A washer, a vital circular piece in hardware programs, plays an essential role in uniformly dispersing the pressure exerted with the aid of screws or nuts. Its multifaceted application extends beyond simple force distribution, encompassing capabilities consisting of friction reduction and prevention of corrosion or leakage. Similarly to these pivotal roles, many types of washers are adept at maintaining tension ranges and can be strategically made use of as spacers in numerous construction projects.

No matter the trustworthy nature of their characteristics, the selection of the ideal types of washers for a given project introduces a layer of complexity. The following material delves into the diverse forms of washer types out there, providing an exploration of their essential characteristics, as well as an in-depth analysis of their uses. Through unravelling the intricacies of washer versions, this guide aims to empower individuals involved in construction endeavours with the information required to make knowledgeable selections, enabling the best performance and longevity in their aims.

Materials and varieties in types of washer creation

Washers come in numerous sizes, colourings, and substances, with each one of them contributing distinct characteristics to the hardware landscape. Whilst stainless steel is the go-to choice, celebrated for its immunity to rust and corrosion, a spectrum of different metals joins the ensemble. Aluminum, copper, brass, and iron provide differing solutions tailor-made for specific work projects. Venturing beyond metals, strong point washers introduce a new element, with plastic, rubber, ceramic, and phenolic materials entering the scene to deal with specific challenges.

Distinguishing themselves through their composition and traits, those substances cater to an extensive spectrum of programs. Plastic washers offer lightweight resilience; rubber washers offer flexibility and sealing abilities; ceramic washers showcase durability in intense conditions; and phenolic washers provide heat resistance. The selection of washer types becomes difficult as far as meeting functionality requirements and demands of the surroundings where they'll be utilized.

Going deeper into the taxonomy of washers, three types are at the forefront: plain washers, spring washers, and lock washers. However, within these classes lies a plethora of specialized washers, each designed with precision to satisfy a particular intent. These nuanced versions address the numerous desires of industries ranging from construction to manufacturing, ensuring that the proper washer is available for each assignment.

A key thing to consider for people in industries where washers are used is the double sizing system, with measurements available in both U.S. And metric devices. This dual metric ensures compatibility and ease of integration across an international spectrum of tasks, underlining the importance of precision in deciding on the perfect washer for a given application.

