Hot runner plates revolutionize injection molding by delivering molten plastic to mold cavities efficiently. But what exactly are they? In this post, you'll learn how hot runner plates enhance efficiency and reduce waste. We'll also cover the crucial design elements for successful injection molding.

Understanding The Hot Runner System

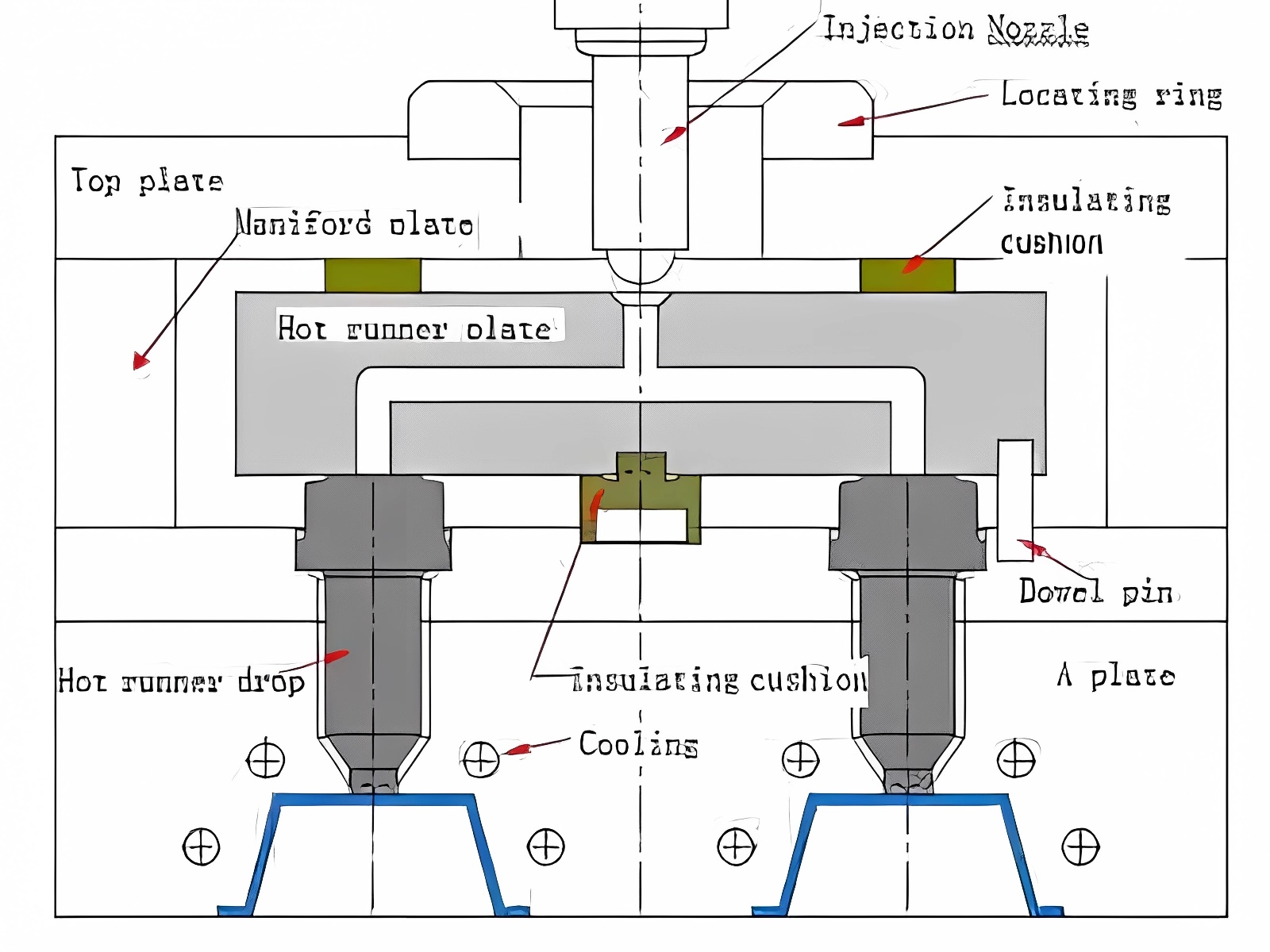

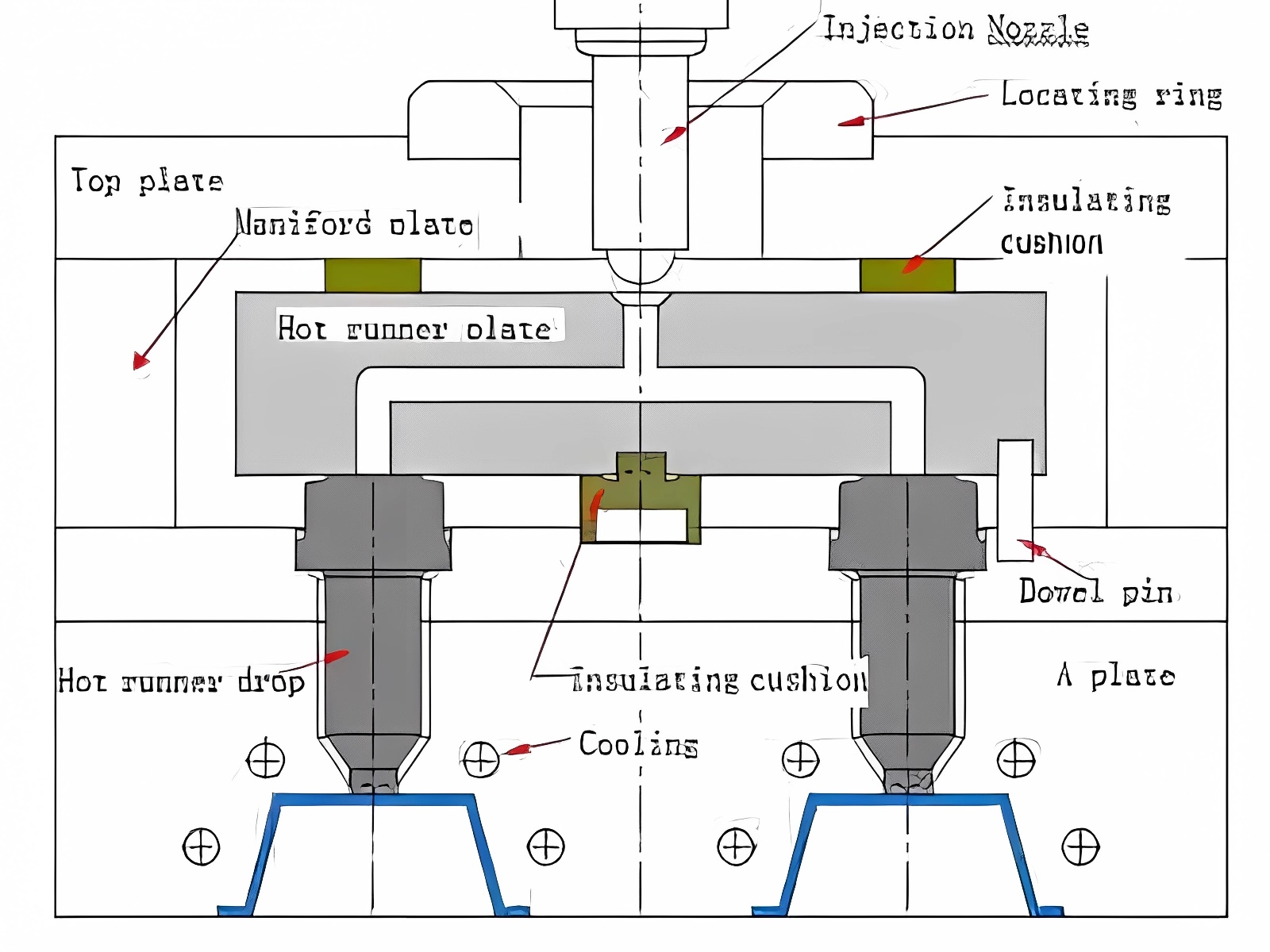

A hot runner system is a critical component in modern injection molding. It consists of several key elements that work together to efficiently deliver molten plastic to the mold cavities.

The main components of a hot runner system include:

Manifold: It distributes the molten plastic from the machine nozzle to the individual nozzles. The manifold contains channels that maintain a consistent temperature.

Nozzles: They are positioned at the gate locations of the mold cavities. The nozzles control the flow of plastic into the cavities.

Heaters: Electric heaters or hot oil circulation systems are used to maintain the desired temperature in the manifold and nozzles.

Temperature sensors: Thermocouples or other sensors monitor and control the temperature throughout the hot runner system.

How does a hot runner system work? The injection molding machine feeds plastic pellets into a heated barrel, where they melt. The molten plastic is then injected into the hot runner manifold.

