The use of aluminum alloys extends across various industries, including construction, aerospace, sports equipment, electrical, and automotive. Their outstanding strength-to-weight ratio, high relative strength, corrosion resistance, and machinability make them highly sought after. But with so many aluminum alloys available, the decision-making process can be quite daunting.

In this article, I will compare 6061 and 7075 aluminum alloys, highlighting their unique features and helping you determine which alloy suits your project needs best. From conductivity and corrosion resistance to overall strength, these two aluminum alloys have their distinct advantages and applications. So, let's dive into the world of 6061 and 7075 aluminum alloys and discover what sets them apart.

Alloy 6061 - A Comprehensive Overview

Cemical Composition of 6061

Aluminum 6061 is a structural metal widely recognized for its versatility. Its chemical makeup includes a mix of magnesium and silicon, which are key to its properties. Here's a simple breakdown:

● Magnesium(Mg): 1.0%

● Silicon: 0.6%

● Chromium(Cr): 0.2%

● Copper(Cu): 0.28%

● Aluminum(Al): 97.9%

This blend is what makes 6061 an alloy. It's not just pure aluminum - the added elements change how it behaves.

Physical and Mechanical Properties

When we talk about 6061, we're looking at a material that's been heat treated to increase its tensile strength. Here are some quick facts:

● Tensile Strength: around 20,000 to 42,000 psi

● Yield Strength: about 8,000 to 35,000 psi

● Density: roughly 2.7 g/cm³

6061 is also known for its good corrosion resistance and weldability. It's not as hard as some other aluminum alloys, but it's strong enough for many jobs. Plus, it has a decent strength-to-weight ratio.

Common Applications and Uses

6061 is used in lots of things. It's common in:

