Why do injection-molded parts have a line around them? This "parting line" is crucial in manufacturing. Understanding it can improve your designs.

In this post, you'll learn what a parting line is and why it's essential. We'll discuss its impact on product quality and functionality.

What is a Parting Line in Injection Molding?

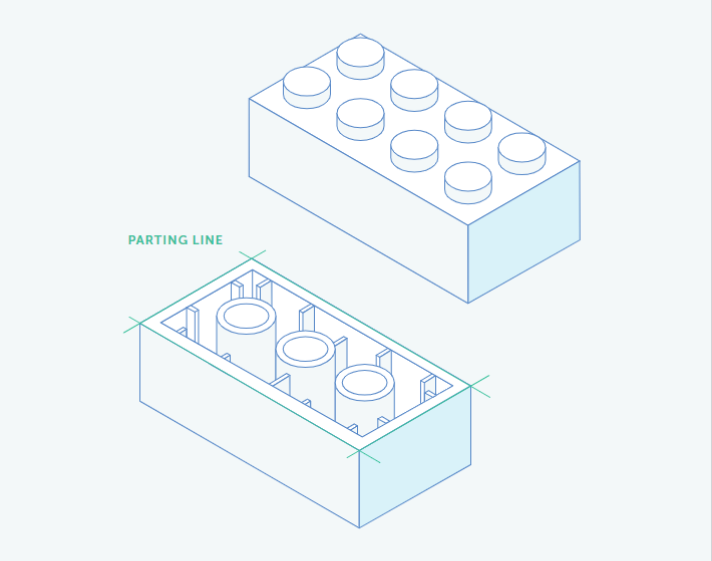

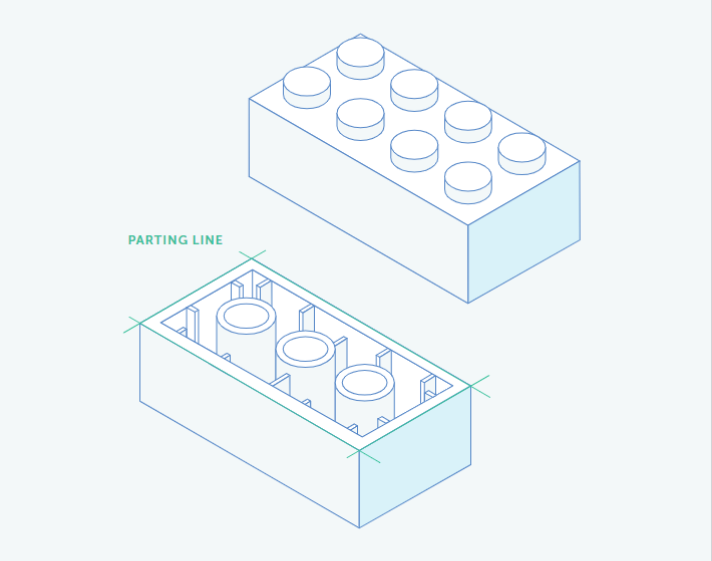

A parting line is where two halves of a mold meet. It appears as a thin line on the surface of injection-molded parts. This line is unavoidable but can be minimized or hidden. Designers often place it in less noticeable areas.