The manifold distributes the plastic evenly to the nozzles. Each nozzle is heated to maintain the plastic's molten state. When the injection process begins, the nozzle gates open, allowing the plastic to flow into the mold cavities.

After the cavities are filled, the plastic cools and solidifies. The mold opens, and the parts are ejected. The hot runner system remains heated, ready for the next injection cycle.

Hot runner systems offer several advantages over traditional cold runner systems:

| Advantages of Hot Runner Systems | Disadvantages of Cold Runner Systems |

| Reduced material waste | Higher material waste due to runners |

| Faster cycle times | Slower cycle times |

| Improved part quality | Potential for lower part quality |

| Increased design flexibility | Limited design options |

| Lower production costs | Higher production costs |

Hot runner systems are suitable for a wide range of applications, including:

High-volume production runs

Parts with complex geometries

Multi-cavity molds

Materials sensitive to thermal degradation

Applications requiring minimal gate vestige

Designing a Hot Runner Plate

When embarking on the design of a hot runner plate, several crucial factors must be considered to ensure optimal performance and part quality. Let's dive into the key aspects of designing a hot runner plate.

Initial Considerations

Before you start designing, it's essential to have a clear understanding of the part specifications and mold requirements. Take the time to analyze the following factors:

Part geometry: Assess the complexity, size, and shape of the part.

Material: Consider the type of plastic being used and its properties.

Gate locations: Determine the optimal gate positions for proper filling and aesthetics.

Number of cavities: Evaluate how many cavities the mold will have.

Injection parameters: Define the desired injection pressure, speed, and temperature.

By thoroughly evaluating these aspects, you'll lay a solid foundation for your hot runner plate design.

Choosing the Right Hot Runner System

Selecting the appropriate hot runner system is crucial for successful injection molding. There are three main types of hot runner systems:

Valve gate systems: They offer precise control over the flow of plastic into the cavities.

Thermal gate systems: These systems rely on thermal control to regulate the plastic flow.

Hot tip systems: They provide a simplified approach with fewer components.

Consider the advantages and disadvantages of each system type:

| System Type | Pros | Cons |

| Valve Gate | - Precise flow control

- Reduced stringing and drooling

- Suitable for large parts | - Higher cost

- More complex maintenance |

| Thermal Gate | - Cost-effective

- Simpler design

- Easier maintenance | - Less precise flow control

- Potential for gate freeze-off |

| Hot Tip | - Simplicity

- Lower cost

- Compact design | - Limited flow control

- Not suitable for large parts |

Choose the system that best aligns with your part requirements, budget, and production needs.

Determining Number of Drops

Calculating the required number of nozzles, or drops, is a critical step in hot runner plate design. Here's how to determine the optimal number of drops:

Consider the number of cavities in the mold. Generally, each cavity requires its own drop.

Evaluate the part size and shot weight. Larger parts may need multiple drops for even filling.

Assess the flow path length. Long flow paths may benefit from additional drops to maintain consistent flow.

Take into account the material viscosity. Higher viscosity materials may require more drops for proper filling.

Other factors influencing drop number and placement include:

By carefully considering these factors, you can determine the optimal number and positioning of drops for your hot runner plate design.

In the next section, we'll explore the intricacies of nozzle size and configuration for hot runner plate design.

Detailed Design Process

With the initial considerations and hot runner system type selected, it's time to dive into the nitty-gritty of hot runner plate design. In this section, we'll explore the critical aspects that ensure optimal performance and part quality.

Nozzle Size and Configuration

Choosing the right nozzle is crucial for successful injection molding. Consider the following factors when selecting a nozzle:

Material properties: Viscosity, thermal conductivity, and flow characteristics

Part design: Size, wall thickness, and complexity

Injection parameters: Pressure, speed, and temperature

Ensure the nozzle diameter matches the melt channel size for smooth flow. The nozzle tip should align perfectly with the mold cavity gate to prevent leakage and flash.

Manifold Layout Design

The manifold layout plays a vital role in ensuring even temperature distribution and balanced material flow. Keep these strategies in mind:

Minimize flow path variations to maintain consistent flow rates

Use a balanced layout with equal runner lengths for multi-cavity molds

Avoid sharp turns and sudden changes in channel cross-section

Incorporate flow simulation to optimize the manifold design

Incorporating Heating Elements

Proper heating is essential for maintaining the desired material temperature throughout the hot runner system. Two common types of heating elements are:

Electric heaters: Cartridge or ceramic heaters embedded in the manifold and nozzles

Hot oil circulation: Channels for circulating heated oil to maintain temperature

Position the heating elements strategically to ensure even heat distribution and minimize cold spots.

