What makes PEEK plastic so unique? As industries push for stronger, more heat-resistant materials, PEEK stands out. Polyetheretherketone (PEEK) is an advanced engineering plastic, developed in the 1980s, known for its high performance under extreme conditions.

In this post, you'll learn what PEEK is, its properties, and why it's crucial across multiple industries. We'll explore its unique characteristics and why it's a top choice for aerospace, medical, and automotive applications.

What is PEEK Plastic?

PEEK, or polyether ether ketone, is a high-performance engineering plastic. It's known for its exceptional properties and versatility across various industries. For more information on how PEEK is used in manufacturing, you can check out our guide on PEEK injection molding.

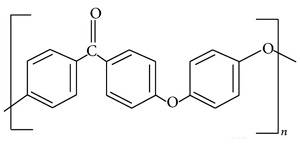

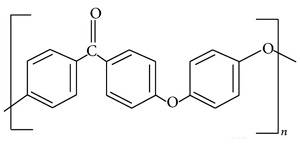

Chemical Composition and Structure

PEEK's molecular structure consists of repeating units of two ether groups and a ketone group. This unique arrangement gives PEEK its remarkable characteristics.

The chemical formula for PEEK is C19H14O3. Its CAS number is 29658-26-2.

Synthesis of PEEK

The production of PEEK involves several steps:

Monomer Preparation:

Key monomers: 4,4'-difluorobenzophenone and hydroquinone

Hydroquinone is treated with a strong base like sodium carbonate

Polymerization Process:

Occurs at high temperatures (around 300°C)

Takes place in a polar aprotic solvent (e.g., diphenyl sulfone)

Involves nucleophilic aromatic substitution

Isolation and Purification:

This process results in PEEK's stiff aromatic polymer backbone. It's why PEEK can withstand temperatures up to 240°C. Understanding these properties is crucial when considering injection molding tolerances for PEEK parts

