Is aluminum an alloy? What are the different types of aluminum? How to identify aluminum grades? These are common questions in manufacturing and engineering. While pure aluminum exists, most applications use aluminum alloys - materials that combine aluminum with other elements to enhance specific properties.

In this comprehensive guide to aluminum types and properties, we'll explore different grades of aluminum, common aluminum alloys, aluminum material types, and compare aluminum vs alloy characteristics. Whether you're choosing between magnesium alloy vs aluminum, looking for the strongest aluminum alloy, or need to understand aluminum specifications, this guide covers everything from aluminum series charts to aluminum hardness scales

What are Aluminum Alloys?

Aluminum alloys are a group of materials that consist of pure aluminum combined with other elements to enhance their properties and performance. These alloys are created by mixing molten aluminum with carefully selected alloying elements, resulting in a homogeneous solid solution upon cooling and solidification. The addition of these elements can significantly improve the strength, durability, and other characteristics of pure aluminum, making it suitable for a wide range of applications.

The composition of aluminum alloys typically includes:

Pure aluminum: The base metal that makes up the majority of the alloy, usually accounting for 85% to 99% of the total mass.

Alloying elements: Various metals and non-metals are added to aluminum to create specific alloys with desired properties. Common alloying elements include copper, magnesium, manganese, silicon, zinc, and lithium.

The effects of alloying elements on aluminum's properties are significant and varied:

Strength: Elements like copper, magnesium, and zinc can greatly increase the strength of aluminum alloys compared to pure aluminum.

Corrosion resistance: Some elements, such as magnesium and silicon, can enhance the natural corrosion resistance of aluminum by promoting the formation of a protective oxide layer.

Thermal and electrical conductivity: While pure aluminum is an excellent conductor of heat and electricity, the addition of certain elements can modify these properties to suit specific applications.

Formability and machinability: Alloying elements can influence the ease with which aluminum alloys can be shaped, formed, and machined, making them more versatile in manufacturing processes.

The importance of aluminum alloys in various industries cannot be overstated:

Transportation: Aluminum alloys are extensively used in the automotive, aerospace, and marine industries due to their high strength-to-weight ratio, which enables the production of lightweight and fuel-efficient vehicles and aircraft.

Construction: The corrosion resistance and durability of aluminum alloys make them ideal for architectural applications, such as window frames, roofing, and cladding.

Electronics: The excellent thermal and electrical conductivity of certain aluminum alloys, combined with their light weight, make them suitable for use in electronic components, heat sinks, and enclosures.

Consumer goods: From household appliances to sports equipment, aluminum alloys are used in a wide range of consumer products, thanks to their versatility, aesthetics, and recyclability.

| Property | Effect of Alloying Elements |

| Strength | Increased by copper, magnesium, and zinc |

| Corrosion resistance | Enhanced by magnesium and silicon |

| Thermal conductivity | Modified to suit specific applications |

| Electrical conductivity | Altered based on the alloying elements used |

| Formability | Influenced by the specific alloying elements present |

| Machinability | Affected by the composition of the aluminum alloy |

Aluminum Alloy Designations and Identification

Aluminum alloys are classified using a standardized naming system that provides essential information about their composition and properties. This system, developed by the Aluminum Association, consists of a four-digit number followed by a letter suffix indicating the temper condition. Let's dive into the details of this naming convention.

The Four-Digit Naming System

The four-digit number in an aluminum alloy designation conveys the following information:

The first digit represents the main alloying element or alloy series, for example:

The second digit indicates alloy modifications or impurity limits:

The third and fourth digits have different meanings depending on the alloy series:

1xxx series: The last two digits indicate the minimum aluminum purity, e.g., 1060 has a minimum of 99.60% pure aluminum.

Other series: The third and fourth digits identify different alloys within the series, but they have no numerical significance.

Here are some examples to illustrate the naming system:

1100: 99.00% minimum aluminum purity, original composition

2024: Copper as the main alloying element, fourth alloy variation in the 2xxx series

6061: Magnesium and silicon as main alloying elements, first alloy variation in the 6xxx series

Letter Suffixes for Temper Conditions

In addition to the four-digit number, aluminum alloy designations often include a letter suffix that indicates the temper condition or heat treatment state of the alloy. The most common temper designations are:

F: As-fabricated, without any specific control over thermal or strain hardening conditions

O: Annealed, the softest temper condition, achieved through high-temperature heating and slow cooling

W: Solution heat-treated, an unstable temper applied to alloys that age spontaneously at room temperature after solution heat treatment

