Springs are fundamental components in countless mechanical systems, from microscopic devices to massive industrial machinery. Their ability to store and release energy makes them indispensable in fields ranging from automotive engineering to aerospace technology.

In this comprehensive guide, we'll explore the science, types, materials, and applications of springs, shedding light on these often-overlooked yet crucial elements of modern engineering.

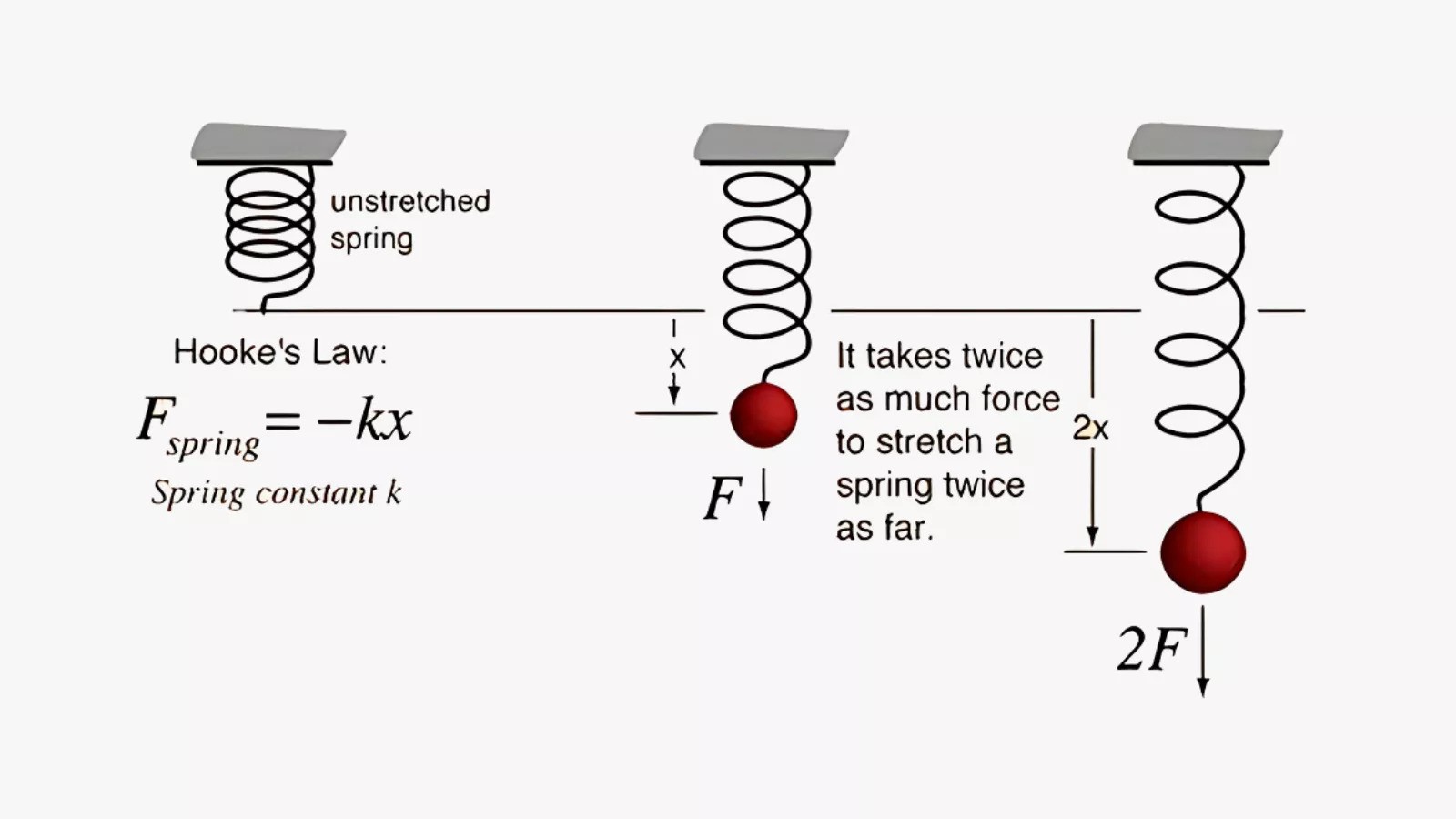

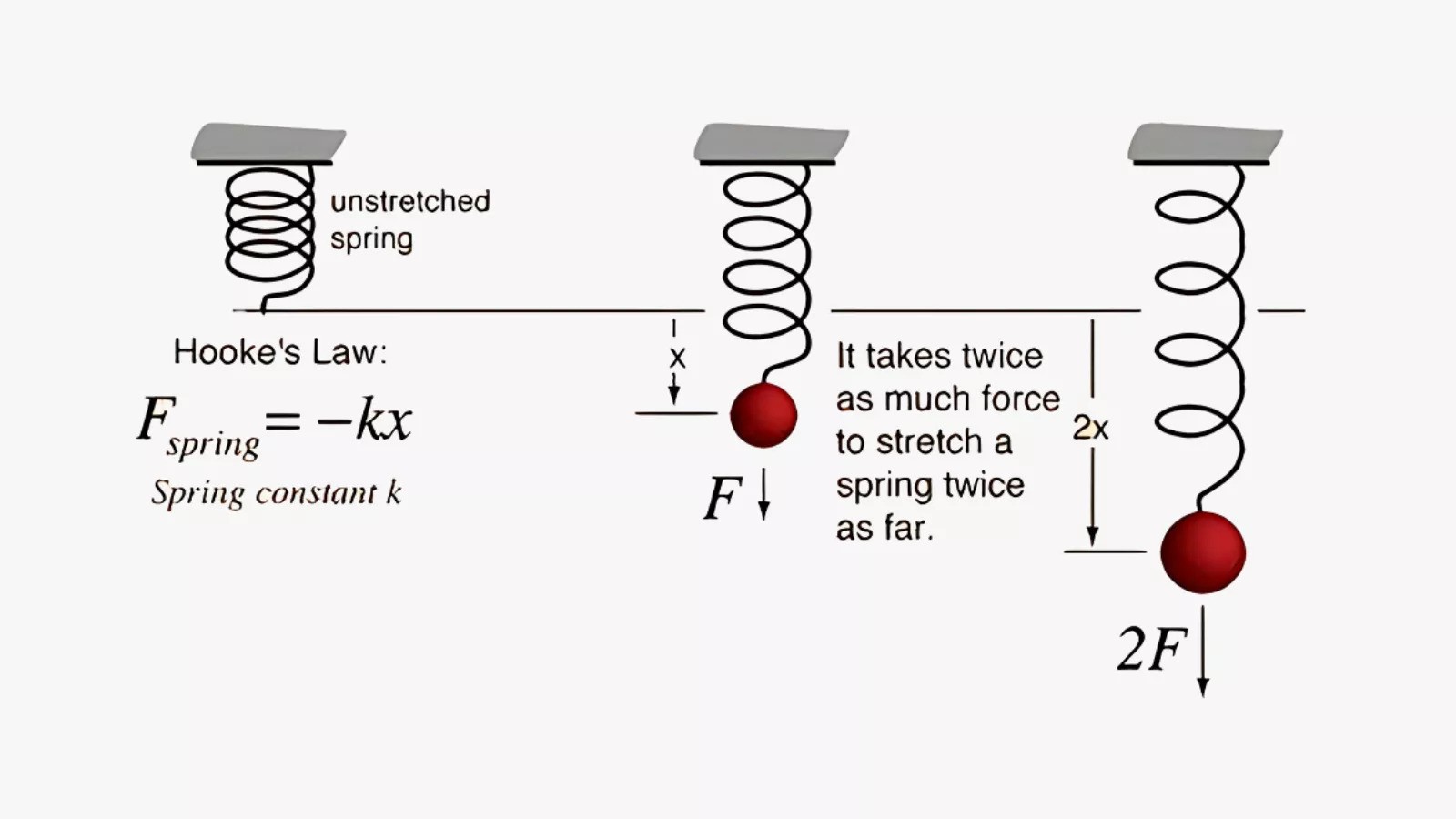

The Science of Springs: Hooke's Law and Beyond

At the heart of spring mechanics lies Hooke's Law, formulated by Robert Hooke in 1660. This principle states that th

e force (F) exerted by a spring is directly proportional to its displacement (x) from its equilibrium position:

F = -kx

Where:

F is the force exerted by the spring (in Newtons, N)

k is the spring constant (in Newtons per meter, N/m)

x is the displacement from the equilibrium position (in meters, m)

The negative sign indicates that the force acts in the opposite direction of the displacement, always seeking to return the spring to its rest state.