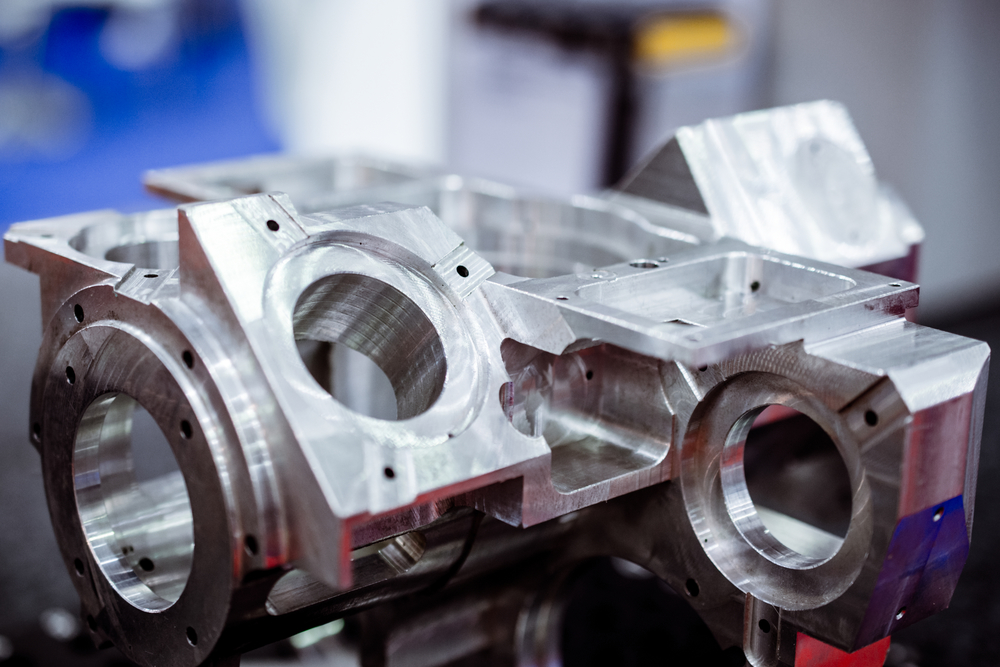

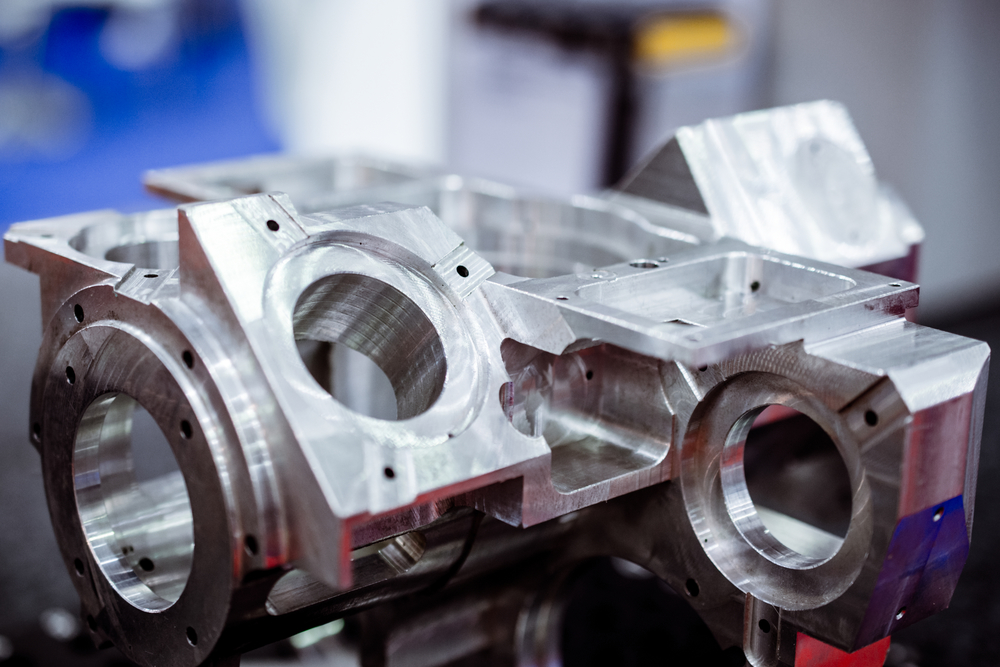

● Aluminum machining projects

● Extrusion projects like tubes and rods

● Parts that need 5-axis precision machining

It's a go-to for CNC machining because it's easy to cut and shape. You'll find it in cars, boats, and even in some buildings.

Advantages and Limitations

Let's talk about the good and not-so-good parts of 6061. First, the pros:

● Good Machinability: It's easy to cut and shape.

● Welding: It welds well, which is great for building things.

● Corrosion Resistance: It stands up to the elements pretty well.

But, it's not perfect. Here are some cons:

● Strength: It's not as strong as 7075, especially in high-stress applications.

● Heat Treatment: It needs to be treated with care to get the best mechanical properties.

Alloy 7075 - An In-Depth Look

Chemical Composition of 7075

Aluminum 7075 stands out due to its unique chemical composition. It's a blend that includes higher levels of zinc and copper, along with some magnesium and silicon. This mix gives it a robust set of attributes. Here's a simple breakdown:

● Zinc: About 5.6-6.1%

● Magnesium: 2.1-2.9%

● Copper: 1.2-2.0%

● Chromium (Cr): 0.23%

These elements work together to create a metal that's tough and ready for challenging tasks.

Physical and Mechanical Properties

When we talk about 7075 alloy, we're looking at some impressive physical and mechanical properties. This metal is heat treated, which boosts its tensile strength significantly. It's why 7075 T6, a specific kind of this alloy, is so sought after. Here are a few key properties:

● Density: 2.81 g/cm³

● Tensile Strength: Up to 83,000 psi

● Yield Strength: Up to 73,000 psi

● Melting Point: 477-635°C (890-1175°F)

These numbers tell us that 7075 aluminum is one tough cookie, especially for high-stress applications.

Industrial Applications and Utilization

In the world of industrial applications, 7075 aluminum is a star. It's the go-to for aerospace parts because of its strength-to-weight ratio. You'll find it in:

● Aircraft fittings

● Gears and shafts

● Missile parts

It's not just about planes and rockets, though. This alloy is also great for extrusion projects and commercial purposes where durability is key.

Strengths and Challenges

Let's chat about the good and the tough parts of working with 7075 alloy. Its strengths are clear:

● Super high-stress resistance

● Great for aerospace and military gear

● Solid corrosion resistance

But, it's not all smooth sailing. There are some challenges too:

● It's harder to weld than 6061

● Not as good at anodizing as other aluminum alloys

● Can be more expensive, so keep an eye on that budget

Mechanical and Physical Properties

When we talk about Aluminum 6061 and Aluminum 7075, we're looking at two top alloy grades with distinct mechanical properties. Now, let's break down these properties to see which metal could be the right choice for your project.

