Polysulfone (PSU) plastic is a high-performance material known for its durability under extreme conditions. From medical tools to aerospace parts, PSU offers incredible strength, heat resistance, and chemical stability. In this post, you'll learn about PSU plastic's unique properties and why it's the top choice across various industries.

What is PSU Plastic?

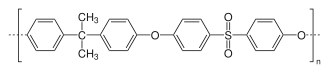

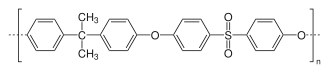

PSU, or polysulfone, is a high-performance thermoplastic known for its excellent properties. It is composed of repeating units of sulfone groups and aromatic rings, creating a strong and stable polymer structure.

This unique chemical composition gives PSU its outstanding characteristics, such as:

High temperature resistance

Excellent dimensional stability

Good chemical resistance

Remarkable mechanical strength

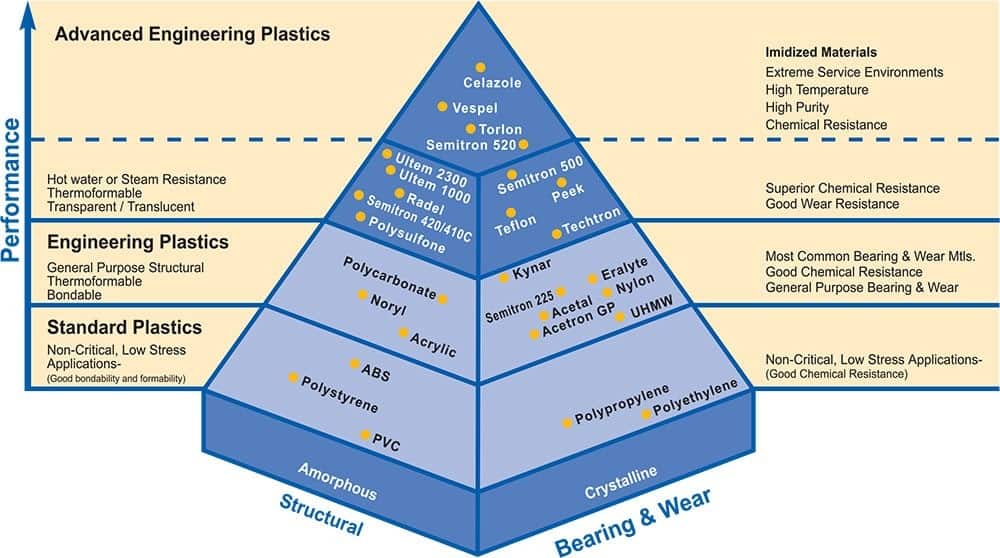

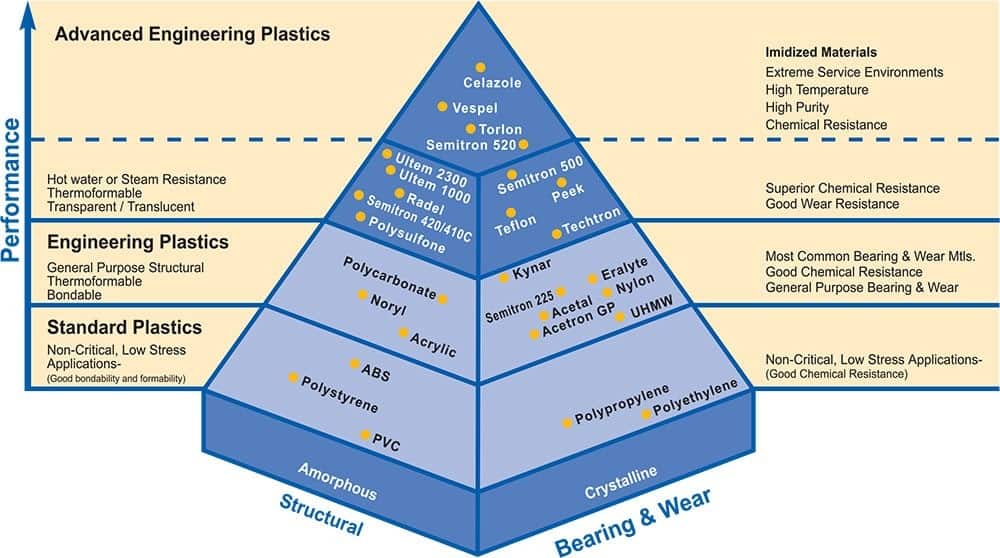

Compared to other thermoplastics, PSU stands out due to its ability to maintain its properties over a wide temperature range. It can withstand temperatures from -150°F (-100°C) to 300°F (150°C), making it suitable for demanding applications.

