Have you ever wondered how complex plastic parts are made? Acrylic injection molding plays a crucial role in creating everyday products. This process shapes acrylic into durable, clear, and precise items.

In this comprehensive guide, we'll explore what acrylic injection molding is and its importance. You'll learn about the injection molding process, benefits, and applications of this versatile technique.

What is Acrylic (PMMA)?

Acrylic, also known as Poly(methyl methacrylate) or PMMA, is a transparent thermoplastic often used in injection molding. It's a synthetic polymer derived from acrylic acid or methacrylic acid.

Compared to other injection molding materials, acrylic stands out for its unique properties:

Glass-like transparency: Acrylic boasts an impressive 92% light transmittance, making it clearer than many other plastics.

Shatter-resistance: Unlike glass, acrylic is much more resistant to shattering or breaking on impact.

Lightweight: It's about half the weight of glass, making it easier to handle and transport.

The advantages of using acrylic in injection molding are numerous:

Optical clarity: With its high transparency and low haze value, acrylic is perfect for applications requiring clear, unobstructed views.

Durability: Acrylic's strength and impact resistance make it suitable for products that need to withstand wear and tear.

Weather resistance: It can endure exposure to UV light and moisture without significant degradation, ideal for outdoor use.

Chemical resistance: Acrylic resists many chemicals, including diluted acids, alkalis, and aliphatic hydrocarbons.

Recyclability: Unlike some other plastics, acrylic is 100% recyclable, reducing its environmental impact.

Properties of Acrylic for Injection Molding

To fully grasp why acrylic is such a fantastic choice for injection molding, we must dive into its unique properties. Let's explore the physical, mechanical, thermal, and optical characteristics that make acrylic stand out.

Physical Properties

Density: Acrylic has a density ranging from 1.13 to 1.19 g/cm³. This makes it lighter than many other plastics, allowing for the creation of lightweight yet durable parts.

Shrinkage Rate: With a shrinkage rate of 0.4-0.61%, acrylic maintains excellent dimensional stability during the injection molding process. It ensures your parts remain true to their designed dimensions.

Rockwell Hardness: Boasting a Rockwell hardness of 71-102 (R scale), acrylic showcases impressive surface hardness. This property contributes to its scratch resistance and overall durability.

Mechanical Properties

Tensile Strength: Acrylic's tensile strength at yield ranges from 6,390 to 10,700 PSI. It can withstand significant stress before deforming or breaking, making it suitable for demanding applications.

Elongation: With an elongation at break of 3.0-12%, acrylic exhibits moderate ductility. While not as flexible as some other plastics, it still offers some give without compromising strength.

Flexural Modulus and Strength: Acrylic's flexural modulus spans from 247,000 to 509,000 PSI, while its flexural strength ranges from 6,770 to 18,900 PSI. These properties highlight its ability to resist bending and maintain structural integrity under load.

Thermal Properties

Melting Point: Acrylic has a melting point between 130-140°C. This relatively low melting temperature allows for efficient processing during injection molding, reducing energy consumption and cycle times.

Glass Transition Temperature: With a glass transition temperature of 85-150°C, acrylic maintains its dimensional stability and mechanical properties across a wide temperature range. It's suitable for applications exposed to varying temperatures.

Thermal Conductivity: Acrylic's low thermal conductivity of around 0.19 W/mK makes it an excellent insulator. This property is beneficial for applications requiring thermal insulation or heat resistance.

Optical Properties

Light Transmittance: One of acrylic's most remarkable properties is its high light transmittance of 91-93%. It allows for crystal-clear parts that rival the transparency of glass.

Refractive Index: Acrylic has a refractive index of 1.49, which is very close to that of glass (1.50). This property enables acrylic to be used in various optical applications, such as lenses and light guides.

