Ever wonder why PVC plastic is everywhere? From pipes to medical devices, this versatile material has revolutionized many industries. Discovered accidentally in 1872 by German chemist Eugen Baumann, PVC has since become a key material worldwide.

In this post, we’ll explore the properties, manufacturing processes, and types of PVC plastic. You’ll also learn about its wide range of uses and modifications that make it essential in industries today.

Understanding Polyvinyl Chloride (PVC)

What is PVC (Polyvinyl Chloride)?

PVC, or Polyvinyl Chloride, also called Vinyl, is a highly versatile thermoplastic polymer. It's known for its durability, affordability, and resistance to chemicals. Used in industries like construction, healthcare, and electronics, PVC is favored for its ability to withstand extreme conditions. Unlike some other plastics, PVC can be flexible or rigid, depending on the additives used during production.

PVC is a lightweight material. It's easy to work with and can be molded into various shapes, making it a go-to choice for many applications. Its excellent electrical insulation properties also make it ideal for wire and cable production.

Brief History of PVC Discovery and Development

PVC’s discovery was a happy accident. In 1872, German chemist Eugen Baumann exposed vinyl chloride gas to sunlight, producing a white solid — PVC. However, it wasn’t until 1913 that Friedrich Klatte patented a process to polymerize PVC using sunlight, paving the way for commercial use.

During World War I, Germany began producing flexible and rigid PVC products, which substituted corrosion-resistant metals. By mid-20th century, PVC had become one of the most widely produced plastics globally.

Properties of PVC Plastic

PVC boasts a unique set of properties that make it a versatile material for various applications.

| Property | Value |

| Density | 1.3-1.45 g/cm³ |

| Water Absorption (24h immersion) | 0.06% |

| Tensile Strength | 7500 psi |

| Flexural Modulus | 481000 psi |

| Notched Izod Impact Strength | 1.0 ft-lbs/in |

| Heat Deflection Temperature (264 psi) | 158°F |

| Coefficient of Thermal Expansion | 3.2 x 10-5 in/in/°F |

| Dielectric Strength | 544 V/mil |

Physical Properties

Density: PVC has a density of 1.3-1.45 g/cm³ for rigid PVC. This relatively high density contributes to its robustness and durability.

Water Absorption: PVC has low water absorption. When immersed for 24 hours, it only absorbs 0.06% water. This makes it resistant to moisture and suitable for outdoor use.

Mechanical Properties

Tensile Strength: PVC has a tensile strength of 7500 psi. This high strength allows it to withstand significant stress without breaking. It's ideal for applications that require toughness.

Flexural Modulus: PVC's flexural modulus is 481000 psi. This measure of stiffness ensures that PVC can maintain its shape under load.

Notched Izod Impact Strength: PVC's notched Izod impact strength is 1.0 ft-lbs/in. This indicates its ability to resist impact forces and avoid fracturing.

Thermal Properties

Heat Deflection Temperature: At 264 psi, PVC's heat deflection temperature is 158°F. This is the temperature at which it starts to deform under load. PVC maintains its shape well under moderate temperatures.

Coefficient of Thermal Expansion: PVC has a coefficient of thermal expansion of 3.2 x 10-5 in/in/°F. This measures how much it expands with temperature changes. PVC's low value means it maintains dimensional stability.

Electrical Properties

Chemical Properties

Chemical Resistance: PVC is resistant to many chemicals, including acids, bases, salts, and aliphatic hydrocarbons. This makes it suitable for use in corrosive environments.

Weathering Resistance: PVC can withstand exposure to sunlight and other weather elements. This property allows for its use in outdoor applications.

Advantages and Disadvantages

PVC's properties offer several advantages:

Low cost

High strength

Corrosion resistance

Flame retardancy

Excellent insulation

Easy to process

However, it also has some disadvantages:

Poor heat stability: PVC can degrade at high temperatures.

Plasticizer migration: Over time, plasticizers can leach out, affecting PVC's properties.

Potential toxicity: PVC contains chlorine, which can release toxic substances during production or disposal.

