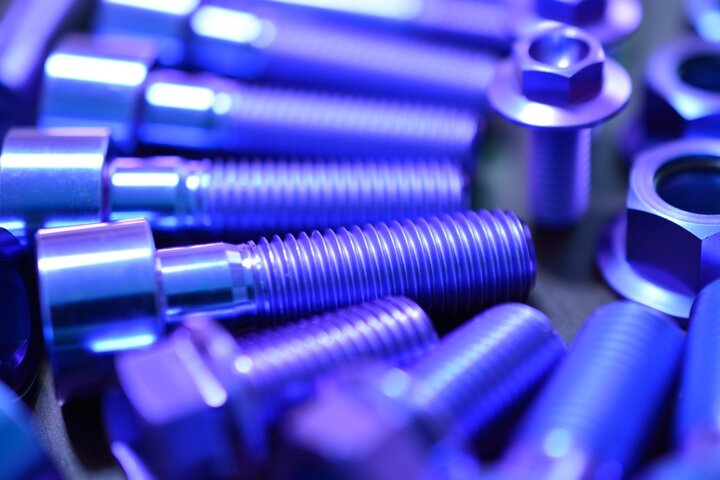

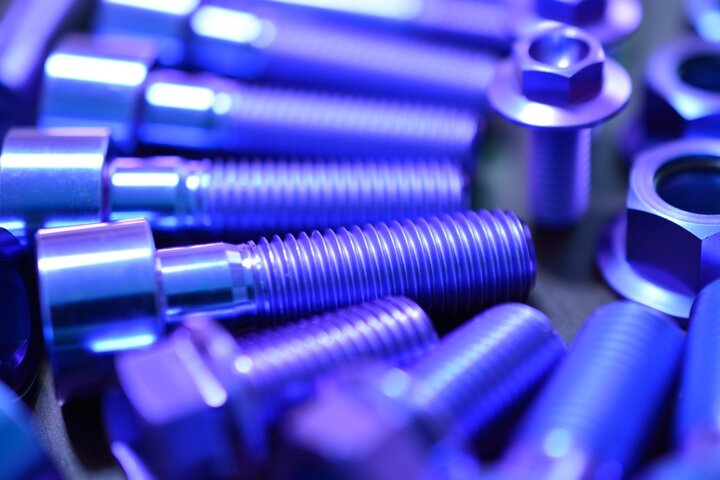

Have you ever wondered how metal parts in everyday products maintain their shiny appearance and resist corrosion? The answer lies in surface finishing techniques like anodizing and electroplating. These processes enhance the properties of metal components, but they work in different ways.

Anodizing and electroplating are two common methods used to improve the durability, corrosion resistance, and appearance of metal parts. While both techniques involve electrochemical processes, they differ in their approach and the results they produce.

In this article, we'll explore the key differences between anodizing and electroplating. You'll learn about the unique characteristics of each process, the metals they can be applied to, and their typical applications in various industries. By understanding these distinctions, you'll be better equipped to choose the right surface finishing technique for your specific needs, whether you're in manufacturing, product design, or engineering.

Understanding Anodizing

The Anodizing Process

Anodizing is an electrochemical process that enhances the natural oxide layer on metal surfaces, particularly aluminum. It involves submerging the metal in an electrolytic bath and applying an electric current. This causes oxygen ions to react with the metal surface, creating a thicker, more resilient oxide layer.

During anodizing, the metal acts as the anode in the electrolytic cell. When electricity is applied, oxygen ions from the electrolyte bond with aluminum atoms on the surface. They form an aluminum oxide layer that's harder and more corrosion-resistant than the metal itself.

The electrochemical mechanism builds the oxide layer through a carefully controlled process:

Aluminum atoms on the surface release electrons and become positively charged ions.

These ions migrate through the existing oxide layer towards the electrolyte.

At the same time, negatively charged oxygen ions move from the electrolyte towards the metal surface.

The oxygen and aluminum ions react, forming aluminum oxide (Al2O3) on the surface.

As this process continues, the oxide layer grows thicker, providing enhanced protection and durability.

Types of Anodizing

There are three main types of anodizing, each with distinct properties and applications:

While aluminum is the most commonly anodized metal, the process can also be applied to titanium, magnesium, and other nonferrous metals.

Chromic Acid Anodize (Type I)

Chromic Acid Anodize (CAA), or Type I anodizing, produces a thin, dense oxide layer using chromic acid as the electrolyte. The resulting film is softer than other anodizing types but offers good corrosion resistance. CAA is often used in aerospace applications where a thin, protective layer is desired.

Sulfuric Anodize (Type II and IIB)

Sulfuric Acid Anodize (SAA), or Type II anodizing, is the most common type. It uses sulfuric acid as the electrolyte, resulting in a thicker oxide layer than Type I. Type II anodizing provides excellent wear and corrosion resistance, making it suitable for architectural, automotive, and consumer products.

