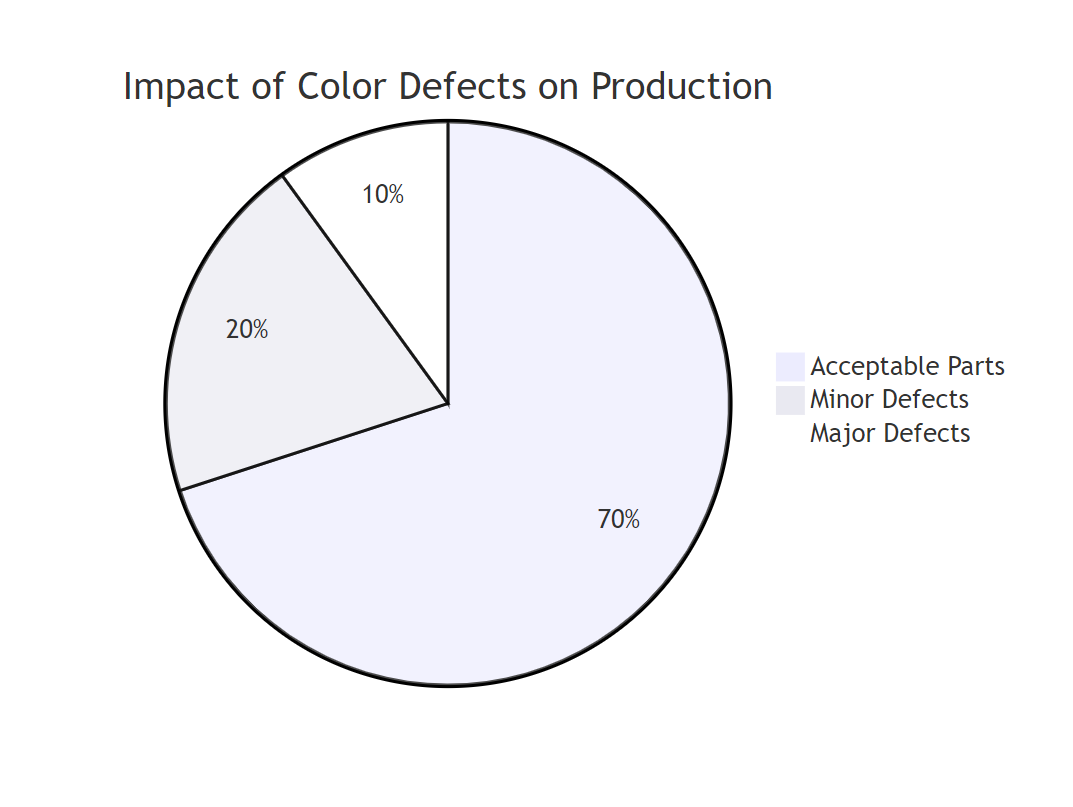

To illustrate the severity of color defects, consider this data:

Color consistency issues don't just affect aesthetics. They can signal underlying problems:

Improper material mixing

Temperature fluctuations

Mold design flaws

Contamination issues

Identifying these symptoms early helps manufacturers:

By understanding color defects, injection molding professionals can:

1.Improve quality control processes 2.Reduce waste 3.Enhance overall production efficiency

Color Difference Detection and Judgment

Identifying color inconsistencies in injection molding requires keen observation and precise measurement. Let's explore the methods used to detect and evaluate color differences.

Visual Inspection Techniques

Visual inspection remains a crucial first step in color quality control. It relies on human perception to spot discrepancies.

Role of Lighting and Environment

Lighting conditions significantly impact color perception. Consider these factors:

Natural vs. artificial light

Color temperature of light sources

Surrounding colors and reflections

Proper lighting setup ensures:

Consistent color evaluation

Accurate detection of subtle variations

Reduced eye strain for inspectors

Limitations of Human Eye vs. Machine Inspection

Human vision, while adaptable, has its drawbacks:

| Human Eye | Machine Inspection |

| Subjective | Objective |

| Prone to fatigue | Consistent performance |

| Limited color sensitivity | High-precision detection |

| Influenced by optical illusions | Data-driven analysis |

Despite limitations, trained inspectors can:

Colorimeter Inspection

For precise color measurement, colorimeters provide quantifiable data. They offer objective analysis beyond human perception.