| Property | PSU | PVC | ABS |

| Maximum Service Temperature (°C) | 150 | 60 | 80 |

| Tensile Strength (MPa) | 70 | 50 | 45 |

| Flexural Modulus (GPa) | 2.48 | 2.4 | 2.3 |

Table 1: Comparison of PSU with other thermoplastics

PSU belongs to the family of amorphous thermoplastics. This means that its molecular structure is randomly arranged, unlike semi-crystalline plastics. The amorphous nature of PSU contributes to its:

Transparency

Dimensional stability

Isotropic properties

Ease of processing

The random molecular arrangement allows PSU to gradually soften when heated, making it suitable for thermoforming and other processing methods.

Figure 1: Simplified representation of PSU's molecular structure

Properties of PSU Plastic

PSU plastic is renowned for its exceptional properties. It offers a unique combination of mechanical, thermal, chemical, and electrical characteristics that make it a top choice for various applications.

Mechanical Properties

High Tensile Strength: PSU has a tensile strength of 10,200 psi (70 MPa). This means it can withstand significant stretching forces without breaking.

Excellent Flexural Strength: With a flexural strength of 15,400 psi (106 MPa), PSU can resist bending forces exceptionally well. It maintains its shape under load.

Good Impact Resistance: PSU has a notched Izod impact strength of 1.3 ft-lbs/in (69 J/m). It can absorb sudden impacts without cracking or shattering.

High Compressive Strength: PSU can withstand compressive forces up to 13,900 psi (96 MPa). This makes it suitable for applications where it may be subjected to crushing forces.

Thermal Properties

High Temperature Resistance: PSU can maintain its properties at elevated temperatures. It has a continuous service temperature of 285°F (140°C).

Excellent Thermal Stability: PSU's properties remain stable over a wide temperature range. Its heat deflection temperature is 358°F (181°C) at 66 psi and 345°F (174°C) at 264 psi.

Low Coefficient of Linear Thermal Expansion: PSU has a low CLTE of 3.1 x 10^-5 in/in/°F (5.6 x 10^-5 m/m/°C). This means it undergoes minimal dimensional changes with temperature fluctuations.

Chemical Resistance

Resistance to Acids, Alkalis, and Salt Solutions: PSU can withstand exposure to various chemicals. It is resistant to mineral acids, alkalis, and salt solutions.

Limitations: PSU is not resistant to esters, chlorine, and aromatic hydrocarbons. These chemicals can cause degradation or dissolution of the material.

Electrical Properties

Good Dielectric Strength: PSU has a dielectric strength of 425 V/mil (16.7 kV/mm). It provides excellent electrical insulation.

Insulating Properties: PSU's high electrical resistivity and low dielectric constant make it a good insulator. It can be used in electrical and electronic applications.

Additional Properties

Inherent Flame Retardancy: PSU is inherently flame retardant. It meets UL94 V-0 flammability rating without the need for additional flame retardants.

Food Grade Variations: Some grades of PSU are FDA compliant. They can be used in food contact applications.

Good Machinability: PSU can be machined using conventional techniques. It allows for the creation of intricate parts and components.

Other Important Properties

Dimensional Stability: PSU maintains its dimensions over time and under various conditions. It has low moisture absorption and minimal shrinkage.

Transparency: PSU is semi-transparent with an amber tint. This allows for visual inspection of contents in certain applications.

Resistance to Radiation: PSU has good resistance to radiation. It can withstand exposure to gamma rays and other forms of radiation without significant degradation.

| Property | Value |

| Tensile Strength | 10,200 psi (70 MPa) |

| Flexural Strength | 15,400 psi (106 MPa) |

| Izod Impact (Notched) | 1.3 ft-lbs/in (69 J/m) |

| Compressive Strength | 13,900 psi (96 MPa) |

| Continuous Service Temperature | 285°F (140°C) |

| Heat Deflection Temperature (66 psi / 264 psi) | 358°F (181°C) / 345°F (174°C) |

| Coefficient of Linear Thermal Expansion | 3.1 x 10^-5 in/in/°F (5.6 x 10^-5 m/m/°C) |

| Dielectric Strength | 425 V/mil (16.7 kV/mm) |

Table : Key properties of PSU plastic

Applications of Polysulfone (PSU)

Polysulfone (PSU) plastic is widely used across industries due to its excellent thermal, mechanical, and chemical properties. Let’s explore some of its key applications.

