Splay marks, or silver streaks, are a common but troublesome defect in injection molding. These streaks can ruin the appearance and strength of plastic parts. Addressing splay marks is crucial for improving both the quality and durability of products. In this post, you'll learn what causes splay marks, how to prevent them, and the best practices for optimizing your injection molding process to eliminate these defects.

What are Splay Marks?

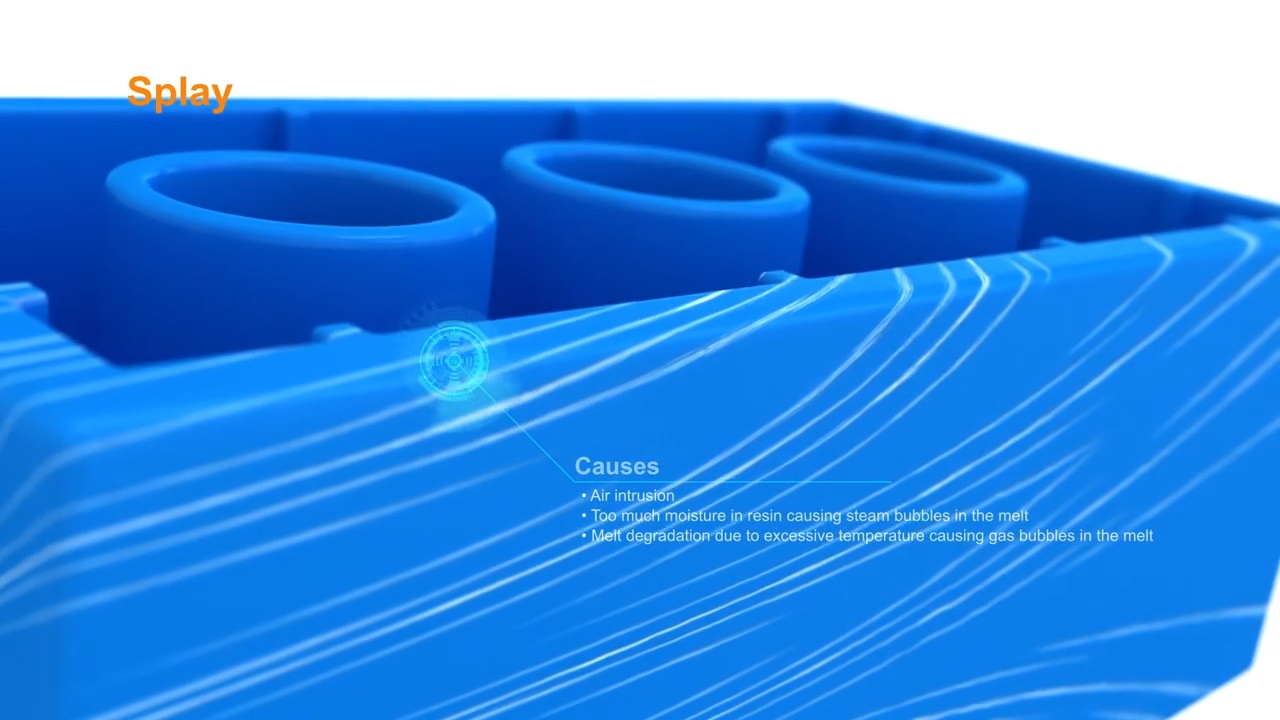

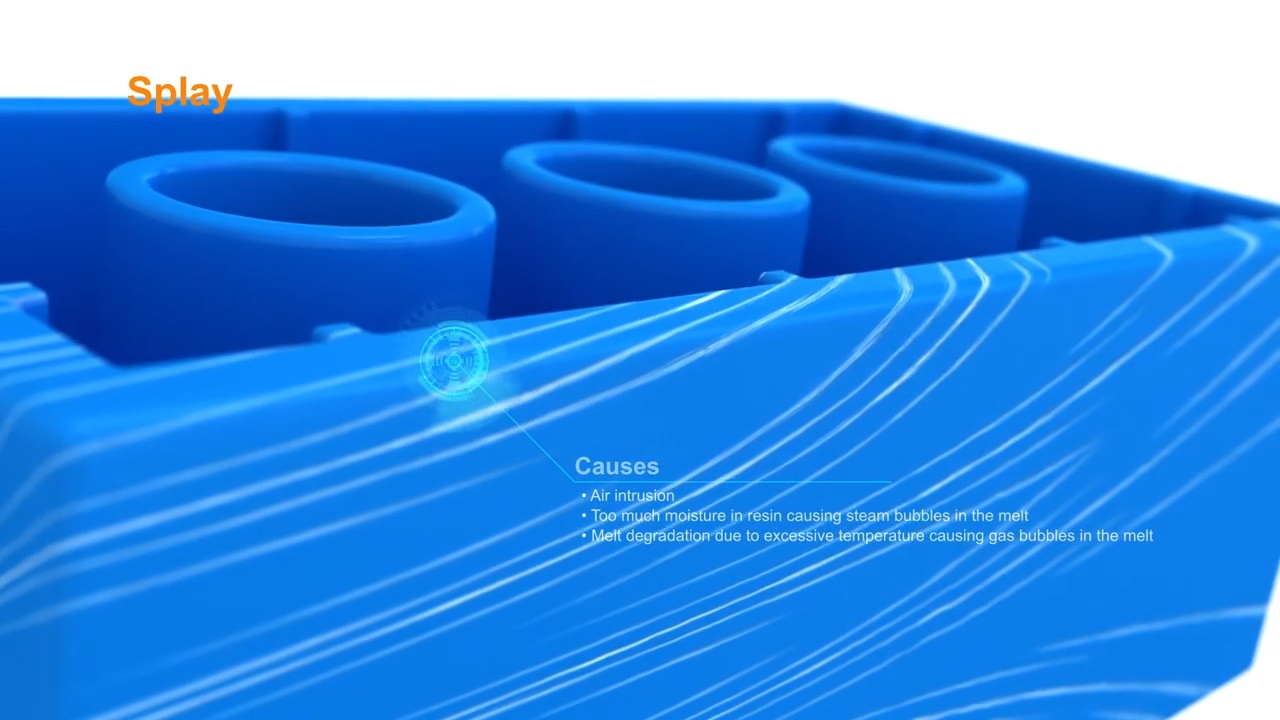

Splay marks, also known as silver streaks, are a common cosmetic defect that occurs in injection molded parts. These marks appear as silvery, streak-like patterns on the surface of the molded product, often following the direction of the material flow.

Detailed Description and Visual Appearance

Splay marks are characterized by their shiny, silver-colored appearance, which stands out against the surrounding surface of the part. They can manifest as thin, elongated lines or wider, more diffuse streaks.

In some cases, splay marks may resemble flow lines or other surface imperfections. However, their distinct silvery color and tendency to follow the material flow direction set them apart.

Impact on Part Aesthetics and Mechanical Properties

The presence of splay marks can significantly impact the visual appeal of injection molded parts. They are particularly noticeable on smooth, glossy surfaces and can detract from the overall aesthetics of the product.

In addition to their visual impact, splay marks may also affect the mechanical properties of the molded part. The areas with splay marks may exhibit reduced strength, brittleness, or other changes in material properties compared to the surrounding regions.

Classification of Splay Marks

Splay marks can be divided into several types, each with distinct characteristics:

Shear Splay: Appears as sharp, linear streaks, often near the gate area. These streaks are aligned with the flow of material and have a jagged or uneven appearance.

Heat Splay: Visible as fine, shiny streaks that look like a silvery film spread across the surface. These marks are often more scattered and less concentrated in one area.

Moisture Splay: Recognizable by their cloudy, hazy appearance, often in the form of irregular, dull streaks. These marks usually have a softer look compared to other types.