Manufacturing Process of PVC Plastic

Have you ever wondered how PVC plastic is made? It's a fascinating process that involves several steps. Let's explore the manufacturing journey of this versatile material.

Raw Materials

The primary raw materials for PVC production are:

Vinyl Chloride Monomer (VCM): VCM is produced by combining chlorine (derived from salt) and ethylene (from natural gas or oil). Ethylene dichloride is formed. It's then heated in a cracking unit to produce VCM.

Additives: Various additives are used to enhance PVC's properties:

Stabilizers: Prevent degradation during processing

Plasticizers: Enhance flexibility

Fillers: Improve mechanical properties

Lubricants: Aid in processing

UV stabilizers: Protect against sunlight degradation

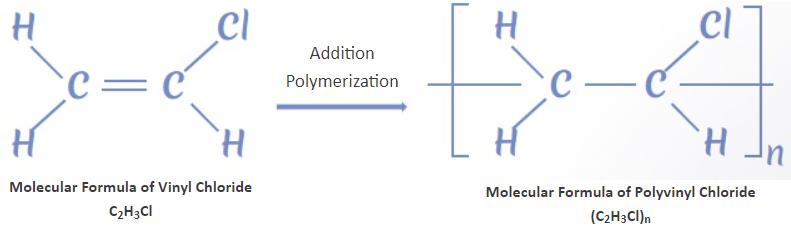

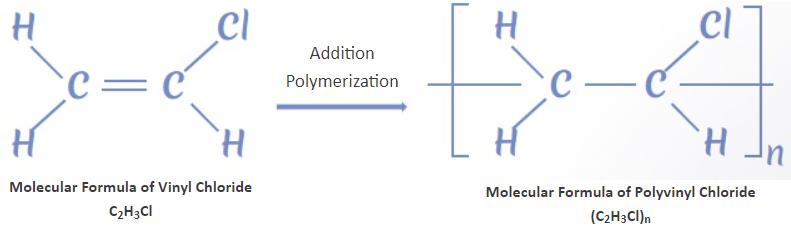

Polymerization Methods

PVC is synthesized through polymerization of VCM. The two main methods are:

Suspension Polymerization:

VCM is dispersed in water with initiators and additives.

Continuous mixing maintains suspension and uniform particle size.

Accounts for 80% of PVC production worldwide.

Emulsion Polymerization:

VCM is trapped inside soap micelles in water.

Water-soluble initiators are used.

Produces PVC with smaller particle size (0.1-100 μm).

Both methods involve heat to initiate polymerization. The resulting PVC resin is a white, brittle solid.

Compounding and Pelletizing

The PVC resin is mixed with additives in a process called compounding. This is done in mixers or extruders to produce a homogeneous blend.

The compounded PVC is then pelletized. It's extruded through a die and cut into small pellets. These pellets are easy to handle and ready for further processing.

Quality Control and Testing

Strict quality control measures are implemented throughout the manufacturing process. This ensures consistent properties and performance of the PVC.

Some common tests include:

Density measurement

Tensile strength testing

Impact resistance testing

Thermal stability testing

Chemical resistance testing

These tests help verify that the PVC meets the required specifications for its intended application.

The table below summarizes the key steps in PVC manufacturing:

| Step | Description |

| Raw Materials | VCM (from chlorine and ethylene) and additives |

| Polymerization | Suspension (80% of production) or emulsion |

| Compounding | Mixing PVC resin with additives to enhance properties |

| Pelletizing | Extruding and cutting compounded PVC into pellets |

| Quality Control & Testing | Verifying properties and performance through various tests |

Types of PVC Plastic

PVC comes in various types, each with unique properties and applications.

