Waterjet cutting is revolutionizing the manufacturing world, offering precision and versatility like never before. But, are you maximizing its potential? Without proper maintenance, troubleshooting, and optimization, this powerful tool may underperform or even fail.

In this post, you'll learn how waterjet cutting works, why regular upkeep is essential, and the key steps to ensure your machine operates at peak performance. We'll explore common issues like nozzle wear and water quality problems, and share tips to optimize your cutting process for efficiency and longevity.

Waterjet Cutting

Overview of Waterjet Cutting Technology

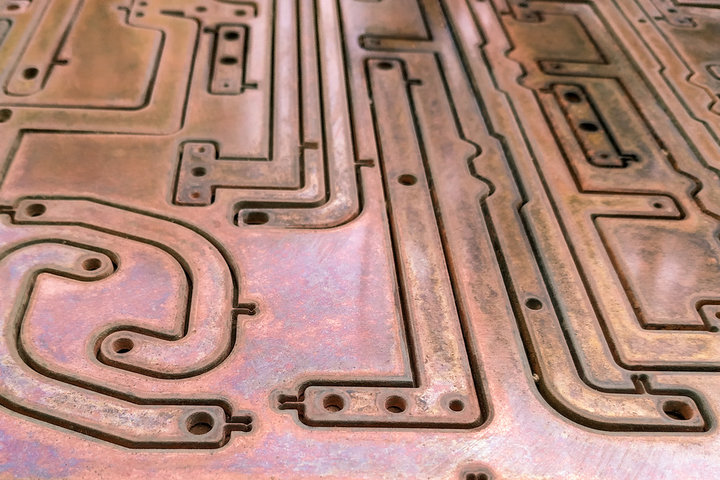

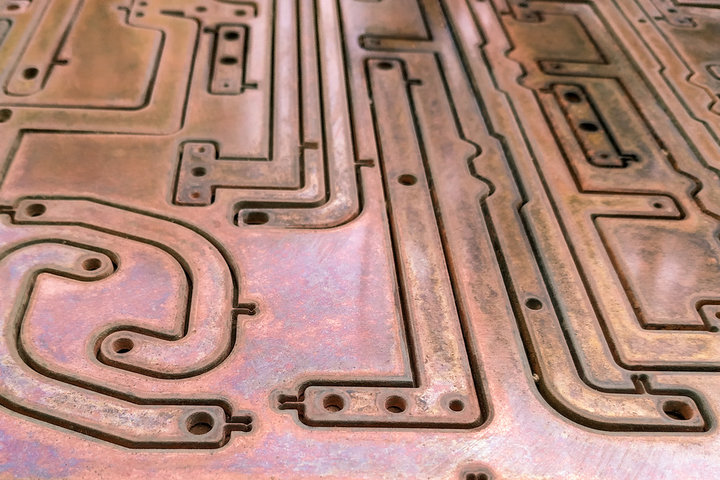

Waterjet cutting is an innovative and versatile manufacturing process that uses a high-pressure stream of water, often mixed with abrasive particles, to cut through a wide range of materials with unparalleled precision. This technology has revolutionized the manufacturing landscape, offering a clean and efficient alternative to traditional cutting methods.

Here's a brief overview of how waterjet cutting works:

Water is pressurized to extremely high levels, typically between 30,000 and 90,000 psi.

The pressurized water is forced through a small orifice, creating a concentrated stream.

Abrasive particles, such as garnet, are introduced into the water stream, increasing its cutting power.

The high-velocity stream of water and abrasive particles is directed at the material, cutting through it with precision and ease.

One of the key advantages of waterjet cutting is its ability to handle a diverse array of materials, including:

The flexibility and precision of waterjet cutting make it an indispensable tool in industries such as aerospace, automotive, construction, and manufacturing.

Importance of Maintenance in Waterjet Cutting

Proper maintenance of waterjet cutting machines is crucial for ensuring optimal performance and extending equipment lifespan. Regular maintenance keeps the machine functioning smoothly, reduces downtime, and prevents costly repairs.