Decompression Splay and Air Splay: Typically show up as silver lines or bubbles, creating a random pattern across the part's surface. They may also appear as small, shiny spots scattered around the part.

Contamination Splay: Shows up as dark or discolored streaks, sometimes accompanied by surface roughness. These streaks often disrupt the uniformity of the part's color and finish.

Causes of Splay Marks in Injection Molding

Splay marks can arise from various factors related to the material, process, mold design, and machine. Let's explore the common causes in detail.

Moisture in the Plastic Material

Moisture is a significant contributor to splay marks. Hygroscopic plastics, such as nylon and polycarbonate, tend to absorb moisture from the environment.

This absorption can occur during storage, transportation, and handling. If not properly dried before molding, the moisture in the plastic will vaporize during the heating process, leading to splay marks.

Overheating of the Plastic Material

Excessive heat can also cause splay marks. This may result from:

When the plastic overheats, it can break down and release gases, which manifest as splay marks on the molded part surface. This is one of the many injection molding defects that can occur due to improper temperature control.

Shear-Induced Splay Marks

High shear stress during injection can lead to splay marks. This can be caused by:

The shearing action can degrade the plastic material, resulting in the formation of silver streaks. This is similar to how flow lines can form due to improper flow of material.

Air Entrapment

Trapped air in the mold cavity can contribute to splay marks. Poor venting in the mold or improper injection speed and pressure can prevent the escape of air, leading to air entrapment and subsequent splay marks. This issue can also contribute to other defects like short shots.

Gate and Runner Design Issues

The design of the gating system can influence the occurrence of splay marks. If the gate size is too small or obstructed, it can restrict the material flow and cause turbulence, leading to splay marks.

Similarly, poor gate location or shape can disrupt the flow pattern and contribute to splay formation. Understanding types of gates for injection molding is crucial in preventing these issues.

Contamination

Contamination of the plastic material can also result in splay marks. This can happen due to:

These contaminants can degrade or discolor the plastic, appearing as silver streaks on the molded part surface. Contamination can also lead to other issues like flash or weld lines.

Machine-Related Causes

The injection molding machine itself can contribute to splay marks. Overheating or improper purging of the machine can lead to degradation of the plastic material.

Poor maintenance and cleanliness of the machine can also introduce contaminants that cause splay marks. Machine-related issues can also lead to other defects like sink marks or warping.

| Cause Category | Specific Factors |

| Moisture | Hygroscopic plastics, absorption during storage/handling, vaporization during heating |

| Overheating | High barrel temperatures, prolonged residence time, high back pressure, thermal degradation |

| Shear | High injection speed/pressure, high screw speed, improper gate size |

| Air Entrapment | Poor mold venting, improper injection speed/pressure |

| Gate and Runner Design | Small/obstructed gate, poor gate location/shape |

| Contamination | Regrind material contamination, foreign particles |

| Machine-Related | Overheating, improper purging, poor maintenance/cleanliness |

Preventing Splay Marks in Injection Molding

Preventing splay marks requires a holistic approach that encompasses material selection, machine optimization, mold design, and contamination control. Let's dive into the key strategies.

Material Selection and Preparation

Choosing the right plastic material is crucial. Non-hygroscopic plastics, such as polypropylene or polyethylene, are less prone to moisture absorption and splay marks.

If hygroscopic materials are necessary, proper drying and storage are essential. Dehumidifying dryers can help control moisture content below 0.03%, minimizing the risk of splay marks.

Machine Settings Optimization

Optimizing machine settings is vital for preventing splay marks. This includes:

Adjusting barrel temperatures to avoid overheating

Controlling back pressure to minimize thermal degradation

Optimizing screw speed to reduce shear stress

Fine-tuning injection speed and pressure to prevent turbulence

Finding the right balance of these parameters is key to producing splay-free parts. Understanding the calculation formulas for injection molding can help in achieving optimal settings.