Haze Value: With a low haze value, acrylic maintains excellent clarity and minimal light scattering. It ensures that your injection molded parts remain transparent and visually appealing.

| Property | Value Range |

| Density | 1.13-1.19 g/cm³ |

| Shrinkage Rate | 0.4-0.61% |

| Rockwell Hardness | 71-102 (R scale) |

| Tensile Strength at Yield | 6,390-10,700 PSI |

| Elongation at Break | 3.0-12% |

| Flexural Modulus | 247,000-509,000 PSI |

| Flexural Strength | 6,770-18,900 PSI |

| Melting Point | 130-140°C |

| Glass Transition Temperature | 85-150°C |

| Thermal Conductivity | ~0.19 W/mK |

| Light Transmittance | 91-93% |

| Refractive Index | 1.49 |

Acrylic Injection Molding Process

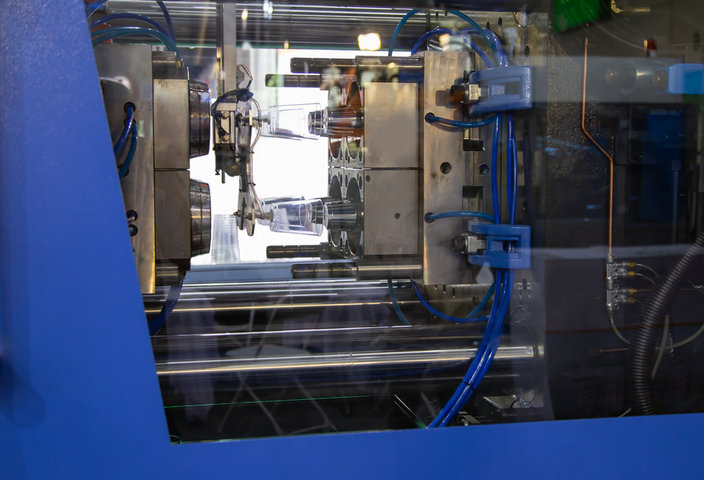

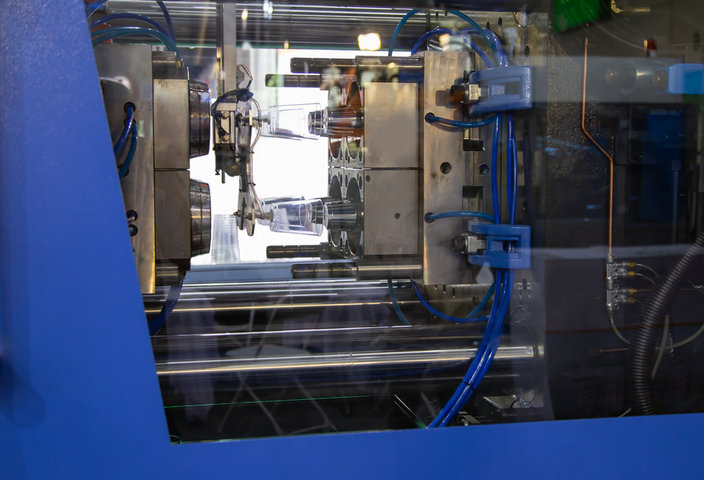

Injection molding is a popular manufacturing method for producing high-quality acrylic parts. It involves melting acrylic pellets and injecting them into a mold cavity under high pressure. The process is highly automated and can produce large quantities of identical parts with consistent quality.

Key Steps in Acrylic Injection Molding

Material Preparation and Drying:

Acrylic pellets are hygroscopic, meaning they absorb moisture from the air. Before molding, they must be dried to prevent defects like bubbles, warping, and discoloration.

Drying typically occurs in a hopper dryer at 80-90°C for 3-4 hours, reducing moisture content to below 0.1%.

Injection Molding Machine Setup:

The dried acrylic pellets are loaded into the hopper of the injection molding machine. The machine heats the pellets until they melt into a viscous liquid.

The mold, designed to create the desired part shape, is installed and securely clamped in the machine.

Mold Clamping and Injection:

The two halves of the mold are tightly clamped together using hydraulic or mechanical force. This prevents molten acrylic from escaping during injection.

The screw inside the machine's barrel pushes the molten acrylic through the nozzle and into the mold cavity at high pressure (usually 5,000-20,000 PSI).

