Polybutylene Terephthalate (PBT) is everywhere, from your car to electronics. But what exactly is it? This semi-crystalline engineering thermoplastic belongs to the polyester family and offers a balance of strength and durability.

In this post, we’ll explore what makes PBT unique, its properties, processing methods, and how it’s used across industries like automotive and electronics.

What is Polybutylene Terephthalate (PBT)?

Polybutylene Terephthalate (PBT) is a semi-crystalline thermoplastic in the polyester family. It’s known for its strength, flexibility, and resistance to chemicals. Because of these properties, PBT is widely used in automotive, electronics, and industrial applications.

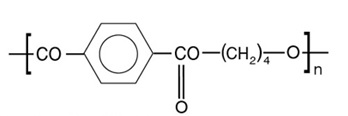

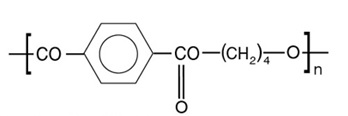

Chemical Composition and Structure of PBT

PBT's chemical structure is represented by the formula (C12H12O4)n. The polymer consists of long chains formed through ester bonds. These bonds provide the material with durability and thermal resistance, which make it ideal for tough environments. Its semi-crystalline structure offers dimensional stability, meaning it retains its shape even under stress.

Molecular Structure of Polybutylene Terephthalate

Key components include:

1,4-Butanediol (BDO): Adds flexibility and helps in chemical resistance.

Terephthalic acid (TPA) or Dimethyl terephthalate (DMT): Provides rigidity and structural integrity.

Synthesis of PBT

The production of PBT involves a polycondensation reaction between Dimethyl Terephthalate (DMT) or Terephthalic Acid (TPA) and 1,4-Butanediol (BDO).

Raw Materials:

The synthesis starts with an esterification reaction, where BDO reacts with either DMT or TPA. When using DMT, methanol is produced as a by-product. With TPA, water is released. The following reaction removes excess BDO, leading to the formation of long polymer chains through condensation reactions.

Chemical Equations:

DMT Reaction:

TPA Reaction:

These reactions occur at high temperatures, typically between 230°C and 250°C, and under vacuum conditions. Catalysts may also be used to speed up the reaction and ensure higher molecular weights.

| Reaction Type | By-product | Reaction Condition |

| DMT with BDO | Methanol | 230-250°C, vacuum |

| TPA with BDO | Water | 230-250°C, vacuum |

This polycondensation process is key to forming the durable, heat-resistant polymer chains that define PBT.

PBT as a Member of the Polyester Family

As a polyester, PBT shares similarities with other polyesters like Polyethylene Terephthalate (PET). However, it sets itself apart through its faster crystallization rate and lower processing temperatures. This allows it to be molded into intricate shapes easily. Compared to other polyesters, PBT has superior mechanical properties and excellent chemical resistance, making it perfect for parts exposed to oils, fuels, and high temperatures.

Properties of PBT

PBT exhibits a unique combination of properties that make it suitable for various applications. Let's take a closer look at its key characteristics.

| Property Type | Property | Details |

| Physical Properties | Density | 1.31 g/cm³ |

| Limiting Oxygen Index | 25% |

| Moisture Absorption (24 hours) | 0.08%-0.1% |

| Dimensional Stability | Excellent |

| UV Resistance | Good |

| Mechanical Properties | Tensile Strength | 40-50 MPa |

| Flexural Modulus | 2-4 GPa |

| Elongation at Break | 5-300% |

| Creep Resistance | High at elevated temperatures |

| Thermal Properties | Heat Deflection Temperature (HDT) | 115-150°C (at 0.46 MPa); 50-85°C (at 1.8 MPa) |

| Max Continuous Service Temperature | 80-140°C |

| Fire Resistance | Available in flame-resistant grades |

| Coefficient of Thermal Expansion | 6-10 x 10⁻⁵/°C |

| Electrical Properties | Dielectric Strength | 15-30 kV/mm |

| Dielectric Constant @ 1 kHz | 2.9-4 |

| Volume Resistivity | 14-17 x 10⊃1;⁵ Ohm.cm |

| Chemical Resistance | Resistance to Chemicals | Strong resistance to diluted acids, alcohols, hydrocarbons, solvents, oils |

| UV and Stain Resistance | High |

| Resistance to Organic Solvents, Oils | Excellent |

Physical Properties

PBT offers excellent dimensional stability, even under varying environmental conditions. It has low moisture absorption, typically around 0.1% after 24 hours of immersion.