Understanding △E Values

△E (Delta E) represents the total color difference between two samples. It's calculated using:

△E = [(△L)⊃2; + (△a)⊃2; + (△b)⊃2;]^(1/2)

Where:

Standards for Acceptable Color Differences

Industry standards often use △E values to define acceptable color variations:

| △E Range | Interpretation |

| 0 - 1 | Barely perceptible difference |

| 1 - 2 | Slight difference |

| 2 - 3.5 | Noticeable difference |

| 3.5 - 5 | Significant difference |

| > 5 | Unacceptable difference |

These ranges may vary depending on:

Industry specifications

Product requirements

Customer expectations

By combining visual and colorimeter inspections, manufacturers can:

What Causes Uneven Color in Injection Molded Parts?

Uneven color in injection molded parts can stem from various factors. Understanding these causes helps manufacturers troubleshoot and prevent color inconsistencies.

Raw Material Factors

Raw materials play a crucial role in color consistency. Several issues can lead to uneven coloration:

Inconsistent quality or contamination

High moisture content

Improper drying techniques

Poor distribution of fiber fillers

Stress discoloration in certain materials

Materials like high-impact polystyrene and ABS are prone to stress-induced color changes. This occurs due to internal stresses after molding.

Colorant Quality and Control

Colorants significantly impact the final product's appearance. Problems arise from:

Poor dispersion of pigments

Low thermal stability

Inappropriate colorant selection

Inadequate quality control

Consider these factors when choosing colorants:

Compatibility with the resin

Process temperature requirements

Dispersibility in the melt

Airborne colorants can contaminate equipment and molds. This leads to unexpected color variations in subsequent production runs.