Medical and Healthcare

PSU is favored in the medical field for its ability to withstand repeated sterilization, ensuring safety and durability.

Sterilization Cases: PSU is perfect for medical sterilization cases due to its heat resistance and ability to endure repeated steam sterilization.

Dental Instruments: Used in various dental tools, PSU offers the necessary strength and resistance to sterilization processes.

Medical Devices: PSU’s chemical stability makes it ideal for components in devices that require constant sterilization.

Aerospace and Automotive

PSU’s strength and resistance to extreme environments make it a go-to material for aerospace and automotive parts.

Aircraft Interiors: PSU is used in aircraft interiors where strength, heat resistance, and flame retardancy are crucial.

Catering Trolleys: Its lightweight nature and durability make PSU ideal for airline catering trolleys.

Bearings and Precision Gears: PSU’s toughness ensures smooth operation in automotive bearings and precision gears, even under stress.

Electrical and Electronics

PSU’s dielectric strength and insulating properties make it valuable in electronics and electrical applications.

Connectors: PSU is often used in electrical connectors, providing excellent insulation and durability.

Coil Bodies: Its resistance to heat and chemicals makes it suitable for coil bodies in electrical equipment.

Insulating Components: PSU is the material of choice for insulating parts in various electronic devices.

Food Industry

PSU is safe for use in food handling and preparation, thanks to its chemical resistance and FDA-compliant grades.

Hot Water Fittings: It is commonly used in hot water fittings due to its ability to handle high temperatures without degrading.

Plumbing Manifolds: PSU’s durability makes it ideal for plumbing manifolds, especially those exposed to hot water.

Food Service Trays: PSU food trays are lightweight, durable, and able to withstand high temperatures in commercial kitchens.

Water Filtration and Purification

PSU’s resistance to chemicals and high temperatures makes it an excellent choice for water filtration components.

Tubes, Flanges, and Pump Components: PSU is used in tubes, flanges, and pumps for water purification systems. It resists chemical degradation, ensuring long-term performance in harsh environments.

| Application | Example Components |

| Medical | Sterilization cases, dental tools, devices |

| Aerospace | Aircraft interiors, trolleys, bearings |

| Electronics | Connectors, coil bodies, insulation |

| Food Industry | Hot water fittings, trays, manifolds |

| Water Filtration | Tubes, flanges, pump parts |

Modifications of Polysulfone (PSU)

While PSU already boasts impressive properties, it can be further enhanced through various modifications. These adaptations allow PSU to be tailored for specific applications and industries.

Blends for Enhanced Properties

Blending PSU with other polymers is an effective way to improve its performance. Two common blends are:

PSU/PA Blends:

Blending PSU with polyamides (PA) enhances its flow properties and toughness.

The semi-crystalline nature of PA also improves the chemical resistance of the blend.

These blends combine the strengths of both materials, resulting in a composite with improved overall properties.

PSU/PC Blends:

Combining PSU with polycarbonate (PC) can improve its flow properties while maintaining mechanical performance.

However, due to the amorphous nature of PC, there is no significant improvement in chemical resistance.

These blends are useful where better processability is required without sacrificing mechanical strength.

Tailored Additives

Incorporating additives into PSU can further enhance its properties. One common approach is using fillers:

Fillers:

Adding fillers to PSU can improve its mechanical strength and chemical resistance.

Common fillers include glass fibers, carbon fibers, and mineral fillers like talc or calcium carbonate.

The choice of filler depends on the specific property enhancement desired and the application requirements.

| Filler | Property Enhancement |

| Glass Fibers | Increased tensile and flexural strength, improved dimensional stability |

| Carbon Fibers | High strength-to-weight ratio, improved thermal and electrical conductivity |

| Talc | Increased stiffness, improved heat resistance, better dimensional stability |

| Calcium Carbonate | Increased stiffness, improved impact resistance, reduced cost |

Table: Common fillers used in PSU and their property enhancements

Application-Specific Modifications

PSU can be customized to meet the unique needs of various industries. Two notable examples are:

Aerospace:

In aerospace applications, PSU is often modified to improve its flame retardancy and smoke emissions.

Additives like phosphorus compounds or nanoclays can be incorporated to enhance these properties.

Additionally, reinforcements like carbon fibers can be used to increase the strength-to-weight ratio of PSU for lightweight aircraft components.