Strength Comparison: 7075 vs 6061

7075 alloy is often called 'aircraft grade' because it's super strong. It has a higher tensile strength than 6061 alloy, which means it can handle more force without breaking. 7075 has zinc as its primary alloying element, giving it this extra strength.

On the other hand, 6061 is made with magnesium and silicon. It's not as strong as 7075, but it's still pretty tough. For projects that don't need the highest strength, like some extrusion projects or commercial purposes, 6061 could be a great fit.

Density and Weight Considerations

When it comes to density and weight, 6061 aluminum is lighter. This makes it a go-to for jobs where you want to keep things light but still sturdy. Think about parts that need to be easy to move or carry.

Heat Treatment and Thermal Conductivity

Both 6061 and 7075 aluminum can be heat treated. Heat treatment can make them even stronger. But they respond differently to it. For instance, 7075 T6 is one of the toughest options out there after heat treatment.

As for thermal conductivity, 6061 is the winner. It spreads heat better, which can be important in keeping things cool, like in aluminum machining.

Electrical Resistivity and Melting Points

7075 and 6061 have similar melting points, around 1080°C to 1200°C. But their electrical resistivity is different. 6061 usually has better conductivity, which could be important for electrical applications.

Mechanical Properties: Elasticity and Hardness

If we talk elasticity, the modulus of elasticity for both aluminum materials is similar. This means they'll both bend a bit under stress but bounce back. For hardness, 7075 often gets the edge, especially in the 7075 T6 condition. It's harder, which means it can resist scratches and wear better.

When choosing between 6061 and 7075 aluminum, consider the strength, weight, heat treatment, conductivity, and mechanical properties like elasticity and hardness. Your choice will depend on your budget, the applications, and the specific fabrication considerations for your project.

Evaluating the Machinability of 7075 and 6061

When we talk about machinability, we mean how easy it is to shape metal using machines. Both Aluminum 6061 and Aluminum 7075 have good machinability, but they are different. 6061 alloy is often chosen because it's easier to cut and shape. This is because it has magnesium and silicon in it. These make it more friendly to work with when using tools like CNC Machining.

7075 alloy, on the other hand, is a bit tougher to work with. It's because it has more zinc and copper. This makes it harder, which is good for strength but can be a challenge for cutting and shaping.

Forming and Welding Capabilities

Now, let's talk about forming and welding. Forming means bending or shaping the metal. Welding is like gluing metals together with heat. Aluminum 6061 is the star here. It's great for projects that need bending and welding because it doesn't crack easily. Plus, it can handle being heated up and cooled down again without getting weak.

7075 Aluminum isn't as easy to weld. That's because it's a heat treated metal. When you heat it, it can lose some of its strength. So, if you need to weld, 6061 might be your best bet.

Case Studies: Practical Applications in Machining

Let's look at real-life examples. Imagine we're making parts for a bike. A bike needs to be strong but also light. 6061 aluminum is often used for the frame because it's strong enough but also easy to shape into tubes. Plus, it doesn't cost a lot.

For things that need to be super strong, like parts of an airplane, 7075 aluminum is often used. It's known as aircraft grade because it has a high strength-to-weight ratio. This means it's really strong for how light it is. But, it's harder to shape and costs more.

If you're making something that needs to be shaped a lot and is on a budget, go for 6061. If you need something super strong for high-stress applications like in aerospace, 7075 might be the way to go, even though it's trickier to work with.

Both these aluminum alloys are great options. It just depends on what you need for your project.

Corrosion Resistance and Anodizing

Corrosion Resistance: A Comparative Study

When we talk about Aluminum 6061 and Aluminum 7075, we're looking at two alloy grades with different chemical compositions. Corrosion resistance is a key factor we consider. Aluminum 6061 has magnesium and silicon as its main alloying elements. This mix gives it a good defense against corrosion. On the other hand, Aluminum 7075 contains more zinc and copper. While it's stronger, it's not as resistant to corrosion as 6061 alloy.

Anodizing Potential of 7075 and 6061

Anodising is a smart way to protect and beautify aluminum. Both 6061 and 7075 can go through this electrochemical process. But, 6061 usually does better. It forms a uniform oxide layer that can take on colors well. This makes it a top pick for projects where looks matter.

