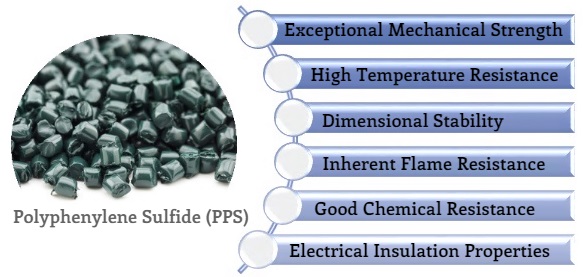

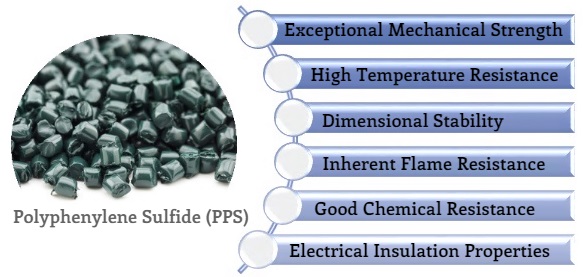

PPS or Polyphenylene Sulfide was first developed in the 1960s as a high-performance polymer. It bridges the gap between standard plastics and advanced materials, offering unique properties that make it essential in various industries.

In this post, we'll explore PPS's unique properties, diverse applications, how processing, and why it's becoming indispensable in various industries.

Chemical Structure of PPS

Polyphenylene sulfide (PPS) offers high-temperature resistance, rigidity, and an opaque appearance as a semi-crystalline thermoplastic.

Molecular Structure

The backbone of PPS consists of para-phenylene units alternating with sulfide linkages. This gives PPS its characteristic properties.

Sulfur atoms form single covalent bonds between benzene rings. They connect in a para (1,4) configuration, creating a linear chain.

Crystalline Structure

PPS forms semi-crystalline structures, contributing to its thermal stability and chemical resistance.

Orthorhombic Unit Cell

The unit cell of PPS is orthorhombic, with the following dimensions:

a = 0.867 nm

b = 0.561 nm

c = 1.026 nm

The calculated heat of fusion for an ideal PPS crystal is 112 J/g. This structure gives PPS its high melting point of 280°C.

Degree of Crystallinity

The degree of crystallinity in PPS ranges from 30% to 45%. It depends on:

Higher crystallinity increases:

Strength

Stiffness

Chemical resistance

Heat resistance

Lower crystallinity improves:

Impact resistance

Elongation

You can prepare amorphous and crosslinked PPS by:

Heating above melting temperature

Cooling to 30°C below melting point

Holding for hours in air presence

This structure gives PPS excellent properties like high-temperature resistance and chemical inertness.

Types of PPS Plastic

PPS resin comes in different forms, each with unique properties tailored for specific applications.

Linear PPS

Has nearly double the molecular weight of regular PPS

Results in higher tenacity, elongation, and impact strength

Cured PPS

Produced by heating regular PPS in the presence of air (O2)

Curing extends molecular chains and creates some branches

Enhances molecular weight and provides thermoset-like characteristics

Branched PPS

Has a higher molecular weight than regular PPS

Features extended polymer chains branching off the backbone

Improves mechanical properties, tenacity, and ductility

The table below compares the molecular weight of different PPS types:

| PPS Type | Molecular Weight Comparison |

| Regular PPS | Baseline |

| Linear PPS | Nearly double regular PPS |

| Cured PPS | Increased from regular PPS due to chain extension and branching |

| Branched PPS | Higher than regular PPS |

The molecular weight of PPS plays a crucial role in determining its properties. Higher molecular weight generally leads to:

However, it can also result in increased viscosity, making processing more challenging.

Properties of PPS(Polyphenylene Sulfide) Plastic

PPS plastic exhibits a unique combination of properties that make it suitable for various applications.

Mechanical Properties

PPS boasts outstanding mechanical properties, making it ideal for demanding applications.

Tensile Strength: With a tensile strength of 12,500 psi (86 MPa), PPS can withstand significant loads without breaking.

Impact Resistance: Despite its rigidity, PPS has an Izod impact strength of 0.5 ft-lbs/in (27 J/m), allowing it to absorb sudden shocks.

Flexural Modulus of Elasticity: At 600,000 psi (4.1 GPa), PPS effectively resists bending forces, maintaining its shape and structural integrity.

Dimensional Stability: PPS maintains its dimensions even under high temperature and humidity conditions, making it suitable for precision parts with tight tolerances.

Thermal Properties

PPS excels in thermal stability and resistance, crucial for high-temperature applications.

Heat Deflection Temperature: PPS can withstand temperatures up to 260°C (500°F) at 1.8 MPa (264 psi) and 110°C (230°F) at 8.0 MPa (1,160 psi).