Rigid PVC (uPVC)

Also known as unplasticized PVC or PVC-U

Stiff and cost-effective

High resistance to impact, water, weather, and corrosive environments

Density: 1.3-1.45 g/cm³

Applications: Pipes, window frames, and construction materials

Flexible PVC

Flexible PVC Pipe

Contains plasticizers that impart flexibility

Classification based on plasticizer content:

Density: 1.1-1.35 g/cm³

Applications: Cables, hoses, and inflatable products

Flexible PVC Properties

Low cost

Flexible and high impact strength

Good resistance to UV, acids, alkalis, and oils

Non-flammable

Versatile performance profile

Chlorinated PVC (CPVC)

Produced by chlorination of PVC resin

Chlorine content increased from 56% to around 66%

Enhanced durability, chemical stability, and flame retardancy

Can withstand higher temperatures than regular PVC

Applications: Hot water pipes and industrial fluid handling

Oriented PVC (PVC-O)

Manufactured by stretching PVC-U pipes

Reorganizes amorphous structure into a layered structure

Enhances physical characteristics:

Stiffness

Fatigue resistance

Lightweight

Applications: High-performance pressure pipes

Modified PVC (PVC-M)

Alloy of PVC formed by adding modifying agents

Improves toughness and impact properties

Applications: Ducts, conduits, and fittings requiring enhanced durability

The table below summarizes the key types of PVC and their characteristics:

| Type | Description | Key Properties | Applications |

| Rigid PVC | Unplasticized, stiff | Impact, weather, and chemical resistance | Pipes, window frames, construction |

| Flexible PVC | Contains plasticizers for flexibility | UV, acid, alkali, and oil resistance | Cables, hoses, inflatables |

| Chlorinated PVC | Chlorine content increased to 66% | Enhanced durability, heat resistance | Hot water pipes, industrial fluid handling |

| Oriented PVC | Stretched PVC-U pipes | Improved stiffness, fatigue resistance | High-performance pressure pipes |

| Modified PVC | PVC alloy with modifying agents | Increased toughness and impact strength | Ducts, conduits, fittings |

Processing Methods for PVC Plastic

PVC's versatility is not just in its properties but also in the ways it can be processed. Let's dive into the various methods used to shape this material into useful products.

Extrusion

Extrusion is a continuous process that creates long, uniform profiles. PVC is melted and forced through a die to create the desired shape.

Injection Molding

Injection molding is used to create complex, three-dimensional parts. Molten PVC is injected into a mold cavity where it cools and solidifies.

Process Parameters:

Melt temperature: 170-210°C

Mold temperature: 20-60°C

These parameters ensure proper flow and cooling of the PVC

Considerations:

Thermoforming

Thermoforming involves heating a PVC sheet until it's pliable and then shaping it over a mold. The sheet is then cooled to retain the new shape.

Blow Molding

Blow molding is used to create hollow objects like bottles and containers. A tube of molten PVC, called a parison, is inflated inside a mold.

Calendering

Calendering is a process that produces thin, continuous sheets or films. PVC is passed through a series of heated rollers that compress and shape it.

3D Printing

3D printing, or additive manufacturing, is a relatively new method for processing PVC. It involves building up an object layer by layer from a digital model.

Advancements:

Limitations:

| Processing Method | Description | Key Points |

| Extrusion | Continuous process to create profiles | Pipe, tubing, sheets; lower temperatures than injection molding |

| Injection Molding | Creates complex parts by injecting into a mold | Melt temp: 170-210°C, mold temp: 20-60°C; corrosion-resistant molds |

| Thermoforming | Shaping heated PVC sheets over a mold | Pliable at 120-150°C; packaging, signs, automotive components |

| Blow Molding | Creates hollow objects by inflating a parison | Bottles, containers; suitable for chemicals |

| Calendering | Produces thin, continuous sheets or films | Films for packaging, labels; sheets for flooring, roofing |

| 3D Printing | Builds objects layer by layer from a digital model | New PVC filaments; potential damage to printer components |

These processing methods showcase PVC's adaptability. Each method has its own advantages and considerations. The choice of processing method depends on the desired end product and its requirements.

