Job Specification:

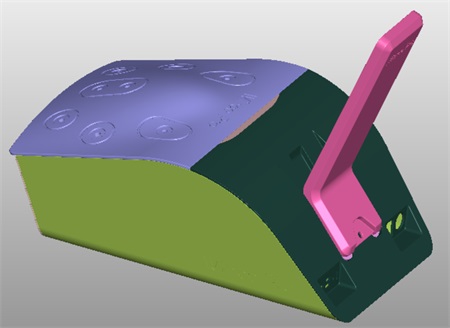

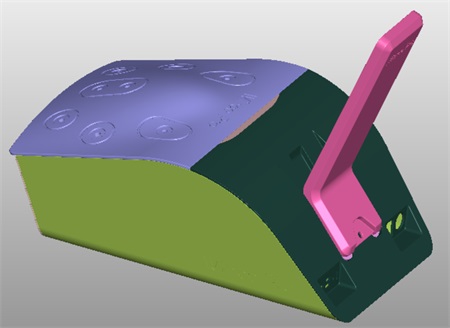

Project: Medical Device

Process Involved: CNC Machining, 3D Printing, Vacuum Casting, Painting, Silk Printing

Order Quantities: 20 Units

Lead-Time: 25 Calendar Days

Project Details:

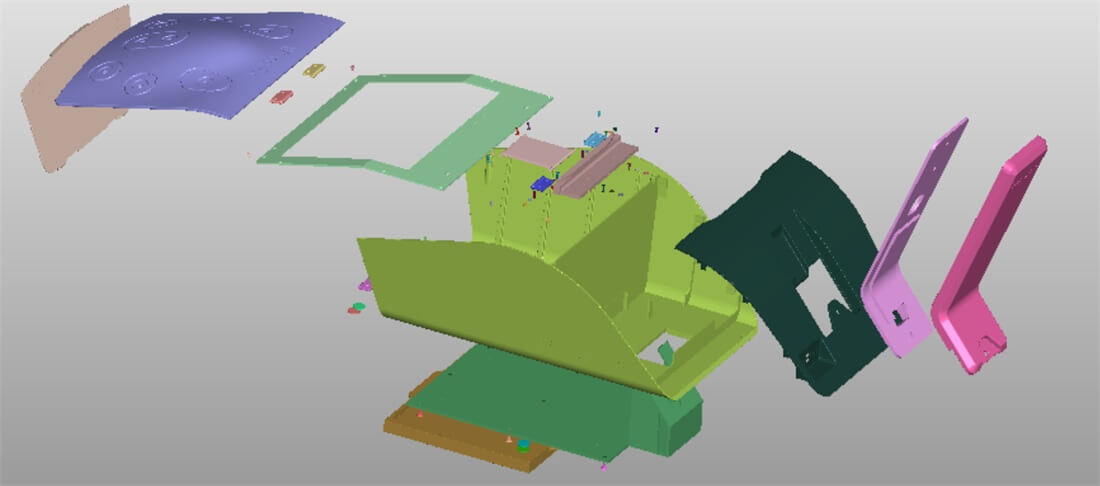

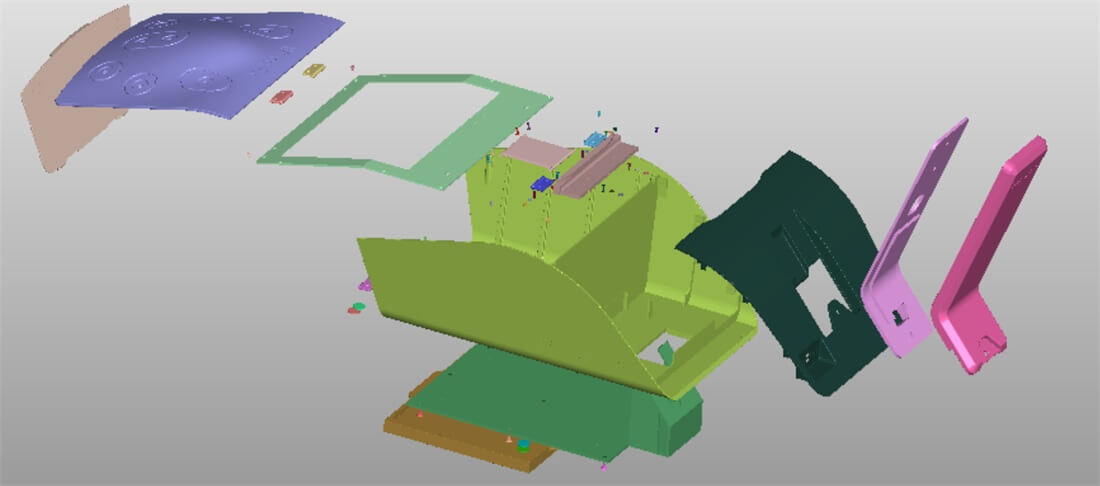

A medical company in Spain develops a new device for better medical treatment. Before moving forward to mass production, they need 20 units rapid prototypes quickly to test the assembly and function. It is a medical device that includes 15 PCS total plastic/metal parts.

How the parts were made:

1. Double confirmed with the customer about part's QTY, material and finish, the assembly especially for the clips, they needed to pay special attention to.

2. According to the device’s function and application, we suggested the manufacturing progress as follow: 4 parts made by CNC, 11 parts made by 3D printing & vacuum casting, and 3 parts processed silk printing after assembly. All the parts were suggested to full test assembly before shipment.

3. Settling down the progress, we started with the first unit parts built. We timely reported to the customer about the manufacturing process by email. Once all these first parts build, we started with assembly, we marked down all the potential issues during assembly and feedback solutions to our customer to improve design for following production.

4. Customer was happy with the first unit parts, TEAM MFG started with the following production. All these 20 units parts were build within 25 calendar days.

Are you looking for supplier to build rapid prototypes? Get in touch with us for your projects.