Cooling and Solidification:

Once the mold is filled, the molten acrylic begins to cool and solidify. Cooling channels in the mold help regulate temperature and speed up the process.

As the acrylic cools, it shrinks slightly. The mold is designed to account for this shrinkage, ensuring dimensional accuracy.

Mold Opening and Part Ejection:

After the acrylic has cooled and solidified, the mold opens, and the part is ejected using pins or an air blast.

The ejected part may have small bits of excess material called "sprues" or "runners," which are removed in the next step.

Post-Processing and Finishing:

The sprues and runners are trimmed off the part using manual or automated methods. Any remaining imperfections are sanded or polished away.

Depending on the application, additional post-processing steps may include painting, printing, or assembly with other components.

Important Parameters to Control

To ensure consistent quality and prevent defects, several key parameters must be carefully controlled during acrylic injection molding:

Injection Pressure and Speed:

Injection pressure affects how well the mold fills and the amount of shrinkage. Too low pressure can cause incomplete filling, while too high pressure can lead to overpacking and warping.

Injection speed influences the appearance and strength of the part. Slow speeds may cause surface defects, while fast speeds can lead to warping or burning.

Melt and Mold Temperatures:

The melt temperature of the acrylic must be high enough to allow easy flow but not so high that it degrades the material. Typical melt temperatures range from 225-272°C.

The mold temperature affects cooling time and part quality. Higher mold temperatures produce better surface finishes but increase cycle times. Typical mold temperatures range from 59-81°C.

Cooling Time and Shrinkage:

Cooling time depends on part thickness, mold temperature, and the type of acrylic used. Thicker parts require longer cooling times to prevent warping or sink marks.

As the part cools, it shrinks. The amount of shrinkage depends on factors like wall thickness, gate location, and processing parameters. Proper mold design and process control help minimize shrinkage.

Design Guidelines for Acrylic Injection Molded Parts

When designing acrylic parts for injection molding, several key guidelines must be followed. These ensure the best possible results in terms of strength, aesthetics, and manufacturability. Let's dive into the essential design considerations.

Wall Thickness Recommendations

Aim for a wall thickness between 0.025" and 0.150" (0.635-3.81mm). This range provides a good balance of strength, flow, and cooling.

Thinner walls allow faster cooling and shorter cycle times. They also reduce material usage and part weight.

Thicker walls provide greater strength and rigidity. However, they increase cooling time and may lead to sink marks or warping.

Importance of Maintaining Consistent Wall Thickness

Strive for uniform wall thickness throughout your part. Varying thickness can cause uneven cooling, leading to warping, sink marks, and internal stresses.

If changes in thickness are unavoidable, make transitions gradual. Avoid abrupt changes that can hinder material flow and cause defects.

Proper Use of Radii to Avoid Sharp Corners

Include radii on all corners and edges. Sharp corners concentrate stress and can cause cracking or premature failure.

A minimum radius of 0.5mm is recommended. Larger radii are even better for reducing stress and improving flow.

Generous radii also make parts easier to eject from the mold. They minimize drag and prevent the acrylic from sticking.

Draft Angles for Easy Part Ejection

Add draft angles to all vertical walls. Draft allows parts to be ejected smoothly without damaging the mold or the part itself.

A minimum draft angle of 1° is recommended for acrylic. More complex parts or textured surfaces may require higher draft angles.

Apply draft to both the core and cavity sides of the mold. This ensures a clean release and minimizes wear on the mold surfaces.

Tolerances for Acrylic Injection Molded Parts

Acrylic parts can be held to tight tolerances, but tighter tolerances increase mold complexity and cost. Consider your application's requirements carefully.

For most commercial applications, tolerances of ±0.1-0.2mm are achievable. This is suitable for parts with basic fits and standard clearances.