Modifications of PVC Plastic

PVC is rarely used in its pure form. It's often modified with various additives to enhance its properties and performance.

| Modification | Examples | Effects |

| Plasticizers | Phthalates, adipates, trimellitates | Increase flexibility, reduce strength |

| Heat Stabilizers | Calcium-zinc, tin-based | Prevent degradation during processing and use |

| Fillers | Calcium carbonate, titanium dioxide, glass fibers | Improve mechanical properties, reduce cost |

| Lubricants | Paraffin wax, stearic acid | Improve processability, reduce friction |

| UV Stabilizers | HALS, benzotriazoles | Protect against UV degradation |

| Impact Modifiers | Acrylic, MBS | Enhance toughness and impact resistance |

| Flame Retardants | Antimony trioxide, aluminum hydroxide | Improve fire resistance |

| Processing Aids | Acrylic-based, silicone-based | Enhance processability and surface quality |

| Blends | PVC/polyester, PVC/PU, PVC/NBR | Improve specific properties for targeted applications |

Plasticizers

Plasticizers are additives that increase the flexibility and workability of PVC. They reduce the polymer's crystallinity, making it more pliable.

Types:

Phthalates: Commonly used for flexibility in cables and hoses

Adipates and trimellitates: Used where higher performance is needed, such as in automotive interiors and medical devices

Effects on Properties:

Increase flexibility and elongation

Reduce tensile strength and hardness

Lower glass transition temperature

Heat Stabilizers

Heat stabilizers prevent PVC degradation during processing and use. They neutralize the hydrochloric acid (HCl) produced when PVC is exposed to heat.

Fillers

Fillers are used to improve PVC's mechanical properties and reduce costs. They can increase rigidity, strength, and dimensional stability.

Calcium Carbonate:

Titanium Dioxide:

Glass Fibers:

Lubricants

Lubricants are added to PVC to improve its processability. They reduce friction during extrusion and molding, preventing sticking and ensuring smooth flow.

External Lubricants:

Internal Lubricants:

UV Stabilizers

UV stabilizers protect PVC from degradation caused by sunlight exposure. They prevent discoloration, chalking, and loss of mechanical properties.

Impact Modifiers

Impact modifiers enhance PVC's toughness and resistance to impact. They improve the material's ability to absorb energy without cracking.

Flame Retardants

Flame retardants improve PVC's fire resistance, making it safer for use in various applications.

Antimony Trioxide:

Aluminum Hydroxide:

Processing Aids

Processing aids are additives that improve PVC's processability and surface quality.

Acrylic-Based Aids:

Silicone-Based Aids:

Blends with Other Thermoplastics

Blending PVC with other thermoplastics can improve its properties for specific applications.

PVC/Polyester Blends:

Enhance mechanical properties like abrasion resistance, tensile strength, and tear resistance

Suitable for automotive and industrial applications

PVC/PU Blends:

PVC/NBR Blends:

Increase flexibility and resilience

Commonly used for hoses, seals, and gaskets

These modifications showcase the incredible adaptability of PVC. By carefully selecting additives, manufacturers can tailor PVC's properties to suit a wide range of applications.

Applications and Uses of PVC Plastic

PVC's versatility makes it a go-to material for countless applications. From construction to healthcare, from automotive to consumer goods, PVC is everywhere.

Construction Industry

PVC is a workhorse in the construction sector. Its durability, resistance to weathering, and ease of installation make it an ideal choice for various applications.

Electrical and Electronics

PVC's excellent insulating properties and fire resistance make it a popular choice in the electrical and electronics industry.

Healthcare and Medical Devices

PVC's biocompatibility, clarity, and ability to be sterilized make it a crucial material in healthcare.

Automotive Sector

PVC's durability, chemical resistance, and moldability make it useful in various automotive applications.

Interior Components:

Used for dashboards, door panels, and seat covers

Provide good aesthetics and durability

Resistant to wear and UV exposure

Underbody Protection:

Protects against road debris and corrosion

Provides sound insulation

Lightweight and easy to apply

Packaging

PVC's clarity, chemical resistance, and ability to be molded make it a popular choice for packaging.

Consumer Goods

PVC's versatility and durability make it a common material in various consumer products.

| Application Area | Examples | Key Benefits |

| Construction | Pipes, windows, flooring | Durability, weathering resistance, easy installation |

| Electrical & Electronics | Cable insulation, conduits | Insulation, fire resistance, chemical resistance |

| Healthcare | Blood bags, surgical gloves | Biocompatibility, clarity, sterilizability |

| Automotive | Interior components, underbody protection | Durability, chemical resistance, moldability |

| Packaging | Food packaging, blister packs | Clarity, chemical resistance, moldability |

| Consumer Goods | Clothing, footwear, toys | Versatility, durability, safety |

These are just a few examples of the countless applications of PVC. Its unique combination of properties makes it an indispensable material in our modern world.

