Polyethylene (PE) is a versatile synthetic resin that has revolutionized our daily lives. It's the most widely used plastic in the world.

Discovered in the 1930s, PE has come a long way from its humble beginnings. Today, it's an essential material in countless industries.

From packaging to construction, PE plastic plays a crucial role in our modern world. In this post, we'll explore the fascinating world of PE plastic.

You'll learn about its properties, types, and applications that make it indispensable in our everyday lives.

Chemical Composition and Structure of PE Plastic

Chemical Formula

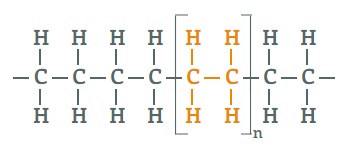

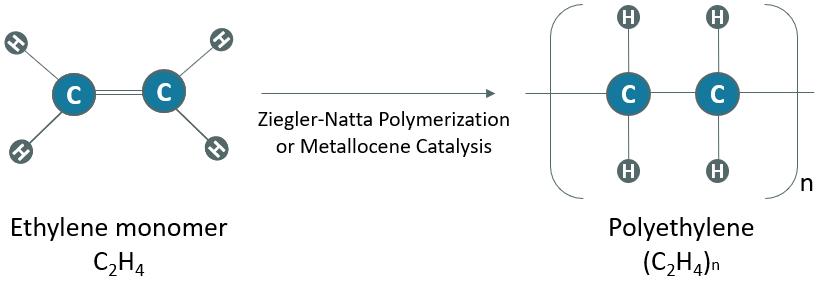

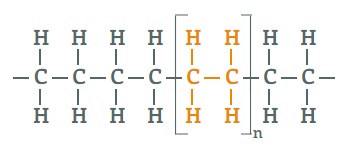

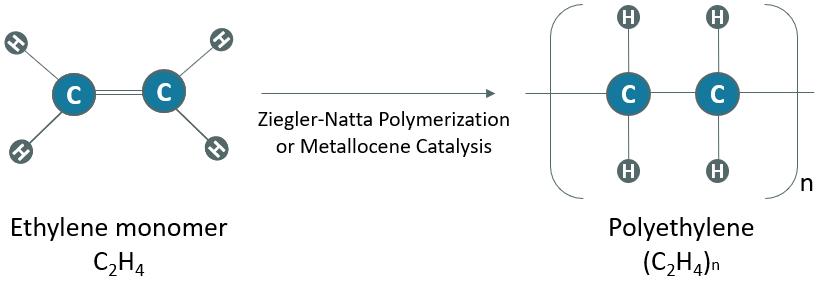

Polyethylene (PE) has a simple chemical formula: (C2H4)n. It consists of two carbon atoms linked to four hydrogen atoms. The "n" in the formula represents the repeating units of this structure. When many ethylene molecules (C2H4) join together, they form long chains, creating polyethylene.

Molecular Structure of PE

The process behind this is called polymerization. Ethylene monomers connect in a chain reaction, transforming into PE. This process can happen through various methods, like Ziegler-Natta polymerization or free radical polymerization. Each method slightly affects the PE's final properties.

Molecular Structure

PE's molecular structure plays a key role in its performance. The molecular weight of PE can vary significantly, and this affects the plastic's strength, flexibility, and durability. Higher molecular weight usually means stronger material, making it suitable for heavy-duty applications.

Branching is another important factor. PE can have different levels of branching in its molecular chains. More branching, like in Low-Density Polyethylene (LDPE), results in softer, more flexible plastic. On the other hand, High-Density Polyethylene (HDPE) has fewer branches, which makes it tougher and more rigid.

Crystallinity also impacts PE's behavior. The more crystalline a PE is, the more rigid and less transparent it becomes. For example, HDPE, which has a high degree of crystallinity, is used in products that require strength, like containers and pipes. In contrast, LDPE, with lower crystallinity, is perfect for plastic bags and flexible films.