Coefficient of Linear Thermal Expansion: PPS shows minimal dimensional changes with temperature variations at 4.0 × 10⁻⁵ in/in/°F (7.2 × 10⁻⁵ m/m/°C).

Maximum Continuous Service Temperature: PPS can be used continuously in air at temperatures up to 220°C (428°F).

Chemical Resistance

PPS is known for its exceptional chemical resistance, making it suitable for harsh environments.

Resistance to Moisture: PPS remains unaffected by moisture, ensuring durability and reliability in humid conditions.

Resistance to Various Chemicals: PPS withstands exposure to aggressive chemicals, including strong acids, bases, organic solvents, oxidizing agents, and hydrocarbons.

Electrical Properties

PPS's electrical insulation properties make it suitable for electronic applications.

High Volume Resistivity: PPS maintains high insulation resistance even in high-humidity environments, with a volume resistivity of 10⊃1;⁶ Ω·cm.

Dielectric Strength: With a dielectric strength of 450 V/mil (18 kV/mm), PPS ensures excellent insulation.

Additional Properties

PPS offers several other desirable properties:

Flame Resistance: Most PPS compounds pass the UL94V-0 standard without additional flame retardants.

High Modulus When Reinforced: Reinforced PPS grades exhibit a high modulus, enhancing mechanical strength.

Low Water Absorption: With a water absorption of just 0.02% after 24 hours of immersion, PPS is ideal for applications requiring minimal moisture uptake.

The following table summarizes the key properties of PPS plastic:

| Property | Value |

| Tensile Strength (ASTM D638) | 12,500 psi (86 MPa) |

| Izod Impact Strength (ASTM D256) | 0.5 ft-lbs/in (27 J/m) |

| Flexural Modulus (ASTM D790) | 600,000 psi (4.1 GPa) |

| Heat Deflection Temperature (ASTM D648) | 500°F (260°C) @ 264 psi |

| Coefficient of Linear Thermal Expansion | 4.0 × 10⁻⁵ in/in/°F |

| Maximum Continuous Service Temperature | 428°F (220°C) |

| Volume Resistivity (ASTM D257) | 10⊃1;⁶ Ω·cm |

| Dielectric Strength (ASTM D149) | 450 V/mil (18 kV/mm) |

| Water Absorption (ASTM D570, 24h) | 0.02% |

These properties make PPS an excellent choice for applications demanding high performance, durability, and reliability in challenging environments.

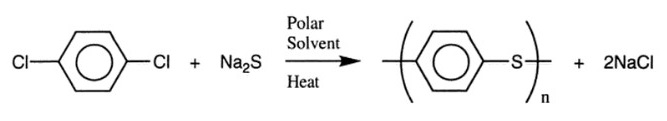

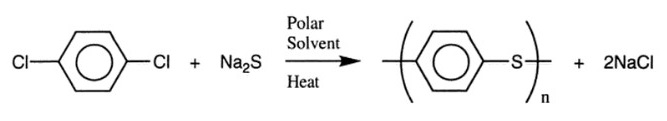

Manufacturing Process of PPS Plastic

The reaction of sodium sulfide and dichlorobenzene in a polar solvent to produce Polyphenylene sulfide (PPS)

Early Innovations in PPS Production

The PPS story began in 1967 with Edmonds and Hill at Philips Petroleum. They developed the first commercial process under the brand name Ryton.

Key features of the original process:

Produced low molecular weight PPS

Ideal for coating applications

Required curing for molding grades

Modern Manufacturing Techniques

Today's PPS production has evolved significantly. Modern processes aim to:

Eliminate the curing stage

Develop products with improved mechanical strength

Increase efficiency and reduce environmental impact

Chemical Reaction and Synthesis

PPS production involves a clever bit of chemistry. Here's the basic recipe:

Mix sodium sulfide and dichlorobenzene

Add a polar solvent (e.g., N-methylpyrrolidone)

Heat to about 250°C (480°F)

Watch the magic happen!

The Curing Process and Its Effects

Curing is crucial for molding grade PPS. It happens around the melting point with a dash of air.

Effects of curing:

Role of Polar Solvents in PPS Production

Polar solvents are the unsung heroes of PPS production. They:

Facilitate the reaction between sodium sulfide and dichlorobenzene

Help control the polymer's molecular weight

Influence the final properties of PPS

Common polar solvents used:

Each solvent brings its own flavour to the PPS party, affecting the final product's characteristics.

Applications of Polyphenylene Sulfide(PPS) Plastic Across Industries

PPS plastic finds use in various industries due to its unique combination of properties.

Automotive and Aerospace

In the automotive and aerospace sectors, PPS is used for components requiring durability, heat resistance, and chemical stability.