For high-precision applications, fine tolerances of ±0.05mm or better are possible. These require specialized mold-making techniques and tighter process control.

| Dimension (mm) | Commercial Tolerances (mm) | Fine Tolerances (mm) |

| 0-50 | ±0.1 | ±0.05 |

| 50-100 | ±0.2 | ±0.1 |

| 100-150 | ±0.3 | ±0.15 |

| 150+ | ±0.4 | ±0.2 |

Design Considerations for Optimizing Strength and Aesthetics

Reinforce areas subjected to high stress with ribs, gussets, or fillets. These features add strength without increasing wall thickness.

Avoid undercuts or overhangs that complicate mold design. If unavoidable, use sliding cores or inserts to create these features.

Consider the parting line location and gate placement. These affect the appearance and strength of the final part.

Utilize texture or surface finishing to enhance aesthetics. Textured surfaces can hide minor defects and create visual interest.

Advantages of Acrylic Injection Molding

Acrylic injection molding offers a host of benefits for manufacturers and designers alike. From design flexibility to cost-effectiveness, this versatile process can help bring your vision to life. Let's explore the key advantages in detail.

Design Flexibility and Complexity

One of the greatest strengths of acrylic injection molding is its ability to produce complex, intricate shapes. With the right mold design, you can create parts with:

This flexibility allows you to design parts that would be difficult or impossible to make with other methods. You can also consolidate multiple components into a single, streamlined part, reducing assembly time and costs.

High-Volume Production Capabilities

Injection molding is the go-to process for high-volume production. Once the mold is created, parts can be produced rapidly and consistently, with cycle times ranging from seconds to minutes.

Ideal for production runs of 1,000+ parts

Highly automated process with minimal manual labor

Consistent quality from part to part

Scalable to meet growing demand

If you need large quantities of identical acrylic parts, injection molding is hard to beat. It can help you ramp up production quickly and efficiently.

Cost-Effectiveness Compared to Other Manufacturing Methods

While the initial cost of creating a mold may seem high, injection molding becomes increasingly cost-effective as production volumes increase.

Compared to other methods like CNC machining or 3D printing, injection molding offers:

Over the life of a product, these savings can add up significantly, making injection molding a smart choice for long-term production.

Ability to Incorporate Multiple Colors and Finishes

Acrylic injection molding allows you to create parts in a wide range of colors and finishes. You can:

Use pre-colored acrylic pellets for consistent, vibrant hues

Add colorants to clear acrylic for translucent effects

Incorporate multiple colors in a single part using co-injection or overmolding

Apply surface finishes like paint, texture, or metallic coatings

This versatility lets you create parts that aren't just functional, but visually stunning as well. You can match corporate colors, create eye-catching designs, or add branding elements with ease.

Faster Production Times than Traditional Glass Manufacturing

Compared to traditional glass manufacturing processes like blowing or casting, acrylic injection molding is much faster. It offers:

Shorter lead times for mold creation

Faster cycle times for part production

Reduced need for secondary finishing operations

Ability to produce complex shapes in a single step

| Process | Typical Lead Time | Cycle Time per Part |

| Acrylic Injection Molding | 4-6 weeks | 30-60 seconds |

| Glass Blowing | 8-12 weeks | 5-15 minutes |

| Glass Casting | 6-10 weeks | 30-60 minutes |

If you need clear, glass-like parts quickly, acrylic injection molding is the way to go. You can bring products to market faster and respond to changing demands with agility.

Applications of Acrylic Injection Molded Parts

Acrylic injection molding is a versatile process that finds use in countless industries and applications. From automotive components to medical devices, this material and manufacturing method offer a unique combination of properties that make it ideal for a wide range of products.

Automotive Industry

In the automotive world, acrylic injection molding is a go-to choice for creating clear, durable parts that can withstand the rigors of the road.

Headlight and Taillight Lenses: Acrylic's transparency and impact resistance make it perfect for crafting lenses that illuminate the way while standing up to debris and weather.

Instrument Panels and Gauges: With its ability to be tinted and printed, acrylic is often used for creating clear, easily readable instrument clusters and gauges.

Automotive manufacturers rely on acrylic to provide both functionality and style in their vehicles.