Types of PE Plastic

Low-Density Polyethylene (LDPE)

Characteristics and Properties

LDPE is known for its flexibility and transparency. It's soft, tough, and resistant to impact.

Key properties:

Manufacturing Process

LDPE is produced using high pressure and temperature. The process involves:

Ethylene gas compression

Polymerization in a reactor

Cooling and pelletizing

Common Applications

High-Density Polyethylene (HDPE)

Unique Features and Benefits

HDPE is stronger and more rigid than LDPE. It offers:

Production Methods

HDPE is manufactured using low pressure and temperature. Methods include:

Slurry polymerization

Gas phase polymerization

Popular Uses in Industry

Linear Low-Density Polyethylene (LLDPE)

Comparison with LDPE

LLDPE combines features of LDPE and HDPE:

Manufacturing Techniques

LLDPE is produced using:

Ziegler-Natta catalysts

Metallocene catalysts

These methods allow for precise control of branching.

Specific Applications

Stretch wrap

Agricultural films

Flexible tubing

Cable coverings

Ultra-High Molecular Weight Polyethylene (UHMWPE)

Exceptional Properties

UHMWPE boasts:

Extremely high impact strength

Low coefficient of friction

Excellent abrasion resistance

Production Challenges

Manufacturing UHMWPE is complex due to:

Special techniques like compression molding are often used.

High-Performance Applications

Cross-Linked Polyethylene (PEX)

Benefits of Cross-Linking

Cross-linking enhances:

Temperature resistance

Chemical resistance

Mechanical strength

Manufacturing Process

PEX is produced by:

Creating HDPE

Cross-linking using peroxides, silane, or electron beam

Uses in Plumbing and Construction

Medium-Density Polyethylene (MDPE)

Properties and Characteristics

MDPE offers a balance between HDPE and LDPE:

Production Methods

MDPE is typically produced using:

Applications in Gas Pipes and Fittings

Ethylene Copolymers

Types of Copolymers

Common ethylene copolymers include:

Ethylene Vinyl Acetate (EVA)

Ethylene Acrylic Acid (EAA)

Ethylene Methacrylic Acid (EMAA)

Unique Properties and Advantages

Ethylene copolymers offer:

Improved flexibility

Enhanced adhesion

Better clarity

Increased toughness

Specific Applications

Key Properties of PE Plastic

Density Variations

PE plastics come in various densities. This property significantly influences their characteristics and applications.

Here's a quick breakdown:

LDPE: 0.910-0.925 g/cm³

LLDPE: 0.915-0.925 g/cm³

MDPE: 0.926-0.940 g/cm³

HDPE: 0.941-0.965 g/cm³

Higher density typically means greater strength and stiffness. Lower density offers more flexibility and impact resistance.

Molecular Weight Impact

Molecular weight plays a crucial role in PE properties. It affects strength, toughness, and processability.

Key points:

UHMWPE, with its extremely high molecular weight, showcases exceptional strength and wear resistance.

Chemical Resistance

PE plastics generally exhibit excellent chemical resistance. They're inert to many substances.

Resistance varies by PE type:

HDPE: Superior resistance to chemicals and solvents

LDPE: Good resistance, but can be affected by some hydrocarbons

PE resists acids, bases, and most solvents. It's not resistant to strong oxidizing agents.

Temperature Tolerance

PE plastics can withstand a range of temperatures. Their performance varies based on type and grade.

General temperature ranges:

LDPE: -50°C to +80°C

HDPE: -60°C to +120°C

UHMWPE: -200°C to +80°C

PEX offers improved high-temperature resistance, suitable for hot water pipes.

UV Resistance

Unmodified PE is susceptible to UV degradation. Prolonged sun exposure can cause brittleness and color changes.

To improve UV resistance:

Add UV stabilizers

Incorporate carbon black (for black PE products)

UV-stabilized PE finds use in outdoor applications like agricultural films and outdoor furniture.

Food Safety Considerations

Many PE types are FDA-approved for food contact. They're non-toxic and don't impart taste or odor.