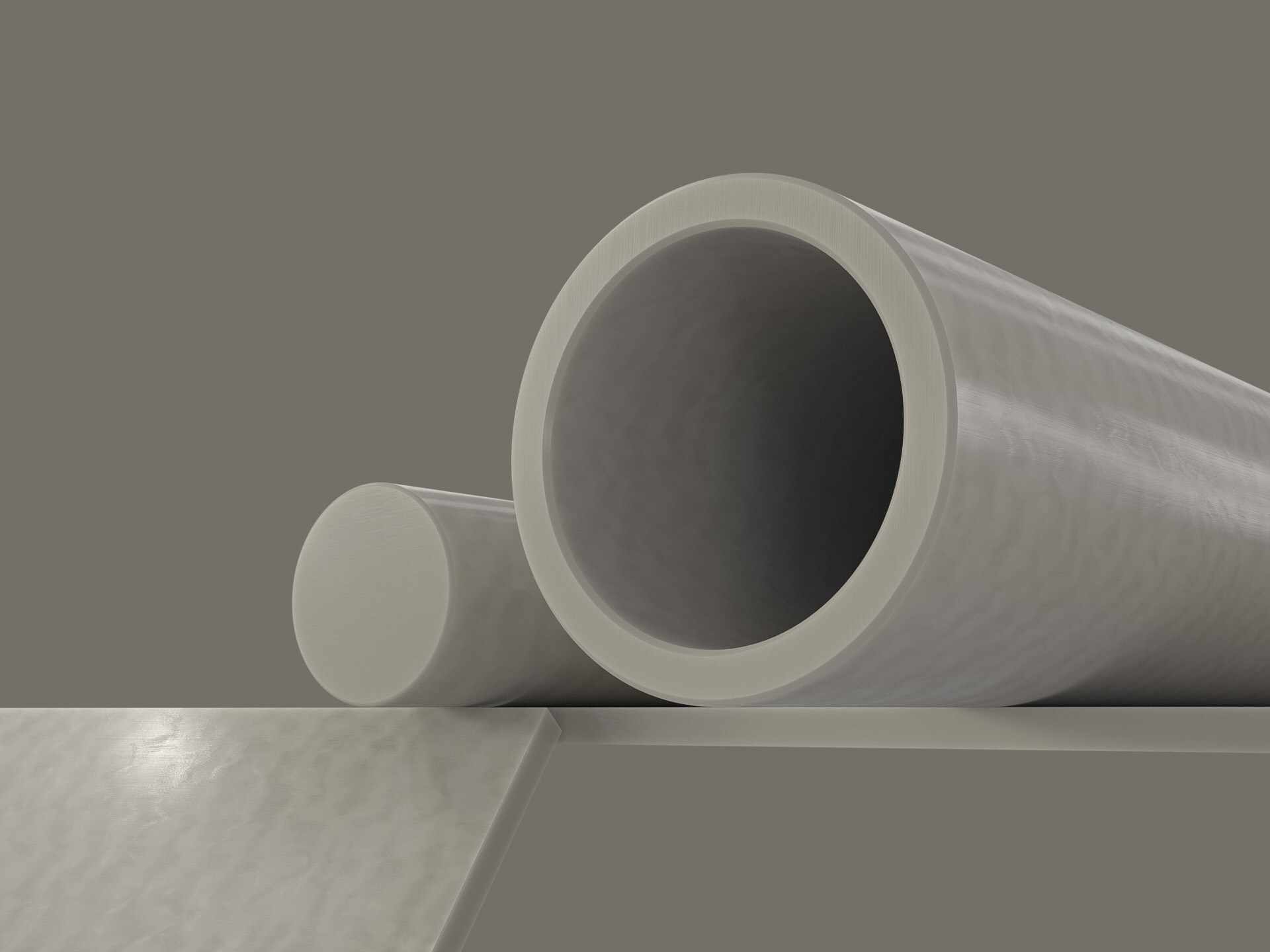

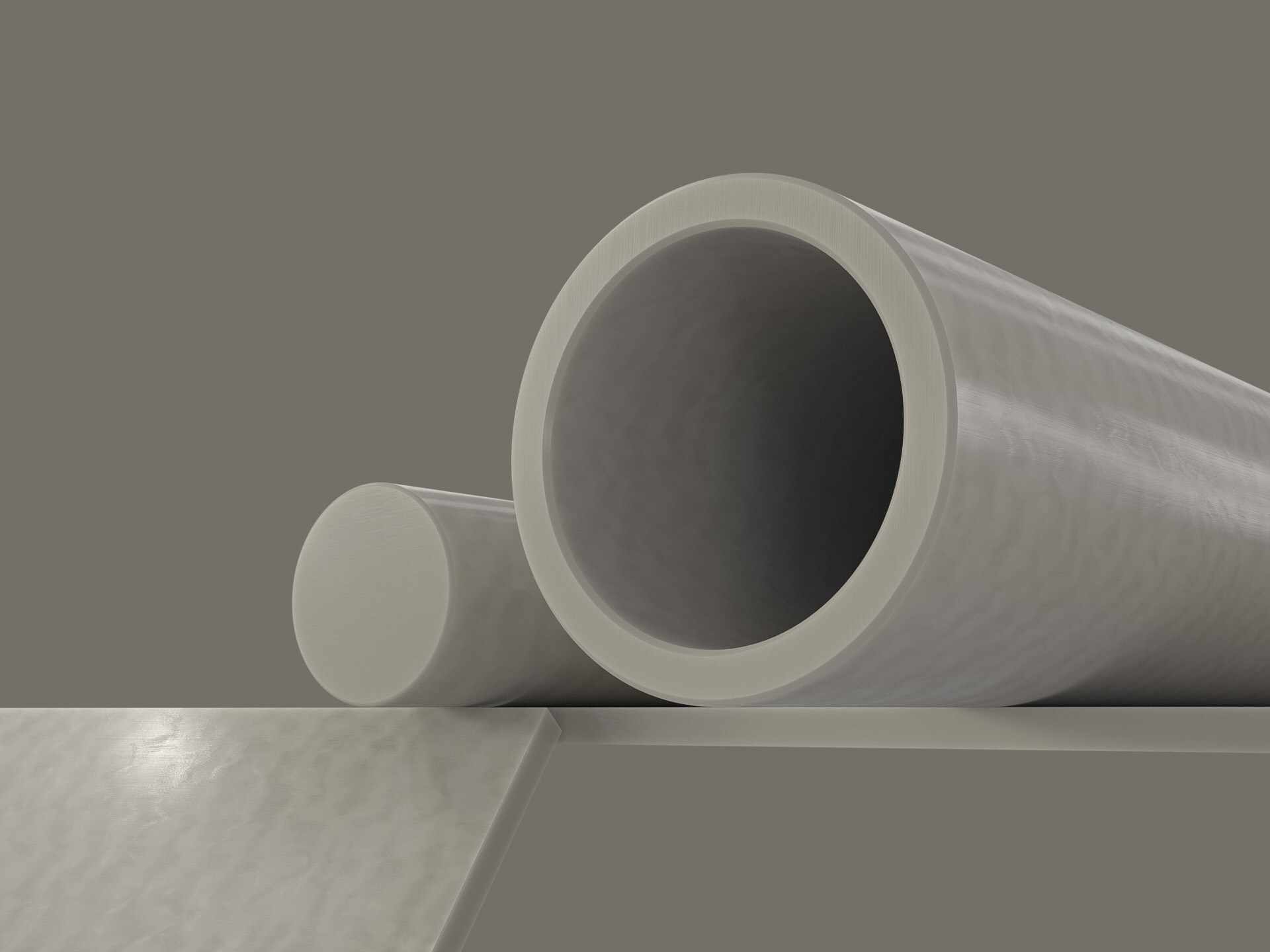

Forms of PEEK

PEEK is available in various forms to suit different manufacturing processes:

| Form | Description |

| Pellets | Small, uniform granules for injection molding |

| Powder | Fine particles for compression molding, 3D printing |

| Rods | Stock shapes for machining custom parts |

| Granules | Similar to pellets, used in various molding processes |

Each form offers unique advantages for specific applications. Choosing the right form is crucial for optimal processing and performance.

Properties of PEEK Plastic

PEEK boasts a unique combination of properties. They make it suitable

Physical Properties

PEEK's physical characteristics make it stand out among engineering plastics:

Density: 1.26 - 1.32 g/cm³

Appearance: Opaque, beige color

Crystallinity: Semi-crystalline structure

Its crystallinity imparts excellent resistance to various liquids. This feature also enhances PEEK's fatigue performance and dimensional stability.

Mechanical Properties

PEEK boasts impressive mechanical strength:

Tensile strength: 90-100 MPa

Tensile modulus: 3.5 - 3.9 GPa

Flexural strength: 170 MPa

Flexural modulus: 4.1 GPa

Impact resistance (notched Izod): 80-94 J/m

These properties remain stable even at elevated temperatures. PEEK's toughness and strength make it ideal for demanding applications, similar to other high-performance plastics like ULTEM (PEI).

Thermal Properties

PEEK's thermal characteristics are exceptional:

Melting point (Tm): 343°C

Glass transition temperature (Tg): 143°C

Heat deflection temperature (HDT): 152°C at 1.8 MPa

Thermal conductivity: 0.25 W/(m·K)

Coefficient of thermal expansion: 47 µm/(m·K)

These properties allow PEEK to maintain performance in high-temperature environments, which is particularly important in the plastic injection molding process.