How Parting Lines are Formed

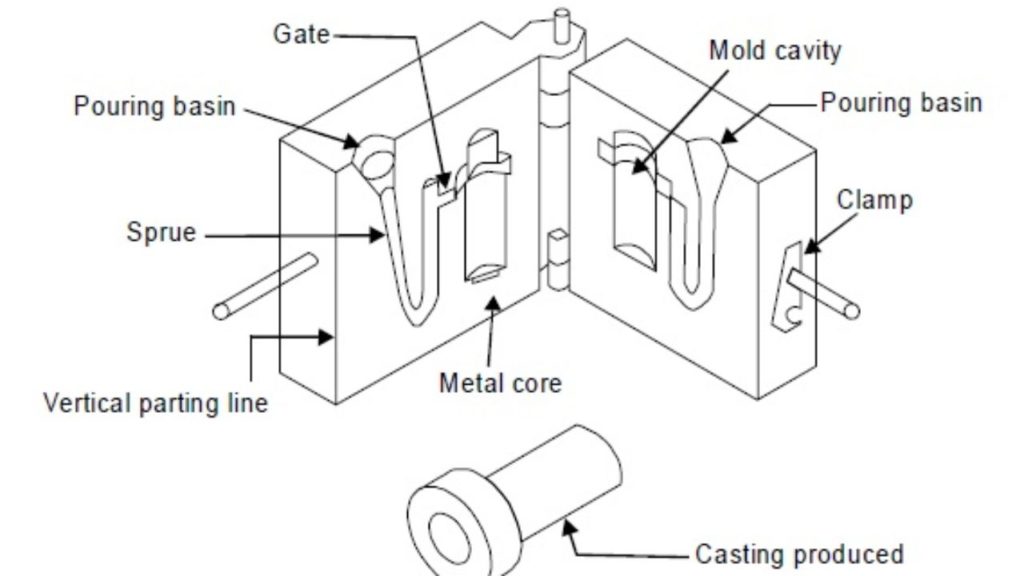

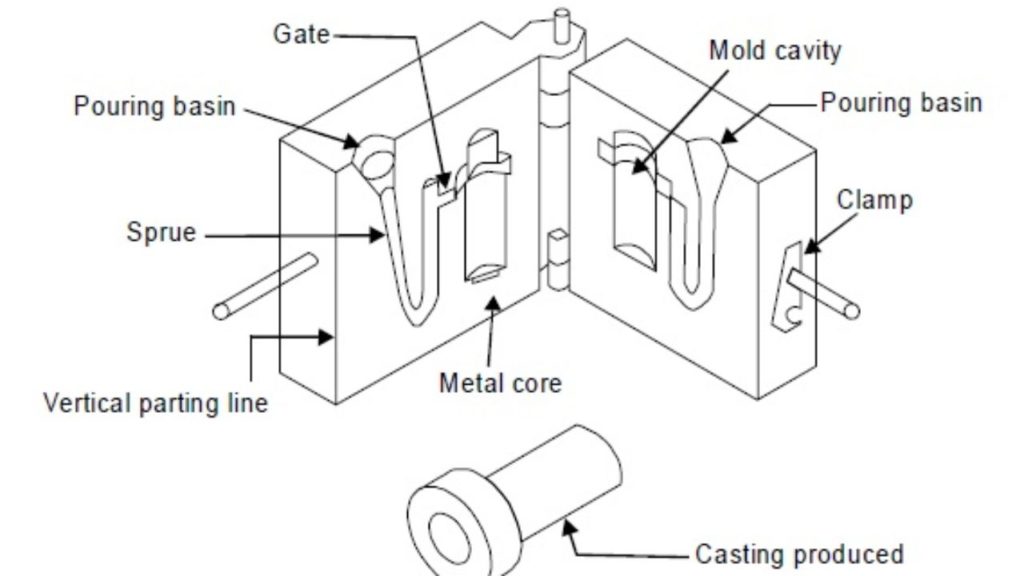

To understand how parting lines are formed, we need to take a closer look at the injection molding process itself. It all starts with the mold, which consists of two halves: the core and the cavity.

The two halves of the mold are clamped together

Molten plastic is injected into the mold cavity under high pressure

The plastic cools and solidifies, taking on the shape of the mold

The mold opens, and the finished part is ejected

It's during this process that the parting line is formed. When the two halves of the mold come together, they meet along a specific line or plane. This is known as the parting line.

The Relationship Between Parting Lines and Mold Halves

The location of the parting line is determined by the design of the mold halves. The core and cavity are carefully engineered to create the desired shape of the finished part.

Where these two halves meet, the parting line is created. It's essentially a seam that runs along the entire perimeter of the part.

| Mold Half | Function |

| Core | Forms internal features |

| Cavity | Forms external features |

The location of the parting line can have a significant impact on the appearance and functionality of the finished part. That's why it's so important for designers and engineers to carefully consider parting line placement during the design process.

Types of Parting Lines in Injection Molding

Now that we've covered the basics of parting lines, let's explore the different types you might encounter in injection molding. Each type has its own unique characteristics and applications.

Vertical Parting Lines

Vertical parting lines are the most common type. They run perpendicular to the direction in which the mold opens and closes. You'll often find them on parts with straightforward geometries, like cups or containers.

Advantages and Disadvantages

| Advantages | Disadvantages |

| Simple and cost-effective | Can be visually apparent |

| Suitable for many part designs | May require additional finishing |

Beveled Parting Lines

Beveled parting lines feature angled or sloped edges rather than straight ones. They're used to reduce the visibility of the parting line and minimize flash formation.

