Have you ever noticed a faint line on your plastic products? That's likely a weld line, and it can be a big problem in injection molding. Weld lines not only affect the appearance of your parts but can also weaken their structure.

In this article, we'll dive deep into injection molding weld lines. You'll learn what causes these pesky imperfections and, more importantly, how to prevent them. Get ready to optimize your injection molding process and create flawless parts every time!

What are Weld Lines in Injection Molding?

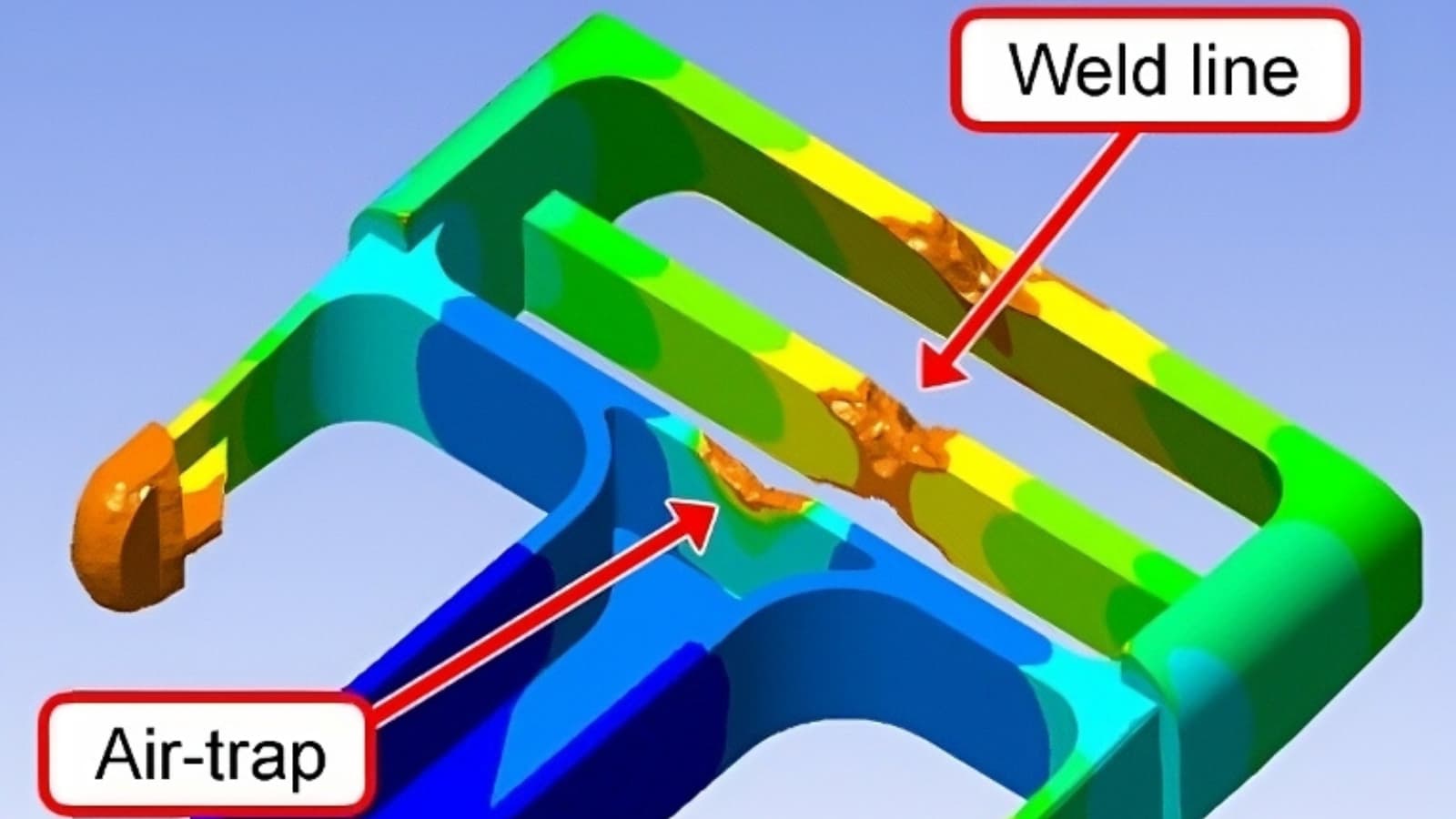