Mold Design Considerations

Mold design plays a significant role in preventing splay marks. Proper venting and gas escape paths are essential to avoid air entrapment.

Mold flow analysis can help optimize the venting design. Gate size and location also impact splay formation. Increasing runner cross-sections and improving gate shape can promote smooth material flow.

Uniform cooling and mold temperature control are crucial for preventing hot spots that can lead to splay marks. Proper temperature control also helps in maintaining injection molding tolerances.

Minimizing Contamination

Contamination control is critical for preventing splay marks. This involves:

Regular maintenance and cleaning of the injection molding machine

Controlled use of regrind material to avoid degradation

Implementing filtration systems to remove foreign particles from the melt

Keeping the machine and material clean and free from contaminants reduces the risk of splay marks.

| Prevention Strategy | Key Actions |

| Material Selection | Choose non-hygroscopic plastics when possible |

| Material Preparation | Proper drying and storage, use dehumidifying dryers |

| Machine Optimization | Adjust barrel temperatures, control back pressure, optimize screw speed, fine-tune injection parameters |

| Mold Design | Ensure proper venting and gas escape paths, optimize gate size and location, maintain uniform cooling |

| Contamination Control | Regular machine maintenance and cleaning, control regrind use, implement filtration systems |

Troubleshooting Splay Marks: Solutions and Remedies

When splay marks appear on injection molded parts, it's crucial to identify the root cause and take appropriate corrective actions. Let's explore the steps involved in troubleshooting splay marks.

| Troubleshooting Step | Key Actions |

| Root Cause Identification | Analyze splay mark appearance and distribution, conduct moisture tests, monitor machine settings, inspect mold |

| Process Parameter Adjustment | Fine-tune barrel temperatures, optimize injection speed and pressure, adjust screw speed and back pressure |

| Mold Modifications | Improve venting and gas escape paths, modify gate size and location, enhance cooling efficiency and uniformity |

| Material Drying and Conditioning | Implement proper drying procedures, use dehumidifiers or dryers, control storage and handling environment |

| Purging and Cleaning | Regularly purge injection molding machine, thoroughly clean mold and machine components |

Identifying the Root Cause

The first step is to analyze the appearance and distribution of the splay marks. Observe their morphological characteristics and location on the part.

This can provide clues about the underlying cause. Conducting material moisture content tests using infrared moisture analyzers can help determine if moisture is the culprit.

Monitoring machine settings and process parameters is also essential. Check if the injection molding parameters are appropriate for the material and part design.

Inspecting the mold for stress cracks, blocked water channels, or other issues can reveal potential contributors to splay marks.

Adjusting Process Parameters

Once the root cause is identified, adjusting the process parameters can often resolve splay marks. This may involve:

Fine-tuning barrel temperatures to prevent overheating

Optimizing injection speed and pressure to reduce shear stress

Adjusting screw speed and back pressure to minimize material degradation

Making incremental changes and monitoring the results can help find the optimal settings for splay-free parts.

Mold Modifications

If the mold design is contributing to splay marks, modifications may be necessary. This can include:

Improving venting and gas escape paths to prevent air entrapment

Modifying gate size and location to promote smooth material flow

Enhancing cooling efficiency and uniformity to avoid hot spots

Working closely with mold designers and toolmakers can help implement these modifications effectively.

Material Drying and Conditioning

For moisture-sensitive materials, proper drying and conditioning are crucial. Implement a robust drying procedure using dehumidifiers or dryers specifically designed for plastics.

Follow the material manufacturer's recommendations for drying temperature, time, and maximum moisture content. Maintaining a controlled environment during storage and handling can also prevent moisture absorption.

Purging and Cleaning

Regular purging of the injection molding machine can help remove degraded material and contaminants that contribute to splay marks. Use appropriate purging compounds and follow the machine manufacturer's guidelines.

Thorough cleaning of the mold and machine components, including nozzles, barrels, and screws, can prevent the buildup of residue that can cause splay marks.

