The advancement of human civilization and societal progress are intrinsically linked to the use of metal materials. Following the Stone Age, the Bronze Age and Iron Age were defined by the utilization of metals. In contemporary times, a diverse array of metal materials forms a critical foundation for the development of human society.

Metals come in various types, each possessing distinct characteristics. While some metals are noted for their hardness, others excel in durability or electrical conductivity. In this blog post, we'll explore the unique properties of different metals and their applications. We'll delve into common alloys and uncover what sets them apart. So, if you're keen to learn more about the fascinating world of metal, stay tuned!

Ferrous Metals: Types and Characteristics

Ferrous metals, encompassing everything from pure iron to complex alloys like stainless steel, are vital in our world. They offer a range of properties like hardness, tensile strength, and corrosion resistance that make them suitable for diverse applications in industrial manufacturing and beyond. With their various kinds, each type of ferrous metal brings something unique to the table, making them indispensable in modern industry.

Understanding Industrial Pure Iron

Pure Iron is a fundamental element in industrial manufacturing. It's a key player in creating various metal alloys. Here's what makes it special:

Malleability: Pure iron is quite soft and easy to shape.

Magnetic Properties: It's naturally magnetic, making it essential in electrical applications.

Cast Iron: Composition and Uses

Cast Iron is an iron alloy with a mix of carbon, silicon, and small amounts of other elements like manganese, sulfur, and phosphorus.

Durability: It's known for its excellent durability and wear resistance.

Applications: You'll find it in cookware, automotive parts, and machinery.

Carbon Steel: Varieties and Applications

Carbon Steel is a blend of iron and carbon, with varieties like low, medium, and high carbon steel. Each type has its unique use.

High Carbon Steel: Known for its hardness and strength, used in tools and blades.

Low Carbon Steel: More ductile and used in structural applications due to its toughne

Stainless Steel: Properties and Industrial Usage

Stainless Steel is an alloy known for its corrosion resistance. It's a mix of iron, carbon, and chromium.

Non-Corrosive: It doesn't rust easily, which is why it's popular in kitchenware and medical equipment.

Versatility: Used in everything from cutlery to skyscraper frames.

Wrought Iron: Properties and Applications

Wrought Iron is an iron alloy with very low carbon concentration. It's known for being strong yet ductile.

Historical Use: Once the main metal for blacksmiths. Today, it's seen in decorative items like fences and gates.

Strength: Its fibrous structure gives it a unique combination of strength and formability.

Other Ferrous Metals: Chromium, Manganese, and Their Alloys

Ferrous metals like Chromium and Manganese play a crucial role in the creation of various steel alloys.

Non-Ferrous Metals: Diverse Applications

Non-ferrous metals play crucial roles in a variety of industries due to their unique properties like corrosion resistance, electrical conductivity, and lightweight nature. From the aerospace industry to modern technology applications, these metals contribute significantly to advancements in industrial manufacturing and everyday life.

Aluminum: Characteristics and Industrial Importance

Aluminum is a silvery metal, known for being part of the boron group with an atomic number of 13. It's famed for being lightweight yet strong.

High Thermal Conductivity: Ideal for applications where heat transfer is key, like in radiators and kitchen utensils.

Industrial Use: Aluminum is widely used in the aerospace industry due to its strength-to-weight ratio.

Nickel: Properties and Various Uses

Nickel, a naturally occurring, malleable, and corrosion-resistant metal, is often found in alloys.

Copper: Applications in Modern Technology

Copper is a transition metal with excellent electrical conductivity. It's malleable and ductile.