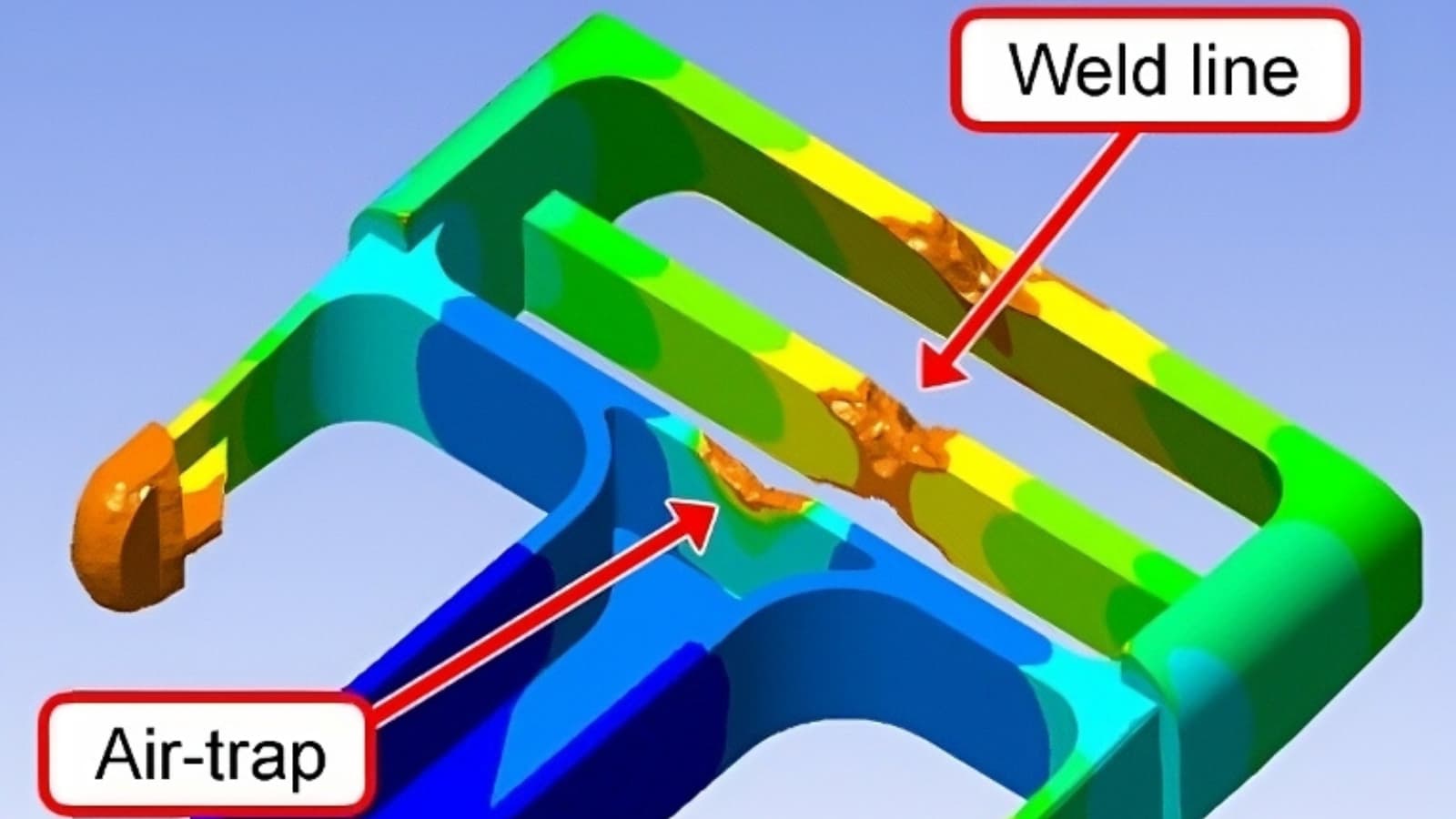

Weld lines, also known as knit lines or meld lines, are common defects in injection molded parts. They appear as faint, often barely visible lines on the surface where two or more flow fronts have converged.

These imperfections occur when the molten plastic flows around obstacles like holes or cores. It then reunites on the other side, creating a weak spot.

Weld lines differ from meld lines based on the angle at which the flow fronts meet:

While meld lines are less severe, both can compromise the strength and appearance of the molded part.