Impact of Regular Maintenance on Machine Performance

Maintaining your waterjet system helps it operate at peak efficiency. Regular upkeep ensures:

Consistent cutting quality

Extended lifespan of critical components like the cutting head and pump

Reduced operating costs by avoiding frequent repairs

Potential Risks of Neglecting Maintenance

Failure to maintain a waterjet machine can lead to:

Nozzle wear, resulting in inaccurate cuts

Abrasive feed issues, causing clogging or uneven cuts

Damage to the pump and other high-pressure components

Key Components of a Waterjet Machine

Understanding the main components of a waterjet machine is critical for maximizing performance and efficiency. Each part plays a specific role in ensuring precision and reliability during cutting operations.

Cutting Head

The cutting head is where the magic happens. It directs the high-pressure water stream that performs the actual cutting. Equipped with multi-axis capabilities, the cutting head allows for both angled and vertical cuts, making it versatile for complex projects.

High-Pressure Pump

The high-pressure pump is the heart of the waterjet system. It generates the extreme pressure required to cut through materials. Maintaining consistent water pressure is vital to avoid cutting inaccuracies or system failures.

Role: Produces the necessary water pressure, typically up to 60,000 PSI.

Importance of Pressure: Insufficient pressure can lead to inefficient cuts or damage to the pump.

Abrasive Feed System

For harder materials, abrasives like garnet are added to the water stream to enhance cutting power. Ensuring that abrasives flow properly is essential for maintaining cutting speed and quality.

Use of Abrasives: Abrasive materials, like garnet, help cut through tougher materials such as metals and ceramics.

Ensuring Flow: Consistent flow of abrasives is crucial for clean and precise cuts.

Mixing Chamber

The mixing chamber is where water and abrasives combine before reaching the cutting head. Proper alignment and cleanliness of the chamber are vital to ensure effective mixing, preventing clogs or imbalances in the cutting stream.

Water Quality System

Water quality directly affects the performance and lifespan of a waterjet machine. Poor-quality water can lead to system failures, nozzle wear, and inconsistent cuts. Filtration systems, such as reverse osmosis, are often employed to maintain water purity and protect the machine.

Impact on Performance: Hard or contaminated water can damage critical components and reduce cutting efficiency.

Water Filtration: Systems like reverse osmosis help ensure water quality meets the machine's specifications.

Waterjet Maintenance Schedule

Regular maintenance is crucial for ensuring the optimal performance, longevity, and reliability of a waterjet cutting machine. A well-planned maintenance schedule helps prevent breakdowns, minimize downtime, and maintain the quality of the cuts. In this section, we will outline the essential tasks that should be performed on a daily, weekly, monthly, half-yearly, and yearly basis.

Daily Maintenance Tasks

Checking weep holes for leaks: Inspect the weep holes on the high-pressure pump for any signs of water leakage. These holes act as an early warning system for seal failure, and any leaks should be addressed promptly to prevent damage to the pump.

Inspecting oil levels and water pressure: Check the oil levels in the hydraulic system and ensure they are within the recommended range. Also, monitor the water pressure to ensure it meets the manufacturer's specifications, as insufficient pressure can lead to poor cutting performance and damage to the machine.

Monitoring sealing head and valves: Examine the sealing head and valves for any signs of wear, damage, or overheating. Address any issues promptly to prevent leaks and ensure proper functioning of the high-pressure system.

Weekly Maintenance Tasks

Purging the pneumatic filter regulator: Drain any accumulated water or debris from the pneumatic filter regulator to maintain proper air pressure and prevent contamination of the system.

Verifying abrasive flow rate: Check the abrasive flow rate to ensure it is consistent and meets the manufacturer's recommendations. Inconsistent flow can lead to poor cut quality and increased wear on the nozzle and mixing tube.

Checking high-pressure pump seals: Inspect the high-pressure pump seals for any signs of wear or leakage. Replace worn seals promptly to prevent damage to the pump and maintain optimal pressure.

Monthly Maintenance Tasks

Cleaning water strainers: Remove and clean the water strainers to remove any accumulated debris that could restrict water flow or damage the high-pressure pump. This is particularly important if cutting materials that tend to float in the water.