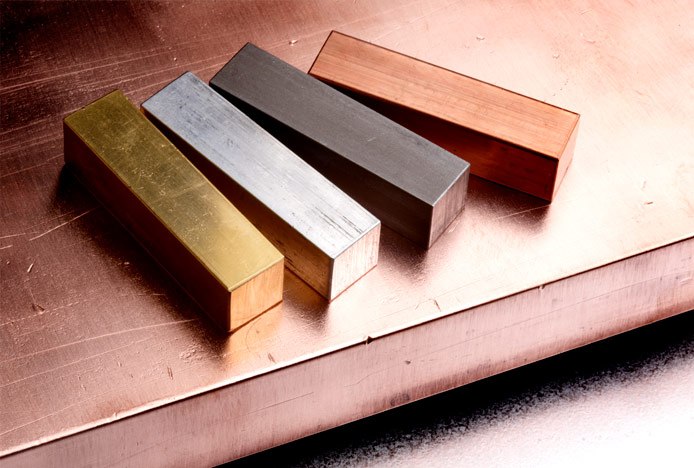

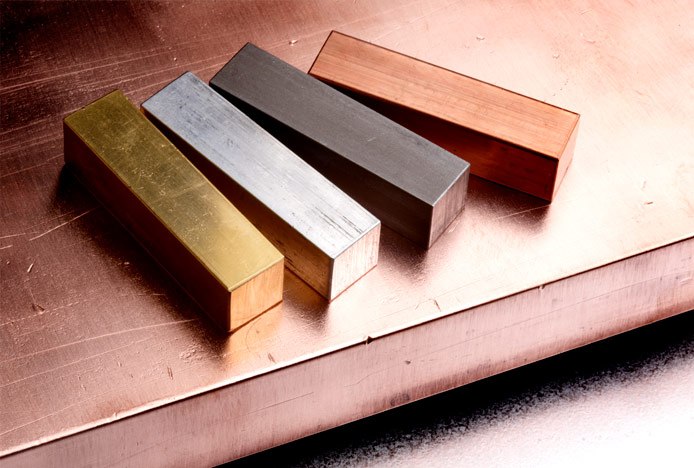

Brass and Bronze: Composition and Uses

Brass and Bronze are important non-ferrous red metals, being alloys of copper and zinc or tin, respectively.

Mechanical and Electrical Characteristics: Brass is used in musical instruments and decorative items, while bronze is favored for its wear resistance in bearings and sculptures.

Historical Importance: Bronze played a crucial role in our early metallurgy, leading to the Bronze Age.

Zinc: Industrial and Commercial Applications

Zinc is known for its corrosion-resistant properties, especially in galvanizing steel.

Galvanization: Protects steel from rusting, extending its life in outdoor applications.

Zinc Alloys: Used in die-casting for precision components in the automotive and electronics industries.

Precious Metals

Precious metals like gold, silver, and platinum play a crucial role beyond their traditional uses in jewelry and currency. Their unique properties, including corrosion resistance, electrical conductivity, and aesthetic appeal, make them indispensable in industries ranging from electronics and medicine to automotive manufacturing. These metals are not just symbols of wealth; they are vital components in advancing technology and improving our quality of life.

Defining Characteristics of Precious Metals

Precious metals are known for their rarity, beauty, and economic value. Key characteristics include:

Corrosion Resistance: They don't corrode or oxidize easily.

High Luster: These metals have a unique, natural shine.

Malleability and Ductility: They can be easily shaped and stretched.

Gold, Silver, Platinum: A Closer Look

Gold: A rich, brilliant yellow metal, known for its corrosion resistance and aesthetic appeal. Often used in jewelry and as a standard for currency.

Purity: Measured in karats, with 24 karats being pure gold.

Silver: Recognized for its shiny white luster and high electrical conductivity. It's not just for jewelry; it's crucial in electrical circuits too.

Industrial Use: Silver is used in solar panels, batteries, and electronics.

Platinum: A non-reactive metal with extraordinary corrosion resistance. It's dense and has a high melting point.

Applications: Used in catalytic converters, electronics, and jewelry.

Uses of Precious Metals in Various Industries

Precious metals are not just for show; they have practical uses across various industries.

Electronics: Gold and silver are key in making reliable and efficient electronic components.

Medicine: Silver has antibacterial properties, making it valuable in medical equipment.

Automotive: Platinum is crucial in the manufacturing of catalytic converters to reduce emissions.