Anodising Process for Aluminium Alloys

Here's how it works. We dip the metal in an acid bath and run a current through it. This builds up an oxide layer on the surface. This layer is what fights off rust and lets us add colors. Both 6061 and 7075 can be anodized, but the results can look different.

Coloration and Aesthetic Considerations

If you want color, 6061 alloy is often the way to go. It takes on dyes evenly, so it looks great. 7075 alloy can also be colored, but it might not be as vibrant. This is something to think about if the look is as important as the function.

Long-term Durability and Maintenance

For something that lasts, both alloys are strong choices. But 6061 might need less care over time because of its better corrosion resistance. It's a balance, though. If you need more strength-to-weight ratio, like in aerospace or high-stress applications, 7075 might be your alloy.

Choosing the right aluminum materials depends on your budget, applications, and the properties of metals you need. Alloy comparison isn't just about one thing. It's about looking at all the attributes, from corrosion resistance to machinability to anodizing potential.

Applications in Industry

Aerospace and Aviation Uses

Aluminum 6061 and Aluminum 7075 are both vital in the aerospace industry. Their light weight and strength make them perfect for aircraft. The 7075 alloy, often referred to as aircraft grade, boasts a high tensile strength and is commonly used in high-stress applications. It's found in wings and fuselages where durability is key. On the other hand, 6061 is used for its welding properties and is often found in aircraft fittings and wing-tips.

Automotive and Transport Applications

In the world of automotive and transport, both aluminum alloys play a big part. The 6061 alloy is known for its versatility and is used in auto parts like wheels and chassis. Its corrosion resistance makes it a good choice for vehicle bodies. The 7075 alloy, with its higher strength, is used in racing applications and for parts that take more stress, like gearboxes and suspension components.

Marine and Structural Engineering

For marine uses, corrosion resistance is super important. That's why Aluminum 6061, with its good resistance to seawater, is often used. It's found in boat hulls and marine fittings. For structural engineering, both alloys are used. 7075's high strength is perfect for structures that need to be light yet strong.

Construction and Structural Applications

In construction, 6061 aluminum is a go-to structural metal. Its good formability and welding properties make it ideal for building frames and bridges. 7075 is less common in construction due to its less favorable fabrication considerations.

Consumer Goods and Miscellaneous Uses

Consumer goods benefit from both aluminum materials. 6061 is often seen in products like bicycles and fishing reels for its machinability and anodising ability. 7075 is used in gadgets and tools that need more hardness and strength, like rock climbing equipment.

Each alloy grade has its own chemical composition and mechanical properties that make it suitable for different industrial applications. Whether it's the silicon and magnesium in 6061 or the zinc, copper, and magnesium in 7075, these alloy types have unique attributes that are essential across various applications. When choosing an alloy for a project, consider factors like budget, strength-to-weight ratio, and specific properties of metals needed.

Aluminum 6061 is known for its workability and corrosion resistance, while Aluminum 7075 is recognized for its superior strength and use in aerospace and other high-stress applications. Each has its place in industrial applications, and the alloy choice depends on the project requirements and desired attributes.

Choosing the Right Alloy for Your Project

When you're picking the right alloy for your project, think about these big ideas: Strength, Cost, and Availability. These are like your compass for making a smart choice.

Decision Factors: Strength, Cost, Availability

● Strength: How strong do you need your metal to be? Aluminum 6061 is pretty tough, but Aluminum 7075 is even stronger. It's like the difference between a good bike helmet and a pro racing helmet.

● Cost: Money matters, right? Generally, 6061 is less expensive. If your budget is tight, this might be the way to go.

● Availability: Can you easily get what you need? Aluminum 6061 is like the bread and butter of aluminum materials – it's everywhere. But 7075 might take a bit more searching.

Project-Specific Alloy Selection

Let's say you're working on a project. You need to think about what you're making. Is it a part for a bike? Maybe some fancy gadget? Here's a quick guide:

● If you're doing something that needs to bend a bit or be shaped, like an aluminum tube or plate, go for 6061. It's got good formability and welding is a breeze.

● But if you're making something that's going to get super stressed out, like parts for an airplane, you'll want 7075. It's got that high-stress application vibe, thanks to its zinc and copper mix.