Inspecting emergency stops and breakaway head: Test the emergency stop buttons and the breakaway head to ensure they function properly. These safety features are critical for preventing accidents and minimizing damage in the event of a malfunction.

Half-Yearly Maintenance Tasks

Replacing moisture absorption oil filter: The moisture absorption oil filter helps maintain the purity of the hydraulic oil by removing any accumulated water. Replace this filter every six months, or sooner if indicated by the filter's condition or the machine's usage.

Yearly Maintenance Tasks

Greasing bearings and slides: Lubricate the bearings and slides on the X, Y, and Z axes to ensure smooth, precise motion and minimize wear. Follow the manufacturer's guidelines for the type and amount of grease to use.

Checking belt tension and condition: Inspect the drive belts for any signs of wear, damage, or insufficient tension. Adjust the tension as needed and replace any worn or damaged belts to maintain optimal performance and prevent unexpected breakdowns.

Inspecting hydraulic components: Examine the hydraulic system components, including hoses, fittings, and cylinders, for any signs of wear, damage, or leakage. Address any issues promptly to prevent more serious problems and ensure the reliable operation of the waterjet cutting machine.

Troubleshooting Common Waterjet Issues

Waterjet cutting machines are complex systems that rely on the precise interaction of various components to deliver accurate, efficient cuts. Despite regular maintenance, issues can still arise that impact the machine's performance and cut quality. In this section, we will explore some of the most common problems encountered in waterjet cutting and provide solutions for troubleshooting them.

Nozzle Wear

The nozzle is one of the most critical components of a waterjet cutting machine, and it is subject to wear due to the high-pressure water and abrasive material passing through it. Over time, this wear can lead to inconsistent cuts and reduced cutting efficiency.

Causes of nozzle wear include:

Abrasive particles eroding the nozzle orifice

High water pressure causing accelerated wear

Improper alignment of the nozzle

Signs of nozzle wear include:

To address nozzle wear, regular inspection and replacement of worn nozzles are essential. Operators should also ensure proper alignment of the nozzle and adjust abrasive flow rates as needed.

Abrasive Feed Problems

The abrasive feed system is responsible for delivering a steady stream of abrasive particles to the cutting head. Issues with this system can lead to inconsistent cuts and reduced cutting efficiency.

Common causes of abrasive feed problems include:

To troubleshoot abrasive feed issues, operators should:

Clean the abrasive hopper and feed lines regularly

Adjust the abrasive flow rate to ensure a consistent stream

Store abrasive material in a dry, moisture-free environment

Clogging of Cutting Head

Clogging of the cutting head can occur when debris or contaminants enter the water stream or abrasive material. This can lead to disrupted water flow, uneven cuts, and potential damage to the cutting head components.

Causes of cutting head clogging include:

Debris in the water supply

Contamination of the abrasive material

Inadequate water filtration

To prevent and address cutting head clogging, operators should:

Implement a robust water filtration system

Regularly clean the cutting head and mixing tube

Ensure the abrasive material is clean and free of contaminants

Water Quality Issues

The quality of the water used in a waterjet cutting machine can significantly impact its performance and the longevity of its components. Hard water, containing high levels of dissolved minerals, can cause scale buildup and accelerate wear on parts.

Effects of hard water on waterjet systems include:

Clogging of nozzles and orifices

Damage to high-pressure seals and valves

Reduced cutting efficiency and precision

To address water quality issues, operators can:

Implement a water softening system to remove dissolved minerals

Use reverse osmosis to purify the water supply

Install and maintain a robust water filtration system

Hydraulic System Failures

The hydraulic system is responsible for generating the high pressure required for waterjet cutting. Failures in this system can lead to decreased cutting performance and potential damage to the machine.

Common hydraulic system issues include:

Overstroking of the hydraulic piston

Increases in hydraulic fluid temperature

Leaks in the hydraulic lines or fittings

To troubleshoot hydraulic system failures, operators should:

Adjust the pressure control settings to prevent overstroking

Monitor hydraulic fluid temperature and address any overheating

Regularly inspect hydraulic lines and fittings for leaks

Leaks in the System

Water leaks in a waterjet cutting machine can lead to decreased performance, component damage, and potential safety hazards. Identifying and addressing leaks promptly is essential for maintaining the machine's efficiency and longevity.