T: Other stable heat-treated conditions, including various combinations of heat treatment and strain hardening

The T temper is further subdivided into several specific conditions, such as:

T3: Solution heat-treated, cold-worked, and naturally aged

T4: Solution heat-treated and naturally aged

T6: Solution heat-treated and artificially aged (precipitation hardened)

For example, 6061-T6 indicates a magnesium and silicon alloy that has been solution heat-treated and artificially aged to increase its strength.

| Temper | Description |

| F | As-fabricated, no specific control over thermal or strain hardening |

| O | Annealed, softest temper condition |

| W | Solution heat-treated, unstable temper |

| T | Other stable heat-treated conditions, including various subcategories |

Different Types of Aluminum Alloys

Aluminum alloys are divided into seven main categories based on their primary alloying elements and resulting properties. Each series is designated by a four-digit number, with the first digit indicating the major alloying element. Here's an overview of these aluminum alloy types:

1xxx Series (Pure Aluminum)

The 1xxx series consists of aluminum alloys with a minimum purity of 99%. They contain only trace amounts of other elements, which gives them unique properties:

High thermal and electrical conductivity, making them ideal for heat exchangers and electrical applications

Excellent corrosion resistance, suitable for use in chemical processing equipment

High ductility, allowing for easy forming and shaping

Common applications of 1xxx series alloys include chemical tanks, bus bars, and rivets.

2xxx Series (Copper)

Copper is the primary alloying element in the 2xxx series. These alloys are known for:

High strength, often comparable to steel

Heat-treatability, which further enhances their strength

Good machinability, facilitating precise manufacturing

Lower corrosion resistance compared to other aluminum alloys

The 2xxx series is commonly used in aerospace, military, and other high-performance applications.

3xxx Series (Manganese)

Manganese is the main alloying element in the 3xxx series. These alloys are characterized by:

Moderate strength, higher than pure aluminum but lower than other alloy series

Good formability, allowing for easy shaping and bending

Excellent corrosion resistance, suitable for use in harsh environments

Non-heat-treatable, meaning their properties cannot be significantly altered through heat treatment

Typical applications of 3xxx series alloys include cookware, automotive parts, and construction materials.

4xxx Series (Silicon)

Silicon is the primary alloying element in the 4xxx series. They are known for:

Excellent castability, making them suitable for complex shapes and designs

Good machinability, enabling precise manufacturing

Moderate strength, higher than pure aluminum but lower than other alloy series

Good heat dispersion, making them ideal for applications that require rapid heat dissipation

The 4xxx series is commonly used in engine blocks and other automotive parts.

5xxx Series (Magnesium)

Magnesium is the main alloying element in the 5xxx series. These alloys are characterized by:

Good strength, often used in structural applications

Excellent weldability, allowing for easy joining and fabrication

High corrosion resistance, particularly in marine environments

Non-heat-treatable, meaning their properties cannot be significantly altered through heat treatment

Common applications of 5xxx series alloys include marine components, automotive parts, and pressure vessels.

6xxx Series (Magnesium and Silicon)

The 6xxx series contains both magnesium and silicon as the primary alloying elements. They are known for:

Good strength, often used in structural applications

Excellent formability, allowing for complex shapes and designs

Good machinability, enabling precise manufacturing

High corrosion resistance, suitable for use in harsh environments

Heat-treatability, which can further enhance their strength and other properties

The 6xxx series is widely used in aerospace, automotive, construction, and other structural applications.

7xxx Series (Zinc)

Zinc is the primary alloying element in the 7xxx series, often combined with small amounts of other elements. They are characterized by:

The highest strength among all aluminum alloys

Good fatigue resistance, making them suitable for high-stress applications

Heat-treatability, which can further enhance their strength and other properties

Lower corrosion resistance compared to other aluminum alloys

Weldability, but with some precautions to avoid cracking

The 7xxx series is commonly used in aerospace, high-performance sports equipment, and other demanding applications.

8xxx Series: Specialized Alloys

The 8xxx series aluminum alloys include rare alloying elements like tin and other uncommon metals, designed for niche applications that demand unique characteristics. These alloys aren’t as widely used as the primary series but are essential in industries that require specific performance attributes.

Key Properties:

Specialized Functionality: Tailored to meet highly specific needs, such as resistance to friction or unique electrical conductivity.

Moderate Strength: Offers sufficient strength for niche applications, though not suited for high-stress environments.

Compatibility with Various Processes: Can be fabricated using different methods depending on the exact alloy composition, providing flexibility for specific industrial needs.