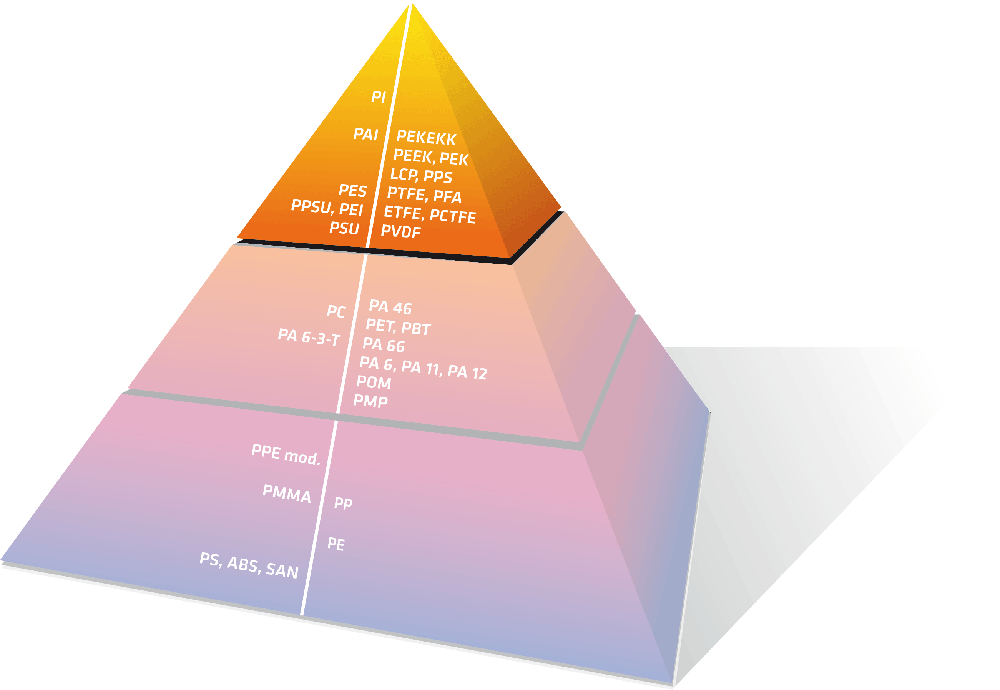

Highest heat resistant plastic: PEEK

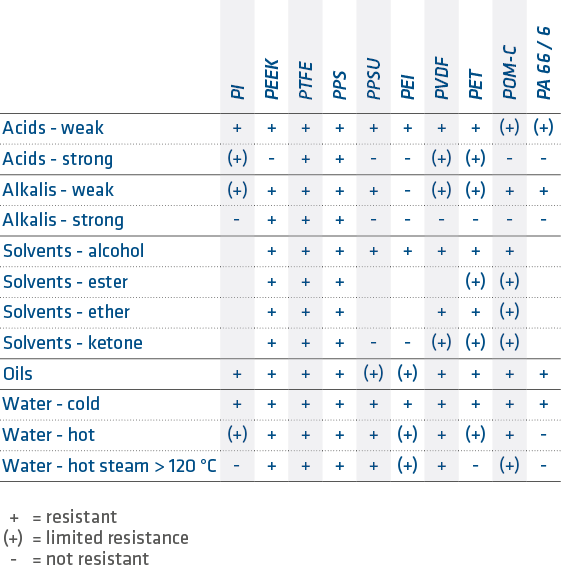

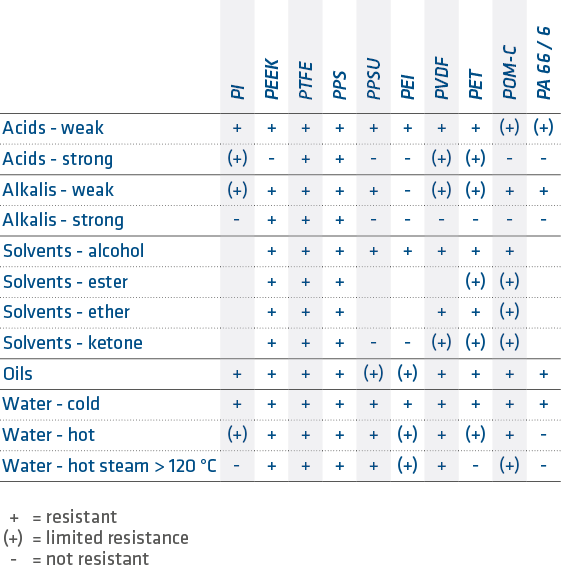

Chemical Properties

PEEK exhibits outstanding chemical resistance:

Resistant to most organic and inorganic chemicals

Excellent hydrolysis resistance (withstands steam, water, seawater)

High radiation resistance

It remains stable in harsh chemical environments. This makes PEEK ideal for corrosive applications.

PEEK Chemical resistance

Electrical Properties

PEEK's electrical characteristics are noteworthy:

Dielectric strength: 20 kV/mm

Volume resistivity: 16 x 10^15 Ω·cm

Surface resistivity: 10^13 Ω

These properties make PEEK an excellent insulator across a wide temperature range.

Other Notable Properties

PEEK offers additional benefits:

Wear resistance: Low coefficient of friction (0.25 dynamic)

Biocompatibility: Suitable for medical implants and devices

Flame retardancy: V0 rating (UL 94) down to 1.45 mm thickness

Its low moisture absorption (0.5% in 24 hours) contributes to dimensional stability. PEEK's inherent purity makes it suitable for clean room environments. These properties make PEEK a superior choice in many applications compared to other manufacturing methods like die casting.

Applications of PEEK Plastic

Aerospace

In aerospace, PEEK offers high performance and reliability. Common applications include:

PEEK's strength, stability, and weight savings are crucial in aerospace.

Automotive

PEEK withstands the harsh conditions in automotive environments:

Its chemical and heat resistance make PEEK a reliable choice.

Medical

PEEK is biocompatible and sterilizable. It's widely used in medical applications:

Surgical instruments

Endoscopic components

Orthopedic tools

Dental instruments

Implantable devices

Spinal implants

Orthopedic implants

Cardiovascular implants

Sterilization equipment

Trays and cases

Instrument handles

PEEK ensures patient safety and device longevity.

Electronics

In electronics, PEEK provides excellent insulation and stability:

PEEK maintains its properties in extreme conditions.