Engine Components: PPS is used in connectors, housings, and thrust washers, where its high-temperature resistance and mechanical strength are crucial.

Fuel System Parts: PPS components are used in fuel systems because of their chemical resistance and ability to withstand high temperatures.

Aircraft Interiors: PPS is found in aircraft ducting components and interior brackets, where its lightweight and durable nature is advantageous.

Electronics and Electrical Components

PPS's electrical insulation properties make it ideal for electronic and electrical applications.

Connectors and Insulators: PPS is used in connectors and insulators due to its high dielectric strength and thermal stability.

Circuit Boards: PPS finds use in circuit boards, supporting miniaturization and high performance.

Microelectronics Applications: PPS is suitable for microelectronics applications, offering excellent dimensional stability and insulation properties.

Chemical Processing Industry

PPS's chemical resistance makes it suitable for components exposed to corrosive chemicals.

Valves and Pumps: PPS is used in valves, pumps, and fittings in chemical processing applications because it withstands aggressive chemicals at elevated temperatures.

Filter Housings: PPS is used in filter housings, ensuring durability and chemical resistance in filtration systems.

Seals and Gaskets: PPS is ideal for seals and gaskets in chemical environments, providing long-lasting performance and resistance to degradation.

Industrial Equipment

PPS is employed in industrial equipment for its wear resistance and mechanical strength.

Gears and Bearings: PPS is used in gears, bearings, and other wear-resistant components requiring high mechanical strength and dimensional stability.

Compressor Components: PPS is used in compressor vanes because it offers high strength and durability in demanding industrial applications.

Wear-Resistant Applications: PPS components are utilized in wear bands and bushings, providing low friction and high wear resistance in industrial machinery.

Semiconductor Industry

PPS finds application in the semiconductor industry due to its purity and insulation properties.

Semiconductor Machinery Components: PPS is used in connectors, contact rails, heat shields, and contact pressure discs in semiconductor production equipment.

Special Grades for Semiconductor Applications: Specialty PPS grades like TECATRON SE and SX are designed for semiconductor applications, offering high purity and enhanced properties.

Mechanical Engineering

PPS is used in various mechanical engineering applications.

Compressor and Pump Parts: PPS is used in compressor and pump components due to its chemical resistance and mechanical strength.

Chain Guides and Base Plates: PPS finds use in chain guides and base plates, providing wear resistance and dimensional stability.

Other Industries

PPS plastic is used in several other industries:

Textile Machinery: PPS components are used in dyeing, printing, and processing equipment, offering durability and chemical resistance.

Medical Devices: PPS is used in surgical instrument parts due to its chemical resistance and ability to withstand sterilization processes.

Oil and Gas Equipment: PPS is used in downhole equipment, seals, and connectors, where its chemical resistance and high-temperature stability are essential.

The following table summarizes the key applications of PPS plastic across various industries:

| Industry | Applications |

| Automotive and Aerospace | Engine components, fuel system parts, aircraft interiors |

| Electronics | Connectors, insulators, circuit boards, microelectronics |

| Chemical Processing | Valves, pumps, filter housings, seals, gaskets |

| Industrial Equipment | Gears, bearings, compressor components, wear-resistant parts |

| Semiconductor | Machinery components, special grades for semiconductor production |

| Mechanical Engineering | Compressor and pump parts, chain guides, base plates |

| Textile | Dyeing and printing equipment, processing machinery |

| Medical | Surgical instrument parts |

| Oil and Gas | Downhole equipment, seals, connectors |

Polyphenylene Sulfide(PPS) Material Properties Optimization

Various additives and reinforcements can be used to enhance the properties of PPS plastic.

Additives and Reinforcements

Glass Fiber Reinforcement

Glass fibers increase the tensile strength, flexural modulus, and dimensional stability of PPS.

They make PPS suitable for applications requiring high mechanical strength.

Standard compounds like PPS-GF40 and PPS-GF MD 65 have a significant market share.

Carbon Fiber Reinforcement

PTFE Additives

Nanoparticles and Nanocomposites

PPS-based nanocomposites can be prepared using carbon nanofillers (e.g., expanded graphite, carbon nanotubes) or inorganic nanoparticles.

Nanofillers are added to PPS primarily to improve its mechanical properties.

Most PPS nanocomposites have been prepared by melt-blending due to PPS's insolubility in common organic solvents.

