Plastic injection molding is a vital manufacturing process used to create many everyday items. But what makes it efficient? The feed system plays a critical role. A well-designed feed system ensures quality, reduces waste, and boosts productivity. In this post, you'll learn about the components of the feed system, its design principles, and how it affects part quality and cost-effectiveness.

What is a Feeding System in Injection Molding?

A feeding system in injection molding is crucial to ensure that molten plastic flows efficiently into the mold cavity. It consists of channels that guide the molten material from the machine nozzle to the mold. This system includes key components such as the sprue, runner, and gate, each serving a unique function.

The Role of the Feeding System

The feeding system has a vital job. It delivers molten plastic into the mold cavity under precise conditions of pressure and temperature. If designed well, it can reduce defects like weld lines and air bubbles, and ensure the even filling of the mold. Proper flow paths also maintain dimensional accuracy.

Importance of a Well-Designed Feeding System

A properly designed feed system boosts efficiency and product quality. By minimizing material waste and balancing the filling process, the system lowers costs. It also prevents common molding defects such as shrinkage, flash, and short shots, which could otherwise affect the part's appearance and structural integrity. Ultimately, a well-structured feed system can shorten cycle times and improve productivity.

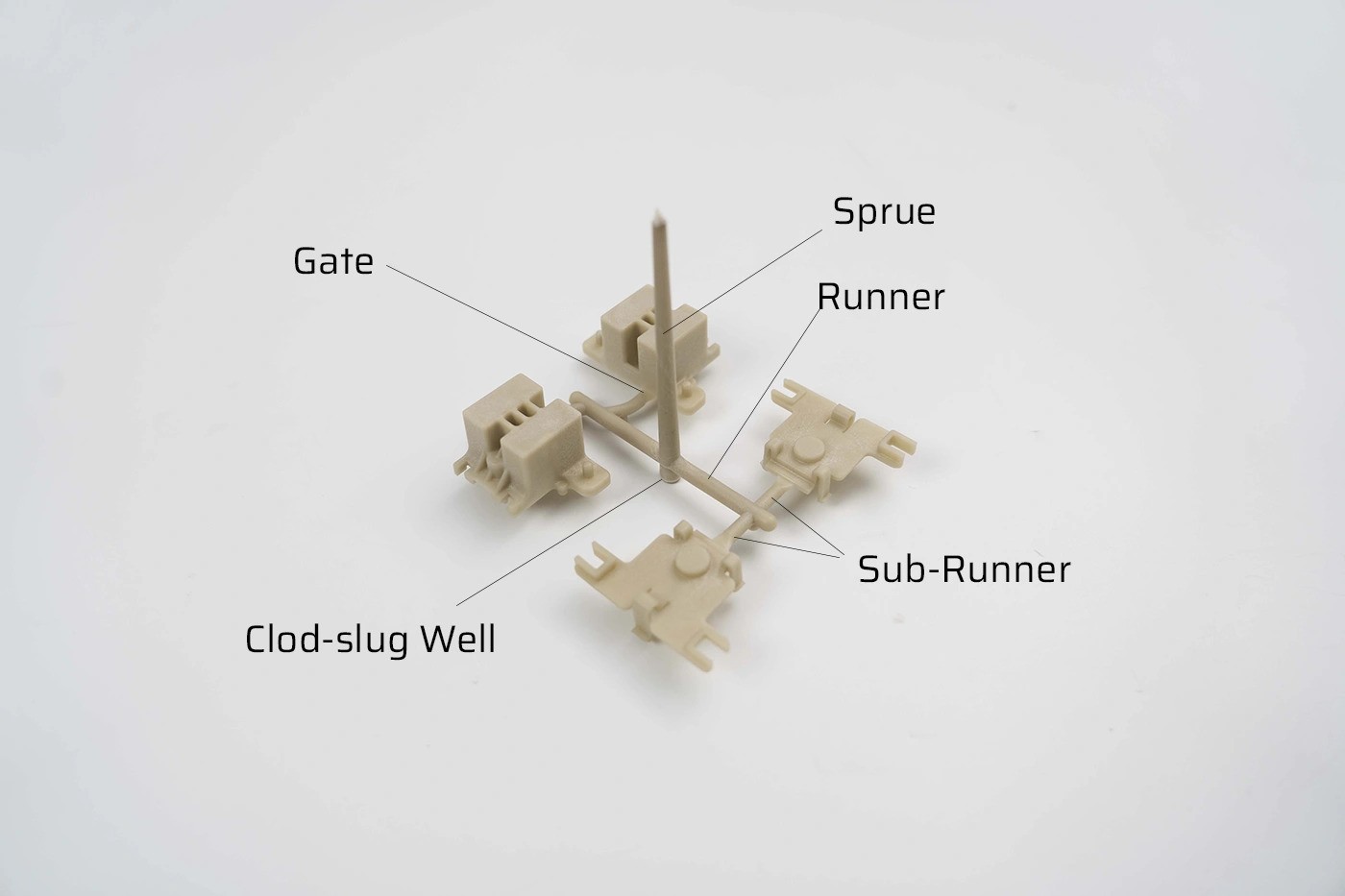

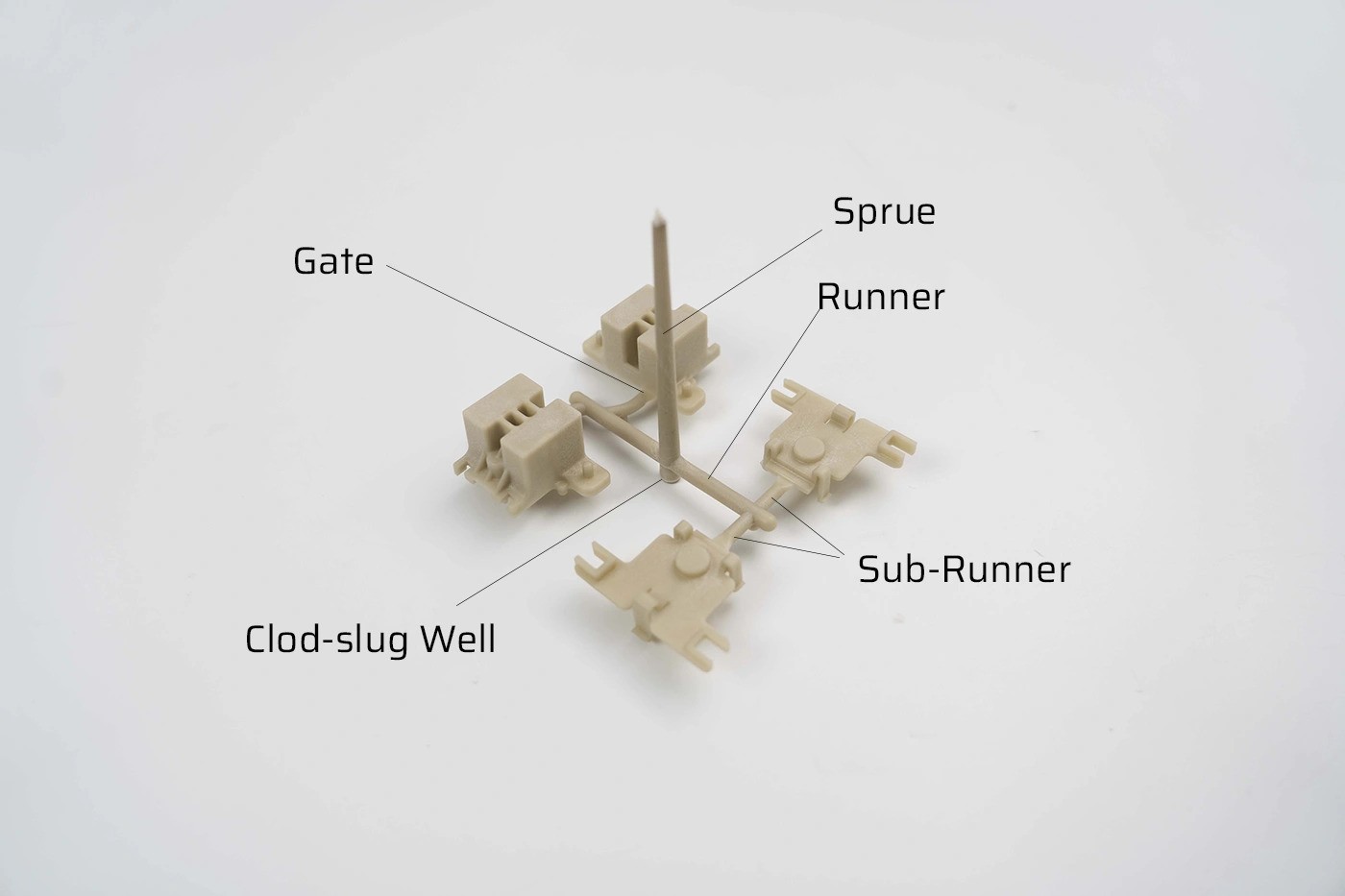

Components of the Feeding System

The feeding system in an injection mold consists of several key components. Let's take a closer look at each one.

Sprue