Type IIB is a variant of Type II, producing a thinner layer than standard Type II. It offers a balance between the thin film of Type I and the thicker layer of Type II.

Hard Anodize (Type III)

Hard Anodize, or Type III anodizing, uses a more concentrated sulfuric acid electrolyte and higher voltage to produce a thick, hard oxide layer. The resulting surface is extremely wear-resistant and durable, making it ideal for industrial applications such as aerospace components, machinery parts, and high-wear surfaces.

Hard anodizing offers superior abrasion and corrosion resistance compared to other types. It provides a long-lasting, protective finish that can withstand harsh environments and mechanical stress.

Benefits and Limitations of Anodizing

Benefits of Anodizing

Anodizing offers several key benefits:

Improved corrosion resistance: The thick oxide layer protects the underlying metal from corrosion, even in harsh environments.

Enhanced surface hardness and wear resistance: Anodized surfaces are harder and more resistant to abrasion and wear, extending the life of the metal.

Decorative color options through dyeing: The porous oxide layer can absorb dyes, allowing for a wide range of decorative color finishes.

Electrical insulation properties: Anodized layers are non-conductive, making them suitable for electrical insulation applications.

Environmentally friendly process: Anodizing is a relatively clean and environmentally friendly process compared to other surface treatments.

Limitations of Anodizing

Despite its benefits, anodizing has some limitations:

Limited to certain metals: Anodizing works best on aluminum and titanium. It is less effective or not suitable for other metals.

Thin oxide layer compared to some other coatings: While anodizing provides good protection, the oxide layer is relatively thin compared to some other surface treatments.

Increased brittleness in certain alloys: The hardening effect of anodizing can make some aluminum alloys more brittle and prone to cracking.

Higher cost for small quantities: Anodizing can be more expensive than other finishes for small production runs due to the setup costs and processing time.

Understanding Electroplating

The Electroplating Process

Electroplating is a process that uses an electric current to coat a metal object with a thin layer of another metal. It enhances the substrate's appearance, corrosion resistance, conductivity, and other properties. The most common metals used in electroplating are chromium, nickel, copper, gold, and silver.

In electroplating, the object to be plated (substrate) is submerged in an electrolyte solution containing dissolved metal ions. A direct current is applied, with the substrate acting as the cathode and a metal electrode (the plating metal) as the anode. The electric current causes the plating metal ions to migrate to the substrate and form a thin, adherent layer.

The electroplating process involves the following steps:

Cleaning and preparation of the substrate surface

Immersion of the substrate and anode in the electrolyte bath

Application of direct current to initiate the metal ion migration

Deposition of the plating metal onto the substrate surface

Rinsing and post-treatment of the plated object

Types of Electroplating and Applications

Electroplating can be broadly categorized into two types:

Decorative electroplating: Enhances the appearance of objects with attractive, shiny, or colorful metal finishes. Examples include chrome-plated automotive trim and gold-plated jewelry.

Functional electroplating: Improves specific properties of the substrate, such as corrosion resistance, wear resistance, or electrical conductivity. This type is widely used in industrial applications.

Another type of plating, electroless plating, does not require an external current source. Instead, it relies on a chemical reduction reaction to deposit the metal onto the substrate.

Nickel Plating

Nickel plating is widely used in various industries for its excellent corrosion and wear resistance properties. It provides a protective and decorative finish to metal parts in automotive, aerospace, electronics, and consumer products. Nickel plating also serves as an undercoat for other plating processes, such as chromium plating.

Chromium Plating

Chromium plating offers a bright, shiny, and durable finish that enhances the aesthetic appeal of objects while providing excellent corrosion and wear resistance. It is commonly used on automotive parts, sanitary fittings, and industrial components. Chromium plating can be decorative or hard, depending on the application requirements.

Copper and Silver Plating

Copper plating is extensively used in the electronics industry due to its excellent electrical conductivity and solderability. It is applied to printed circuit boards, connectors, and other electronic components. Copper plating also serves as an undercoat for other plating processes, such as nickel and chromium.

Silver plating, like copper, offers high electrical conductivity and is used in electrical contacts, switches, and connectors. The aerospace industry uses silver plating for its excellent thermal conductivity and anti-galling properties.

Advantages and Disadvantages of Electroplating

Advantages of Electroplating

Electroplating offers several advantages:

A wide range of metals can be deposited, allowing for versatility in applications.

Improved corrosion resistance extends the lifespan of plated objects.

Enhanced electrical conductivity makes it ideal for electronic components.

Decorative finishes with various metals provide aesthetic appeal.

Repair and restoration of worn surfaces can be achieved through electroplating.

Disadvantages of Electroplating

Despite its benefits, electroplating has some drawbacks:

The process involves toxic chemicals and heavy metals, which can pose environmental risks if not properly managed.