However, real-world springs often deviate from this linear relationship, especially under large displacements or in extreme conditions. Engineers must consider factors such as:

Spring rate: The change in force per unit deflection, which may vary in non-linear springs

Elastic limit: The point beyond which the spring will not return to its original shape

Fatigue life: The number of cycles a spring can endure before failure

Types of Springs: A Diverse Mechanical Ecosystem

Springs come in various forms, each optimized for specific applications. Here's a comparison of the most common types:

| Spring Type | Typical Applications | Key Characteristics | Load Capacity Range |

| Compression Springs | Automotive suspension, Pens | Resist compressive forces | 1 N - 1,000 kN |

| Extension Springs | Garage doors, Trampolines | Resist tensile forces | 1 N - 5 kN |

| Torsion Springs | Clothespins, Hinges | Resist rotational forces | 0.1 N·m - 1,000 N·m |

| Leaf Springs | Heavy vehicle suspension | High load capacity | 5 kN - 100 kN |

| Disc Springs | Industrial valves, Bolted joints | High load in limited space | 1 kN - 1,000 kN |

| Gas Springs | Automobile hoods, Office chairs | Constant force over stroke | 50 N - 5 kN |

Types of Springs: A Comprehensive Guide

Springs are versatile mechanical components that come in various shapes and sizes, each designed for specific applications. Understanding the different types of springs is crucial for engineers and designers to select the right spring for their projects. Let's explore the main categories of springs and their unique characteristics.

1. Helical Springs

Helical springs are the most common type, featuring a coil design. They are further divided into three main subcategories:

Compression Springs

Description: Open-coiled springs that resist compressive forces

Applications: Automotive suspension, ballpoint pens, mattresses

Key Feature: Stores energy when compressed

Compression springs are open-coiled springs designed to resist compressive forces. Commonly found in automotive suspensions, ballpoint pens, and mattresses, these springs store energy when compressed, making them essential for shock absorption and load support.

Extension Springs

Description: Tightly coiled springs that resist tensile forces

Applications: Garage doors, trampolines, farm machinery

Key Feature: Stores energy when stretched

Extension springs, in contrast, are tightly coiled and resist tensile forces. They are often used in garage doors, trampolines, and farm machinery. Their key feature is their ability to store energy when stretched.

Torsion Springs

Description: Springs that store energy when twisted

Applications: Clothespins, door hinges, automotive components

Key Feature: Provides rotational force

Torsion springs operate differently by storing energy when twisted. These springs provide rotational force and are used in applications such as clothespins, door hinges, and various automotive components.

2. Leaf Springs

Description: Consists of several layers (leaves) of metal strips

Applications: Heavy vehicle suspension, railway cars

Key Feature: High load-bearing capacity

Leaf springs consist of multiple layers (leaves) of metal strips stacked upon one another. These springs are renowned for their high load-bearing capacity and are frequently used in the suspension systems of heavy vehicles, such as trucks and railway cars.

Types of Leaf Springs:

Multi-leaf springs

Mono-leaf springs

Parabolic leaf springs

3. Disc Springs (Belleville Washers)

Description: Conical disk-shaped springs

Applications: Aerospace, industrial valves, bolted joints

Key Feature: High load capacity in a compact space

Disc springs, also known as Belleville washers, are conical disk-shaped springs. They are notable for their high load capacity despite their compact size, making them ideal for applications in aerospace, industrial valves, and bolted joints where space is limited but load-bearing is critical.