Medical Devices

The medical field also benefits greatly from acrylic injection molding. Its clarity, biocompatibility, and ease of sterilization make it a top choice for various applications.

Syringes and Vials: Acrylic's glass-like appearance and precision moldability allow for the creation of syringes and vials that are both functional and visually inspectable.

Diagnostic Equipment: From test tubes to cuvettes, acrylic's optical properties and chemical resistance make it ideal for diagnostic equipment that requires clear, reliable results.

| Application | Key Benefits |

| Syringes | Transparency, precision, sterilizable |

| Vials | Clarity, chemical resistance, moldability |

| Test Tubes | Optical properties, durability, cost-effective |

| Cuvettes | Transparency, consistent dimensions, disposable |

Acrylic helps medical professionals deliver better care with tools they can trust.

Consumer Products

In the world of consumer goods, acrylic injection molding offers endless possibilities for creating products that are both functional and stylish.

Eyewear and Sunglasses: Acrylic's lightweight nature, UV resistance, and ability to be tinted make it a popular choice for crafting fashionable, protective eyewear.

Mobile Phone Cases and Screens: With its impact resistance and moldability, acrylic is often used to create durable, clear cases and screen protectors for smartphones and other devices.

From fashion accessories to electronic gadgets, acrylic helps create products that consumers love to use and show off.

Lighting Fixtures and Lenses

Acrylic's outstanding optical clarity and light transmission properties make it a natural fit for various lighting applications.

Used to create everything from light diffusers and lampshades to LED lenses and light guides.

Can be tinted, textured, or patterned to create unique lighting effects and designs.

Offers durability and UV resistance for both indoor and outdoor lighting fixtures.

Acrylic helps illuminate spaces while enhancing aesthetics and ambiance.

Signage and Displays

The world of signage and displays is another area where acrylic injection molding shines.

Frequently used for creating eye-catching, durable signs and displays for both indoor and outdoor use.

Can be tinted, printed, or etched with logos, graphics, and text for effective branding and communication.

Provides a modern, professional look that captures attention and conveys quality.

From store signs to trade show displays, acrylic helps businesses make a lasting impression.

Home Appliances and Kitchenware

Finally, acrylic injection molding is also making its way into our homes through various appliances and kitchenware.

Used for creating clear, stylish components like refrigerator drawers, blender jars, and food storage containers.

Offers a combination of aesthetics, durability, and food safety that glass and other plastics can't match.

Allows for unique designs and features that enhance the user experience and functionality of appliances.

Acrylic is helping create home products that are as beautiful as they are practical, elevating everyday tasks and spaces.

Troubleshooting Common Acrylic Injection Molding Issues

Acrylic injection molding is a precise process that requires careful control of various parameters. When things go wrong, it can lead to a range of defects that compromise the quality and functionality of the final parts. Let's explore some common issues and how to solve them.

Bubbles and Voids

Bubbles and voids are empty spaces that form within the walls of a molded part. They can weaken the structure and create unsightly blemishes on the surface.

Causes:

Moisture in the acrylic pellets

Low injection pressure or speed

Inadequate venting of the mold

Excessive mold release agent

Solutions:

Ensure proper drying of acrylic before molding

Increase injection pressure and speed to fill the mold completely

Add or enlarge vents in the mold to allow air to escape

Reduce the amount of mold release agent used

Sink Marks and Warpage

Sink marks are shallow depressions that appear on the surface of a part, while warpage is a distortion or twist in the overall shape.

Causes:

Thick wall sections that cool unevenly

Insufficient cooling time

Excessive injection pressure or speed

Non-uniform mold temperature

Solutions:

Maintain consistent wall thickness throughout the part

Increase cooling time to allow the part to solidify evenly

Reduce injection pressure and speed to prevent over-packing

Ensure uniform mold temperature with proper cooling channels

Weld Lines and Flow Marks

Weld lines are visible seams that occur when two flow fronts meet, while flow marks are streaks or patterns on the surface caused by inconsistent material flow.