This low moisture uptake contributes to its durability under thermal stress and harsh chemical environments. PBT can maintain its shape and performance in demanding situations.

Mechanical Properties

PBT boasts high strength, toughness, and stiffness. Here are some quantitative indicators:

| Property | Value |

| Tensile Strength | 50-60 MPa |

| Flexural Modulus | 2.3-2.8 GPa |

| Elongation at Break | 50-300% |

PBT also exhibits good practical impact strength. It can withstand sudden loads without cracking or breaking.

Another important feature is its creep resistance. PBT can maintain its shape under constant stress, even at elevated temperatures.

Thermal Properties

PBT has a high heat deflection temperature (HDT) compared to many other engineering plastics. For example, at 1.8 MPa load, its HDT is around 60°C, while polypropylene's is only 50°C.

It also has a high temperature index rating, indicating its ability to retain properties at elevated temperatures. PBT can withstand short-term thermal excursions and long-term heat exposure without significant degradation.

Electrical Properties

PBT offers high electrical resistance and dielectric strength. These properties make it ideal for insulating electrical components.

It protects against discharge, leakage, and breakdown in power circuitry. PBT's low dielectric loss also makes it suitable for high-frequency electronic applications.

Chemical Resistance

PBT exhibits resistance to a wide range of chemicals, including:

Diluted acids

Alcohols

Hydrocarbons

Aromatic solvents

Oils and greases

This chemical resistance makes PBT suitable for parts exposed to organic solvents, gasoline, and oils. It can maintain its integrity in chemically aggressive environments.

PBT also offers good UV resistance, preventing degradation from sunlight exposure. Its stain resistance further enhances its durability and aesthetic appeal.

Types and Modifications of PBT

Unfilled PBT Grades

Unfilled PBT grades are the basic form of the material without any additives. They offer a balance of properties suitable for many applications.

These grades come in a range of melt viscosities, providing processing flexibility for injection molding and extrusion.

Glass Fiber Reinforced PBT

Glass fiber reinforced PBT is a popular modification. The addition of glass fibers significantly enhances the mechanical properties of the material.

Tensile strength, flexural modulus, and compressive strength can increase by 2 to 3 times compared to unfilled grades. This makes glass fiber reinforced PBT ideal for structural applications.

The fiber content can vary, typically ranging from 10% to 50%. Higher fiber content results in greater strength and stiffness but reduced ductility.

Mineral-Filled PBT

Mineral fillers, such as talc and calcium carbonate, can be added to PBT. These fillers improve dimensional stability and reduce shrinkage during molding.

Mineral-filled PBT grades offer increased stiffness and heat resistance compared to unfilled grades. However, the impact strength may be slightly reduced.

Flame-Retardant PBT

Flame-retardant PBT is crucial for applications with stringent fire safety requirements. Various flame retardants can be used, each with its own benefits and drawbacks.

Halogenated flame retardants, such as brominated compounds, are effective but may face environmental concerns. Non-halogenated alternatives, like phosphorus-based additives, are gaining popularity.

The choice of flame retardant affects not only the fire performance but also other properties like mechanical strength, heat resistance, and electrical insulation.

Impact-Modified PBT

Impact modification is used to improve the toughness and ductility of PBT. The most common impact modifiers are elastomers, such as:

These modifiers form a separate rubbery phase within the PBT matrix. They absorb energy during impact, preventing crack initiation and propagation.

The impact strength can be significantly increased, especially at low temperatures. However, the modulus and heat resistance may be slightly compromised.

Other Modifications

PBT can undergo various other modifications to meet specific requirements:

UV stabilizers can be added to improve resistance to sunlight and weathering.

Lubricants, like PTFE or silicone, can be incorporated to reduce friction and wear.

Food-grade PBT is available for applications in contact with food and beverages.

Antistatic agents can be used to dissipate static charges in electronic applications.

Colorants and pigments can be added for aesthetic purposes.