4. Gas Springs

Description: Uses compressed gas to exert force

Applications: Automobile hood lifts, office chairs

Key Feature: Provides near-constant force throughout the stroke

Gas springs operate by using compressed gas to exert force. These springs provide nearly constant force throughout their stroke, making them popular in applications like automobile hood lifts and adjustable office chairs. Their consistent force makes them highly reliable for a wide range of adjustable applications

5. Flat Springs

Description: Flat pieces of metal designed to flex under load

Applications: Electrical contacts, automotive sensors

Key Feature: Compact design for limited spaces

Flat springs are simple, flat pieces of metal that flex under load. They are compact and ideal for limited spaces, often found in electrical contacts and automotive sensors. Their space-efficient design makes them a versatile choice for electronic and automotive industries.

6. Volute Springs

Description: Conical-shaped springs made from a flat strip

Applications: Heavy-duty applications, shock absorption

Key Feature: Progressive spring rate

Volute springs feature a conical shape made from a flat strip of metal. These springs are designed for heavy-duty applications and are especially effective in shock absorption due to their progressive spring rate, which increases stiffness as they compress.

7. Wave Springs

Description: Flat wire formed into a wave-like shape

Applications: Bearings, seals, clutches

Key Feature: Space-saving alternative to traditional coil springs

Wave springs are constructed from flat wire formed into a wave-like shape. They offer a space-saving alternative to traditional coil springs, as their design allows them to provide similar force in a smaller area. Common applications include bearings, seals, and clutches where compact design and efficiency are critical.

8. Constant Force Springs

Description: A rolled ribbon of spring material that exerts constant force when unrolled

Applications: Counterbalances, retractable reels

Key Feature: Near-constant force throughout deflection

Constant force springs are made from a rolled ribbon of spring material that exerts a nearly constant force when unrolled. These springs are used in applications like counterbalances and retractable reels where consistent force is needed throughout the entire range of motion.

9. Variable Force Springs

Description: Springs with a non-linear force-deflection curve

Applications: Precision instruments, specialized mechanical devices

Key Feature: Force varies non-linearly with deflection

Variable force springs have a non-linear force-deflection curve. These springs are designed for precision instruments and specialized mechanical devices where force needs to vary with deflection, providing tailored performance for intricate applications.

Comparison Table

| Spring Type | Load Type | Space Efficiency | Typical Load Range | Common Applications |

| Compression | Compressive | Moderate | 1 N - 1,000 kN | Automotive, Industrial |

| Extension | Tensile | High | 1 N - 5 kN | Consumer goods, Machinery |

| Torsion | Rotational | High | 0.1 N·m - 1,000 N·m | Hinges, Clips |

| Leaf | Compressive | Low | 5 kN - 100 kN | Heavy vehicles |

| Disc | Compressive | Very High | 1 kN - 1,000 kN | Aerospace, Valves |

| Gas | Compressive | High | 50 N - 5 kN | Furniture, Automotive |

Each type of spring has its unique properties and ideal applications. The choice of spring depends on factors such as required force, available space, operating environment, and desired performance characteristics. Understanding these different types allows engineers to select the most appropriate spring for their specific needs, ensuring optimal performance and longevity of their mechanical systems.

Materials: The Foundation of Spring Performance

The choice of material significantly impacts a spring's performance characteristics. Here's a comparison of common spring materials:

| Material | Tensile Strength (MPa) | Corrosion Resistance | Max Operating Temp (°C) | Typical Applications |

| AISI 302 Stainless Steel | 860-1100 | Excellent | 250 | Food processing, Marine |

| AISI 4340 Low-Alloy Steel | 745-1950 | Moderate | 300 | Automotive, Aerospace |

| Inconel X-750 | 1200 | Excellent | 700 | Jet engines, Nuclear reactors |

| Beryllium Copper | 1300 | Good | 300 | Explosive environments |

| Titanium Ti-6Al-4V | 900-1200 | Excellent | 400 | Aerospace, Medical implants |

