Plastic injection molding has long been a vital manufacturing process for producing a wide range of plastic products. Traditionally, this technique has been accessible only to large-scale manufacturers with substantial financial resources. However, with the advent of do-it-yourself (DIY) plastic injection molding equipment, the barriers to entry have been significantly lowered, opening up new possibilities for entrepreneurs and small businesses. This technology empowers individuals to turn their ideas into tangible products and revolutionizes the way we think about manufacturing.

DIY plastic injection molding equipment allows individuals to set up their own compact and affordable production systems. These machines are typically compact, user-friendly, and designed to fit in small spaces, such as garages or workshops. They offer a cost-effective alternative to outsourcing production or investing in expensive industrial-scale machinery.

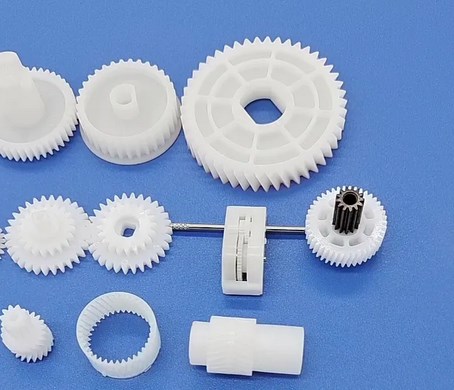

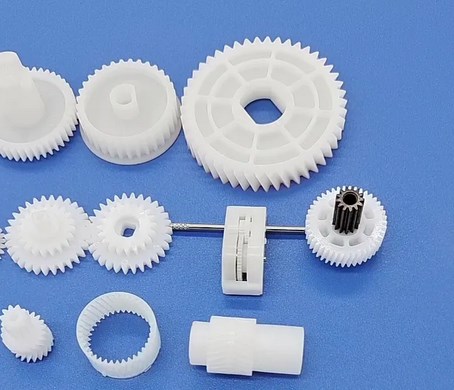

One of the most significant advantages of DIY plastic injection molding equipment is its versatility. It can accommodate various types of thermoplastics, allowing entrepreneurs to create a diverse range of products. From consumer goods like household items and toys to industrial components and custom-designed parts, the possibilities are virtually endless. With the right design and mold, entrepreneurs can quickly prototype and manufacture their products without relying on external manufacturers.

Moreover, DIY plastic injection molding equipment enables entrepreneurs to exercise full control over the production process. They can customize and modify their designs as needed, make rapid iterations, and respond to market demands swiftly. This flexibility fosters innovation and creativity, as entrepreneurs can experiment with different designs and materials without significant financial risks.

The accessibility of DIY plastic injection molding equipment also empowers entrepreneurs to produce small-batch or on-demand manufacturing. This is particularly advantageous for businesses catering to niche markets or offering personalized products. By producing in small quantities, entrepreneurs can reduce inventory costs and avoid the risks associated with overproduction. This lean approach to manufacturing allows for more efficient resource allocation and reduces waste, contributing to a more sustainable and environmentally friendly business model.

Another key benefit of DIY plastic injection molding equipment is the ability to localize production. By bringing manufacturing capabilities in-house, entrepreneurs can reduce reliance on offshore manufacturers, thereby minimizing supply chain disruptions and improving lead times. This localization of production can also be a catalyst for local economic growth, creating job opportunities and supporting entrepreneurship within communities.

However, it is important to note that while DIY plastic injection molding equipment brings numerous advantages, it also requires a certain level of technical knowledge and skill. Entrepreneurs should familiarize themselves with the equipment, materials, and safety protocols to ensure successful and safe operation. Fortunately, there are online resources, tutorials, and communities dedicated to sharing knowledge and providing support to individuals embarking on their DIY plastic injection molding journey.

In conclusion, DIY plastic injection molding equipment has revolutionized the manufacturing landscape, unlocking the potential for entrepreneurs to bring their ideas to life. By providing accessibility, affordability, versatility, and control over the production process, this technology empowers individuals to create and innovate like never before. The democratization of plastic injection molding opens up new opportunities for entrepreneurship, fosters localized manufacturing, and contributes to a more sustainable and efficient approach to production. As more individuals embrace this technology, we can expect a wave of creativity, economic growth, and positive change in the entrepreneurial landscape.