Oil & Gas

PEEK withstands the challenges of oil and gas environments:

Downhole equipment

Electrical connectors

Sensor housings

Valve components

Seals and backup rings

High-pressure seals

High-temperature seals

Chemical-resistant seals

It provides reliable performance in hostile conditions.

Food processing

In food processing, PEEK offers purity and wear resistance:

Fillers and scrapers

Valve seats and bearings

Non-contaminating valve seats

Corrosion-resistant bearings

Chemically inert components

PEEK ensures food safety and equipment durability.

Grades of PEEK Plastic

PEEK is available in various grades. Each offers unique properties tailored for specific applications.

Unfilled (virgin) PEEK

Unfilled PEEK is the purest form. It provides:

Excellent chemical resistance

High toughness and elongation (up to 150%)

Good electrical insulation

Natural color (beige)

It's ideal for applications requiring purity and cleanliness, such as semiconductor processing and medical devices.

Glass fiber reinforced PEEK

Glass fiber reinforcement enhances PEEK's properties:

Increased strength and stiffness (flexural modulus up to 10 GPa)

Higher thermal stability (HDT up to 315°C)

Better dimensional stability

Lower thermal expansion (CLTE down to 1.1 ppm/°C)

Typical grades contain 30% glass fiber. They're great for structural applications in automotive, aerospace, and industrial equipment.

Carbon fiber reinforced PEEK

Carbon fiber takes PEEK's performance to the highest level:

Highest strength and stiffness (tensile strength up to 300 MPa)

Excellent fatigue resistance

Superior wear resistance

Low thermal expansion (CLTE as low as 0.2 ppm/°C)

Black color

Grades with 30% carbon fiber are common. They're used in the most demanding environments, such as aerospace structures and high-performance automotive parts.

Bearing grade PEEK

Bearing grades are tailored for wear and friction applications:

Reduced coefficient of friction (as low as 0.10)

Enhanced wear resistance (up to 10x better than virgin PEEK)

Improved thermal conductivity (up to 2x higher)

Added lubricants (PTFE, graphite)

They're ideal for bushings, bearings, and seals in industrial equipment, pumps, and valves. PEEK bearing grades outperform traditional metal and plastic materials.

FDA compliant grades for food and medical

Some PEEK grades meet strict FDA requirements:

Food contact compliance (FDA 21 CFR 177.2415)

Biocompatibility (ISO 10993, USP Class VI)

Sterilization resistance (autoclave, gamma, EtO)

Natural or medical blue colors

They're used in food processing equipment, surgical tools, and implantable medical devices. Safety and purity are assured for the most sensitive applications.

| Grade | Properties | Applications |

| Unfilled | Purity, toughness | Semiconductor, medical |

| Glass Fiber (30%) | Strength, stability | Automotive, aerospace, industrial |

| Carbon Fiber (30%) | Highest performance | Aerospace, high-end automotive |

| Bearing | Low friction & wear | Bushings, seals, bearings |

| FDA Compliant | Food & medical safety | Surgical tools, implants, food processing |

Modifications and Enhancements of PEEK

PEEK can be modified to enhance its properties. Various additives and treatments are used. They tailor PEEK for specific applications.

Fillers and reinforcements

Fillers and reinforcements improve PEEK's mechanical and thermal properties:

The type and amount of filler are chosen based on the application requirements.

Annealing and stress relieving

Annealing and stress relieving optimize PEEK's properties:

Annealing

Stress relieving

Reduces internal stresses

Minimizes warpage and distortion

Improves machining and cutting performance

These treatments are often applied to machined or formed parts.

Chemical additives

Chemical additives extend PEEK's performance in harsh environments:

UV stabilizers

Protect against ultraviolet degradation

Maintain mechanical properties outdoors

Extend service life in sunlight

Flame retardants

They allow PEEK to be used in demanding applications safely.

| Modification | Effect | Applications |

| Glass fiber | Strength, stability | Structural, automotive |

| Carbon fiber | Highest performance | Aerospace, wear parts |

| Lubricants | Low friction & wear | Bearings, gears, seals |

| Annealing | Crystallinity, stability | Precision parts, chemical resistant |

| Stress relieving | Reduced warpage | Machined & formed parts |

| UV stabilizers | Outdoor durability | Exterior components |

| Flame retardants | Fire safety | Transportation, electronics |

Processing Techniques for PEEK Plastic

PEEK can be processed using various methods. Each has its own considerations. Let's explore the main techniques.