Specialized Metals and Their Roles

Specialized metals like lead, cobalt, tin, titanium, tungsten, palladium, uranium, and bismuth have specific, often critical roles in various industrial applications. Their unique properties, ranging from corrosion resistance to high melting points, make them indispensable in fields like aerospace, energy, and technology. These metals are not just part of the vast spectrum of metallic elements; they are vital to the advancement and functionality of modern industry.

Lead: Utility and Health Considerations

Lead is a heavy metal known for its high density and softness. It has a low melting point, making it easy to work with.

Uses: Commonly used in batteries, cable sheathing, and radiation shielding.

Health Concerns: Lead is toxic. Its use is now limited, especially in household items, to prevent health risks.

Cobalt: Versatile Applications in Modern Industry

Cobalt is a transition metal that plays a vital role in modern industries. It's known for its strength at high temperatures.

Applications: Used in jet engines, gas turbines, and in the production of strong, permanent magnets.

Alloys: Forms alloys with high-temperature resistance, making it perfect for cutting tools and aircraft parts.

Tin, Titanium, and Tungsten: Specific Uses

● Tin: A corrosion-resistant metal often used for coating other metals like steel to prevent rust.

● Titanium: Known for being light, high-strength, and low-corrosion. It's used in aerospace components, medical devices, and sports equipment.

● Tungsten: With the highest melting point of all metals, it's essential in metalworking, mining, and as tungsten carbide in drill bits.

Emerging Metals: Palladium, Uranium, and Bismuth

● Palladium: This expensive metal is primarily used in pollution-control devices like catalytic converters and in various electronics.

● Uranium: A heavy metal used as nuclear fuel in nuclear power plants. It's key in producing nuclear energy.

● Bismuth: Known for being hard, brittle, and lustrous. It's used in fire alarms, electric fuses, and low-melting alloys.

Light vs Heavy Metals

Defining Light Metals: Titanium, Aluminum, Magnesium

Light Metals like Titanium, Aluminum, and Magnesium are known for their low density and high strength-to-weight ratio.

Titanium: Offers high strength and resistance to corrosion. It's as strong as steel but much lighter.

Aluminum: Famous for its lightweight and thermal conductivity. It's easy to work with and recyclable.

Magnesium: The lightest structural metal, used in alloys to make things lighter without losing strength.

Heavy Metals and Their Unique Properties

Heavy Metals like lead, uranium, and tungsten have high densities and unique properties.

Lead: Known for its density and softness. Used in batteries and radiation shielding, but has health concerns.

Uranium: A dense, heavy metal used primarily as nuclear fuel.

Tungsten: Has the highest melting point of all metals, essential in applications that require high heat resistance.

Practical Applications of Light and Heavy Metals

Both light and heavy metals have their unique uses in various industries.

Light Metals:

Aerospace: Titanium and aluminum are used extensively due to their strength and lightweight.

Electronics: Aluminum is used in electronic devices for its conductivity and lightweight nature.

Heavy Metals:

Energy: Uranium is key in nuclear power plants.

Medical: Lead is used in radiation protection in X-ray rooms and during radiation therapy.

The contrast between light and heavy metals highlights the diversity in the world of metals. Light metals like titanium, aluminum, and magnesium are prized for their low weight and high strength, making them ideal for aerospace and electronics. On the other hand, heavy metals such as lead, uranium, and tungsten have specialized uses in energy production and medical applications due to their density and unique properties. Understanding these differences is crucial in industrial manufacturing and the development of new technologies.

Metalloids and Their Role

Metalloids play a critical role in bridging the gap between metals and non-metals. Their distinctive properties, such as variable electrical conductivity and physical characteristics, make them indispensable in various fields, particularly in industrial manufacturing and technology. From the silicon in our smartphones to the germanium in fiber optics, metalloids are at the heart of many cutting-edge technologies. They are not just another category of elements; they are crucial in advancing our technological capabilities and enhancing the performance of many common products.