Case Studies: Solving Splay Marks in Injection Molding

Example 1: Eliminating Splay Marks in an Automotive Interior Part

In this case, an automotive manufacturer faced silver streaks on a dashboard component. The splay marks appeared near the edges and on curved sections of the part. The team analyzed the characteristics and distribution of the splay marks, noting their random patterns across the surface.

Checking Injection Molding Parameters: The team adjusted the injection speed and temperature to ensure smoother material flow.

Inspecting Mold for Defects: They found minor imperfections in the venting system that were trapping air.

Testing Plastic Moisture Content: The plastic material was tested for moisture and found to be above recommended levels, requiring better drying procedures.

Comparing Part Surface Quality Before and After Adjustments: After optimizing the process, the streaks disappeared, and the surface quality improved significantly.

Example 2: Resolving Splay Marks in a Medical Device Component

A medical device manufacturer noticed splay marks on a critical plastic component used in surgical tools. These silver streaks affected the aesthetic and performance of the part, requiring immediate action.

Analyzing Splay Marks: The marks were predominantly on the narrow ends of the device.

Adjusting Machine Settings: The team reduced barrel temperature and adjusted back pressure.

Improving Mold Venting: Additional venting was added to allow trapped air to escape during the injection process.

After these modifications, the splay marks were eliminated, restoring the part’s appearance and functionality.

Example 3: Overcoming Splay Marks in a Consumer Electronics Housing

A company producing plastic housings for smartphones experienced splay marks along the edges and near screw bosses. The streaks were most prominent after cooling, causing issues with assembly.

Optimizing Material Drying: The team increased drying time to reduce moisture levels.

Reworking Gate Design: The gates were enlarged to improve material flow into the mold cavity.

Fine-Tuning Injection Speed: Slower injection speeds were applied to prevent shear-related streaking.

With these adjustments, the consumer electronics housing met quality standards, and production delays were avoided.

Conclusion

Addressing splay marks in injection molding is essential for ensuring high-quality, durable products. Preventing splay marks requires proper material drying, optimized mold design, and precise machine settings. Effective troubleshooting saves time and resources. Collaboration between designers, material suppliers, and injection molders is key to resolving these defects and improving overall production efficiency.

FAQs

Q: What are the most common causes of splay marks in injection molding?

A: The most common causes are moisture in the plastic, overheating, high shear stress, air entrapment, and contamination.

Q: How can I tell if moisture is causing splay marks in my parts?

A: Analyze the appearance and distribution of the splay marks. Conduct moisture content tests using infrared analyzers.

Q: What are the best practices for storing and drying plastic materials?

A: Store plastics in a controlled environment. Use dehumidifying dryers to remove moisture before molding.

Q: How do I optimize my injection molding process to prevent splay marks?

A: Adjust barrel temperatures, control back pressure, optimize screw speed, and fine-tune injection parameters. Ensure proper mold venting.

Q: Can splay marks be completely eliminated in injection molded parts?

A: While it may not be possible to eliminate them completely, splay marks can be significantly reduced through proper prevention and troubleshooting.

Q: What are the effects of splay marks on part performance?

A: Splay marks can impact the aesthetic appearance of parts. They may also indicate changes in material properties and reduced mechanical strength.

Q: Are splay marks always considered defects? Are there designs that "utilize" splay marks?

A: Splay marks are generally considered defects due to their impact on aesthetics and potential effects on part performance. There are no common designs that intentionally incorporate splay marks.

Q: What are the key points for daily maintenance and upkeep of molds and injection molding machines?

A: Regular cleaning and inspection of molds and machine components. Proper lubrication and timely replacement of worn parts.

Q: How to balance the trade-off between splay mark defects and production efficiency?

A: Implement robust process controls and monitoring systems. Utilize statistical process control to identify and address issues promptly. Continuously optimize process parameters for both quality and efficiency.