Have you ever wondered how plastic products pop out of molds perfectly shaped? Ejector pins play a crucial role. These small components ensure the efficient release of molded parts in injection molding.

In this post, you’ll learn what ejector pins are, why they’re essential, and how they fit into the injection molding process.

What Are Ejector Pins?

Ejector pins are crucial in plastic injection molding. These small components push molded parts out of the mold after cooling. Without ejector pins, removing parts would be difficult and could damage the mold.

Detailed Explanation of Ejector Pins

Ejector pins are part of the ejector system in mold making. They are installed in the B-side of the mold, which holds the formed part after cooling. When the mold opens, the ejector pins push the part out of the mold cavity.

The pins move perpendicularly to the mold surface. This ensures smooth part ejection without damaging the cavity surface. Ejector pins come in various types like through-hard pins, nitride H13 pins, and black ejector pins. Each type is chosen based on the specific needs of the molding process.

Importance in the Injection Molding Process

Ejector pins are vital for efficient production. They prevent parts from sticking to the mold, ensuring a smooth and fast ejection process. This helps maintain the quality of the molded parts and extends the mold's life.

Proper placement of ejector pins is crucial. Misplaced pins can cause defects like pin marks or pin impressions on the part surface. These blemishes affect the surface quality and appearance of the finished product. In high-volume production, even small delays or defects can lead to significant losses.

Common Materials Used for Ejector Pins

Ejector pins must withstand high temperatures and repeated use. Common materials include hardened steel, H13 tool steel, and stainless steel. Hardened steel pins offer durability and resistance to wear. H13 tool steel pins are known for their heat resistance, making them ideal for high-temperature molding processes. Stainless steel pins resist corrosion, ensuring longevity in various manufacturing environments.

Types of Ejector Pins

Through-Hard Ejector Pins

Characteristics and Applications

Through-hard ejector pins are made from materials hardened throughout their entire diameter. This uniform hardness ensures they withstand high stress during the molding process. They are ideal for plastic injection molding where precision and durability are critical.

These pins are commonly used in applications where the molding process operates below 200°C. Their consistent hardness makes them suitable for producing parts with complex geometries, ensuring minimal wear and tear.

Advantages and Disadvantages

Through-hard pins offer several benefits:

Durability: With uniform hardness, they resist deformation.

Precision: Ideal for high-precision molds, ensuring accurate part ejection.

However, they also have some drawbacks:

Nitride H13 Ejector Pins (Case-Hardened Pins)

Properties and Suitable Use Cases

Nitride H13 ejector pins, also known as case-hardened pins, have a hard surface layer and a tougher core. This design provides a balance between hardness and flexibility. These pins can withstand temperatures up to 600°C, making them suitable for high-temperature molding processes.

They are ideal for applications involving abrasive or corrosive materials. The hard surface resists wear, while the tougher core prevents bending or breaking.

Comparison with Through-Hard Pins

Compared to through-hard pins, nitride H13 pins offer:

However, they are typically more expensive and can be more challenging to machine.

Black Ejector Pins

Features and Benefits

Black ejector pins are treated with a special coating that enhances their performance. This coating, often a form of DLC (Diamond-Like Carbon), provides excellent lubricity and wear resistance. These pins can operate at temperatures up to 1000°C, making them ideal for the most demanding applications.

High-Temperature Applications

Due to their high heat resistance, black ejector pins are perfect for use in automotive and aerospace industries where parts must endure extreme temperatures. They help maintain surface smoothness and quality, even under harsh conditions.

Cost Considerations

While black ejector pins offer superior performance, they come at a higher cost. The advanced coating and heat treatment process make them more expensive than through-hard or nitride H13 pins. However, their longevity and performance benefits often justify the investment in high-stakes manufacturing processes.