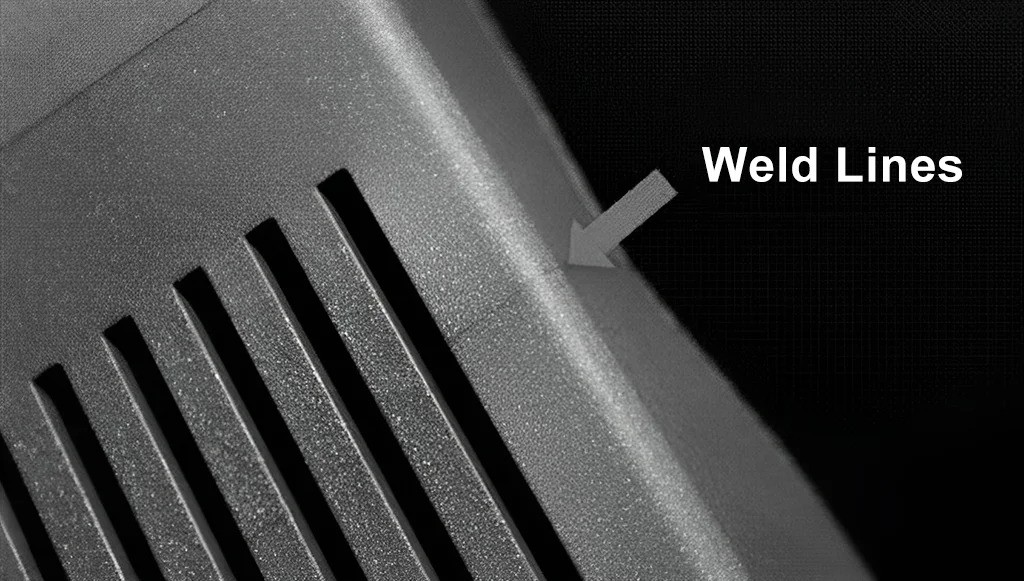

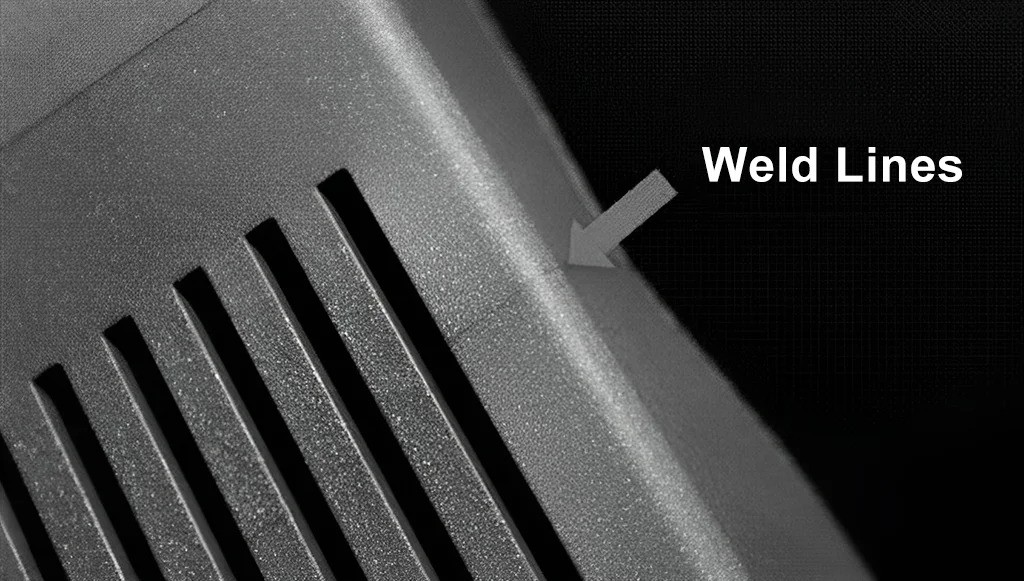

Take a look at these examples of weld lines on various plastic components:

As you can see, they're not always easy to spot. But even the faintest weld line can be a weak point, especially under stress or impact.

How are Weld Lines Formed in Injection Molding?