The sprue is the initial channel where molten plastic enters the mold. It's responsible for conveying the plastic melt from the injection machine's nozzle to the runners.

When designing the sprue, consider:

Sprue length and diameter

Taper angle for easy part removal

Smooth transitions to runners

Runner and Sub-runner

Runners are channels that transport molten plastic from the sprue to the gates. Sub-runners branch off from the main runner to distribute the melt to multiple cavities.

They play a crucial role in:

Guiding the melt to the desired locations

Ensuring even distribution of plastic

Maintaining pressure and temperature

Gate

Gates are the entry points where molten plastic flows into the mold cavity. They control the flow and help pack the cavity with melt.

Common types of gates include:

Tab gate

Edge gate

Hot tip gate

Tunnel gate

The type of gate used depends on factors like part geometry, material, and desired appearance.

Cold Slug Well

Cold slug wells, also known as cold material traps, are located at the end of the runner system. They collect the cold material that first enters the mold, which can contain impurities or degraded plastic.

By trapping this cold material, they prevent it from entering the mold cavity and causing defects like:

Including cold slug wells in your feeding system design helps ensure the quality of your molded parts.

Types of Feed Systems in Injection Molding

Choosing the right feed system is crucial in injection molding. Different systems can affect product quality, cost, and production efficiency. The three main types are cold runner systems, hot runner systems, and insulated runner systems. Each has its strengths and weaknesses.

Cold Runner Systems

Cold runner systems are the traditional method of injection molding. They use unheated runners to transport molten plastic to the mold cavity.