Injection molding

Injection molding is common for producing complex PEEK parts:

Proper setup is crucial for quality parts. Specialized equipment is needed due to the high temperatures.

Extrusion

Extrusion produces continuous PEEK profiles:

Profiles, films, tubes

Rods, sheets, and custom shapes

Thin films and membranes

Seamless and reinforced tubes

Cooling considerations

Controlled cooling for crystallinity

Water baths or cooling rolls

Annealing for dimensional stability

The cooling rate affects the final properties. It must be optimized for each product.

3D Printing

3D printing offers design freedom for PEEK parts:

PEEK is challenging to 3D print. But it enables unique, high-performance parts.

Machining

PEEK can be machined like metals:

Turning, milling, drilling

Tool selection and wear issues

Proper techniques yield tight tolerances. Tool wear can be significant due to PEEK's abrasiveness.

Other methods

PEEK can be processed in other ways:

Compression molding

Casting

Welding

These methods expand PEEK's processing options. They're used for specific applications and requirements.

| Method | Typical Applications | Key Considerations |

| Injection molding | Complex parts, high volume | High temperature, mold design |

| Extrusion | Profiles, films, tubes | Cooling, dimensional control |

| 3D Printing | Custom parts, prototypes | Warping, layer bonding |

| Machining | Precision parts, low volume | Tool wear, chip control |

| Compression molding | Simple shapes, thick parts | Preheating, pressure |

| Casting | Prototypes, small runs | Mold material, shrinkage |

| Welding | Joining, assembly | Surface preparation, parameters |

For a comprehensive understanding of plastic processing techniques, including those used for PEEK, you can refer to our guide on the plastic injection molding process.

Design Considerations for PEEK Parts

Wall thickness and geometry

Wall thickness affects strength, stiffness, and moldability:

Aim for uniform thickness (± 0.025 in/0.64 mm)

Avoid thick sections (>0.16 in/4 mm) to prevent sink marks and voids

Use ribs and gussets for reinforcement, with a thickness of 50-60% of the main wall

Design for draft angles (1-2°) to facilitate ejection and prevent distortion

Proper geometry optimizes material usage and ensures smooth mold filling and ejection. Use coring and hollowing to reduce thick sections and minimize material consumption.

Shrinkage and warpage control

PEEK has high shrinkage (1-2%) during cooling, which can lead to warpage:

Use uniform wall thickness to promote even cooling and shrinkage

Incorporate the expected shrinkage into the mold design (1.5% is a good starting point)

Balance gating and filling to ensure uniform flow and pressure distribution

Control the cooling rate and temperature to minimize differential shrinkage

Warpage occurs due to differential shrinkage between different part sections. It can be minimized through proper design (e.g., symmetric geometry) and processing (e.g., gradual cooling).

Creep and fatigue resistance

PEEK has excellent creep and fatigue resistance, but it can be further enhanced through design:

Avoid sharp corners and notches, which can concentrate stress and initiate cracks

Use generous radii (>0.06 in/1.5 mm) and fillets to distribute stress evenly

Orient reinforcement fibers in the direction of the main stress to maximize strength

Control stress levels and cycling to stay within the material's endurance limit

Designing for long-term loading is crucial to ensure reliable performance over the part's entire lifetime. Use ribbing and material accumulation in high-stress areas to improve strength and stiffness.

Wear and friction optimization

PEEK has good inherent wear and friction properties, which can be optimized through design:

Use smooth, polished surfaces (Ra <0.8 µm) to reduce abrasion and wear

Avoid abrasive contact with rough or hard surfaces, which can accelerate wear

Incorporate lubrication features such as oil grooves, reservoirs, or self-lubricating additives

Select appropriate mating materials (e.g., metal, ceramic) based on the tribological requirements

Proper design minimizes wear and friction, extending the service life of moving parts like bearings, gears, and seals. Consider using specialized bearing grades of PEEK for the most demanding applications.