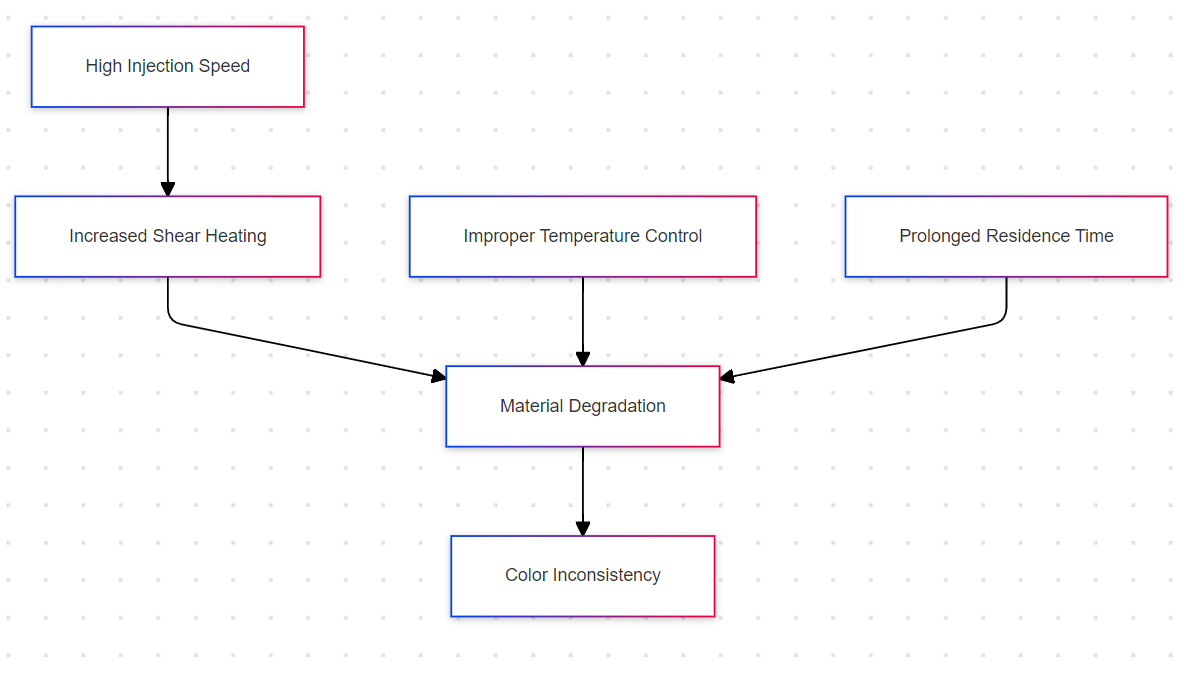

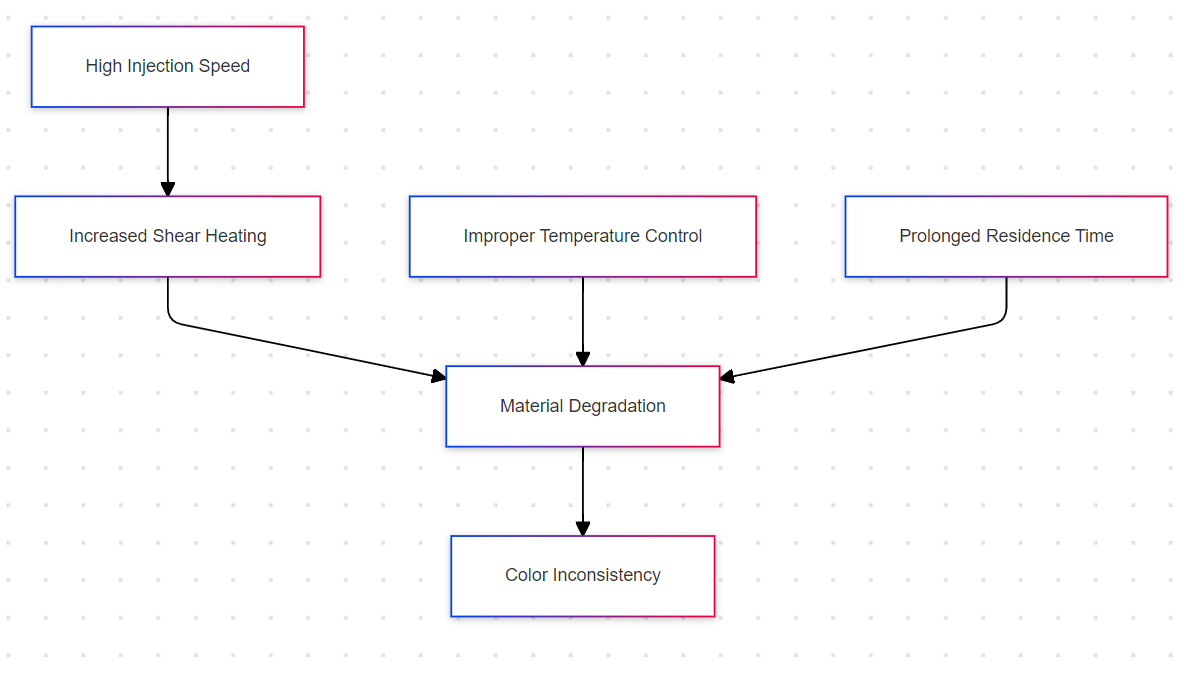

Injection Molding Machine Issues

Machine-related problems often result in color inconsistencies:

| Issue | Impact on Color |

| Inconsistent barrel temperatures | Overheating or poor plasticization |

| Component contamination or wear | Inconsistent melt quality |

| Inappropriate machine specifications | Inadequate processing control |

Regular maintenance and proper machine selection are crucial for color consistency.

Molding Process Parameters

Process settings greatly influence color uniformity:

Excessive injection speed

High pressure or back pressure

Improper melt temperature control

Insufficient plasticization

Prolonged melt residence time

Incorrect colorant dosing or mixing

Optimizing these parameters helps maintain color consistency throughout production.

Mold Design and Maintenance

Mold-related factors affecting color uniformity include:

Uneven cooling and temperature distribution

Poor venting leading to air entrapment

Contamination from release agents or lubricants

Suboptimal gate location or design

Surface roughness or polish issues

Rust on mold surfaces

Proper mold design and regular maintenance are essential. They ensure uniform melt flow and cooling, preventing color variations.