The table below summarizes the key effects of different modifications on PBT properties:

| Modification | Strength | Stiffness | Impact | Heat Resistance | Dimensional Stability |

| Glass Fiber | ↑ | ↑ | ↓ | ↑ | ↑ |

| Mineral Filler | ↑ | ↑ | ↓ | ↑ | ↑ |

| Flame Retardant | ↓ | ↓ | ↓ | ↓ | ↓ |

| Impact Modifier | ↓ | ↓ | ↑ | ↓ | ↓ |

Processing Techniques for PBT

PBT is a thermoplastic material that can be processed using various techniques. Let's explore the most common methods and their key parameters.

Injection Molding

Injection molding is the most common method used for processing PBT. The material is heated to a melt temperature between 230°C and 270°C. It’s then injected into a mold maintained at 40-80°C under high pressure (typically 100-140 MPa). Optimizing the processing parameters—such as melt temperature and injection pressure—ensures better part quality and reduces defects like warping or sink marks.

| Parameter | Optimal Range |

| Melt Temperature | 230-270°C |

| Mold Temperature | 40-80°C |

| Injection Pressure | 100-140 MPa |

Extrusion

Extrusion is another widely used technique for producing semi-finished products like sheets, rods, and profiles. During extrusion, PBT is melted and forced through a die, with the melt temperature controlled between 230°C and 250°C. Maintaining the right screw speed and cooling rate is essential for dimensional accuracy.

| Extrusion Parameter | Optimal Value |

| Melt Temperature | 230-250°C |

| Screw Speed | Adjusted based on output |

Blow Molding

Blow molding is used for making hollow parts like bottles or containers. In this process, PBT is extruded into a tube, called a parison, then air is blown into it to form the shape. Melt temperature and air pressure play key roles in ensuring a smooth, uniform product.

| Parameter | Application |

| Melt Temperature | 230-250°C |

| Air Pressure | Optimized for hollow parts |

Compression Molding

Compression molding involves placing PBT into a heated mold and compressing it under pressure. This method is typically used for large or thick-walled parts. It’s ideal for applications requiring strong, durable components that need precise shape retention.

The typical processing parameters for PBT compression molding are:

Melt temperature: 230°C to 250°C

Mold temperature: 150°C to 180°C

Molding pressure: 10 to 50 MPa

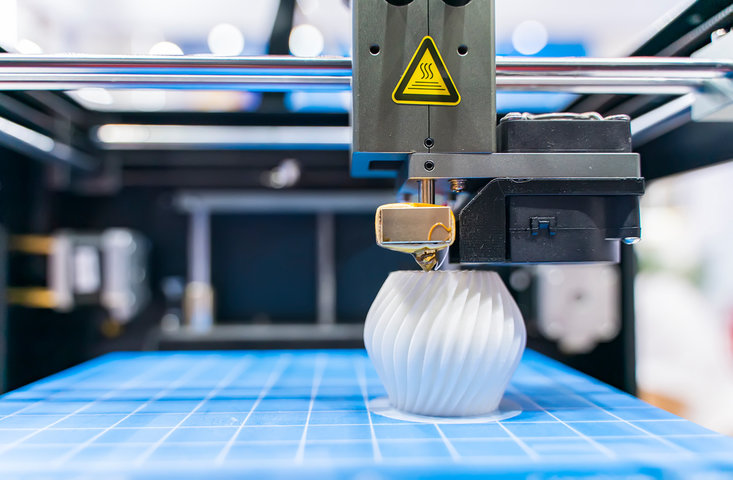

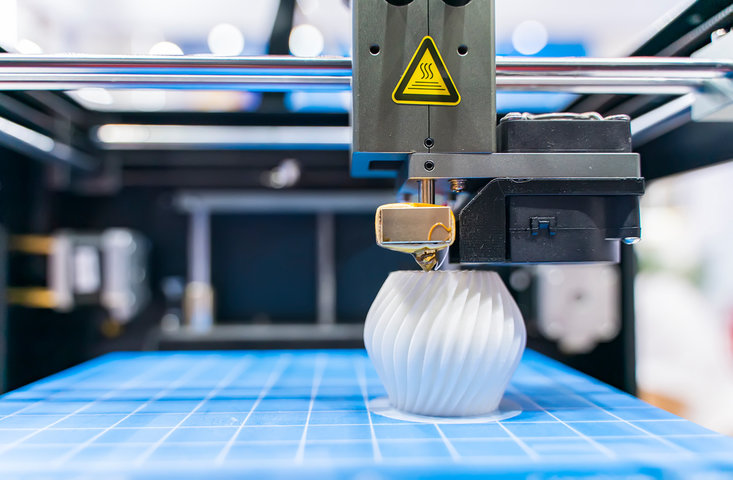

3D Printing with PBT

Although less common, PBT can be processed using 3D printing techniques like fused filament fabrication (FFF) or selective laser sintering (SLS). It’s suitable for producing complex, durable parts with high strength. Optimizing print settings like extrusion temperature and print speed ensures smooth layers and strong adhesion.