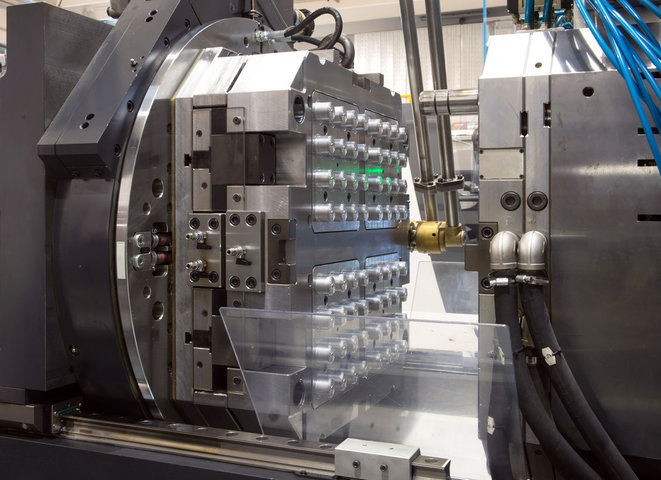

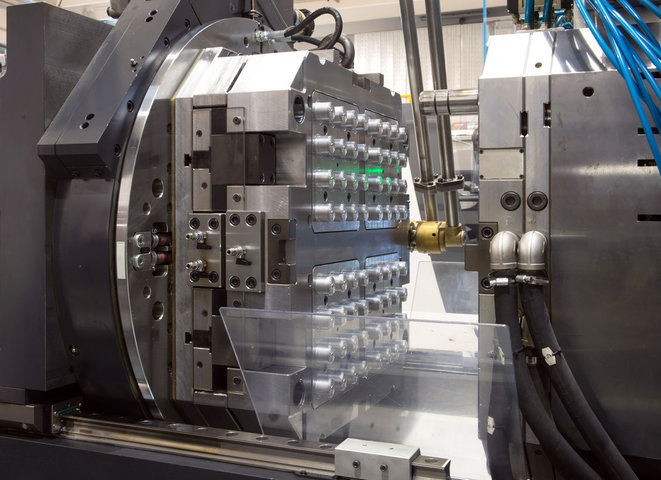

How Ejector Pins Work in Injection Molding

Ejector pins are crucial to the injection molding process, but how do they actually work? Let's break it down into three key phases:

Injection Phase

This is where the magic begins. Melted plastic material is injected into the mold cavity under high pressure. The material fills every nook and cranny of the mold, taking its shape.

Cooling Phase

Once the material is in the mold, it needs to cool and solidify. This is where patience comes into play. The cooling time depends on the material and the part's thickness.

Part Release Phase

Now for the grand finale – getting the part out of the mold! This is where ejector pins shine. There are two main methods:

Manual Ejection Systems

Operator manually removes the part

Often used for low-volume or custom molding

Allows for precise control and handling

Automatic Ejection Systems

Ejector pins or other mechanisms automatically push the part out

Ideal for high-volume production

Ensures consistent and efficient part removal

In automatic systems, the ejector pins are activated once the mold opens. They extend into the cavity, pushing against the solidified part. The part is then ejected and collected by a conveyor or other automated system.

Injection Molding Design Considerations for Ejector Pins

Draft Angles

Importance of Draft Angles for Part Removal

Draft angles are essential in injection molding. They facilitate the easy removal of molded parts from the mold cavity. Without draft angles, parts can stick to the mold, causing damage and defects. Draft angles ensure smooth part ejection and reduce the force required to remove the parts.

Recommended Draft Angle Values

The recommended draft angle varies depending on the material and part design. Generally, a draft angle of 1 to 2 degrees per side is sufficient. For parts with a textured surface, a draft angle of 3 to 5 degrees may be needed. Proper draft angles help maintain the surface quality of the molded parts.

Uniform Wall Thickness

Ensuring Proper Material Flow and Cooling

Uniform wall thickness is crucial for the proper flow and cooling of the material. It ensures consistent cooling rates and reduces the risk of defects like warping and shrinkage. Consistent wall thickness helps in achieving better surface finish and structural integrity.

Remedies for Non-Uniform Wall Thickness (Coring and Gussets)

Non-uniform wall thickness can cause issues in the molding process. Coring is one remedy, where material is removed from thick sections to make the walls uniform. Adding gussets can also help by providing support and reducing thickness variation. These techniques ensure even cooling and reduce stress on the molded parts.

Round Edges

Benefits of Round Corners for Part Ejection

Round corners are beneficial for part ejection. They reduce stress concentration and improve the flow of molten plastic into the mold. This results in smoother ejection and fewer defects. Round edges also prevent damage to the mold cavity.

Problems Associated with Sharp Corners

Sharp corners can cause several issues. They hinder the flow of plastic, leading to incomplete filling of the mold. Sharp corners also increase stress concentration, making the parts prone to cracking. Additionally, they can damage the mold, leading to higher maintenance costs.

Undercut Reduction

Impact of Undercuts on Part Ejection

Undercuts complicate the part ejection process. They create obstacles that prevent the part from being ejected smoothly. This can lead to defects like pin marks or pin impressions. Undercuts also increase the complexity and cost of mold making.

Strategies to Minimize Undercuts

Minimizing undercuts is essential for efficient part ejection. One strategy is to redesign the part to eliminate unnecessary undercuts. Another approach is to use side actions or lifters in the mold to handle necessary undercuts. These strategies help in reducing the risk of defects and improving the ejection process.

Gate Locations

Placement of Gates and Their Effect on Ejector Pin Marks

Gate placement affects the quality of molded parts. Poorly placed gates can cause pin marks or pin indentations. Proper gate placement ensures even filling of the mold and minimizes defects. Gates should be placed in locations that allow smooth flow of material and easy ejection of parts.

Using Edge Gates and Ejector Pin Extensions

Edge gates are beneficial in reducing ejector pin marks. They direct the flow of material towards the edges, reducing the likelihood of pin imprints on the visible surfaces. Ejector pin extensions can also help by pushing the part from less visible areas, ensuring a cleaner surface finish.