Manufacturing Processes: Precision and Quality Control

Spring manufacturing involves several critical steps, each contributing to the final performance:

| Process Step | Purpose | Typical Tolerances/Parameters |

| Wire Drawing | Material preparation | ±0.01 mm diameter tolerance |

| Coiling | Forming spring shape | ±0.1 mm pitch tolerance |

| Heat Treatment | Enhance mechanical properties | ±10°C temperature control |

| Shot Peening | Improve fatigue life | 200% - 300% increase in fatigue strength |

| Grinding | Ensure flat end surfaces | ±0.05 mm flatness tolerance |

| Coating | Corrosion resistance/appearance | 5-25 µm coating thickness |

Applications: Springs in Action

Springs play crucial roles in various fields. Here's a comparison of spring applications across different industries:

| Industry | Application | Spring Type | Key Performance Metric |

| Automotive | Engine valve springs | Compression | Endurance at 8000+ RPM |

| Automotive | Suspension | Coil/Leaf | Load capacity up to 1000 kg/wheel |

| Aerospace | Landing gear | Shock absorber | Impact absorption up to 3g |

| Electronics | Keyboard switches | Compression | 0.4-0.8 N actuation force |

| Medical | Cardiovascular stents | Expansion | 400+ million cycle lifetime |

| Industrial | Pressure relief valves | Compression | Precision to ±1% of set pressure |

Automotive Industry

Aerospace

Consumer Electronics

Medical Devices

Challenges and Innovations

Engineers continually push the boundaries of spring technology:

| Innovation | Description | Potential Impact |

| Shape Memory Alloys | Springs that "remember" shape | Self-adjusting components |

| Composite Springs | Fiber-reinforced polymers | Up to 70% weight reduction |

| Smart Springs | Integrated sensors | Real-time load monitoring |

| Nano-springs | Microscopic scale springs | Advanced MEMS devices |

Shape Memory Alloys: Springs that "remember" their shape after deformation

Composite Springs: Utilizing materials like fiber-reinforced polymers for weight reduction

Smart Springs: Integrating sensors for real-time load monitoring

Conclusion: The Elastic Future

Springs remain at the forefront of mechanical engineering, continually adapted to meet new challenges. From the nanoscale springs in MEMS devices to the massive leaf springs in industrial machinery, these elastic components continue to play a vital role in technological advancement.

As we push the boundaries of what's possible in engineering, springs will undoubtedly continue to flex, twist, and compress their way into the future of innovation. Their versatility, combined with ongoing material and design innovations, ensures that springs will remain essential components in the machines and devices of tomorrow.

Whether it's in the pursuit of more efficient transportation, more precise medical devices, or more durable consumer products, springs will continue to provide the necessary force, flexibility, and functionality. For expert guidance on your manufacturing project, contact us. Our experienced engineers will help you navigate the design, material selection, and manufacturing process to ensure optimal results. Partner with TEAM FMG for success. We will take your production to the next level.

FAQs

1. What is a spring?

A spring is a mechanical component that deforms when subjected to external force and stores energy, returning to its original shape when the force is removed. Springs are used to absorb shock, store energy, or maintain spacing between objects.

2. What are the main types of springs?

There are three main types of springs: compression springs (resist compression), extension springs (resist stretching), and torsion springs (store torque). Each spring is designed differently depending on the application.

3. What materials are springs made of?

Springs are usually made from high-strength materials such as carbon steel, stainless steel, copper alloys, and even some plastic materials, depending on the environment and application requirements.

4. How do I choose the right spring?

Choosing the right spring requires considering the type of application, load requirements, material properties, and the working environment (temperature, corrosion, etc.). Precise calculation and testing help ensure the correct choice.

5. What is spring fatigue failure?

Spring fatigue failure occurs when repeated loading and unloading cause the spring material to gradually lose elasticity or break. Design considerations should include lifespan, stress limits, and fatigue resistance of the material.

6. How can I extend the lifespan of a spring?

Regular maintenance and inspection can extend a spring’s lifespan. Avoid overloading, ensure proper lubrication, correct installation, and choose materials suited for the working environment.

7. Why do springs fail?

Springs can fail due to fatigue damage, corrosion, overloading, or material defects. Regular inspections and proper maintenance can prevent most failure issues.