| 3D Printing Parameter | Effect on Quality |

| Extrusion Temperature | Affects layer bonding |

| Print Speed | Controls precision |

Applications of PBT

PBT finds use in a wide range of industries due to its excellent properties. Let's explore some of the key application areas.

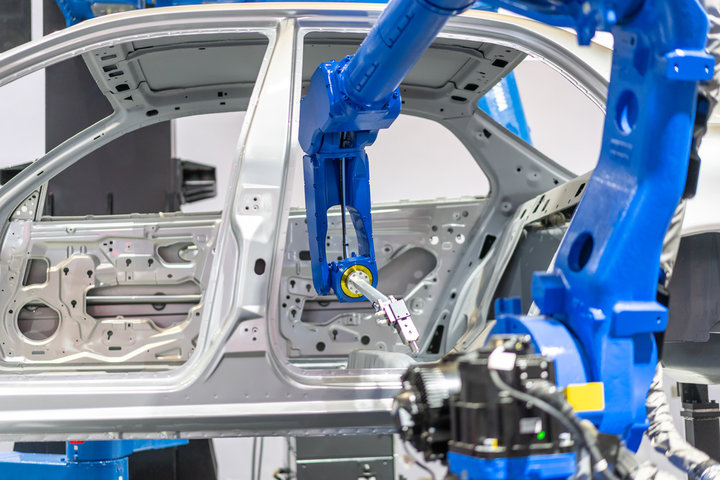

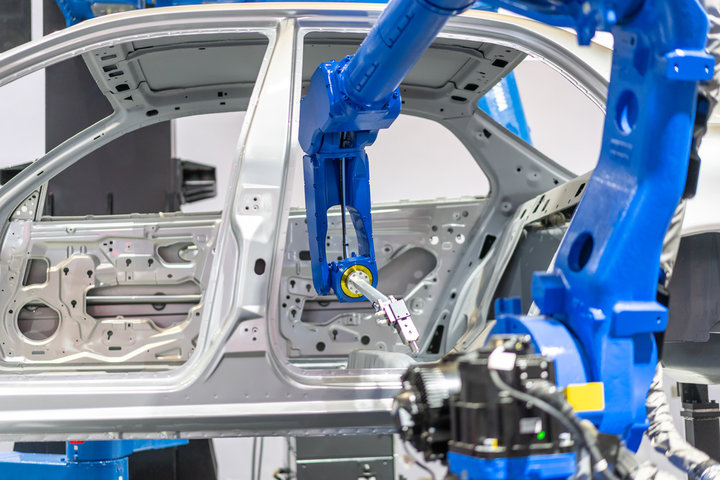

Automotive Industry

PBT is widely used in the automotive industry due to its durability, heat resistance, and chemical resistance. It’s ideal for components like bumpers, body panels, motor parts, and transmission components. For instance, PBT is commonly found in window motor shells, gearboxes, and radiator windows, where it provides excellent performance in harsh environments.

| Automotive Part | PBT Application |

| Bumpers | Impact resistance and flexibility |

| Motor Parts | Electrical insulation and durability |

| Transmission Components | Chemical resistance to oils |

Electronics and Electrical Appliances

In the electronics sector, PBT is valued for its electrical insulation properties. It’s used in connectors, cooling fans, and transformers, ensuring safety and durability. PBT is also a popular material in consumer electronics and home appliances like refrigerators and washing machines, where it offers both mechanical strength and thermal stability.

| Electronic Component | PBT Usage |

| Connectors | Electrical insulation |

| Cooling Fans | Heat resistance |

| Transformers and Relays | Durable housing, heat management |

Consumer Goods

In consumer goods, PBT is commonly found in household items such as vacuum cleaner components and coffee maker parts. Its strength and durability also make it an ideal choice for sporting goods, including ice skate soles and power drill housings.