Characteristics and Classification

Cold runners can be classified into two main types: side gate systems and point gate systems. In both, the plastic solidifies in the runner, requiring additional processes to remove excess material.

Advantages

Simple to use and maintain

Works with a wide range of materials

Lower tooling cost than hot runner systems

Disadvantages

Creates waste in the form of runners, which must be recycled or discarded

Longer cycle times due to the cooling of runners

Not suitable for complex or large-volume production

Visible gate marks on the final product

Hot Runner Systems

Hot runner systems, unlike cold runners, maintain the plastic in a molten state throughout the process, eliminating the need for material removal after molding.

Structure and Design Principles

Hot runners use heated manifolds and hot nozzles to deliver plastic directly into the mold cavities. This design ensures consistent temperature and flow throughout the injection process.

Pros

Reduces material waste as runners remain molten

Shortens cycle times by avoiding cooling and removal steps

Ideal for complex parts and high-volume production

Cons

High initial cost for tooling and maintenance

Difficult to clean and maintain, especially for heat-sensitive materials

Not suitable for all materials

You can also learn more about both in our Hot vs Cold Runner.

Insulated Runner Systems

Insulated runner systems are a hybrid between cold and hot runner systems. They maintain a layer of molten plastic within a solidified outer layer to insulate the material.

Working Principle

Using cartridge heaters or other forms of external heating, insulated runners keep the internal plastic molten while the outer layer cools. This reduces waste, similar to hot runner systems, but at a lower cost.