Ejector Pin Placement and Arrangement

Proper ejector pin placement is crucial for smooth part removal and to avoid defects. But how do you know where to put them? Several factors come into play.

Factors Influencing Ejector Pin Placement

Part Complexity and Mold Design

Material Characteristics

Ejector Pin Placement Tips

Spacing Between Pins and Cooling Channels

Placing Pins on Hard Parts

Focus pin placement on areas like inserts, pillars, and ribs

These areas can withstand ejection force better

Avoiding Placement on Slopes or Steps

Here's a quick reference table for pin placement:

| Part Feature | Pin Placement Tip |

| Hard areas (inserts, ribs) | Prioritize placement |

| Flat surfaces | Ideal location |

| Sloped or stepped surfaces | Avoid if possible |

| Near cooling channels | Ensure proper spacing |

Common Defects and Solutions Related to Ejector Pins

As crucial as ejector pins are, they can sometimes cause defects in molded parts. Don't worry, though! These issues can be solved with the right approach.

Ejector Pin Marks

Those pesky little dents on your part? They're likely caused by ejector pins. Here's what might be happening:

Causes:

Solutions:

Optimize pin placement to distribute force evenly

Adjust ejection force to the minimum necessary

Ensure adequate cooling time before ejection

Ejector Pin Breaks

Broken pins can bring production to a screeching halt. Why do they break?

Reasons:

Remedies:

Choose appropriate pin material and size for the application

Adjust ejection force and ensure even distribution

Regularly inspect and maintain mold components

Jetting

Jetting defects occur when the molten material doesn't flow smoothly into the mold. Instead, it "jets" in, causing visible flow lines or surface imperfections.

Causes:

Small gate size

Rapid injection speed

Improper gate location

Corrective Measures:

Increase gate size to allow better material flow

Adjust injection speed and pressure

Optimize gate location for even material distribution

Selecting the Right Ejector Pins for Your Application

Choosing the perfect ejector pins can feel like trying to find a needle in a haystack. But don't fret! We're here to help you navigate the options.

Pin Diameter and Size

Size matters when it comes to ejector pins. Consider these factors:

Larger diameters provide more ejection force

Smaller sizes minimize the visibility of pin marks

Match the pin size to your part's requirements

Strength Requirements

Your pins need to be strong enough to handle the ejection process without breaking. Keep in mind:

The ejection force required for your specific part

The material being molded

The number of cycles the mold will undergo

Material Selection

Not all ejector pin materials are created equal. Let's compare some common options:

| Material | Tensile Strength (MPa) | Benefits |

| Stainless Steel | 1900-2000 | Corrosion resistance, durability |

| Tool Steel | 1500 | Wear resistance, toughness |

| High-Speed Steel | 3900 | Extreme wear resistance, long life |

Stainless steel offers excellent strength and corrosion resistance. Tool steel provides a balance of wear resistance and toughness. High-speed steel, with its incredible tensile strength, is ideal for demanding, high-volume applications.

Ultimately, the right ejector pin material depends on your specific needs. Consider the molding environment, the material being molded, and the expected mold life.

Other Types of Ejectors in Injection Molding

While ejector pins are the most common type of ejectors, they're not the only players in the game. Let's take a look at some other ejector types that can help streamline your molding process.

Ejector Sleeves

Ejector sleeves are like the overprotective big brothers of ejector pins. They consist of a hardened outer sleeve and a pin that fits inside.

The sleeve protects the pin from wear and tear, making them ideal for molding abrasive materials. Plus, the added support of the sleeve allows for longer, more slender pin designs.

Ejector Plates

If ejector pins are the soldiers, ejector plates are the generals. These plates hold multiple ejector pins in place, ensuring they all work together in perfect harmony.

Ejector plates are especially useful for larger molds with many ejector pins. They provide a stable base for the pins and help distribute the ejection force evenly.

Ejector Blades

Ejector blades are like the ninjas of the ejection world. They're thin, flat strips of metal that sneak into tight spaces where regular pins can't go.

These blades are perfect for parts with narrow ribs or deep cavities. They apply ejection force over a larger area, reducing the risk of distortion or damage to the part.

Here's a quick comparison table:

| Ejector Type | Key Benefit |

| Sleeves | Protects pins from wear |

| Plates | Holds multiple pins in place |

| Blades | Fits in tight spaces |

Final Thought

Ejector pins are crucial in injection molding. They ensure smooth part ejection, maintaining the quality and integrity of molded parts.

Key takeaways for designing and using ejector pins include proper placement, ensuring uniform wall thickness, and using the right pin types. Draft angles, reducing undercuts, and strategic gate locations also improve ejection efficiency.

Experienced professionals play a vital role in optimizing ejector pin design. Their expertise helps in achieving high-quality molded products with minimal defects. Proper design and placement of ejector pins are essential for efficient, high-quality injection molding.

Need reliable injection molding services? Contact Team Mfg for high-quality parts at competitive prices. Our experienced team delivers results on time, every time. Reach out today to discuss your project needs.