Cooling System Design

Efficient cooling is crucial for part quality and cycle time optimization. When designing cooling channels, consider:

Placing channels close to the mold cavity for effective heat removal

Ensuring uniform cooling to prevent warpage and residual stresses

Avoiding interference with the manifold, nozzles, and other components

Using conformal cooling channels for complex geometries

Material Selection

Choose materials that can withstand the demanding conditions of injection molding. Key criteria include:

High thermal conductivity for efficient heat transfer

Corrosion resistance to withstand harsh plastics and chemicals

Mechanical strength to endure high pressure and wear

Common materials for hot runner plates include tool steel (H13, P20) and copper alloys (Beryllium Copper).

Gate Design and Geometry

The gate design significantly affects part quality and appearance. Optimize the gate by:

Selecting the appropriate gate type (pin, edge, hot tip) based on part requirements

Sizing the gate to balance fill speed and pressure drop

Positioning gates to minimize gate remnants and improve part aesthetics

Using simulation to validate gate location and sizing

Thermal Management

Maintaining consistent temperature throughout the hot runner system is critical for process stability. Implement these techniques:

Use thermocouples or temperature sensors for accurate monitoring and control

Employ a closed-loop temperature control system for precise adjustments

Regularly calibrate and maintain the thermal management system

Collaboration And Validation In Hot Runner Plate Design

Designing a high-performance hot runner plate is not a solo endeavor. It requires close collaboration with various experts to ensure the best possible outcome. In this section, we'll explore the importance of teamwork and validation in the design process.

Working with Mold Designers, Hot Runner Suppliers, and Experienced Tool Makers

To create a successful hot runner plate design, you must work closely with:

Mold Designers: They provide valuable insights into the overall mold design and requirements.

Hot Runner Suppliers: These specialists offer expertise in hot runner systems and components.

Experienced Tool Makers: They contribute practical knowledge of manufacturing and assembly.

Collaborating with these experts allows you to:

Identify potential design issues early on

Optimize the design for manufacturability and assembly

Leverage their experience to make informed decisions

Ensure compatibility between the hot runner plate and other mold components

Maintain open communication throughout the design process. Share ideas, discuss challenges, and be receptive to feedback.

Utilizing Simulation and Mold Flow Analysis

Simulation and mold flow analysis are powerful tools for evaluating and optimizing your hot runner plate design. They allow you to:

Predict the filling behavior of the plastic melt

Identify potential flow imbalances or air traps

Optimize gate locations and sizes

Assess the thermal performance of the hot runner system

Minimize warpage and residual stresses in the molded parts

By utilizing these tools, you can make data-driven decisions and refine your design before manufacturing. This saves time, reduces costs, and improves the overall quality of the hot runner plate.

Importance of Experience and Expertise

While collaboration and simulation are essential, nothing replaces the value of experience and expertise in hot runner plate design. Seasoned designers and engineers bring:

In-depth knowledge of injection molding principles and best practices

Familiarity with a wide range of materials and their behavior

Understanding of the intricacies of hot runner systems

Problem-solving skills honed through years of hands-on experience

Ability to anticipate and mitigate potential issues

When working on a hot runner plate design, seek out the guidance and mentorship of experienced professionals. Their insights can help you navigate complex challenges and make informed decisions.

Manufacturing Considerations For Hot Runner Plates

Designing a high-performance hot runner plate is just the beginning. To ensure optimal functionality and longevity, you must also consider the manufacturing aspects. In this section, we'll delve into the key manufacturing considerations for hot runner plates.

Precision Machining and Tight Tolerances

Hot runner plates require exceptional precision in machining. They demand tight tolerances to ensure proper fit and function. Why is this so critical? Here's why:

Precise alignment of melt channels and components is essential for smooth material flow

Tight tolerances prevent leakage and ensure consistent part quality

Accurate machining maintains the integrity of the hot runner system

To achieve the necessary precision, use advanced machining techniques like:

Partner with experienced machining vendors who specialize in hot runner components. They have the expertise and equipment to meet the stringent requirements.