Electroplating consumes a high amount of electrical energy, making it energy-intensive.

Workers may face potential health risks due to exposure to hazardous chemicals. 4.Stringent waste management requirements are necessary to prevent environmental contamination.

Comparative Analysis

Key Differences Between Anodizing and Electroplating

Anodizing surface finish and electroplating are distinct surface treatment processes with fundamental differences in their methods and results. Anodizing forms a protective oxide layer on the metal surface, while electroplating deposits a layer of another metal onto the substrate.

Anodizing is primarily used for aluminum and titanium, whereas electroplating can be applied to various metals, including steel, copper, and brass. The anodizing process produces a thinner oxide layer compared to the metal layer deposited by electroplating.

The properties of the coatings also differ:

Environmentally, anodizing is generally considered safer, as it doesn't involve heavy metals. Electroplating, however, can pose environmental and health risks due to the use of toxic chemicals.

| Aspect | Anodizing | Electroplating |

| Processing Method | Forms oxide layer | Deposits metal layer |

| Metals Used | Primarily aluminum and titanium | Various metals (steel, copper, etc.) |

| Coating Thickness | Thinner layers | Thicker layers |

| Hardness | Higher | Lower |

| Wear Resistance | Higher | Lower |

| Conductivity | Lower | Higher |

| Environmental Impact | Generally safer | Potential risks from chemicals |

Applications of Anodizing and Electroplating

Anodizing finds extensive use in the aerospace, automotive, architecture, and consumer goods industries. Anodized aluminum parts are common in aircraft components, architectural facades, and consumer electronics. The process offers corrosion resistance, durability, and aesthetic options for these applications.

Electroplating is widely used in the automotive, electronics, jewelry, and aerospace industries. Examples include:

Chrome-plated automotive trim and wheels

Gold-plated jewelry and electronics

Nickel-plated aerospace components

Copper-plated printed circuit boards

The choice between anodizing and electroplating depends on the specific requirements of the application, such as the substrate metal, desired properties, cost, and environmental considerations.

Decision Factors in Choosing Between Anodizing and Electroplating

When deciding between anodizing and electroplating, consider the following factors:

Substrate metal: Anodizing is suitable for aluminum and titanium, while electroplating can be applied to various metals.

Desired properties: Anodizing offers better wear resistance and hardness, while electroplating provides superior conductivity and decorative options.

Cost: Anodizing is generally more cost-effective for large-scale operations, while electroplating can be economical for smaller batches.

Environmental impact: Anodizing is often preferred due to its lower environmental and health risks compared to electroplating.

Anodizing is preferred when:

The substrate is aluminum or titanium.

High wear resistance and hardness are required.

A durable, corrosion-resistant finish is desired.

Environmental concerns are a priority.

Electroplating is preferred when:

The substrate is a metal other than aluminum or titanium.

Electrical conductivity is critical.

A wide range of decorative finishes is desired.

Thick, protective coatings are required.

In some cases, both processes can be combined, such as using anodizing as a pre-treatment before electroplating. This combination can enhance the adhesion and durability of the electroplated coating.

Ultimately, the choice between anodizing and electroplating depends on the specific requirements of the application. Consider the material, desired properties, cost, and environmental factors to select the most appropriate method for your needs.

FAQs

Q:Can both metals and non-metals be anodized?

No, only certain metals like aluminum, titanium, and magnesium can be anodized. Non-metals and other metals like steel cannot form the required oxide layer during anodizing.

Q:What are the environmental impacts of anodizing vs. electroplating?

Anodizing is generally considered more environmentally friendly than electroplating. It doesn't involve heavy metals and toxic chemicals, making it safer for workers and easier to manage waste.

Q:How does the cost of anodizing compare to electroplating for large-scale projects?

Anodizing can be more cost-effective than electroplating for large-scale projects. The setup costs and processing time for anodizing are often lower, especially when dealing with aluminum parts.

Q:What are some common troubleshooting tips for both processes?

For both anodizing and electroplating, proper surface preparation is crucial. Ensure the parts are clean and free from contaminants. Monitor the electrolyte composition and maintain appropriate current density and temperature for optimal results.

Conclusion

Anodizing and electroplating offer distinct benefits for metal surface finishing. Anodizing forms a protective oxide layer, while electroplating deposits a metal layer onto the substrate. The choice depends on factors like base metal, desired properties, cost, and environmental impact.

Each technique has specific applications in industries such as aerospace, automotive, electronics, and consumer goods.

Consider your specific requirements when selecting a surface finishing process. Consult with experts to determine the best option for your project.

Choose anodizing for aluminum or titanium parts needing corrosion resistance and durability. Opt for electroplating when conductivity or decorative appeal is crucial for other metals.

Understanding the differences between anodizing and electroplating enables informed decisions that optimize performance, cost, and sustainability.