How to Prevent and Troubleshoot Color Inconsistency in Injection Molding

Color inconsistency in injection molding can be a significant challenge. It affects product quality and customer satisfaction. Let's explore effective strategies to prevent and troubleshoot this issue.

Quality Control of Raw Materials and Colorants

Ensuring high-quality inputs is crucial for consistent color output:

Source wisely: Choose reliable suppliers for consistent, high-quality raw materials.

Proper storage: Handle and store materials correctly to maintain their properties.

Drying protocols: Implement proper drying procedures for hygroscopic materials.

Colorant selection: Carefully test colorants for compatibility and performance.

Equipment maintenance: Regularly inspect and clean material handling equipment.

Fine-tuning machine settings is essential for color consistency:

Calibration: Regularly calibrate temperature control systems.

Parameter monitoring: Adjust key process parameters like injection speed and pressure.

Machine sizing: Ensure the molding machine is properly sized for the job.

Thorough cleaning: Purge and clean the machine thoroughly between color changes.

Fine-Tuning the Molding Process

A well-controlled process is key to consistent coloration:

Process control: Establish a robust system for monitoring and adjusting parameters.

Temperature optimization: Fine-tune melt temperature for optimal color dispersion.

Injection profiling: Adjust injection speed and pressure profiles for uniform color distribution.

Residence time: Minimize material residence time in the barrel.

Scientific molding: Implement principles for repeatable, predictable results.

Mold Design Considerations for Even Coloration

Mold design plays a crucial role in achieving uniform color:

Uniform cooling: Design molds for balanced temperature distribution.

Adequate venting: Prevent air entrapment and burn marks through proper venting.

Gate optimization: Choose gate locations and designs for balanced melt flow.

Maintenance: Regularly clean and treat mold surfaces to prevent contamination.

Optimization of Coloring Methods and Equipment

Improve color consistency through advanced coloring techniques:

Quality masterbatches: Use high-quality color masterbatches precise content.

Pre-coloring: Adopt pre-coloring methods when possible for better control.

Dehumidifying dryers: Prevent material moisture issues using advanced dryers.

Metal detection: Install detectors in the feeding system to prevent contamination.

Troubleshooting Techniques for Color Variation Issues

When color issues arise, systematic troubleshooting is essential:

Problem-solving approach: Use tools like Ishikawa diagrams and PDCA cycles.

Root cause analysis: Isolate and identify the primary sources of color inconsistency.

Incremental adjustment: Test process parameters systematically to pinpoint issues.

Team collaboration: Foster communication between design, production, and quality control teams.

By implementing these strategies, manufacturers can significantly improve color consistency in injection molding. Regular monitoring and continuous improvement are key to maintaining high-quality, uniform coloration.