Common Applications:

Electrical and Electronic Components: High conductivity alloys in the 8xxx series are used in power cables, connectors, and wiring where conductivity is key.

Bearing and Bushing Applications: Alloys with tin provide low friction, making them suitable for bearings and other moving components where wear resistance is crucial.

Specialty Industrial Components: Other custom applications requiring properties like high ductility, low weight, or specific chemical resistance.

Aluminum Alloy Chart and Classification

The aluminum series chart below shows different types of aluminium materials:

| Alloy Series | Primary Alloying Element(s) | Key Properties |

| 1xxx | None (pure aluminum) | High conductivity, corrosion resistance, ductility |

| 2xxx | Copper | High strength, heat-treatable, good machinability |

| 3xxx | Manganese | Moderate strength, good formability, corrosion resistance |

| 4xxx | Silicon | Excellent castability, good machinability, heat dispersion |

| 5xxx | Magnesium | Good strength, weldability, corrosion resistance |

| 6xxx | Magnesium and Silicon | Good strength, formability, machinability, corrosion resistance |

| 7xxx | Zinc | Highest strength, good fatigue resistance, heat-treatable |

| 8xxx | Tin, Iron and Nickel, Other Rare Metals | Demand unique characteristics |

Key Aluminum Alloy Grades and Their Applications

Aluminum alloys come in various grades, each tailored for specific applications by balancing properties like strength, corrosion resistance, and formability. Below are some key aluminum alloy grades and the industries they support.

Detailed Overview of Specific Grades

1100

This grade is commercially pure aluminum, known for its excellent corrosion resistance and high thermal and electrical conductivity. Although it’s relatively soft, it’s ideal for applications where strength isn’t the primary requirement.

Applications: Commonly used in chemical handling, HVAC components, food processing equipment, and electrical conductors.

3003

A versatile, non-heat-treatable alloy, 3003 aluminum includes manganese for added strength and formability, making it suitable for a wide range of products.

Applications: Used in cookware, storage tanks, roofing, and general sheet metal work, due to its workability and corrosion resistance.

5052

5052 aluminum is recognized for its strong corrosion resistance, particularly in marine environments, as well as moderate-to-high strength. This makes it a top choice in settings exposed to saltwater.

Applications: Commonly used in marine applications, fuel tanks, pressure vessels, and industrial equipment due to its durability and weldability.

6061

Known as one of the most versatile aluminum grades, 6061 offers a balanced combination of strength, corrosion resistance, and machinability. It is heat-treatable, making it adaptable for structural applications.

Applications: Ideal for aerospace components, automotive frames, construction materials, and structural support elements.

7075

With one of the highest strength levels among aluminum alloys, 7075 is primarily used in high-stress applications. It’s less corrosion-resistant than other grades but excels in settings where high strength is critical.

Applications: Common in aerospace, defense, and high-performance sporting goods, where lightweight and high durability are essential.

Comparison Table of Key Aluminum Grades

| Alloy Grade | Composition Highlights | Key Properties | Common Applications |

| 1100 | 99% pure aluminum | High corrosion resistance, ductile | HVAC, chemical handling, food processing |

| 3003 | Aluminum with manganese | Moderate strength, good workability | Cookware, storage tanks, roofing |

| 5052 | Aluminum with magnesium | Strong corrosion resistance, weldable | Marine, fuel tanks, pressure vessels |

| 6061 | Magnesium and silicon | Heat-treatable, highly versatile | Structural components, aerospace, automotive |

| 7075 | Zinc as primary alloying element | Highest strength, low corrosion resistance | Aerospace, defense, sports equipment |

These aluminum grades provide manufacturers with options that balance performance and cost, meeting the requirements of industries from marine to aerospace.

Heat Treatment Processes for Aluminum Alloys

Heat treatment is a crucial step in the production of many aluminum alloys, as it can significantly enhance their mechanical properties, such as strength, hardness, and ductility. By carefully controlling the heating and cooling cycles, as well as the accompanying processes like cold working and aging, engineers can tailor the properties of aluminum alloys to meet specific application requirements.

Common Heat Treatment Processes and Their Designations

There are several common heat treatment processes used for aluminum alloys, each with its own unique designation. These designations provide a quick and standardized way to identify the specific heat treatment an alloy has undergone. Let's explore some of the most frequently used heat treatment processes and their designations.