When to Use Beveled Parting Lines

Consider using beveled parting lines when:

Aesthetics are a top priority

You need to minimize flash

The part has intricate details near the parting line

Curved Parting Lines

As the name suggests, curved parting lines follow the contours of a part's curved surfaces. They're more complex than straight parting lines and require specialized mold design.

Applications for Curved Parting Lines

Curved parting lines are ideal for:

Parts with complex curves or contours

Designs that require a seamless appearance

Products with ergonomic features

Stepped Parting Lines

Stepped parting lines feature multiple levels or "steps" along the parting line. They're used to accommodate parts with varying wall thicknesses or to balance the clamping force on the mold.

Reasons for Using Stepped Parting Lines

You might choose stepped parting lines when:

The part has significant variations in wall thickness

You need to distribute clamping force evenly

The design requires multiple parting lines

Comprehensive Parting Lines

Comprehensive parting lines are a combination of vertical, beveled, curved, and stepped parting lines. They're the most complex type and are used for parts with highly intricate geometries.

Complex Parts That Require Comprehensive Parting Lines

Examples of parts that may require comprehensive parting lines include:

Automotive components with multiple features

Medical devices with precise tolerances

Consumer products with complex shapes and details

Designing for Parting Lines

When it comes to injection molding, parting line placement is just the beginning. To ensure high-quality parts, you need to consider a range of design factors that can impact the appearance and performance of your finished product.

Mold Design Factors

The design of your mold plays a crucial role in determining the location and appearance of parting lines. Here are a few key considerations:

Cavity and Core Alignment: The way the two halves of the mold come together can affect the visibility of the parting line. Proper alignment is essential for minimizing flash and ensuring a clean, seamless finish.

Surface Finish: The texture and finish of your mold surfaces can help to camouflage parting lines. Textured or matte finishes are often less likely to highlight parting lines than smooth, glossy surfaces.

Mold Flow: The flow of molten plastic within the mold can also impact parting line appearance. Strategic gate placement and flow simulation can help to optimize material distribution and minimize visible flow lines.

| Factor | Impact on Parting Lines |

| Cavity and Core Alignment | Affects visibility and flash formation |

| Surface Finish | Can help to camouflage parting lines |

| Mold Flow | Influences material distribution and flow lines |

Cooling and Shearing Rates

The way your part cools and solidifies within the mold can have a significant impact on its quality and durability. Here's what you need to know:

Cooling Rate: Uneven cooling can lead to warping, shrinkage, and other defects that can compromise the integrity of your part. Proper cooling system design is essential for maintaining consistent temperatures throughout the mold.

Shearing Rate: As molten plastic flows through the mold, it experiences shear forces that can affect its properties. High shear rates can lead to degradation and weakness, particularly along parting lines. Optimizing flow rates and gate locations can help to minimize these effects.

To optimize cooling and reduce stress on your parts, consider the following techniques:

Incorporate conformal cooling channels that follow the contours of your part

Use high-conductivity materials like beryllium copper for inserts and cores

Minimize variations in wall thickness to promote even cooling

Adjust injection speed and pressure to control shear rates

Ejection Process

Once your part has cooled and solidified, it needs to be ejected from the mold. This is where ejector pins come into play. However, if not properly designed, they can leave marks or cause damage along the parting line.

To minimize the impact of ejector pins on your parting lines, consider the following strategies:

Pin Placement: Position ejector pins away from critical surfaces or features whenever possible. This can help to minimize visible marks and maintain the integrity of your parting line.

Pin Design: Use ejector pins with a small diameter and a smooth, polished surface to reduce the risk of damage or flash formation. Specialized pin designs like blade ejectors or valve gate pins can also be used for specific applications.

Mold Release: Apply a suitable mold release agent to the surfaces of your mold to facilitate easy part removal and minimize the force required for ejection. This can help to reduce stress on the parting line and prevent flash formation.

Challenges with Parting Lines

While parting lines are a necessary part of injection molding, they can present some unique challenges, particularly when dealing with complex parts or trying to achieve a flawless finish. Let's take a closer look at some of these challenges and how to overcome them.

Handling Complex Shapes

Intricate designs with curves, undercuts, or multiple features can make parting line placement tricky. Here are some strategies for dealing with complex shapes:

Multi-Step Parting: Instead of a single straight parting line, use a multi-step approach that follows the contours of the part. This can help to minimize the visual impact of the parting line and ensure proper mold alignment.

Side Actions: Incorporate side actions or sliding cores into the mold design to create undercuts or features that would be impossible with a simple two-part mold. These additional mold components can help to create clean, precise parting lines in complex areas.