The following table compares the properties of unfilled, glass-reinforced, and glass-mineral filled PPS:

| Property (Unit) | Unfilled | Glass Reinforced (40%) | Glass-Mineral Filled* |

| Density (kg/l) | 1.35 | 1.66 | 1.90 - 2.05 |

| Tensile Strength (MPa) | 65-85 | 190 | 110-130 |

| Elongation at Break (%) | 6-8 | 1.9 | 1.0-1.3 |

| Flexural Modulus (MPa) | 3800 | 14000 | 16000-19000 |

| Flexural Strength (MPa) | 100-130 | 290 | 180-220 |

| Izod Notched Impact Strength (kJ/m²) | - | 11 | 5-6 |

| HDT/A @ 1.8 MPa (°C) | 110 | 270 | 270 |

*Depending on the glass/mineral filler ratio

Specific Additives for Property Enhancement

Specific additives can be used to target and enhance particular properties of PPS:

Alkali Metal Silicates for Viscosity Control

Alkali metal silicates, alkali metal sulfites, amino acids, and oligomers of a silyl ether can be used to control the melt flow and viscosity of PPS.

Calcium Chloride for Molecular Weight Increase

Block Copolymers for Impact Resistance Improvement

Sulfonic Acid Esters for Crystallization Rate Enhancement

The following table summarizes the additives used for specific property enhancements:

| Property Requirement | Suitable Additives |

| Low melt flow, high viscosity | Alkali metal silicates, alkali metal sulfites, amino acids, oligomers of a silyl ether |

| Increased molecular weight | Calcium chloride added during polymerization |

| Improved impact resistance | Inclusion of block copolymers in the initial reaction |

| Increased crystallization rate | Sulfonic acid esters along with a nucleating agent |

| Increased heat stability, low crystallization temperature | Alkali metal or alkali earth metal dithionate |

Processing Techniques for PPS Plastic

PPS resins can be processed using various techniques, including injection molding, extrusion, blow molding, and machining.

Injection Molding

Injection molding is a common processing method for PPS, offering high productivity and precision.

Extrusion

PPS can be extruded into various shapes, such as fibers, films, rods, and slabs.

Blow Molding

PPS can be processed using blow molding techniques.

Machining PPS

PPS is highly machinable, allowing for precise and complex part fabrication.

Importance of Pre-drying in Processing

Pre-drying PPS is crucial for achieving optimal processing results.

The following table summarizes the processing techniques and their key considerations:

| Processing Technique | Key Considerations |

| Injection Molding | Pre-drying, temperature and pressure settings, mold tightness |

| Extrusion | Drying conditions, temperature control, fiber and film production |

| Blow Molding | Temperature ranges, considerations for filled grades |

| Machining | Coolant selection, annealing process, achieving precision |

By understanding and optimizing these processing techniques, manufacturers can produce high-quality PPS parts and components for various applications.

Design Considerations for PPS Applications

When designing with PPS plastic, several factors must be considered to ensure optimal performance and cost-effectiveness.

Selecting PPS for Specific Applications

Choosing PPS for a specific application requires careful evaluation of its unique properties.

Machining and Finishing Considerations

PPS can be machined to close tolerances, making it suitable for complex, precision parts.

Machining can cause surface cracking and internal stresses in PPS.

These issues can be mitigated through annealing and the use of appropriate coolants.

Non-aromatic, water-soluble coolants, such as pressurized air and spray mists, are recommended for achieving high-quality surface finishes.

Dimensional Stability Across Temperatures

PPS maintains excellent dimensional stability across various temperatures.

Cost Considerations Compared to Alternative Materials

While PPS offers excellent performance, it is more expensive than many standard engineering plastics.

Designers should evaluate the cost-benefit ratio of using PPS.

Alternative materials, such as PEEK, may be considered for less demanding applications.

However, PPS's unique combination of properties often justifies its higher cost in specific applications.

Environmental and Safety Considerations

PPS is generally considered safe and non-toxic, but proper handling and safety protocols must be followed.

PPS can pose risks to human health and the environment if not handled properly or used inappropriately.

Proper safety protocols and guidelines should be followed to minimize risks.

PPS has poor UV resistance, making it unsuitable for outdoor applications without protective coatings.

The following table summarizes the key design considerations for PPS applications:

| Design Consideration | Key Points |

| Selecting PPS for Specific Applications | Chemical resistance, high-temperature stability, dimensional stability |

| Machining and Finishing | Annealing, appropriate coolants, surface cracking and internal stress mitigation |

| Dimensional Stability Across Temperatures | Minimal dimensional changes, reliable performance in varying conditions |

| Cost Considerations | Higher cost than standard plastics, cost-benefit evaluation, alternative materials |

| Environmental and Safety | Generally safe, proper handling and safety protocols, poor UV resistance |

Conclusion

PPS plastic offers exceptional versatility and high performance, making it ideal for demanding applications. Its chemical resistance, thermal stability, and mechanical strength ensure reliability across industries.

Understanding PPS’s modifications, processing methods, and design guidelines is crucial to maximizing its potential. With proper application, PPS creates durable products in automotive, aerospace, electronics, and more.

Tips: You maybe interested to the all plastics