Medical:

For medical applications, PSU may be modified to improve its biocompatibility and sterilizability.

Antimicrobial additives can be incorporated to prevent the growth of bacteria and other microorganisms on medical devices.

The polymer matrix can also be tailored to ensure compatibility with various sterilization methods, such as autoclaving or gamma irradiation.

These are just a few examples of how PSU can be modified for specific industries. The versatility of PSU allows for countless customization possibilities, making it a valuable material for a wide range of applications.

Design Considerations

When designing products with PSU plastic, there are several critical factors to consider to ensure optimal performance.

Dimensional Stability

PSU is prized for its low coefficient of thermal expansion, making it ideal for parts that need to maintain exact dimensions.

| Property | PSU Plastic | Alternative Thermoplastics |

| Coefficient of Thermal Expansion | Low | Higher (less stable) |

| Temperature Tolerance | Up to 160°C | Lower in many materials |

Transparency Requirements

While PSU is semi-transparent, machining can affect its clarity.

Environmental Limitations

PSU is not suited for prolonged outdoor use without protection.

Lack of UV Resistance: Exposure to UV light can degrade PSU, leading to discoloration and weakened performance. It’s best used indoors or with protective coatings.

Weatherability: PSU performs poorly in environments with high exposure to sunlight or harsh weather. Alternative materials or coatings should be considered for outdoor applications.

Cost Considerations

While PSU delivers high performance, it comes at a higher price compared to other thermoplastics.

Balancing Cost and Performance: PSU's exceptional attributes, such as heat and chemical resistance, justify its cost for critical applications. However, for less demanding uses, materials like polycarbonate or acrylic may offer a more cost-effective solution.

| Material | Cost | Application Suitability |

| PSU | Higher | High-performance, high-temperature |

| Polycarbonate | Moderate | General-purpose, lower temperatures |

| Acrylic | Lower | Transparency-focused, outdoor use |

Precision Machining of PSU Plastic

Achieving precision machining of PSU plastic requires careful consideration of several factors. Annealing, machining best practices, and contamination prevention are crucial for optimal results.

Annealing

Annealing is a vital process in the precision machining of PSU plastic. It helps relieve internal stresses that can lead to cracking or premature failure.

The necessity and operating standards for stress relief annealing processes cannot be overstated. Proper annealing protocols ensure that machined PSU parts maintain their dimensional stability and mechanical properties over time.

Machining Best Practices

Selecting the right coolants and following best practices are essential for optimal machining results.

Suitable Coolants:

Non-aromatic, water-soluble coolants, such as pressurized air and spray mists, are most suitable for machining PSU.

They provide optimal surface finishes and maintain close tolerances.

Avoid using petroleum-based coolants, as they can attack and degrade PSU.

Extending Tool Life:

Proper coolant selection not only ensures better machining results but also extends tool life.

Coolants reduce heat and friction during machining, minimizing wear on cutting tools.

This leads to longer tool life, reduced tool replacement costs, and improved overall machining efficiency.

| Coolant Type | Suitability | Benefits |

| Non-aromatic, water-soluble coolants | Highly suitable | Optimal surface finish, close tolerances |

| Pressurized air and spray mists | Highly suitable | Reduced heat and friction, extended tool life |

| Petroleum-based coolants | Not suitable | Can attack and degrade PSU |

Table : Coolant suitability and benefits for machining PSU

Preventing Contamination

Contamination prevention is crucial when machining PSU, especially for industries with stringent cleanliness requirements, such as aerospace and medical.

Illustrative examples of the hazards of metal contamination include:

A medical device manufacturer found metal particles embedded in machined PSU components, leading to a product recall and significant financial losses.

An aerospace company experienced premature failure of PSU parts due to metal contamination, resulting in safety concerns and costly repairs.

To prevent such incidents, implement strict contamination control measures, such as:

Proper cleaning and maintenance of machining equipment

Regular inspection of machined parts for contaminants

Use of HEPA filtration systems to maintain a clean machining environment

Strict adherence to cleanliness protocols and standard operating procedures

Conclusion

Polysulfone (PSU) plastic stands out for its high temperature and chemical resistance. It offers mechanical strength and dimensional stability, making it suitable for industries like aerospace and medical devices.

When selecting PSU, balance cost and performance. PSU's higher price may not always be necessary for less demanding applications. Proper processing and contamination prevention are key to maximizing its performance.

Tips: You maybe interested to the all plastics