Introduction to Metalloid Elements

Metalloids are elements with properties in between metals and non-metals. They are unique because they can act as either, depending on the conditions. Metalloids include:

Specific Metalloids: Germanium, Antimony, Polonium

● Germanium: It's used in semiconductors. Germanium can conduct electricity, but not as well as metals.

● Antimony: Known for its hardness and strength when alloyed. It's used in batteries, low-friction metals, and cable sheathing.

● Polonium: Highly radioactive and used in small amounts in devices like anti-static brushes.

Applications of Metalloids in Modern Technology

Metalloids have found their way into many modern technologies due to their unique properties.

Semiconductors: Both germanium and silicon (another metalloid) are key in making computer chips and solar cells.

Medicine: Certain metalloids are used in medical treatments and diagnostics.

Alloys: Adding metalloids like antimony to metals can improve their strength and corrosion resistance.

Radioactive Metals

Overview of Radioactive Metals

Radioactive metals are elements that emit radiation as they break down. This process is known as radioactive decay. These metals include:

Uranium: Heavily used in nuclear power plants.

Plutonium: A byproduct of nuclear reactors, used in some types of nuclear weapons.

Radium: Once used in glow-in-the-dark paints.

Health and Safety Aspects of Handling Radioactive Metals

Handling radioactive metals requires strict safety measures due to their health risks.

Radiation Exposure: Can cause serious health issues, including cancer.

Safety Measures: Lead-lined gloves and containers, and limiting time of exposure are crucial.

Disposal: Radioactive metals must be disposed of carefully to avoid environmental contamination.

Radioactive Metals in Energy and Medical Fields

Despite their risks, radioactive metals have important uses in various fields.

Energy Production: Uranium is key in nuclear power generation, providing a significant source of energy.

Medical Applications: Used in certain types of cancer treatments and medical imaging techniques.

Radioactive metals like uranium, plutonium, and radium, while hazardous, play a significant role in our world, particularly in energy production and the medical field. Their ability to release energy through radioactive decay is harnessed in nuclear power plants, providing a potent energy source. In medicine, carefully controlled use of radiation from these metals offers benefits in treating and diagnosing illnesses. Handling these metals, however, requires strict safety protocols to protect health and the environment.

Common Types of Metals and Their Properties

Metals like aluminum, copper, iron, and steel are fundamental in our daily lives, each possessing unique properties that make them suitable for various applications. From the lightweight aluminum in aircraft to the corrosion-resistant stainless steel in kitchenware, these metals are essential in industrial manufacturing and beyond. Niche metals like cobalt, titanium, and tungsten, though used less commonly, play crucial roles in specialized applications due to their specific characteristics. Understanding the properties and uses of these metals is key to appreciating their significance in our modern world.

Aluminum: Lightweight and Conductive

Aluminum is a silvery metal, recognized for its lightweight nature and excellent thermal conductivity.

Applications: Widely used in aircraft manufacturing, packaging, and construction.

Features: It's non-magnetic, non-sparking, and can be recycled without loss of properties.

Copper and Its Alloys: Brass and Bronze

Copper is a versatile metal known for its ductility and electrical conductivity.

Brass: An alloy of copper and zinc, known for its corrosion resistance and acoustic properties.

Bronze: An alloy primarily of copper and tin, used for its strength and resistance to corrosion.

Iron Varieties: Wrought, Cast, and Pig Iron

Iron is used in various forms, each with distinct properties.

Wrought Iron: With a low carbon concentration, it's malleable and tough, perfect for decorative ironwork.

Cast Iron: Known for its durability, it's used in heavy-duty cookware and machinery.

Pig Iron: The basic form of iron used in industrial applications and as a raw material for further refining.

Steel Types: From Tool Steel to High Carbon Steel

Steel, an alloy of iron and carbon, comes in various types.

Tool Steel: Contains additives like tungsten and cobalt, known for its hardness and resistance to abrasion.

High Carbon Steel: Characterized by its strength and used in cutting tools and blades.