Food-safe PE characteristics:

Low migration of additives

Resistant to microbial growth

Easy to clean and sterilize

HDPE and LDPE are commonly used in food packaging. UHMWPE is suitable for food processing equipment.

Remember: Always check specific grades for food safety compliance.

Detailed Property Comparison of PE Types

| Property | LDPE | LLDPE | MDPE | HDPE | UHMWPE |

| Density (g/cm³) | 0.910 - 0.925 | 0.915 - 0.925 | 0.926 - 0.940 | 0.941 - 0.965 | 0.930 - 0.935 |

| Crystallinity | Low (40-50%) | Medium (50-60%) | Medium-High | High (70-80%) | Very High (>85%) |

| Tensile Strength (MPa) | 8-12 | 10-30 | 20-35 | 20-40 | 40-48 |

| Melting Point (°C) | 105 - 115 | 120 - 130 | 125 - 135 | 130 - 137 | 130 - 135 |

| Flexibility | Most flexible | Flexible | Moderate | Less flexible | Least flexible |

| Rigidity | Least rigid | Slightly rigid | Moderately rigid | Rigid | Most rigid |

| Key Features | Flexible, transparent | Improved strength, puncture resistant | Balance of properties | Strong, chemical resistant | Extremely strong, wear resistant |

| Common Applications | Films, bags | Stretch wrap, tubing | Gas pipes, cables | Bottles, pipes | High-performance parts |

Note: The exact values may vary slightly depending on specific grades and manufacturers.

Processing Techniques for PE

PE plastic is versatile. It can be processed using various methods.

Injection Molding

Injection molding is popular for mass-producing PE parts. Here's how it works:

PE pellets are melted.

The molten plastic is injected into a mold.

The mold is cooled, solidifying the plastic.

The finished part is ejected.

This method is great for creating complex shapes. It's used for bottle caps, containers, and toys.

Extrusion

Extrusion is used to create continuous profiles. The process involves:

Melting PE pellets.

Forcing the molten plastic through a die.

Cooling and solidifying the extruded shape.

It's ideal for producing pipes, tubing, and wire coatings.

Blow Molding

Injection molding is perfect for hollow objects. Here's the process:

A PE tube (parison) is extruded.

The parison is clamped in a mold.

Air is blown into the parison, expanding it to the mold's shape.

The part cools and is ejected.

This technique is used for bottles, fuel tanks, and large containers.

Rotational Molding

Rotational molding is great for large, hollow parts. The steps are:

PE powder is placed in a mold.

The mold is heated and rotated.

The powder melts and coats the mold's interior.

The mold is cooled, and the part is removed.

It's used for tanks, playground equipment, and kayaks.

Compression Molding (for UHMWPE)

UHMWPE requires special processing. Compression molding is often used:

UHMWPE powder is placed in a heated mold.

Pressure is applied to compress the powder.

The material is heated to its melting point.

The part is cooled under pressure.

This method produces high-strength parts like artificial joints.

Film Blowing

Film blowing creates thin PE films. The process:

PE is melted and extruded into a tube.

Air is blown into the tube, expanding it.

The bubble is cooled and collapsed.

The film is wound onto rolls.

This technique produces plastic bags and packaging films.

3D Printing with PE

3D printing with PE is emerging. It offers new possibilities:

HDPE filaments are available for FDM printers.

It allows for custom, small-batch production.

Recycled PE can be used, promoting sustainability.

Challenges remain, but it's an exciting area of development.

Modifications and Additives for PE Plastic

Cross-linking to Create PEX

Cross-linked PE (PEX) offers improved properties:

Higher temperature resistance

Better chemical resistance

Increased impact strength

PEX is created through three methods:

Peroxide (PEX-a)

Silane (PEX-b)

Electron beam (PEX-c)

It's widely used in plumbing and radiant heating systems.