Environmental Considerations

Potential Release of Toxic Substances

PVC production and use can release harmful substances, particularly during manufacturing and disposal. Dioxins and vinyl chloride are by-products of PVC production, posing significant environmental and health risks. When PVC is burned or improperly processed, it can release these toxic chemicals, contributing to air pollution and health hazards for workers.

Plasticizer Migration and Residue

Flexible PVC often contains plasticizers to enhance its flexibility. Over time, these plasticizers may migrate from the material, potentially leaving harmful residues. Studies have shown that phthalates, a common type of plasticizer, can disrupt human health, affecting hormones and reproductive systems. This has led to growing concerns about the safety of flexible PVC in consumer products.

Impact of Heavy Metal-Based Heat Stabilizers

Historically, PVC has relied on heavy metal-based heat stabilizers, particularly lead, to prevent degradation during processing. While effective, these stabilizers pose significant risks when PVC is disposed of or recycled. Lead contamination in PVC waste makes recycling difficult and poses long-term environmental hazards.

| Heat Stabilizers | Potential Risks |

| Lead-based stabilizers | Environmental pollution, recycling challenges |

| Tin-based stabilizers | Safer but more costly |

| Calcium-zinc stabilizers | Non-toxic, eco-friendly alternatives |

Development of Non-Toxic Additives

In response to these concerns, the industry has shifted toward non-toxic and eco-friendly additive systems. Alternatives like calcium-zinc stabilizers have been developed to replace harmful heavy metals. These new additives maintain PVC's performance without compromising environmental or human health. Efforts are also underway to create bio-based plasticizers that do not pose the same risks as traditional phthalates.

Closed-Loop Recycling Systems

A key focus in the PVC industry is establishing closed-loop recycling systems. This involves recycling PVC waste back into production, reducing the need for new raw materials and minimizing environmental impact. VinylPlus, a European PVC recycling initiative, has made strides in facilitating the collection and recycling of PVC products. By ensuring that PVC waste can be reprocessed and reused, manufacturers aim to decrease landfill waste and promote a circular economy.

Recycling and Disposal of PVC

Recycling PVC is challenging due to the presence of additives and impurities. There are two main methods of recycling PVC:

Mechanical Recycling: Involves grinding and reprocessing PVC waste into new products. However, the presence of contaminants can reduce the quality of the recycled material.

Chemical Recycling: Breaks PVC down into its base components, which can be reused in new production processes. This method is more complex but allows for purer recycling.

Improper disposal of PVC, especially through incineration, releases harmful gases like hydrogen chloride. Safe disposal methods are critical to minimizing environmental harm.

Sustainable Manufacturing Practices

To address the environmental impact of PVC, manufacturers are adopting sustainable practices. These include reducing emissions during production and using renewable energy sources. By incorporating recycled PVC into new products, the industry can lessen its reliance on virgin materials. Companies are also exploring the use of bio-PVC, derived from renewable feedstocks, as a greener alternative to conventional PVC.

Alternatives to PVC

In certain applications, industries are exploring alternatives to PVC. Materials like polypropylene and thermoplastic elastomers (TPE) offer similar benefits with fewer environmental drawbacks. For example, TPE can replace flexible PVC in medical tubing, while polyethylene is often used in packaging applications. These alternatives are part of a broader effort to reduce reliance on potentially harmful materials.

Summary

PVC plastic is versatile, durable, and widely used in industries like construction and healthcare. It comes in flexible and rigid forms, with applications ranging from pipes to medical devices. New advancements in eco-friendly additives and recycling methods aim to make PVC more sustainable. As technology improves, bio-based PVC and non-toxic alternatives are emerging. To protect the environment, responsible use and proper disposal of PVC products are crucial for minimizing their impact.

Tips: You maybe interested to the all plastics