Stainless Steel: Noted for its corrosion resistance, making it ideal for kitchenware and medical instruments.

Niche Metals: Cobalt, Titanium, and Tungsten

These metals are used for specific applications due to their unique properties.

Cobalt: Used in high-strength alloys, permanent magnets, and in the medical field.

Titanium: Known for its strength, low density, and resistance to corrosion, used in aerospace and medical implants.

Tungsten: Has the highest melting point of all metals, used in light bulb filaments and cutting tools.

Understanding the Characteristics of Different Metals

Different metals boast a variety of properties - from the strength and hardness of tool steel to the ductility of copper. These characteristics determine their suitability for various applications in industrial manufacturing and beyond. Understanding these properties is crucial when selecting the right metal for a specific application, whether it's for constructing a building, wiring a house, or manufacturing an aircraft. Each metal, with its unique blend of mechanical, chemical, physical, and technological properties, plays a vital role in the vast world of metal mastery.

Mechanical Properties: Strength, Ductility, and Hardness

Metals are often chosen for their mechanical properties.

Strength: This is how much force a metal can handle. For example, high carbon steel is known for its impressive strength.

Ductility: The ability to stretch without breaking. Metals like copper are highly ductile, perfect for wiring.

Hardness: The resistance to scratching or bending. Tool steel, with elements like tungsten, is incredibly hard.

Chemical Properties: Corrosion Resistance and Reactivity

The chemical properties of metals determine their longevity and safety.

Corrosion Resistance: Metals like stainless steel resist rust and corrosion, making them ideal for kitchenware.

Reactivity: Some metals, like aluminum, react with air to form a protective layer, preventing further corrosion.

Physical Properties: Density, Thermal and Electrical Conductivity

Physical properties influence how metals are used in practical applications.

Density: Heavier metals like lead are dense and used for radiation shielding, while titanium is light and strong, suitable for aerospace.

Thermal and Electrical Conductivity: Metals like copper and silver conduct heat and electricity efficiently, crucial in electrical components.

Technological Properties: Machinability and Weldability

Technological properties affect how metals are manipulated and used in manufacturing.

Machinability: This refers to how easy it is to cut and shape the metal. Aluminum alloys are known for their good machinability.

Weldability: Metals like low carbon steel are easier to weld, making them popular in construction and industrial applications.

Detailed Analysis of Metallic Material Properties

Exploring Hardness: Brinell, Rockwell, and Vickers Tests

Hardness in metals is a crucial attribute, indicating resistance to deformation and wear.

Brinell Hardness Test: Uses a steel ball indenter. Common for testing softer metals like aluminum.

Rockwell Hardness Test: Measures the depth of penetration under load. Used for a variety of metals.

Vickers Test: Employs a diamond pyramid indenter, suitable for thin materials and small areas.

Yield Strength and Tensile Strength: Significance in Metal Usage

Strength is vital in determining how a metal will perform under stress.

Yield Strength: The stress at which a metal begins to deform plastically. Important in choosing materials for construction.

Tensile Strength: The maximum stress a metal can withstand while being stretched or pulled. High tensile strength metals like some alloy steels are used in high-stress applications.

Elongation and Impact Toughness: Understanding Plasticity

These properties are crucial in applications where flexibility and durability are key.

Elongation: A measure of ductility, indicating how much a metal can stretch before breaking.

Impact Toughness: The ability of a metal to absorb energy and plastically deform without fracturing. Metals like wrought iron, known for their toughness, are used in applications requiring resistance to impact.

Specialized Properties: Heat Resistance and Radiation Resistance

Some applications require metals with specialized properties.

Heat Resistance: Metals like tungsten and nickel alloys maintain strength at high temperatures, essential for aerospace and industrial furnaces.

Radiation Resistance: Certain metals like lead are used for radiation shielding due to their high density and ability to absorb radiation.

