CNC machines and injection molding are two different manufacturing processes that have their own unique advantages and applications. While they both involve the use of computer-controlled equipment to produce parts and products, they operate in very different ways and are used for different purposes. In this article, we will explore the differences between CNC machines and injection molding, and explain why they should not be considered the same.

CNC Machines

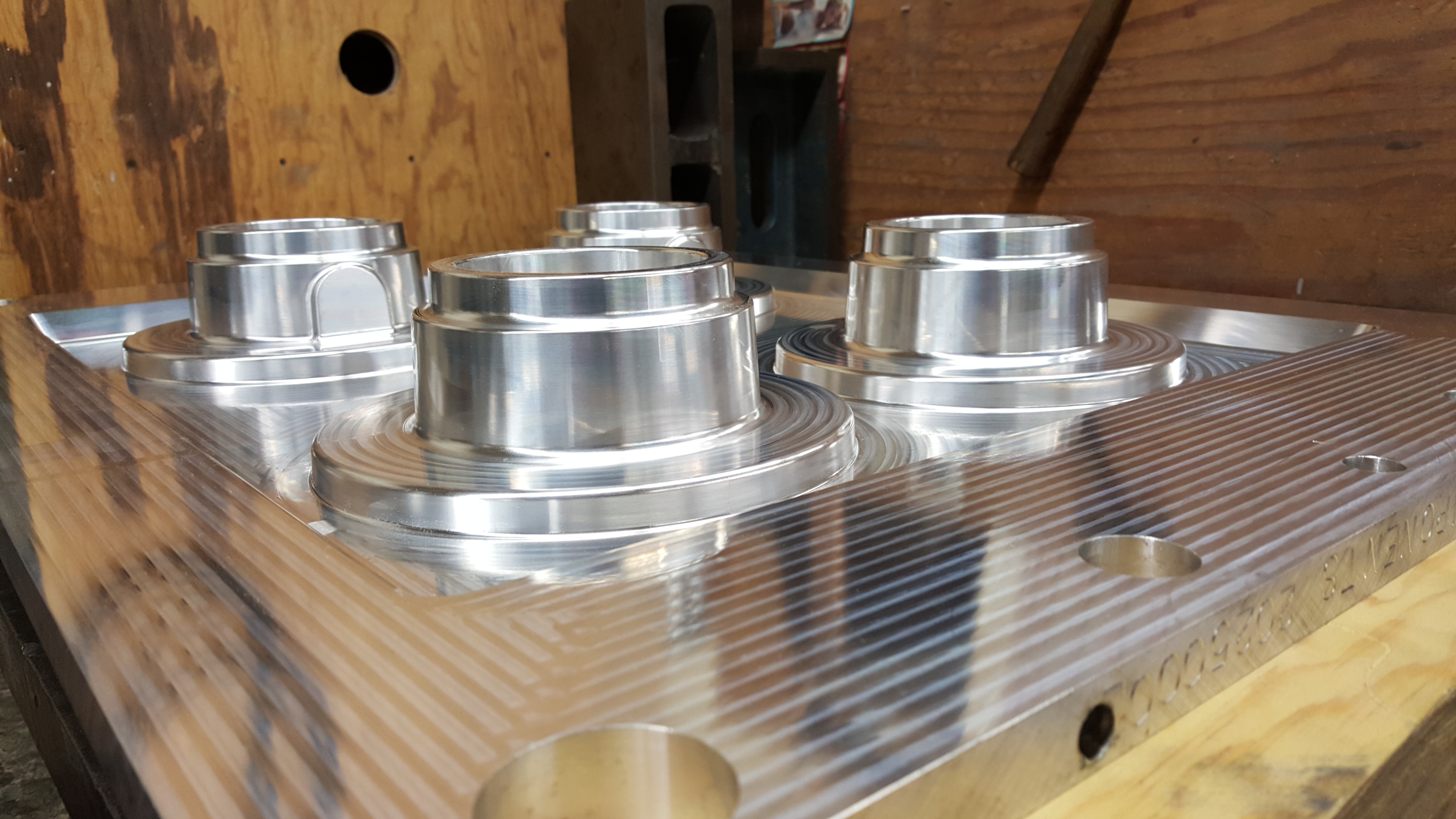

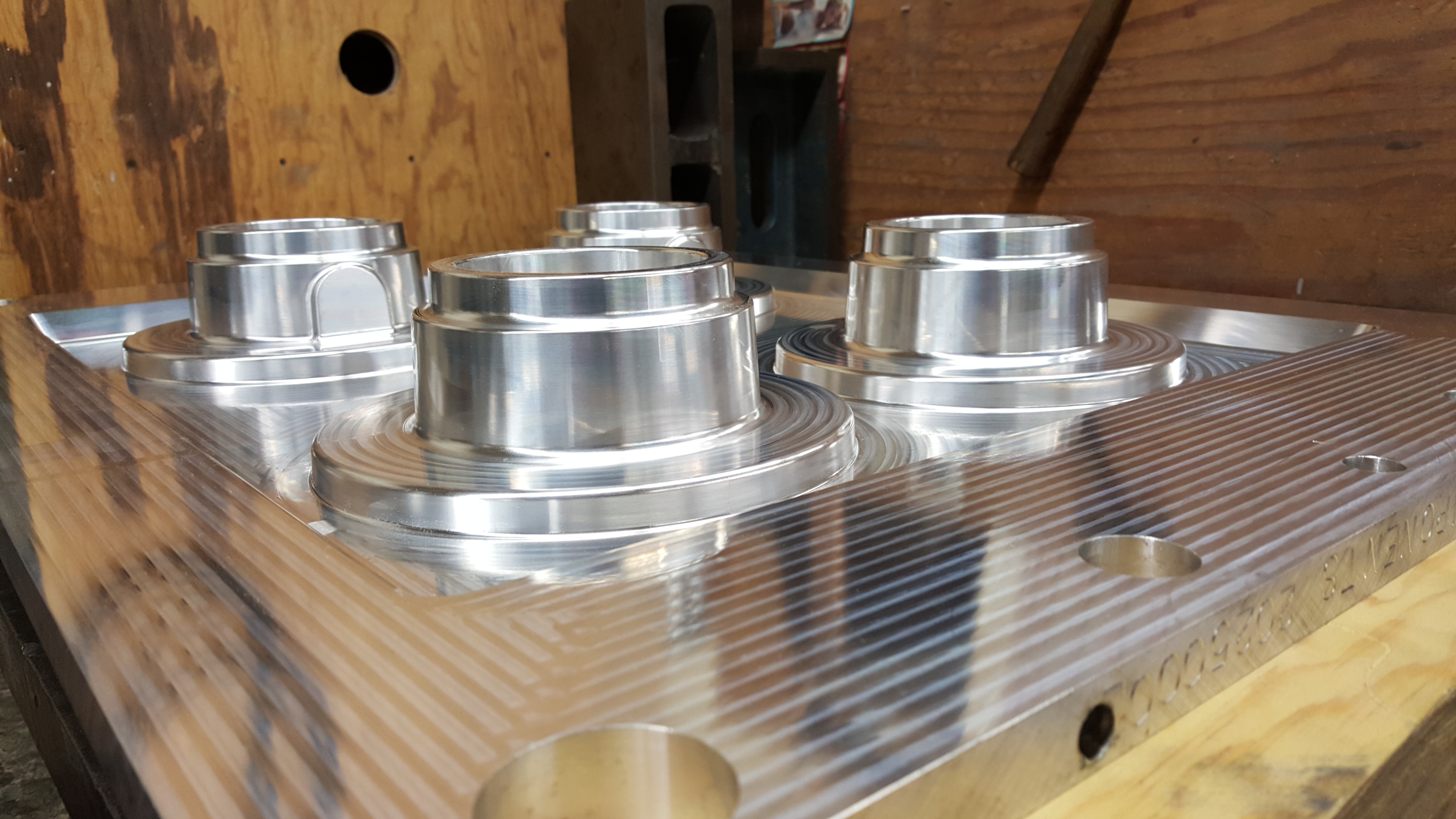

CNC machines, or Computer Numerical Control machines, are automated machine tools that use pre-programmed instructions to control their movements. They can be used to produce a wide range of parts and products, from simple shapes to complex geometries, using a variety of materials such as metals, plastics, and wood. CNC machines can perform a variety of operations, including cutting, drilling, milling, turning, and grinding, with high precision and accuracy.

One of the main advantages of CNC machines is their flexibility. They can be programmed to produce a wide range of parts and products, and can be easily reconfigured to produce different parts as needed. This makes them ideal for small-batch production and prototyping. They also offer high accuracy and repeatability, which is important for producing parts with tight tolerances.

Injection Molding

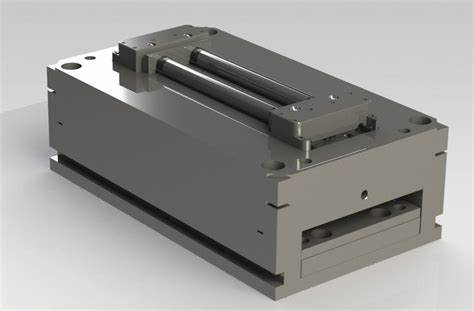

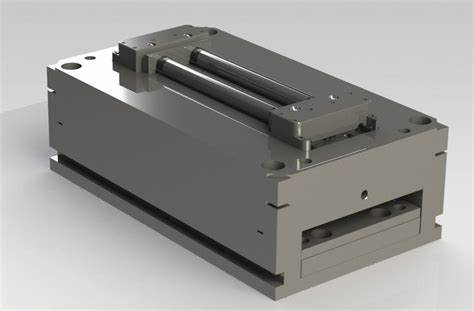

Injection molding, on the other hand, is a manufacturing process that involves melting plastic pellets and injecting the molten material into a mold cavity. Once the plastic cools and solidifies, the mold is opened, and the finished part is ejected. Injection molding is commonly used to produce plastic parts for a wide range of applications, from automotive components to consumer products.

Injection molding has several advantages over other manufacturing processes. It can produce parts with complex geometries, including thin walls and internal features, with high precision and accuracy. It also offers high production rates, making it ideal for high-volume production.

Differences between CNC Machines and Injection Molding

While both CNC machines and injection molding use computer-controlled equipment to produce parts and products, they are fundamentally different processes. CNC machines are used to remove material from a solid block or sheet of material, while injection molding involves adding material to a mold cavity.

Another key difference is the materials that can be used. CNC machines can work with a wide range of materials, including metals, plastics, and wood, while injection molding is primarily used for plastics.

Finally, the applications of these processes differ as well. CNC machines are used for small-batch production and prototyping, while injection molding is used for high-volume production of plastic parts.

Conclusion

In conclusion, while CNC machines and injection molding may seem similar on the surface, they are fundamentally different processes used for different purposes. CNC machines are used to remove material from a solid block or sheet of material, while injection molding involves adding material to a mold cavity. CNC machines are used for small-batch production and prototyping, while injection molding is used for high-volume production of plastic parts. It is important to understand these differences in order to choose the right manufacturing process for your needs.