Dimensional stability and precision

PEEK offers excellent dimensional stability due to its low moisture absorption and high glass transition temperature. Precision can be achieved through careful design and processing:

Use tight tolerances (±0.002 in/0.05 mm) for critical dimensions and fits

Allow for uniform shrinkage (1.5%) in the mold design to compensate for post-molding changes

Optimize gating and ejection to minimize distortion and residual stress

Consider post-molding annealing to relieve stress and improve stability

Precise, stable parts are essential for critical applications like aerospace, medical, and electronics. They ensure consistent performance, easy assembly, and long-term reliability.

| Design Aspect | Key Considerations | Benefits |

| Wall thickness | Uniform (±0.025 in), avoid >0.16 in, ribs 50-60% | Strength, moldability, minimal sink |

| Shrinkage and warpage | Balance gating, 1.5% allowance, gradual cooling | Dimensional accuracy, minimal distortion |

| Creep and fatigue | Radii >0.06 in, fiber orientation, stress control | Long-term reliability, high strength |

| Wear and friction | Smooth surfaces (Ra <0.8 µm), lubrication, material pairs | Extended service life, low friction |

| Dimensional stability | Tolerances ±0.002 in, uniform shrinkage, annealing | Precision, consistency, easy assembly |

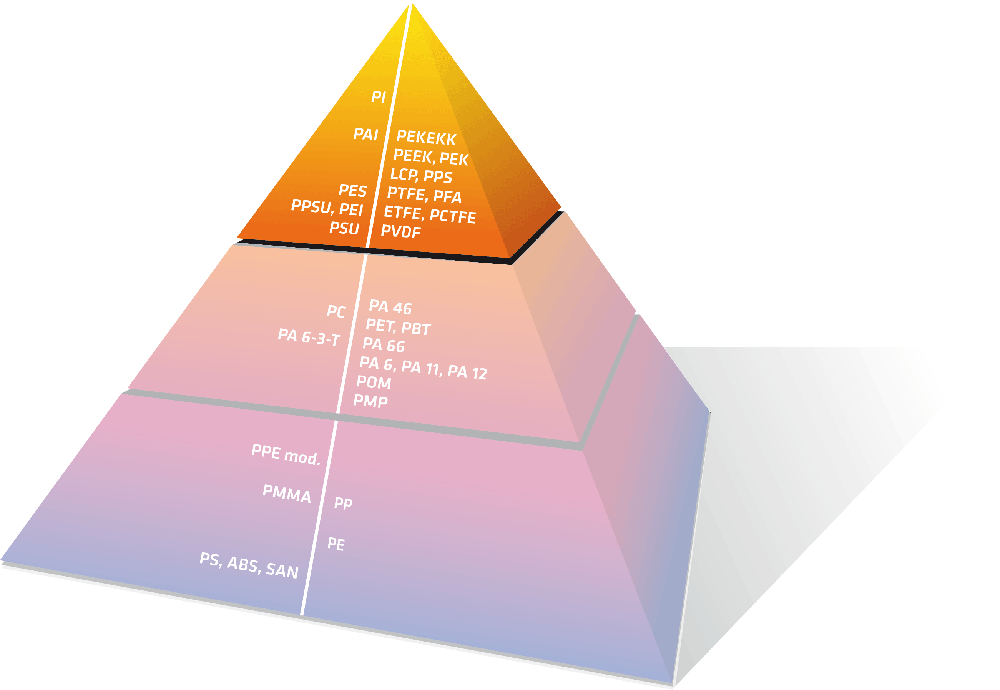

Comparison of PEEK with Other High-Performance Plastics

PEEK is one of the highest-performing thermoplastics available. But how does it compare to other advanced materials? Let's take a detailed look.

| Property | PEEK | PEI | PPS | PTFE | PI |

| Max. Service Temp. (°C) | 260 | 170 | 240 | 260 | 400 |

| Tensile Strength (MPa) | 100 | 105 | 80 | 25 | 150 |

| Flexural Modulus (GPa) | 4.1 | 3.3 | 4.0 | 0.5 | 3.5 |

| Notched Izod Impact (kJ/m²) | 7 | 6 | 3 | 2 | 4 |

| Chemical Resistance | Excellent | Excellent | Excellent | Outstanding | Good |

| Wear Resistance | Excellent | Good | Good | Fair | Good |

| Coefficient of Friction | 0.10-0.25 | 0.20-0.35 | 0.15-0.30 | 0.05-0.10 | 0.10-0.25 |

| Moisture Absorption (%) | 0.5 | 1.2 | 0.05 | <0.01 | 1.5 |

PEEK vs. PEI (Ultem)

PEI (polyetherimide), known by the brand name Ultem, is another high-performance polymer:

PEEK has higher strength, stiffness, and thermal stability

PEEK tensile strength: 100 MPa, PEI: 105 MPa

PEEK flexural modulus: 4.1 GPa, PEI: 3.3 GPa

PEEK glass transition temperature (Tg): 143°C, PEI: 217°C

PEEK maintains its mechanical properties at higher temperatures (260°C vs. 170°C continuous use)

PEI has better dimensional stability, lower moisture absorption, and higher dielectric strength

Both have excellent chemical resistance and inherent flame retardancy

PEEK outperforms PEI in extreme temperatures and mechanical loading. PEI is a good choice for structural and electrical applications.