Causes:

Insufficient injection pressure or speed

Low melt temperature

Poorly designed gate locations

Thin wall sections that cool too quickly

Solutions:

Increase injection pressure and speed to ensure proper filling

Raise the melt temperature to improve flow and reduce viscosity

Optimize gate locations to promote even flow and minimize weld lines

Increase wall thickness in problem areas to slow down cooling

Discoloration and Burning

Discoloration is an unintended change in the color of the acrylic, while burning is a more severe degradation that results in dark streaks or specks.

Causes:

Excessive melt temperature

Prolonged residence time in the barrel

Contamination from degraded material

Inadequate venting of gases

Solutions:

Lower the melt temperature to prevent overheating and degradation

Reduce residence time by optimizing shot size and cycle times

Purge the machine regularly to remove degraded material

Improve venting to allow gases to escape and prevent burning

Short Shots and Incomplete Filling

Short shots are parts that are not completely filled out, resulting in missing features or uneven surfaces.

Causes:

Low injection pressure or speed

Insufficient material in the shot

Restricted flow due to thin walls or long flow paths

Cold mold or melt temperature

Solutions:

Increase injection pressure and speed to ensure complete filling

Adjust the shot size to provide enough material for the part

Increase wall thickness or redesign flow paths to improve flow

Raise the mold and melt temperatures to promote better flow

| Issue | Causes | Solutions |

| Bubbles and Voids | Moisture, low pressure, poor venting | Dry material, increase pressure, add vents |

| Sink Marks and Warpage | Thick walls, insufficient cooling | Consistent thickness, increase cooling time |

| Weld Lines and Flow Marks | Low pressure, low temperature, poor gating | Increase pressure and temperature, optimize gates |

| Discoloration and Burning | High temperature, long residence time, contamination | Lower temperature, reduce residence time, purge machine |

| Short Shots and Incomplete Filling | Low pressure, insufficient material, restricted flow | Increase pressure, adjust shot size, improve flow paths |

Choosing the Right Acrylic Grade for Your Application

Not all acrylics are created equal. Different grades offer unique properties and benefits that can make or break your application. Let's explore the various types of acrylic and how to choose the best one for your needs.

Different Types of Acrylic Grades and Their Properties

Acrylic comes in a range of grades, each with its own set of characteristics. Some common types include:

General Purpose (GP) Acrylic: Offers a balance of clarity, strength, and affordability. Suitable for a wide range of applications.

High Heat (HH) Acrylic: Can withstand higher temperatures without deforming or degrading. Ideal for lighting fixtures and automotive components.

High Flow (HF) Acrylic: Has a lower viscosity, allowing for easier filling of thin-walled or intricate molds. Perfect for complex designs.

| Grade | Key Properties | Typical Applications |

| GP Acrylic | Balanced performance | Signs, displays, food containers |

| HH Acrylic | Thermal stability | Lighting, automotive, appliances |

| HF Acrylic | Easy flow, thin walls | Electronics, medical devices, packaging |

Impact-Modified Acrylic for Improved Toughness

For applications that require extra durability, impact-modified acrylic is a great choice. It contains additives that enhance its impact resistance without sacrificing clarity.

Ideal for parts that may be dropped or subjected to sudden forces, like tool handles or safety glasses.

Offers up to 10 times the impact strength of standard acrylic.

Maintains excellent transparency and weatherability.

UV-Stabilized Acrylic for Outdoor Applications

If your parts will be exposed to sunlight, UV-stabilized acrylic is a must. It contains special additives that prevent yellowing and degradation caused by UV rays.

Essential for outdoor signage, lighting fixtures, and automotive components.

Prolongs the life and appearance of parts exposed to sunlight.

Available in various grades with different levels of UV protection.

