Tapped holes are threaded openings in materials. They're essential in manufacturing and assembly processes. These holes allow screws or bolts to be securely fastened.

Imagine a nut with internal threads. Now, picture that thread pattern directly in a workpiece. That's a tapped hole!

This article will demonstrate features(definition, materials, sizes,types,etc.) of tapped holes before revealing procedures and techniques when putting it into practice, thus weighing up the pros and cons of this product to better serve human’s needs.

What Are Tapped Holes?

A tapped hole is a hole that has been drilled to a specific diameter and then threaded using a cutting tool known as a tap. This process creates internal threads that are used to accommodate screws or bolts, allowing for secure fastening. The precision of the tapped hole is crucial, as the threads must match the dimensions of the fastener to ensure proper engagement and load distribution. Tapped holes are frequently used in mechanical systems and assemblies where components need to be firmly fastened and withstand considerable stress or vibration

Materials for Tapped Holes

Tapped holes can be created in a wide range of materials:

Metals: Steel, aluminum, brass, titanium

Plastics: Nylon, polycarbonate, ABS

Wood: Hardwoods, softwoods

Composites: Fiberglass, carbon fiber

Sizing Tapped Holes

Tapped holes follow several common standards:

· Metric (ISO): M6x1.0, M8x1.25

· Unified Thread Standard (UNC): 1/4-20, 3/8-16

· British Standard Whitworth (BSW): 1/4" BSW, 3/8" BSW

Tapped hole sizes are crucial for proper fit. They're typically described by:

1. Thread size (major diameter)

2. Threads per inch (TPI) or pitch

3. Depth of the threaded portion

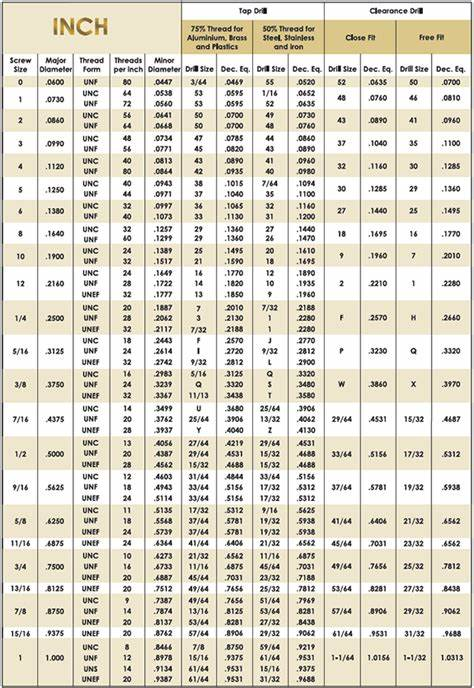

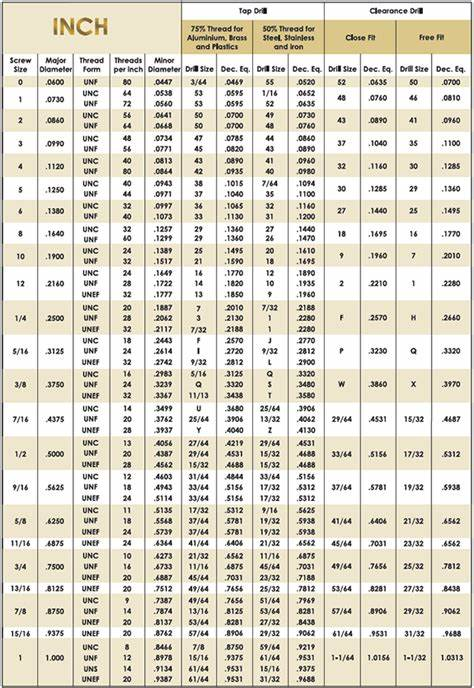

Here's a quick reference table for common sizes:

| Thread Size | TPI | Typical Applications |

| #4-40 | 40 | Small electronics |

| 1/4-20 | 20 | General purpose |

| M6 x 1.0 | 1.0 | Metric standard |

tapped holes chart

Types of Holes in Machining

1. Through Holes: Drilled entirely through the material.

2. Blind Holes: Drilled to a specific depth without breaking through.

3. Counterbore Holes: Have a cylindrical recess for flush-fitting fasteners.

4. Reamed Holes: Drilled undersized and then reamed for precision.

Comparison of Threaded Hole Types

| Type | Creation Method | Suitable Materials | Strength |

| Tapped Holes | Tapped after drilling | Most materials | High |

| Self-Tapping Screw Holes | Created by screw insertion | Softer materials | Medium |

| Threaded Inserts | Pre-fabricated inserts | Materials with poor thread retention | High |

| Helical Inserts (Helicoils) | Coiled wire inserts | Softer materials, high-stress applications | Very High |

| Pre-Tapped Holes | Machined during manufacturing | Most materials | High |

Tapped holes offer robust, accurate threads for high-stress environments. They're versatile and can be created in a wide range of materials. The choice between different threaded hole types depends on the specific application, material properties, and required strength.