T3: Solution Heat-Treated + Cold Worked + Naturally Aged

The T3 heat treatment process involves the following steps:

Solution heat treatment: The alloy is heated to a specific temperature and held there long enough to allow the alloying elements to dissolve into the aluminum matrix.

Cold working: The alloy is then cold worked, typically through stretching or rolling, to improve its strength and stress-corrosion resistance.

Natural aging: Finally, the alloy is allowed to age naturally at room temperature, which further enhances its strength and stability.

T3 heat treatment is commonly applied to alloys like 2024 and 7075, which are used in aerospace and other high-performance applications.

T4: Solution Heat-Treated + Naturally Aged

The T4 heat treatment process consists of two main steps:

Solution heat treatment: Similar to T3, the alloy is heated to a specific temperature and held there to allow the alloying elements to dissolve into the aluminum matrix.

Natural aging: The alloy is then allowed to age naturally at room temperature, which increases its strength and stability over time.

T4 heat treatment is often used for alloys like 6061, which find applications in various industries, including automotive, construction, and recreation.

T6: Solution Heat-Treated + Artificially Aged

The T6 heat treatment process involves the following steps:

Solution heat treatment: The alloy is heated to a specific temperature and held there to allow the alloying elements to dissolve into the aluminum matrix.

Artificial aging: The alloy is then heated to an elevated temperature (typically lower than the solution heat treatment temperature) and held there for a specific time to promote the controlled precipitation of the alloying elements, which significantly increases the alloy's strength and hardness.

T6 heat treatment is widely used for alloys like 2024, 6061, and 7075, which require high strength and hardness for demanding applications.

T7: Solution Heat-Treated + Overaged

The T7 heat treatment process consists of two main steps:

Solution heat treatment: The alloy is heated to a specific temperature and held there to allow the alloying elements to dissolve into the aluminum matrix.

Overaging: The alloy is then heated to a higher temperature than that used in T6 artificial aging and held there for an extended period. This process sacrifices some strength in favor of improved ductility, toughness, and dimensional stability.

T7 heat treatment is often applied to alloys like 7075, which are used in aerospace and other high-performance applications where a balance of strength and toughness is required.

T8: Solution Heat-Treated + Cold Worked + Artificially Aged

The T8 heat treatment process combines the benefits of cold working and artificial aging:

Solution heat treatment: The alloy is heated to a specific temperature and held there to allow the alloying elements to dissolve into the aluminum matrix.

Cold working: The alloy is then cold worked, typically through stretching or rolling, to improve its strength and stress-corrosion resistance.

Artificial aging: Finally, the alloy is heated to an elevated temperature and held there for a specific time to promote the controlled precipitation of the alloying elements, further enhancing its strength and hardness.

T8 heat treatment is commonly used for alloys like 2024 and 7075, which require a combination of high strength, hardness, and stress-corrosion resistance.

Special Secondary Designations for Stress Relief or Aging Extent

In addition to the primary heat treatment designations, there are also special secondary designations used to indicate specific stress relief or aging conditions. These designations are appended to the primary heat treatment designation, such as T7351 or T6511. Some common secondary designations include:

51: Stress relieved by stretching

511: Stress relieved by stretching and minor straightening after stretching

52: Stress relieved by compressing

54: Stress relieved by combined stretching and compressing

For example, 7075-T7351 indicates that the alloy has been solution heat-treated, overaged, stress relieved by stretching, and straightened after stretching.

Cast vs. Wrought Aluminum Alloys

Aluminum alloys can be broadly classified into two main categories: cast alloys and wrought alloys. While both types of alloys share the basic properties of aluminum, they differ in their composition, fabrication methods, and end-use applications. Let's explore these differences in more detail.

Differences in Alloy Composition

One of the primary distinctions between cast and wrought aluminum alloys lies in their chemical composition, specifically the percentage of alloying elements present.

Die Casting alloys typically contain higher amounts of alloying elements, often exceeding 5% of the total mass. These higher alloying percentages allow for improved castability, fluidity, and mold-filling capabilities during the casting process.

Wrought alloys, on the other hand, generally have lower alloying element percentages, usually below 5%. The lower alloying content in wrought alloys helps maintain good formability, workability, and ductility, which are essential for subsequent shaping and forming processes.

The differences in alloying element percentages can have significant effects on the mechanical and chemical properties of the final products:

Strength: Cast alloys often have higher strength compared to wrought alloys due to their higher alloying content. However, this increased strength comes at the cost of reduced ductility and toughness.

Ductility: Wrought alloys generally exhibit better ductility and formability than cast alloys, thanks to their lower alloying element percentages. This makes them more suitable for applications that require extensive shaping or forming.