Expert Opinions and Case Studies

Experts in aluminum machining love to talk about these two alloy grades. They'll tell you that 6061 is your go-to for most things. It's like the friendly neighborhood metal. It's got magnesium and silicon, which is a solid team for structural materials.

But then you've got 7075 – the aircraft-grade hero. It's the one you call in when things get tough. 7075 T6, for instance, is heat treated to be super strong. It's used in aerospace because it has an amazing strength-to-weight ratio.

Here's what one machinist said: "For 5-axis precision machining, 7075 can be a dream. It's tough, but it can handle the challenge." And about extrusion projects, 6061 was more cost-effective and just right for the job.

FAQs on 7075 and 6061 Aluminium Alloys

What are the key differences in chemical composition?

Aluminum 6061 is made up of magnesium and silicon as its main alloying elements. On the other hand, Aluminum 7075 contains higher levels of zinc and copper. This difference in chemical composition leads to distinct mechanical properties.

How does the choice of alloy affect the end product?

The alloy choice can make a big difference. For instance, 6061 alloy is known for its versatility and good corrosion resistance, making it suitable for commercial purposes like making aluminum plates or extrusion projects. 7075 alloy, with its high tensile strength and hardness, is often used in high-stress applications like in aerospace or military equipment.

Can both alloys be used interchangeably in certain applications?

Sometimes, yes. But, it depends on the application. If the project needs high strength-to-weight ratio and can handle the cost, 7075 might be used. Yet, for projects that need good welding and formability, 6061 is often the better pick.

What Makes 6061 Suitable for Welding Compared to 7075?

Aluminum 6061 has a better welding attribute due to its chemical composition. It's less likely to crack during the welding process, unlike 7075 which is more prone to failure because of its high zinc content.

Why is 7075 Preferred in High-Stress Applications?

Aluminum 7075 is often called aircraft grade because it has a very high tensile strength and yield strength. This means it can handle a lot of stress before it deforms. That's why it's great for parts that will be under a lot of pressure or weight.

● Aluminum Alloys like 6061 and 7075 are used in many things because they are strong but light.

● 6061 is often used to make things like aluminum tubes or frames because it's easy to shape and join together.

● 7075 is used when you need something really strong, like parts for planes or bikes that go really fast.

● Even though they are both aluminum, they have different ingredients that make them good for different jobs.

Conclusion

When we look at Aluminum 6061 versus Aluminum 7075, there are a few important points to remember. The 6061 alloy is known for its versatility. It contains magnesium and silicon and offers good corrosion resistance and weldability. This makes it a go-to for many commercial purposes.

On the other hand, Aluminum 7075 is much stronger. It is heat treated and contains more zinc. This gives it a higher tensile strength, which is why it's often used in aerospace and other high-stress applications. However, it's a bit harder to work with. Its machinability is lower, and it's not as good for welding.

Best Practices in Selecting the Right Aluminum Alloy

When deciding between 6061 and 7075, think about these points:

1. Applications: What will you use the metal for? If it's for structural materials that need to be strong, 7075 might be best. If it's for extrusion projects or items that need shaping, 6061 could be better.

2. Budget: Often, 6061 is less expensive. If your budget is tight, this might influence your alloy choice.

3. Fabrication Considerations: If your project involves a lot of aluminum machining, like CNC machining or 5-axis precision machining, you'll need to consider the metal grades' machinability. 6061 generally offers better workability.

4. Mechanical Properties: You must look at the strength-to-weight ratio, yield strength, and hardness. 7075 generally wins in strength, but 6061 is more ductile.

5. Chemical Composition: The alloy composition affects the properties of metals. 7075 has more copper and zinc, while 6061 has more silicon and magnesium.

6. Corrosion Resistance: If the metal will be exposed to the elements, corrosion resistance is key. 6061 has a natural oxide layer that protects it, making it a good choice for outdoor applications.

7. Heat Treatment: 7075 can be found in the 7075 T6 form, which is fully heat treated and known for its use in aircraft grade applications. 6061 can be heat treated as well, but it's also available in an annealed condition, offering more formability.

Always consider the specific needs of your project. Each alloy has its own unique set of attributes. Understanding the alloy grades, physical properties, and mechanical properties will help you make an informed decision.