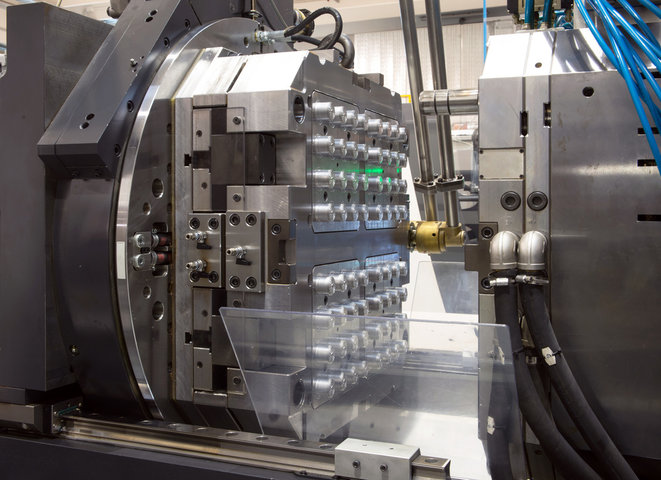

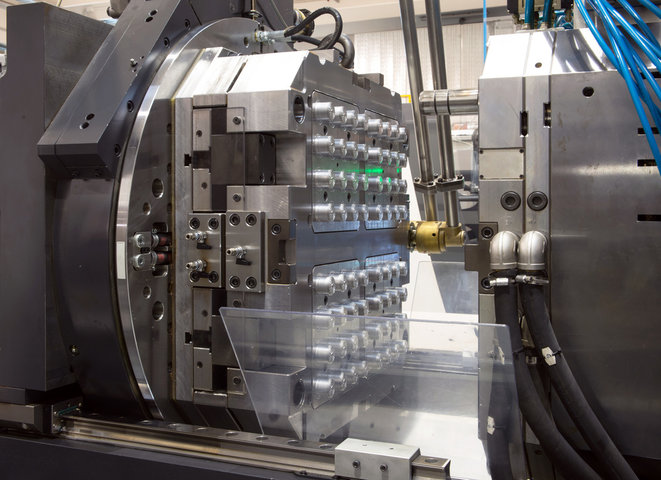

To understand how weld lines form, let's first take a quick look at the injection molding process:

Melted plastic is injected into a mold cavity

It flows through the mold, filling it

The plastic cools and solidifies

The part is ejected from the mold

Now, imagine the molten plastic flowing through the mold. When it encounters an obstacle like a hole or core, the flow splits into two separate streams. These flow fronts then move around the obstacle and reunite on the other side.

If conditions aren't perfect, the fronts may not fully fuse back together. This creates a weld line - a weak point in the part.

Several common scenarios can lead to weld line formation:

Holes or cores in the mold

Thin sections that cause flow to split

Multiple gates introducing separate flow fronts

Poorly placed gates causing fronts to meet

The severity of the weld line depends on factors like:

In general, anything that hinders proper flow front fusion can contribute to more pronounced weld lines. We'll explore ways to mitigate these factors later on.

Why are Weld Lines a Concern in Injection Molding?

You might be thinking, "So what if there's a little line on my part?" Well, weld lines are more than just a cosmetic issue. They can have a significant impact on your product's appearance and performance.

First, let's talk aesthetics. Weld lines are often visible on the surface of the part, especially with glossy or transparent materials. They can appear as:

These imperfections can make your product look cheap or poorly made, even if it's functionally sound.

But the real concern with weld lines is their effect on part strength. Remember, a weld line is a weak point where the flow fronts didn't fully fuse. This means the material at that location is less dense and more prone to failure.

Under stress or impact, a part is likely to break at the weld line. This can be a major problem for load-bearing components or parts subjected to regular wear and tear.

In some cases, a weld line can reduce the strength of a part by up to 50%! That's a massive difference that could lead to premature failure or even pose a safety hazard.

Preventing weld lines is crucial for ensuring:

Consistent product appearance

Reliable part performance

Overall product quality and durability

No one wants their product to fail because of a preventable molding defect. By understanding and addressing weld lines, you can create parts that look great and stand up to real-world use.

Causes of Weld Lines in Injection Molding

Several factors can contribute to the formation of weld lines during injection molding. Let's dive into each one and explore how they impact your parts.

Incorrect Injection Pressure

Injection pressure plays a crucial role in the molding process. If the pressure is too low, the molten plastic may not have enough force to properly fuse when flow fronts meet. This can lead to incomplete bonding and visible weld lines.

To prevent this, it's important to:

Set the appropriate injection pressure for the material and mold

Regularly maintain and calibrate the injection molding machine

Monitor pressure during the molding process

Improper Melt Temperature

Melt temperature is another key factor. If the temperature is too low, the plastic may start to cool and solidify before the flow fronts have a chance to fully merge. This can result in a weak weld line.

Proper temperature control is essential throughout the molding process:

In the barrel and nozzle of the injection molding machine

In the runners and gates of the mold

In the mold cavity itself

Poor Mold Design

The design of the mold can greatly influence the formation of weld lines. Thin walls or poorly placed gates can cause the flow to split and create weak points.