Additional Solutions and Best Practices

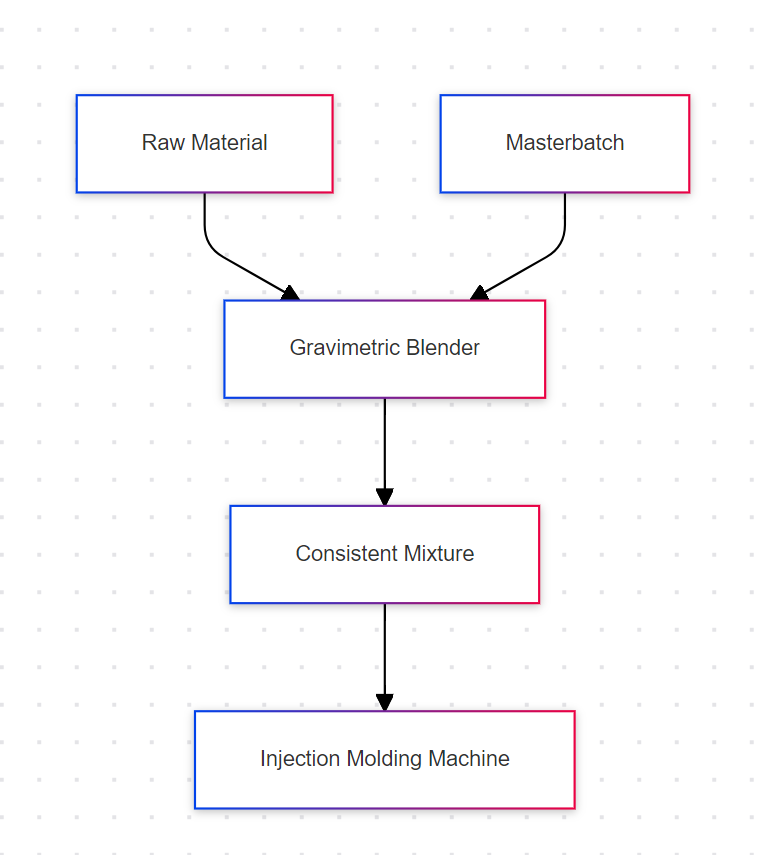

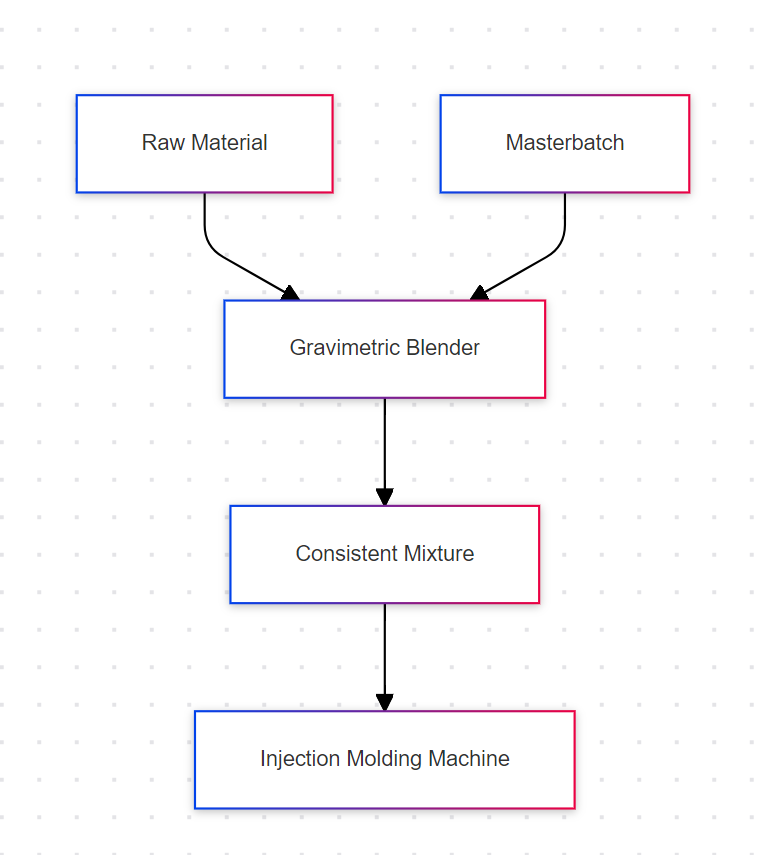

Use of Gravimetric Blenders

Gravimetric blenders offer precise control over material mixing. They ensure consistent ratios of masterbatch and raw materials.

Key benefits include:

Accurate dosing of colorants

Real-time adjustment of blend ratios

Elimination of human error in material preparation

This technology significantly reduces color variations caused by inconsistent mixing.

Static Electricity Control Measures

Static electricity can cause material separation during transport. This leads to color unevenness in the final product.

Effective static control methods include:

Ionizers in material transport lines

Anti-static additives in raw materials

Grounding of equipment and transport systems

| Location | Control Measure |

| Hopper | Screen cone installation |

| Transport hoses | Ionizers or KI blow static eliminators |

| Molding machine | Grounding straps |

These measures prevent material clumping and ensure uniform distribution of colorants.

Liquid Color Blenders

For transparent light-colored molding, liquid color blenders offer unique advantages:

Improved color dispersion

Reduced risk of streaking or marbling

Easy adjustment of color intensity

Liquid colorants are introduced just before the material enters the molding machine. This timing allows for:

Uniform mixing with transparent resin

Minimal exposure to heat degradation

Precise color control in real-time

By implementing these advanced solutions, manufacturers can:

Improve color consistency

Reduce waste from color defects

Enhance overall product quality

Case Studies

Real-world examples provide valuable insights into solving color inconsistency issues. Let's examine three cases and their solutions.