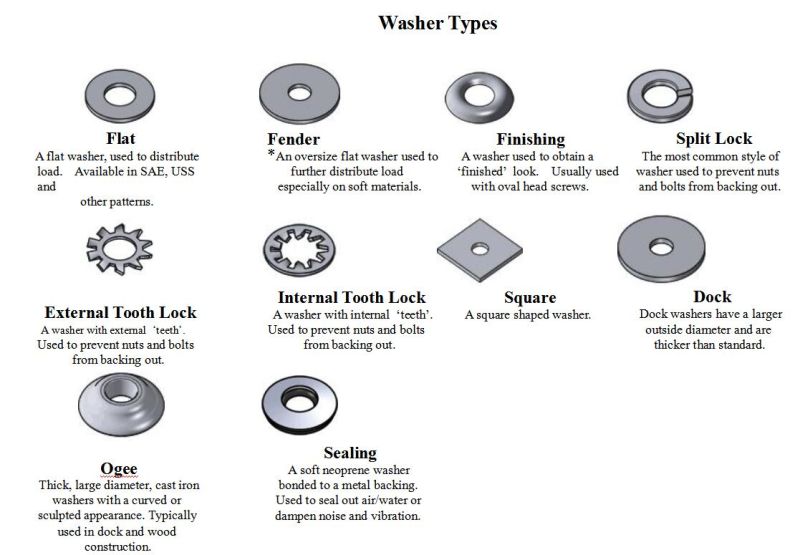

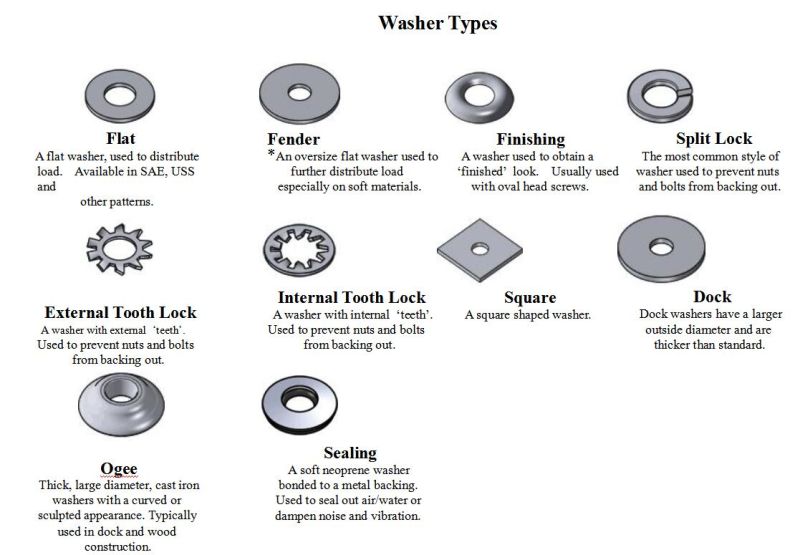

16 Types of Washers

Plain Washers

Frequently called flat washers, plain washers constitute the maximum standard range in this class. Their number one characteristic entails the even distribution of pressure and safeguarding the item to which the screw or nut is affixed. In instances in which a hole exceeds types of fasteners' dimensions, the use of a simple washing machine will become instrumental in rectifying the disparity in dimensions.

Types of Washers: Flat washer

Termed as "type A plain washers", the flat washer embodies the traditional image linked with this hardware. Round and balanced, it has a central hole accommodating a bolt, with various thicknesses.

Application: usually employed for pressure distribution or hole size correction, suitable for general use.

Fender washer

Named for their established use on automobile fenders, these flat washers possess a tiny hole and a comparably sizeable external diameter.

Application: Designed for dispensing pressure over a vast surface vicinity, specifically powerful on skinny metallic.

Types of Washers: Torque washer

Distinctive by a square hole and outer prongs, the torque washer prevents the accompanying bolt from rotating even as it's fastening a nut.

Utility: best to be used with carriage bolts in woodworking tasks.

C-washer

Similar in appearance to a flat washer, the C-washer features a slot taken out from the center hole, forming a "C" shape.

Application: employed on every occasion, a washer must be removed, adjusted, or switched out, all while not dislodging the fastener.

Types of Washers: Finishing washer

Additionally identified as a countersunk washer, the finishing washer's capabilities consist of a recessed pinnacle designed to capture the fastener.

Utility: ensures a flush surface area when secured with countersunk screws, supplying a polished finish.

Spring Washers

Spring washers exhibit axial flexibility, letting them circulate in reaction to vibrations. This flexibility prevents them from becoming unfastened or disengaging due to vibrational forces, enhancing the elastic components of a joint.

Types of Washers: Belleville washer

Occasionally termed a conical spring washer, the Belleville washer has bevelled facets that offer vital help with minimal deflections in opposition to heavy force.

Application: ideal for projects related to thermal enlargement.

Crescent Spring washer

Also known as curved spring washers, these resemble flat washers barely curved to exert mild stress and preserve flexibility.

Application: Used to absorb motion and hold joint flexibility.

Types of Washers: Dome Spring washer

With rounded elements such as Belleville washers, dome spring washers are employed in instances that require flexibility as well as a flatter surface.

Application: Used anywhere, a crescent spring washer is essential, in addition to surfaces that demand more evenness.

Finger Spring washer

Having three curved flanges, finger spring washers find their use in dampening vibrations and lowering noise.

Application: Primarily used for vibration absorption and noise reduction.

Types of Washers: Wave Spring washer

Curved in two distinct directions, wave spring washers present an extraordinary wave-like form.

Application: commonly applied as cushions or spacers in diverse areas.

Lock Washers

Lock washers play an essential part in securing fasteners susceptible to rotation or lack of friction.

Types of Washers: Split lock washer

Also called helical washers, split lock washers are with ends bent continuous rings bent outward just barely in opposing directions, flattening once they've been secured.

Application: Used to lock a fastener securely in an area.

Outside tooth Lock washer

With teeth in the internal diameter, outside teeth lock washers bite into the fastener, efficiently locking shallow-headed fasteners and soaking up shock and vibrations.

Application: best for securing shallow-headed fasteners and minimizing shocks and vibrations.

Types of Washers: Internal tooth Lock washer

Much like external teeth lock washers, internal teeth lock washers have teeth on the inner diameter biting into the fastener.

Application: suitable for locking shallow-headed fasteners and dampening shock and vibrations.

Conclusion

The industry of washers involves a numerous array of material components and types, each meticulously designed to meet specific hardware problems that can come up. From the versatile plain washers that distribute pressure and accurate size disparities to the flexible spring washers adept at soaking up vibrations and the dependable lock washers securing fasteners towards rotation and friction loss—each category serves a utterly unique purpose. The careful choice of washers, considering their uses and compatibility with distinctive fasteners, will become paramount in ensuring the performance, durability, and toughness of construction and manufacturing initiatives. As hardware components, washers stand as silent but vital contributors to the seamless operation of numerous mechanical systems, embodying precision and adaptability in their varied spaces.

Besides from offering types of washers, TEAM MFG also offers rapid prototyping services, CNC machining services, and high pressure die casting services to meet your needs. Contact us today!