To minimize weld lines, mold designers should:

Maintain consistent wall thickness

Place gates to promote balanced flow

Use simulation software to optimize design

Slow Injection Speed

Injection speed affects how quickly the molten plastic fills the mold. If the speed is too slow, the plastic may cool unevenly, leading to weld lines.

Finding the right balance is key:

Impurities in the Resin

Contaminants in the plastic resin can disrupt the flow and cause imperfections like weld lines. These impurities can be:

To ensure a clean melt:

Use high-quality, virgin resins

Properly store and handle materials

Use appropriate purging compounds

Excessive Mold Release Agent

Mold release agents help parts eject smoothly from the mold. However, too much release agent can interfere with the fusion of flow fronts, causing weld lines.

Proper application is important:

Use the minimum amount necessary

Apply evenly to the mold surface

Avoid buildup over multiple cycles

Solutions for Preventing Weld Lines in Injection Molding

Now that we understand the causes of weld lines, let's explore some solutions to prevent them. By optimizing your part design, mold design, processing parameters, and material selection, you can significantly reduce the occurrence of these pesky defects.

Optimizing Part Design

The design of your part can greatly influence the formation of weld lines. Here are some tips to optimize your design:

Adjust wall thickness

Minimize obstructions and holes

Reduce the number of features that can split the flow

If holes are necessary, place them strategically to minimize weld lines

Strategic placement of inserts and features

Improving Mold Design

The mold is the foundation of the injection molding process. Proper mold design can help prevent weld lines and other defects:

Proper gate sizing and placement

Incorporating adequate venting

Optimizing runner systems

Fine-Tuning Injection Molding Parameters

Adjusting the processing parameters can have a significant impact on weld line formation. Here are some key factors to consider:

Injection pressure and time

Melt temperature

Injection speed

Find the right balance between slow and fast injection speeds

Too slow can cause uneven cooling, while too fast can lead to other defects

Screw speed and back pressure

Material Selection and Handling

Choosing the right resin and handling it properly can also help minimize weld lines:

Resins with good flow properties and heat resistance

Proper drying and handling

Lubricants and stabilizers

Use additives to enhance resin flow and reduce weld lines

Consider using mold release agents, lubricants, or flow enhancers

Advanced Techniques for Managing Weld Lines

While optimizing part design, mold design, and processing parameters can significantly reduce weld lines, sometimes you need to take your efforts to the next level. Let's explore some advanced techniques for managing these pesky defects.

Computer Simulations and DFM Analysis

One of the most powerful tools in your arsenal is computer-aided engineering (CAE) software. These programs allow you to simulate the injection molding process and predict potential issues like weld lines before you ever cut steel.

Design for manufacturability (DFM) analysis is a key part of this process. By analyzing your part design through a DFM lens, you can identify areas prone to weld lines and make adjustments before moving to production.

With CAE and DFM, you can:

Predict flow behavior and weld line formation

Optimize gate locations and runner systems

Identify and correct potential design issues

Save time and money by reducing mold iterations

Post-Molding Machining

In some cases, it may be more efficient to mold a simplified part and add features post-molding. This can help eliminate weld lines caused by holes, inserts, or other obstructions.

Common post-molding machining techniques include:

While this adds an extra step to the manufacturing process, it can be a cost-effective solution for managing weld lines in complex parts.

Material Innovations

Advancements in polymer science have led to the development of new materials that are less prone to weld lines. These resins often have lower viscosity and melting points, allowing for better flow and fusion of flow fronts.

Some examples include:

High-flow polypropylene (PP) grades

Low-viscosity nylon (PA) variants

Specialized blends and alloys

By exploring these material options, you may find a solution that reduces weld lines without significant changes to your part or mold design.

Of course, it's important to consider the specific requirements of your application when selecting a material. Factors like strength, stiffness, temperature resistance, and chemical compatibility all play a role in determining the best choice for your part.

Conclusion

In this article, we've explored the world of injection molding weld lines. We've learned what causes these unsightly defects, from incorrect pressures and temperatures to poor mold design and material issues.

But more importantly, we've armed ourselves with the knowledge and techniques to prevent weld lines from forming in the first place. By optimizing part and mold design, fine-tuning processing parameters, and selecting the right materials, we can create plastic parts that are strong, beautiful, and free of weld lines.

Ready to tackle your injection molding challenges? Contact Team Mfg today. Our experts will work with you to optimize your design, minimize defects, and deliver top-quality parts. Trust us to bring your vision to life. Get started now - your success is our priority.