3D Printed Inserts: For particularly challenging geometries, consider using 3D printed inserts or cavities that can be easily swapped out or replaced. This can provide greater design flexibility and allow for more precise parting line control.

| Strategy | Advantage |

| Multi-Step Parting | Follows contours, minimizes visual impact |

| Side Actions | Creates undercuts and complex features |

| 3D Printed Inserts | Provides design flexibility and precision |

Regardless of the strategy you choose, precise mold alignment is critical. Even the slightest misalignment can lead to visible parting lines, flash, or other defects.

To ensure proper alignment, consider the following:

Use guide pins and bushings to maintain precise alignment between mold halves

Incorporate interlocks or alignment features into the mold design

Regularly inspect and maintain mold components to prevent wear and misalignment

Preventing Flash

Flash, or excess material that forms along the parting line, is a common challenge in injection molding. Not only does it detract from the appearance of the part, but it can also interfere with fit and function. So, what causes flash, and how can you prevent it?

Causes of flash formation include:

Poor mold alignment or wear

Insufficient clamping force

Excessive injection pressure or speed

Inadequate venting or cooling

To reduce and remove flash, try these methods:

Mold Maintenance: Regularly inspect and maintain your molds to ensure proper alignment and prevent wear. Replace worn components as needed and keep surfaces clean and free of debris.

Process Optimization: Adjust injection pressure, speed, and other process parameters to minimize flash formation. Use simulation software to identify potential problem areas and optimize your process accordingly.

Flash Traps: Incorporate flash traps or overflow wells into your mold design to catch excess material and prevent it from spreading along the parting line. These features can help to contain flash and make it easier to remove during post-processing.

Secondary Operations: If flash does occur, it can often be removed through secondary operations like trimming, sanding, or tumbling. Cryogenic deflashing, which uses extreme cold to embrittle the flash, can also be effective for certain materials.

Techniques to Reduce the Visibility of Parting Lines

While parting lines are an inevitable part of injection molding, they don't have to be a visible eyesore. There are several techniques you can use to minimize their appearance and create a more seamless finished product.

Surface Texture Camouflaging

One effective way to hide parting lines is by using surface textures that help to break up the visual continuity of the line. Here's how it works:

Texture Selection: Choose a texture that complements the design and function of your part. Options range from subtle matte finishes to more aggressive patterns like stipples or grooves.

Mold Texturing: The selected texture is applied directly to the mold surface, either through etching, engraving, or other means. When the molten plastic fills the mold, it takes on the texture of the mold surface.

Parting Line Placement: Strategic placement of the parting line within the textured area can help to further disguise its appearance. The texture helps to break up the line and make it less noticeable.

Examples of effective texture applications include:

Leather grain texture on automotive interior parts

Brushed metal finish on electronic housings

Woodgrain texture on furniture components

| Texture | Application |

| Leather grain | Automotive interiors |

| Brushed metal | Electronic housings |

| Woodgrain | Furniture components |

Secondary Processing Techniques

Even with careful design and mold texturing, some parting lines may still be visible or require additional finishing. That's where secondary processing techniques come in. Here are a few options:

Vibratory Tumbling: Parts are placed in a tumbler with abrasive media and vibrated for a set period. The abrasive action helps to smooth out parting lines and other surface imperfections.

Cryogenic Deflashing: Parts are exposed to extremely cold temperatures, typically using liquid nitrogen. This causes any flash or excess material along the parting line to become brittle and easily removable.

Hand Trimming: For smaller runs or delicate parts, manual trimming with a sharp blade or scissors can be effective at removing parting line flash. This method allows for greater precision and control.

Media Blasting: Parts are bombarded with a stream of abrasive media, such as sand, glass beads, or plastic pellets. This helps to smooth out parting lines and provide a more uniform surface finish.

The choice of secondary processing technique depends on several factors, including:

Material type and durability

Part geometry and complexity

Surface finish requirements

Production volume and cost constraints

Conclusion

In this article, we've explored the critical role of parting lines in injection molding. From understanding what they are and how they're formed to exploring the different types and design considerations.

By considering parting lines early in the design process and working closely with your injection molding partner, you can create high-quality parts that meet your performance and aesthetic requirements.

Need help with injection molding and parting line design? Team Mfg's experienced engineers are ready to assist. We offer comprehensive services, from design optimization to mold manufacturing and production. Contact us today for a free consultation and quote. Let Team Mfg bring your vision to life!