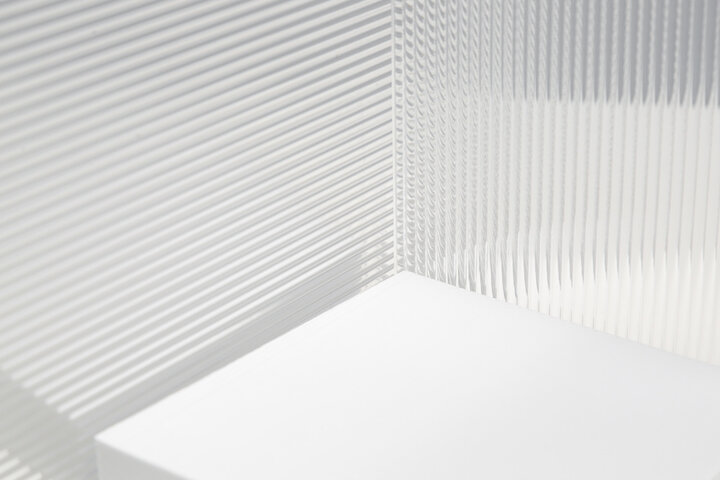

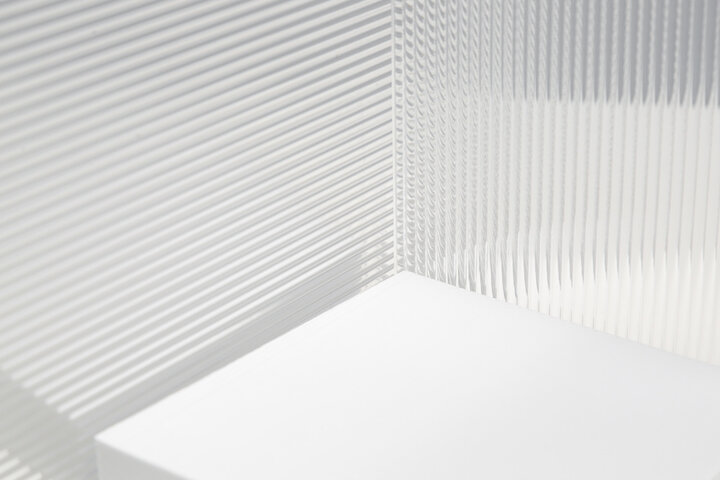

Transparent, Translucent, and Opaque Options

Acrylic can be molded in a range of transparencies to suit your aesthetic and functional needs.

Transparent Acrylic: Offers the highest level of clarity, allowing for maximum light transmission and visibility. Ideal for lenses, windows, and displays.

Translucent Acrylic: Allows some light to pass through while diffusing it for a softened, frosted appearance. Perfect for light fixtures and decorative panels.

Opaque Acrylic: Completely blocks light transmission for a solid, uniform appearance. Can be colored or textured for various effects. Suitable for signage, appliances, and automotive components.

Factors to Consider When Selecting an Acrylic Grade

With so many options available, how do you choose the right acrylic grade for your application? Consider these key factors:

Mechanical Properties: Evaluate the strength, stiffness, and impact resistance required for your part. Consider factors like load-bearing capacity, flexural modulus, and tensile strength.

Thermal Properties: Assess the temperature range your part will be exposed to. Look for grades with higher heat deflection temperatures (HDT) if necessary.

Optical Properties: Determine the level of transparency, light transmission, and haze that is acceptable for your application. Consider any color or tint requirements as well.

Chemical Resistance: Evaluate the chemicals and solvents your part may come into contact with. Choose a grade that offers adequate resistance to prevent degradation or stress cracking.

UV Resistance: If your part will be used outdoors or exposed to sunlight, select a UV-stabilized grade to prevent yellowing and maintain mechanical properties over time.

Processing Requirements: Consider the flow properties, shrinkage rates, and molding temperatures of different grades. Some grades may be easier to process or more suitable for certain mold designs.

Conclusion

Acrylic injection molding is essential for making clear, strong, and precise parts. It offers many benefits, like excellent optical clarity and durability. This process is vital in industries from automotive to medical devices.

Consider acrylic injection molding for your next project. It’s versatile and reliable for various applications. Explore further resources and consult with experts for professional services. You'll find it valuable and beneficial for your manufacturing needs.