Chlorination to Produce CPE

Chlorinated PE (CPE) adds new features:

CPE is used in:

Roofing membranes

Wire and cable jacketing

Automotive parts

Copolymers (EVA, Ethylene-Acrylic Acid)

Copolymers combine PE with other monomers:

Ethylene Vinyl Acetate (EVA)

EVA is used in:

Shoe soles

Packaging films

Hot melt adhesives

Ethylene-Acrylic Acid (EAA)

EAA finds applications in:

Multilayer packaging

Coatings

Adhesives

Metallocene PE (mPE) for Enhanced Properties

mPE offers several advantages:

More uniform molecular structure

Improved strength and toughness

Better optical properties

It's used in:

Other Modifications for Specific Applications

PE can be modified with various additives:

| Additive Type | Purpose | Application |

| UV stabilizers | Prevent degradation from sunlight | Outdoor products |

| Antioxidants | Prevent oxidation during processing | All PE products |

| Colorants | Add color | Consumer goods |

| Flame retardants | Reduce flammability | Construction materials |

Applications Across Industries

PE plastic is incredibly versatile. It's used in numerous industries.

Packaging

Food Packaging

PE is perfect for food packaging. It's used in:

Plastic bags

Food containers

Bottle caps

LDPE and HDPE are common choices. They keep food fresh and safe.

Image Source U-nuo HDPE Shampoo 16 oz lotion bottles

Industrial Packaging

PE shines in industrial packaging too:

Shipping sacks

Drum liners

Protective wraps

HDPE is often used for its strength and chemical resistance.

Advantages in the Packaging Industry

PE offers many benefits:

Lightweight

Moisture resistant

Cost-effective

Recyclable

These qualities make PE a top choice for packaging.

Construction and Building Materials

Pipes and Fittings

PE pipes are widely used. They're great for:

Water supply

Gas distribution

Sewage systems

HDPE pipes are durable and corrosion-resistant.

Insulation Materials

PE foam is an excellent insulator. It's used in:

Wall insulation

Roof underlayment

Sound dampening

It's lightweight and moisture-resistant.

Geomembranes

PE geomembranes are crucial in construction:

Landfill liners

Pond liners

Erosion control

They provide excellent chemical resistance and durability.

Automotive Industry

Fuel Tanks

HDPE fuel tanks are common in vehicles. They're:

This helps improve fuel efficiency and safety.

Interior Components

PE is used in many car interiors:

Door panels

Seat backs

Cup holders

It's cost-effective and easy to mold.

Benefits in Vehicle Manufacturing

PE offers several advantages:

Weight reduction

Improved fuel efficiency

Lower production costs

Recyclability

These benefits make PE popular in automotive manufacturing.

Agriculture

Greenhouse Films

LDPE films are perfect for greenhouses:

Light transmission

Heat retention

Durability

They help create ideal growing conditions.

Irrigation Systems

PE pipes are widely used in irrigation:

Drip irrigation tubes

Sprinkler systems

Water storage tanks

They're resistant to chemicals and UV radiation.

Mulching Applications

PE mulch films offer benefits:

They help increase crop yields and quality.

Healthcare and Medical Devices

Medical-Grade PE Plastics

Medical-grade PE is specially formulated:

Biocompatible

Sterilizable

Chemical resistant

It meets strict healthcare standards.

Common Medical Applications

PE is used in various medical items:

Prosthetics

Surgical implants

Pharmaceutical packaging

UHMWPE is particularly valuable for joint replacements.

Consumer Goods

Household Items

PE is found in many household products:

Storage containers

Cutting boards

Trash cans

It's durable, easy to clean, and affordable.

Toys and Recreational Products

PE is ideal for toys and sports equipment:

Playground equipment

Sports balls

Beach toys

It's safe, durable, and resistant to impact.

Electrical and Electronics

Cable Insulation

PE is an excellent electrical insulator:

It provides protection and durability.