Maintaining Alignment of Melt Channels and Components

Proper alignment of melt channels and components is crucial for the performance of the hot runner plate. Any misalignment can lead to:

Flow imbalances and inconsistent filling

Leakage and material degradation

Premature wear and failure of components

To maintain alignment during manufacturing, consider these techniques:

Precision boring and reaming of melt channels

Use of guide pins and dowels for accurate assembly

In-process inspection and measurement using CMM (Coordinate Measuring Machine)

Implement robust quality control measures to verify alignment at various stages of manufacturing.

Surface Treatments and Coatings

Hot runner plates are subjected to harsh conditions during injection molding. They face high temperatures, pressures, and abrasive plastics. To enhance wear resistance and performance, consider applying surface treatments or coatings.

Some common surface treatments and coatings include:

Nitriding: It creates a hard, wear-resistant surface layer

PVD (Physical Vapor Deposition) coatings: These thin films improve hardness and corrosion resistance

PTFE (Polytetrafluoroethylene) coatings: They provide non-stick properties and reduce friction

| Treatment/Coating | Benefits |

| Nitriding | - Increased surface hardness

- Improved wear resistance

- Enhanced fatigue strength |

| PVD Coatings | - High hardness

- Excellent corrosion resistance

- Low friction coefficient |

| PTFE Coatings | - Non-stick properties

- Reduced material adhesion

- Improved release characteristics |

Choose the appropriate surface treatment or coating based on the specific requirements of your application. Consider factors like the type of plastic being molded, the operating temperatures, and the expected production volume.

Maintenance And Troubleshooting Of Hot Runner Systems

Designing and manufacturing a high-quality hot runner plate is essential, but it's just the beginning. To ensure consistent performance and longevity, regular maintenance and troubleshooting are crucial. In this section, we'll explore the key aspects of maintaining and troubleshooting hot runner systems.

Regular Maintenance Practices

Proper maintenance is the key to keeping your hot runner system in top shape. It helps prevent downtime, improves part quality, and extends the life of your mold. Here are some essential maintenance practices:

Clean the nozzle tips and gate areas regularly to prevent material buildup

Check and replace heater elements and thermocouples as needed

Inspect and replace worn or damaged components, such as nozzle tips and insulators

Lubricate moving parts, like valve pins, to ensure smooth operation

Perform regular leak checks to identify and fix any leakage issues

Establish a maintenance schedule based on your production volume and the complexity of your hot runner system. Keep detailed records of maintenance activities for future reference.

Common Issues and Troubleshooting Techniques

Despite regular maintenance, issues can still arise in hot runner systems. Here are some common problems and troubleshooting techniques:

Leakage:

Check for worn or damaged nozzle tips and replace them if necessary

Verify that the nozzle and manifold temperatures are set correctly

Inspect the parting line and mating surfaces for damage or misalignment

Blockages:

Purge the hot runner system with a cleaning compound to remove material buildup

Check for cold spots in the manifold or nozzles that can cause material to solidify

Verify that the gate size is appropriate for the material being molded

Inconsistent Heating:

Check for faulty heater elements or thermocouples and replace them if needed

Verify that the temperature control settings are correct and consistent

Inspect the wiring and connections for any damage or loose contacts

When troubleshooting, start with the most likely cause and work systematically. Use a process of elimination to isolate the problem. Consult with experienced technicians or the hot runner supplier if needed.

| Issue | Possible Causes | Troubleshooting Steps |

| Leakage | - Worn or damaged nozzle tips

- Incorrect temperature settings

- Parting line or surface damage | - Replace nozzle tips

- Verify temperature settings

- Inspect and repair surfaces |

| Blockages | - Material buildup

- Cold spots in the system

- Incorrect gate size | - Purge with cleaning compound

- Check for cold spots

- Verify gate size |

| Inconsistent Heating | - Faulty heater elements or thermocouples

- Incorrect temperature control settings

- Damaged wiring or connections | - Replace faulty components

- Verify control settings

- Inspect wiring and connections |

Importance of Proper Maintenance

Investing time and resources in proper maintenance of your hot runner system pays off in the long run. The benefits include:

Reduced downtime and increased productivity

Consistent part quality and fewer rejects

Extended mold life and lower replacement costs

Improved efficiency and energy savings

Don't underestimate the value of regular maintenance. It's essential for the smooth operation of your injection molding process and the success of your business.

Conclusion

Proper hot runner plate design is vital for efficient injection molding. It boosts cycle speed and reduces waste, ensuring high-quality products. A well-designed system improves production efficiency and product consistency. Staying updated with the latest advancements in hot runner technology is essential for continuous improvement. This keeps your process efficient and competitive. Investing in proper design and technology will enhance your injection molding success.