Common sources of leaks include:

Worn or damaged high-pressure seals

Loose or faulty fittings and connections

Damage to water lines or hoses

To troubleshoot leaks, operators should:

Regularly inspect the machine for signs of water accumulation

Replace worn or damaged seals and fittings

Tighten connections and repair any damaged water lines

Electrical Problems

Electrical issues in a waterjet cutting machine can cause erratic behavior, loss of control, and potential safety hazards. These problems can range from simple wiring issues to more complex control system failures.

Common electrical problems include:

Loose or damaged wiring connections

Malfunctioning sensors or switches

Failure of the CNC control system

To address electrical issues, operators should:

Regularly inspect wiring and connections for signs of wear or damage

Test sensors and switches to ensure proper functioning

Consult with trained technicians for complex control system issues

Optimizing Waterjet Cutting Performance

To maximize the efficiency, precision, and quality of waterjet cutting, it is essential to optimize various aspects of the machining process. In this section, we will explore key factors that contribute to optimal waterjet cutting performance and provide strategies for fine-tuning these elements to achieve the best possible results.

Cutting Parameters

Cutting parameters, such as cutting speed and standoff distance, play a crucial role in determining the quality and efficiency of waterjet cuts. Adjusting these parameters to suit the specific material being cut and the desired outcome is essential for achieving optimal results.

Adjusting cutting speed for different materialsThe optimal cutting speed varies depending on the material being cut, its thickness, and the desired cut quality. Harder materials, such as metals, generally require slower cutting speeds to ensure precision and minimize wear on the nozzle. Softer materials, like plastics or foam, can often be cut at higher speeds without sacrificing quality.

To determine the best cutting speed for a given material, operators should:

Consult the manufacturer's guidelines for recommended cutting speeds

Conduct test cuts on scrap material to assess quality and adjust speed accordingly

Monitor the cutting process and make fine adjustments as needed

Fine-tuning standoff distance for precisionThe standoff distance, which is the gap between the nozzle and the material being cut, also plays a significant role in cut quality. A smaller standoff distance generally results in a narrower kerf and more precise cuts, while a larger distance can lead to a wider kerf and potentially uneven edges.

To optimize standoff distance, operators should:

Begin with the manufacturer's recommended standoff distance for the material being cut

Make small adjustments to the distance and assess the impact on cut quality

Find the balance between precision and nozzle wear, as a smaller standoff distance can lead to increased wear on the nozzle tip

Abrasive Management

The quality and condition of the abrasive material used in waterjet cutting can significantly impact the cutting performance and the longevity of the machine's components. Proper abrasive management is crucial for maintaining optimal cutting efficiency and minimizing wear on the nozzle and other parts.

Using high-quality abrasivesHigh-quality abrasives, such as garnet, are essential for achieving clean, precise cuts and extending the life of the nozzle and other components. Lower-quality abrasives may contain impurities that can clog the nozzle, leading to inconsistent cuts and increased wear.

When selecting abrasives, operators should:

Choose abrasives specifically designed for waterjet cutting

Opt for high-quality, consistently sized particles

Consider the hardness and durability of the abrasive material

Ensuring dry and contaminant-free abrasivesMoisture and contaminants in the abrasive material can lead to clumping, clogging, and inconsistent abrasive flow. This can result in uneven cuts, reduced cutting efficiency, and potential damage to the machine's components.

To maintain dry and contaminant-free abrasives, operators should:

Store abrasives in a dry, moisture-free environment

Use airtight containers to prevent humidity and contaminants from entering the abrasive supply

Regularly inspect the abrasive material for signs of moisture or contamination

Water Pressure Regulation

Consistent and appropriate water pressure is essential for achieving precise, efficient cuts with a waterjet machine. Fluctuations in water pressure can lead to inconsistent cut quality, while inadequate pressure can reduce cutting speed and efficiency.

Maintaining consistent water pressureTo ensure optimal cutting performance, it is crucial to maintain a consistent water pressure throughout the cutting process. This involves regularly monitoring the pressure gauge and making adjustments as needed to keep the pressure within the manufacturer's recommended range.