PEEK vs. PPS

PPS (polyphenylene sulfide) is a high-temperature semi-crystalline engineering plastic:

PEEK has higher strength, impact resistance, and wear resistance

PEEK tensile strength: 100 MPa, PPS: 80 MPa

PEEK notched Izod impact strength: 7 kJ/m², PPS: 3 kJ/m²

PPS has better chemical resistance, especially to strong acids, bases, and solvents

PEEK is more expensive but offers superior mechanical performance and thermal stability

PPS is easier to process (lower melting point) and has lower moisture absorption

PEEK is the top choice for demanding mechanical and tribological applications. PPS is suitable for chemically aggressive environments and cost-sensitive projects.

PEEK vs. PTFE

PTFE (polytetrafluoroethylene), known by the trade name Teflon, is a unique fluoropolymer:

PEEK has much higher strength, stiffness, and wear resistance

PEEK tensile strength: 100 MPa, PTFE: 25 MPa

PEEK flexural modulus: 4.1 GPa, PTFE: 0.5 GPa

PTFE has the lowest coefficient of friction (0.05-0.10) and best non-stick properties

PEEK can withstand higher temperatures in air (260°C vs. 260°C continuous use)

PTFE is more chemically inert and resistant to virtually all solvents

PEEK is better suited for structural, load-bearing, and wear applications. PTFE excels in low-friction, non-stick, and chemically inert uses.

PEEK vs. Polyimides (PI)

Polyimides (PI) are a family of high-temperature, high-performance polymers:

PEEK has higher toughness, impact strength, and wear resistance

PEEK elongation at break: 50%, PI: 10-30%

PEEK notched Izod impact strength: 7 kJ/m², PI: 3-5 kJ/m²

Some PIs, like PMR-15 and BPDA-PPD, can withstand even higher temperatures (up to 400°C)

PEEK is easier to process (thermoplastic vs. thermoset) and has better chemical resistance

PIs are often used as coatings, films, fibers, and composites

PEEK is the preferred choice for most demanding structural and tribological applications. PIs are used when the highest temperature resistance is needed, often in aerospace and electronics.

While this comparison focuses on high-performance plastics, it's worth noting that in some applications, these materials might compete with high-strength metals. For instance, in aerospace applications, engineers might need to choose between PEEK and high-strength aluminum alloys like 6061 and 7075 aluminum.

For less demanding applications, engineers might consider more common plastics like ABS (Acrylonitrile Butadiene Styren

Environmental and Sustainability Aspects of PEEK

Recyclability of PEEK

PEEK is a fully recyclable thermoplastic:

It can be remelted and reprocessed multiple times

Recycling methods include mechanical and chemical recycling

Recycled PEEK retains most of its original properties

It can be blended with virgin PEEK or other polymers

Recycling PEEK helps reduce waste and conserve resources. It's an important aspect of sustainable manufacturing.

Energy efficiency in production

The production of PEEK is relatively energy-efficient:

It uses a solvent-free process (high-temperature melt polymerization)

This reduces the need for energy-intensive solvent recovery

The raw materials are stable and don't require special handling

PEEK's high performance allows for lighter, more efficient designs

These factors contribute to lower energy consumption and emissions. They make PEEK an environmentally friendly choice.

Life cycle assessment

Life cycle assessment (LCA) studies show PEEK's sustainability benefits:

PEEK parts have a long service life, reducing replacement needs

They can replace heavier metal components, reducing fuel consumption

PEEK's high-temperature resistance enables more efficient processes

Its chemical resistance minimizes the need for protective coatings

Over its entire life cycle, PEEK offers environmental advantages. It contributes to resource efficiency and reduced emissions.

| Aspect | Benefit |

| Recyclability | Reduced waste, conserved resources |

| Energy efficiency | Lower consumption and emissions |

| Life cycle performance | Long service life, efficient designs |

Summary

PEEK plastic offers a unique combination of properties, including high strength, heat resistance, and chemical resistance. These properties enable PEEK to perform in demanding applications across industries like aerospace, medical, and automotive. By understanding PEEK's grades, processing methods, and design considerations, engineers can harness its full potential.

Tips: You maybe interested to the all plastics