Electronic Components

PE is used in electronic manufacturing:

It offers good electrical properties and chemical resistance

Design Considerations for Polyethylene Products

Material Selection

When selecting polyethylene (PE) for product design, you need to consider several factors. These include the mechanical properties, like tensile strength and flexibility, which vary across PE types. Environmental resistance is crucial, particularly if the product will face UV exposure or chemical environments. For example, HDPE offers excellent chemical resistance, while LDPE is better for flexible, low-stress applications. Finally, the processing method matters—whether you're using injection molding, extrusion, or blow molding—because not all PE types work well with every method.

Manufacturability

Ensuring manufacturability is key to producing efficient and cost-effective PE products. Design elements such as simplicity reduce production time and complexity. Maintaining a uniform wall thickness prevents defects like warping or sinking, which can occur during cooling. Draft angles are also essential in injection molding, allowing the molded parts to be easily removed from the mold. Skipping these considerations can result in increased production costs and lower product quality.

| Design Factor | Importance |

| Simplicity | Reduces complexity and production time |

| Uniform Wall Thickness | Prevents warping and sinking |

| Draft Angles | Facilitates easy removal from molds |

Recyclability

As sustainability becomes more important, designing PE products for recyclability is a growing priority. Using a single material, like pure HDPE or LDPE, makes recycling easier. Multi-material products complicate the process and often end up in landfills. Designing for disassembly is another strategy, where products are built so they can be easily taken apart for recycling. Clear material labeling is crucial too—it helps recyclers identify and sort plastics effectively.

| Key Recyclability Considerations | Description |

| Single Material Use | Simplifies recycling |

| Design for Disassembly | Facilitates easier product breakdown |

| Clear Material Labeling | Assists in sorting for recycling processes |

Testing and Quality Control

Mechanical Testing

Mechanical testing ensures that PE products meet required strength and durability standards. Tensile strength tests measure how much force a PE material can withstand before it breaks. This is crucial for products like pipes or bottles, where structural integrity matters. Impact testing evaluates the material's resistance to sudden forces, ensuring it won’t crack or shatter under stress. Meanwhile, flexural strength tests assess how much bending a product can endure before it fails, which is especially important in flexible PE materials like LDPE.

| Mechanical Test | Purpose | Example Applications |

| Tensile Strength | Measures resistance to pulling forces | Pipes, containers |

| Impact Testing | Tests material's resistance to sudden impacts | Packaging, automotive parts |

| Flexural Strength | Assesses how much bending force it can handle | Flexible packaging, films |

For example, the above mechanical tests need to be included in the perfume bottle packaging test options.

Thermal Testing

To ensure PE products perform well in various temperatures, thermal testing is essential. Differential Scanning Calorimetry (DSC) analyzes how PE behaves under heat, helping determine its melting point and crystallinity. This is key for choosing the right type of PE for high-heat environments. Another useful method is Thermogravimetric Analysis (TGA), which tests the material’s thermal stability and measures how much weight it loses as it decomposes. This helps manufacturers understand how the material will behave under extreme conditions.

Chemical Testing

PE products often encounter harsh chemicals, making chemical testing crucial. Environmental Stress Crack Resistance (ESCR) evaluates how well PE materials resist cracking under the combined influence of stress and exposure to chemicals. This is vital for products used in chemical storage or outdoor environments, where they might come into contact with aggressive substances. ESCR ensures long-lasting performance, reducing the risk of material failure over time.

| Test Type | Purpose | Common Uses |

| Differential Scanning Calorimetry | Measures melting point and crystallinity | High-heat applications |

| Thermogravimetric Analysis | Evaluates thermal stability | Extreme temperature environments |

| Environmental Stress Crack Resistance | Tests chemical and stress crack resistance | Chemical storage, outdoor products |

Conclusion: The Future of PE Plastic

PE plastic is a versatile material with numerous benefits. Its durability and adaptability make it ideal for various applications.

The key advantages of PE include:

However, with increased plastic waste, balancing its industrial use with environmental responsibility is crucial. Continued innovation in recycling and sustainable alternatives will help ensure PE’s future while reducing its environmental impact.

Tips: You maybe interested to the all plastics