Operators should also:

Inspect the high-pressure pump and valves for any leaks or signs of wear

Ensure the water filtration and treatment system is functioning properly

Monitor the water temperature to prevent overheating, which can impact pressure stability

Impact of water pressure on cutting precisionWater pressure directly affects the cutting precision and the ability to achieve clean, smooth edges. Higher water pressure generally results in a narrower kerf and more precise cuts, while lower pressure can lead to wider, less precise cuts.

To optimize cutting precision, operators should:

Adjust the water pressure to suit the material being cut and the desired cut quality

Conduct test cuts to assess the impact of pressure changes on precision

Regularly maintain and calibrate the high-pressure pump to ensure consistent pressure output

Material Handling and Positioning

Proper material handling and positioning are essential for achieving accurate, stable cuts and minimizing waste. Securely fastening the material to the cutting table and using jigs or fixtures can help ensure consistent, precise cuts.

Properly securing materials for stable cutsTo achieve stable, accurate cuts, the material being cut must be securely fastened to the cutting table. This prevents the material from shifting or vibrating during the cutting process, which can lead to uneven or distorted cuts.

Operators should:

Use appropriate clamps, weights, or vacuum systems to hold the material in place

Ensure the material is flat and level on the cutting table

Check the security of the material periodically during the cutting process

Using jigs and fixtures to improve accuracyJigs and fixtures are tools used to hold and position materials consistently and accurately for repeated cuts. They can be especially useful when cutting complex shapes or producing multiple identical parts.

Benefits of using jigs and fixtures include:

Improved cut accuracy and repeatability

Reduced setup time for repeated cuts

Minimized material waste due to consistent positioning

Preventive Maintenance Programs

A well-structured preventive maintenance program is essential for keeping your waterjet cutting machine in peak condition. It helps reduce unexpected downtime, extends equipment lifespan, and ensures consistent performance.

Setting Up a Preventive Maintenance Program

Creating a preventive maintenance program ensures that maintenance tasks are performed regularly and on time, preventing costly breakdowns.

Importance of a Structured Maintenance Schedule: A maintenance schedule keeps track of regular tasks like checking nozzles, pumps, and filters. It helps in planning downtime for maintenance without affecting production schedules.

Monitoring Machine Performance and Component Wear: Regularly monitor key components like the cutting head, abrasive feed system, and water filters for signs of wear. Early detection of issues can prevent major failures and extend the machine’s operating life.

Training Operators

Proper operator training is a critical component of any preventive maintenance program. Well-trained staff can identify potential issues before they escalate.

Providing Comprehensive Training for Operators: Operators should receive detailed training on how to perform routine checks and maintenance tasks. This helps minimize errors and improves overall machine efficiency.

Safety Protocols and Troubleshooting Training: Ensuring operators know how to follow safety protocols and troubleshoot common problems reduces the risk of accidents and machine damage.

Utilizing Maintenance Software

Maintenance software streamlines the maintenance process by automating many routine tasks and providing alerts when action is needed.

Benefits of Preventive Maintenance Software: Tools like Intelli-VISOR track system performance, predict potential issues, and provide alerts before failures occur. This helps in planning maintenance activities efficiently.

Tracking Component Lifecycles and Issuing Maintenance Alerts: Software can monitor component lifecycles, track wear patterns, and issue maintenance alerts, ensuring timely part replacements and reducing the risk of breakdowns.

By setting up a structured maintenance program, investing in operator training, and utilizing advanced software tools, you can significantly improve the reliability and performance of your waterjet cutting system.

Conclusion

Waterjet cutting is a powerful tool, but maintaining peak performance requires proactive care. Key components like the cutting head, pump, and abrasive system need regular attention. Setting up a structured maintenance program ensures smooth operations and fewer breakdowns.

Proactive maintenance and troubleshooting help extend equipment life and reduce costs. Staying up-to-date with best practices is vital for continuous improvement. By investing in operator training and using modern maintenance tools, you can maximize efficiency and keep your waterjet system running at its best.

Reference Sources

water jet cutter

Best CNC Machining Services In China