Corrosion resistance: The corrosion resistance of aluminum alloys can vary depending on the specific alloying elements present. Some wrought alloys, like the 5xxx series with magnesium, offer excellent corrosion resistance, while certain cast alloys may be more susceptible to corrosion in harsh environments.

Fabrication Techniques

Another key difference between cast and wrought aluminum alloys is the way they are manufactured and shaped into final products.

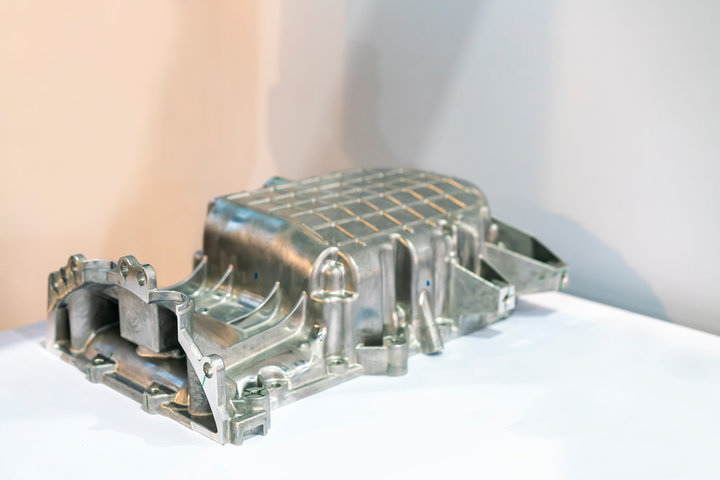

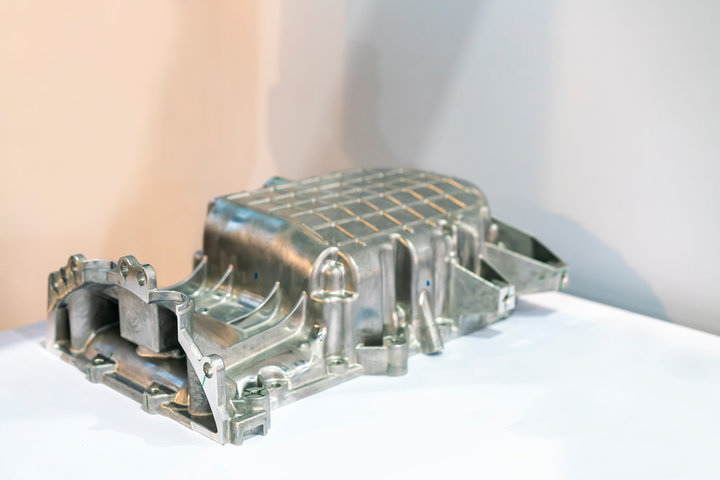

Cast aluminum alloys are produced using various casting methods, including:

Sand casting: Molten aluminum is poured into a sand mold, which is created using a pattern of the desired shape. Sand casting is versatile and cost-effective for low-volume production or large, complex parts.

Die casting: Molten aluminum is injected under high pressure into a steel die cavity. Die casting is suitable for high-volume production of parts with intricate details and tight tolerances.

Investment casting: A wax pattern is coated with a ceramic slurry, which is then heated to melt out the wax, leaving a hollow ceramic shell. Molten aluminum is poured into the shell to create the final part. Investment casting offers excellent surface finish and dimensional accuracy.

Wrought aluminum alloys, in contrast, are fabricated using various forming and shaping processes, such as:

Extrusion: Aluminum billets are pushed through a die opening to create long, continuous profiles with a consistent cross-section. Extrusion is commonly used to produce bars, tubes, and complex shapes.

Rolling: Aluminum slabs or ingots are passed through a series of rollers to reduce their thickness and create flat sheets or plates. Rolling can be done hot or cold, depending on the alloy and desired properties.

Bending: Wrought aluminum sheets or profiles are bent or formed into the desired shape using press brakes, roll formers, or other bending equipment. Bending allows for the creation of curved or angled parts.

Applications and Properties

The differences in composition and fabrication methods between cast and wrought aluminum alloys lead to distinct applications and properties.

Typical uses of cast aluminum alloys include:

Automotive parts, such as engine blocks, cylinder heads, and transmission cases, where complex shapes and high strength are required.

Cookware and bakeware, thanks to their good thermal conductivity and ease of forming intricate designs.

Decorative and ornamental items, like furniture and lighting fixtures, due to their ability to create detailed and aesthetically pleasing shapes.