Benefits

Less expensive than hot runner systems

Easier material and color changes

Reduced material waste compared to cold runner systems

Suitable for small to medium production runs

Limitations

Not ideal for demanding engineering-grade plastics

Longer cycle times compared to hot runner systems

Requires careful design and optimization

Design Principles of the Feeding System in Injection Molds

A well-designed feeding system in injection molding is essential for high-quality products and efficient production. The following principles guide its design to ensure optimal performance.

Ensuring Product Quality

To ensure the quality of your molded parts, consider these factors when designing the feeding system:

Avoid weld marks by optimizing gate location and size

Prevent overpacking and insufficient packing pressure by balancing the flow

Minimize defects like short shots, flash, air trapping, and warpage

Additionally, aim for:

Optimizing Production Efficiency

To optimize production efficiency, focus on these aspects of feeding system design:

Minimize post-processing requirements

Shorten the molding cycle

Improve overall production efficiency

Considering Plastic Material Properties

Different plastic materials have unique flow characteristics. When designing the feeding system, consider:

Select flow channel dimensions that accommodate the specific properties of the plastic material being used.

Facilitating Solidification Residue Removal

To ensure easy removal of solidified material from the feeding system:

Design for convenient and reliable residue removal

Choose appropriate ejection positions

Proper design for residue removal helps maintain part quality and reduces cycle times.

Minimizing Waste and Mold Size

To minimize waste and mold size:

Reduce the cross-section and length of the feeding system

Minimize plastic usage and mold size

Minimizing waste and mold size helps reduce material costs and improves sustainability.

Reducing Heat Dissipation and Pressure Drop

To reduce heat dissipation and pressure drop in the feeding system:

Keep flow paths short and ensure adequate cross-sectional area

Avoid sharp bends and sudden changes in flow direction

Maintain low surface roughness in flow paths

Consider multi-gating to reduce pressure drop and required injection pressure

By minimizing heat loss and pressure drop, you can improve the efficiency of the injection molding process.

Achieving Simultaneous Filling

In multi-cavity molds, it's important to achieve simultaneous filling of all cavities. To do this:

Ensure simultaneous material entry into each cavity

Maintain equal pressure at each cavity entrance

Achieving simultaneous filling helps ensure consistent part quality and reduces cycle times.

Feeding System Design Steps

Designing a feeding system for an injection mold involves several key steps. Each step plays a crucial role in ensuring the quality and efficiency of the molding process.

Determine the feeding method

Decide between a side gate, point gate, or runner-less system

Consider the product structure, size, and appearance requirements

Choose a feeding method that ensures proper filling and minimizes defects

Design the gate

Select the appropriate gate type (e.g., tab, edge, hot tip, tunnel)

Determine the gate location, size, and quantity based on the product design

Ensure the gate design facilitates easy removal and minimizes visible marks

Main runner dimensions and location

Calculate the main runner diameter based on the shot weight and material

Determine the main runner location considering the mold layout and gating points

Ensure adequate cross-sectional area to minimize pressure drop and heat loss

Sub-runner design

Determine the sub-runner layout based on the number and location of cavities

Select the appropriate sub-runner shape (e.g., circular, trapezoidal, half-round)

Size the sub-runners to ensure balanced flow and minimize pressure drop

Assistant runner design

Evaluate the need for assistant runners based on the product geometry and gating

Design assistant runners to improve flow balance and cavity filling

Determine the shape and size of assistant runners for optimal performance

Cold slug well design

Identify locations prone to cold material accumulation

Incorporate cold slug wells to trap cold material and prevent it from entering the cavity

Size the cold slug wells based on the runner system volume and material properties

Conclusion

A well-designed feeding system is crucial for producing high-quality injection molded parts efficiently. It ensures proper filling, minimizes defects, and reduces waste.

Collaborative efforts between OEMs and contract manufacturers are essential for optimizing feeding system design. By working together, they can leverage their expertise to create robust, cost-effective solutions that meet the unique requirements of each project.

Team Mfg has more than ten years of experience in injection molding services. Thousands of customers have achieved success because of us. If you have injection molding needs, please contact us immediately.