Understanding the properties of metals such as hardness, strength, plasticity, and specialized attributes like heat and radiation resistance is critical in their application across various industries. From the Brinell test for determining the hardness of aluminum to the use of tungsten in high-temperature environments, these properties define the utility and functionality of metals in industrial manufacturing and beyond. Each metal, with its unique set of characteristics, plays a pivotal role in advancing technology and industrial applications.

Innovations in Metalworking

Cutting-Edge Techniques in Metalworking

The field of metalworking is continuously evolving, incorporating advanced technologies to enhance precision and efficiency.

Laser Cutting and Welding: These methods offer unmatched accuracy, ideal for complex and intricate designs.

Automated and Robotic Systems: These systems increase productivity and reduce human error in repetitive tasks.

Future Trends: 3D Printing and Smart Materials

Looking ahead, the future of metalworking is exciting with the advent of new technologies.

3D Printing: Revolutionizing manufacturing by allowing complex metal parts to be built layer by layer.

Smart Materials: Metals that can change properties based on external stimuli, opening doors for innovative applications in various industries.

Sustainability in Metal Production and Recycling

Sustainability is becoming a key focus in the metal industry.

Eco-Friendly Processes: Reducing the environmental impact of metal production through cleaner processes and renewable energy sources.

Recycling: Metals are highly recyclable, and increasing recycling rates is a major goal to reduce waste and conserve resources.

Metalworking is an ever-evolving field, with new technologies like laser cutting and 3D printing pushing the boundaries of what's possible. As we look to the future, trends like smart materials promise to revolutionize the industry even further. At the same time, a focus on sustainability in production and recycling is essential to ensure that the metal industry continues to thrive without harming the planet. These innovations are not just transforming the way we work with metals; they're shaping the future of manufacturing and technology.

FAQs

Differences between Various Aluminum Alloys

Aluminum alloys are popular due to their lightweight and strength. Key differences include:

Alloy Series: Based on elements added, like copper, magnesium, or silicon, affecting properties like strength and corrosion resistance.

Applications: Varying from aircraft structures (high-strength alloys) to beverage cans (malleable alloys).

Brass vs. Bronze: Composition and Uses

Brass and bronze are both copper alloys but have distinct differences.

Brass: A mix of copper and zinc. Used in musical instruments and decorative items for its acoustic properties.

Bronze: Copper and tin, known for its strength and corrosion resistance. Common in sculptures and industrial bearings.

Stainless Steel vs. Aluminum: A Comparative Study

These metals are widely used but have different characteristics.

Stainless Steel: An iron alloy, known for its corrosion resistance. Heavier than aluminum but very strong.

Aluminum: Lightweight and with good conductivity. Less strong than stainless steel but doesn't rust.

Ferrous vs. Non-Ferrous Metals: Identifying Key Features

Understanding the difference between these metal types is key in material selection.

Ferrous Metals: Contain iron. Magnetic and prone to rust, but very strong (e.g., steel).

Non-Ferrous Metals: Do not contain iron. Not magnetic and more resistant to corrosion (e.g., aluminum, copper).

CNC Machining: Suitable Metals and Their Properties

CNC machining requires metals that can withstand the process.

Suitable Metals: Include aluminum, brass, and stainless steel, known for their machinability and strength.

Considerations: Metal selection depends on the desired properties of the final product, like hardness or corrosion resistance.

Conclusion

We've explored a vast array of metals, each with unique properties and applications. From ferrous metals like steel and iron, known for their strength and durability, to non-ferrous metals such as aluminum and copper, prized for their corrosion resistance and electrical conductivity. We've seen how alloys like brass and bronze combine the best of different metals, and how niche metals like titanium and tungsten play crucial roles in specialized industries.

Metals, in all their diverse forms, are more than just materials; they are the foundation of modern civilization and technology. From the steel in our buildings to the aluminum in our aircraft, metals shape our world in countless ways. As we look to the future, the role of metals in industry and technology will only grow, driven by innovation and a commitment to sustainability. The journey through the world of metals is an ongoing adventure, one that promises new discoveries and advancements with each passing day.