Cast alloys are generally preferred for applications that require:

Complex geometries or intricate details that are difficult to achieve with wrought alloys

High strength-to-weight ratio, especially in load-bearing components

Good thermal conductivity for heat dissipation or heat transfer applications

On the other hand, typical uses of wrought aluminum alloys include:

Structural components in buildings, bridges, and transportation equipment, where high strength and good formability are essential

Aerospace parts, such as fuselage and wing components, due to their excellent strength-to-weight ratio and fatigue resistance

Electronic enclosures and heat sinks, thanks to their good thermal conductivity and ability to be formed into precise shapes

Wrought alloys are generally chosen for applications that require:

High ductility and formability for shaping and bending

Excellent strength-to-weight ratio for lightweight structural components

Good corrosion resistance in harsh environments or outdoor applications

| Property | Cast Alloys | Wrought Alloys |

| Alloying element % | Higher (>5%) | Lower (<5%) |

| Strength | Higher strength, lower ductility | Lower strength, higher ductility |

| Corrosion resistance | Varies depending on alloying elements | Generally good, especially 5xxx series |

| Typical fabrication | Sand casting, die casting, investment casting | Extrusion, rolling, bending |

| Common applications | Automotive parts, cookware, decorative items | Structural components, aerospace parts, electronics |

Considerations for Selecting Aluminum Alloys

Choosing the right aluminum alloy for a project requires understanding its machinability, cost, and compatibility with heat treatment. These factors influence manufacturing efficiency, costs, and product performance.

Machinability Rating

The machinability rating of an aluminum alloy impacts how easily it can be shaped using CNC machining. Alloys with high machinability save time and reduce tool wear, enhancing productivity in complex manufacturing.

Material Cost and Availability

Material selection significantly affects project budgets and manufacturing speed. High-cost alloys may offer superior properties but are less accessible or sustainable for large-scale projects.

Key Points to Consider:

Budget Constraints: Choosing an affordable alloy without compromising quality.

Supply Chain Availability: Ensuring steady supply to avoid delays in production.

Application-Specific Needs: Balancing cost with necessary properties like corrosion resistance and strength.

Heat Treatment Compatibility

Heat treatment allows specific aluminum alloys to increase their strength, durability, and performance. Not all alloys respond well to heat treatment, so understanding compatibility is crucial for applications requiring high strength.

| Consideration | Benefits in Selection | Key Alloys |

| Machinability Rating | Faster machining, less tool wear | 6061, 2011, 7075 |

| Material Cost & Availability | Budget-friendly, steady supply | 3003, 5052 |

| Heat Treatment Compatibility | Enhanced strength and hardness | 2024, 6061, 7075 |

Evaluating these factors ensures that the chosen aluminum alloy meets the project’s performance, budget, and processing needs, leading to optimized manufacturing and product reliability.

Summary

Understanding aluminum alloy types is essential for optimizing manufacturing and product performance. Selecting the right alloy for specific applications—whether it’s for strength, corrosion resistance, or machinability—can greatly impact quality and cost. From lightweight structures in aerospace to durable components in marine settings, each alloy serves a unique purpose. This guide provides a foundation for informed choices. Explore additional resources to deepen your knowledge and make the best alloy decisions for any project.

Reference Sources

Aluminum

Aluminum Alloy

6061 vs. 7075 Aluminum

Top Aluminum Process Manufacturer

Frequently Asked Questions (FAQs)

Q: What is an aluminum alloy?

An aluminum alloy is a metal created by mixing pure aluminum with other elements like magnesium, copper, or zinc to enhance strength, corrosion resistance, and durability.

Q: How do aluminum alloys compare to steel in terms of strength and weight?

Aluminum alloys are generally lighter than steel, providing a higher strength-to-weight ratio. They’re often used where weight reduction is essential, like in aerospace and automotive applications.

Q: What factors affect the machinability of aluminum alloys?

Machinability in aluminum alloys is influenced by alloy composition, heat treatment, and hardness. For instance, 6061 and 7075 alloys offer excellent machinability in CNC machining.

Q: How can I prevent corrosion when using aluminum alloys?

For best corrosion resistance, choose alloys with magnesium (like 5052) or apply protective coatings. Regular cleaning also prevents environmental build-up that can cause corrosion.

Q: Where are aluminum alloys commonly used?

Aluminum alloys are widely used in aerospace, automotive, construction, and electronics. Each industry selects specific alloys based on needs like strength, weight, and corrosion resistance.