Case 1: Improper Colorant Selection

A smartphone case manufacturer faced persistent color variations in their products. Investigation revealed the root cause: improper colorant selection.

Problem:

Solution:

Conducted thermal stability tests on colorants

Selected heat-resistant pigments

Adjusted processing parameters for new colorant

Outcome:

95% reduction in color-related defects

Improved customer satisfaction

Decreased production waste

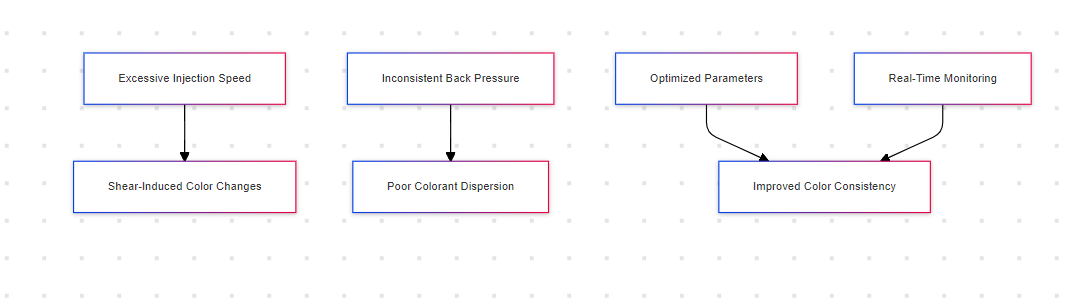

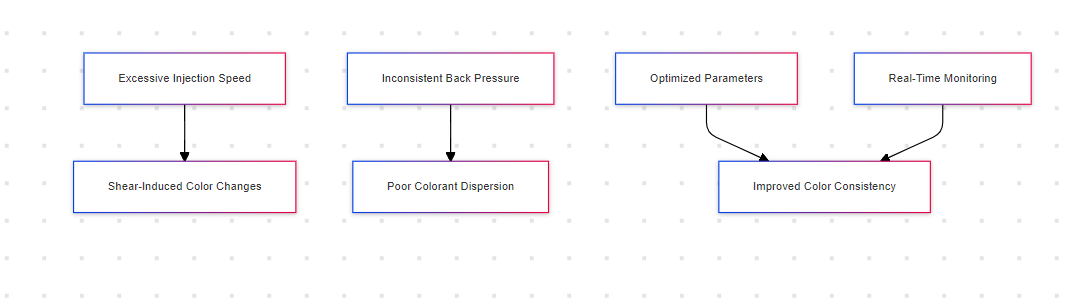

Case 2: Injection Molding Process Parameters

An automotive parts supplier experienced color deviations in dashboard components. Analysis pointed to improper injection molding process parameters.

Problem:

Solution:

Optimized injection speed profile

Fine-tuned back pressure settings

Implemented real-time process monitoring

Outcome:

Color consistency improved by 80%

Scrap rate reduced from 7% to 1.5%

Production efficiency increased by 12%

Case 3: Mold Temperature Control

A cosmetic packaging manufacturer noticed local color differences in their products. Investigation revealed improper mold temperature control as the culprit.

Problem:

Solution:

Redesigned mold cooling channels

Installed additional temperature sensors

Implemented adaptive mold temperature control

| Area | Before | After |

| Color Consistency | 75% | 98% |

| Cycle Time | 28 seconds | 24 seconds |

| Scrap Rate | 5.5% | 1.2% |

Outcome:

Achieved uniform color across all product areas

Reduced cycle time by 14%

Improved overall product quality

Conclusion

Color consistency in injection molding hinges on various factors. Raw materials, colorants, machine issues, and process parameters all play crucial roles. Regular maintenance, inspections, and adjustments prevent problems before they start. Collaborating with suppliers ensures high-quality materials. By addressing these aspects, manufacturers can achieve consistent, high-quality colored products.