Medical Devices

PBT’s biocompatibility and chemical resistance make it suitable for medical devices. It’s often used in surgical instruments, orthopedic implants, and medical equipment that require precise, durable, and hygienic materials. The low moisture absorption ensures long-term reliability in medical environments.

| Medical Device | PBT Role |

| Surgical Instruments | Durability and biocompatibility |

| Orthopedic Implants | Chemical resistance and stability |

Plumbing and Fluid Handling

In plumbing and fluid handling systems, PBT is used for valves, fittings, and pump impellers. Its resistance to chemicals, low moisture absorption, and high durability make it perfect for components exposed to water, oils, and cleaning agents.

| Plumbing Component | PBT Usage |

| Valves and Fittings | Chemical resistance |

| Pump Impellers | Durability under fluid exposure |

Industrial Machinery

PBT plays a significant role in industrial machinery, where it’s used to manufacture bearings, gears, cams, and rollers. These components benefit from PBT’s low friction, wear resistance, and high mechanical strength.

| Industrial Part | PBT Application |

| Bearings and Gears | Wear resistance, low friction |

| Rollers and Cams | Durability and precision |

Food Processing Equipment

PBT is used in food-grade applications due to its compliance with FDA regulations. It’s often found in conveyor belts, food processing blades, and other machinery that handles food. PBT’s resistance to moisture and cleaning agents makes it ideal for hygienic and reliable food processing equipment.

| Food Processing Component | PBT Usage |

| Conveyor Belts | FDA compliance, moisture resistance |

| Food Processing Blades | Durability and cleanliness |

Advantages and Disadvantages of PBT

Like any material, PBT has its strengths and limitations.

Advantages

PBT offers several key advantages across multiple industries, making it a popular choice for high-performance applications.

Excellent Mechanical Properties and Dimensional Stability

PBT boasts high strength, toughness, and stiffness, making it durable under mechanical stress. It maintains dimensional stability, even under varying environmental conditions, ensuring components retain their shape.

High Chemical and Wear Resistance

PBT resists a wide range of chemicals, including solvents, fuels, and oils. Its wear resistance makes it suitable for moving parts like gears, where friction reduction is essential.

Good Electrical Insulation

This polymer excels in electrical insulation, with high dielectric strength and low dielectric loss. It prevents energy leakage and is widely used in electronics and electrical components.

Low Moisture Absorption and UV Resistance

With low moisture absorption, PBT maintains its mechanical properties in humid environments. It also resists UV radiation, making it ideal for outdoor use without significant degradation over time.

Disadvantages

While PBT has many strengths, it also has some limitations that must be considered.

High Mold Shrinkage

PBT exhibits high mold shrinkage during processing, making it challenging to maintain dimensional accuracy in complex parts. Precise molding techniques are necessary to minimize shrinkage.

Sensitivity to Hydrolysis

One significant drawback of PBT is its sensitivity to hydrolysis. Prolonged exposure to moisture and hot water can degrade the material over time, limiting its use in water-exposed environments.

Prone to Warping and Notch Sensitivity

Due to high differential shrinkage, PBT is prone to warping, particularly in large or intricate parts. Additionally, unreinforced PBT shows notch sensitivity, making it more susceptible to stress-related fractures.

Lower Heat Deflection Temperature (HDT)

Compared to other engineering plastics, PBT has a lower HDT, meaning it may not be suitable for high-temperature applications without reinforcement or special grades.

| Advantages | Disadvantages |

| Excellent mechanical properties | High mold shrinkage |

| High dimensional stability | Sensitivity to hydrolysis |

| Good chemical and wear resistance | Prone to warping and notch sensitivity |

| Reliable electrical insulation | Lower heat deflection temperature compared to others |

| Low moisture absorption and UV resistance |

|

Conclusion

Polybutylene Terephthalate (PBT) stands out for its mechanical strength, chemical resistance, and dimensional stability. Its versatility makes it essential across industries like automotive, electronics, and medical devices. Understanding PBT’s properties, processing techniques, and applications is critical for selecting the right material and ensuring optimal product design.

Tips: You maybe interested to the all plastics