Tapping Process

Creating precise and reliable tapped holes requires a systematic approach that encompasses several critical steps. The following is a detailed guide to the tapping process, ensuring optimal results:

· Step 1: Gather Tools and Materials: Drill, taps, cutting fluid, safety gear.

· Step 2: Select the Correct Tap and Drill Bit: Using a tap drill chart for proper size.

· Step 3: Drill the Hole: Accurate drilling, perpendicular alignment, and cutting fluid application.

· Step 4: Prepare for Tapping: Clean the hole, remove debris, and inspect the depth.

· Step 5: Tap the Hole: Correct alignment, use of lubrication, and chip removal to ensure a clean cut.

· Step 6: Quality Control: Inspect the threads using gauges to ensure precision.

Considerations and Tips for Machining Tapped Holes

To ensure strong, precise threaded connections when machining tapped holes, consider the following factors:

Material Hardness

Harder materials require more force and proper tools, such as carbide taps

Reduce cutting speeds for harder materials to prevent tool breakage

Precise Placement

Diameter and Thread Engagement

Hole diameter determines the strength of the connection

Too small: threads won't engage properly, resulting in a loose joint

Too large: insufficient material for threads to bite into, compromising integrity

Refer to design specifications and use the correct drill bit size

Angled Surfaces

Machining threaded holes in angled surfaces presents unique challenges

Use a floating tap holder or custom fixture to maintain hole depth and alignment

Verify final hole depth meets design specifications

Lubrication and Chip Evacuation

Proper lubrication reduces friction, heat buildup, and prevents tap breakage

Lubrication helps flush away chips, preventing clogging

Use tapping fluids with good flushing properties

Consider spiral point taps for better chip evacuation in deep holes

Pros and Cons of Tapped Holes

Pros

Solid Connection

Tapped holes provide a strong and reliable means of fastening components together. They create a secure connection that can withstand significant forces and vibrations, thus ensuring the structural integrity of the assembled parts.

Space Efficiency

Space efficiency eliminates the need for additional hardware such as nuts or washers. By threading directly into the material, tapped holes save space and simplify the assembly process.

Versatility

Tapped holes accommodate various types of screws and bolts, making them suitable for a wide range of applications. Also, they can be used in different materials, including metals, plastics, and composites.

Ease of Assembly and Disassembly

Tapped holes facilitate easy assembly and disassembly of components. They allow for quick and straightforward insertion or removal of screws or bolts, which proves advantageous during maintenance, repairs, or upgrades.

Thread Reinforcement

In some cases, tapped holes can be reinforced with inserts or helicoils. These elements are installed into the tapped hole to provide additional strength and durability to the threads. Thread reinforcement prolongs the life of the tapped hole, especially in softer materials or high-stress applications.

Cons

Thread Wear

One potential drawback of tapped holes is thread wear. Repeated insertion and removal of screws or bolts can gradually wear out the threads, particularly in softer materials. Over time, this wear can lead to loosening of the connection or difficulty in achieving a tight fit.

Cross-Threading

Cross-threading is another concern with tapped holes. It occurs when the screw or bolt is misaligned with the threads during insertion. This misalignment can cause damage to the threads, compromising the integrity of the connection. Careful alignment and proper technique are essential to prevent cross-threading.

Tap Breakage

During the tapping process, especially in hard materials, there is a risk of tap breakage. If a tap breaks inside the hole, it can be challenging to remove, leading to delays and potential damage to the workpiece. Proper tap selection, lubrication, and technique help minimize the risk of tap breakage.

Limited Load Capacity

Tapped holes in softer materials may have limited load capacity compared to other fastening methods. The threads in soft materials may not provide sufficient holding power under heavy loads or high-stress conditions. In such cases, alternative fastening techniques or thread reinforcement may be necessary.

Applications of Tapped Holes

Tapped holes find widespread use across various industries. Their ability to create strong, detachable joints makes them indispensable in countless products and applications. Let's explore some key areas where tapped holes play a crucial role.

Automotive Parts

The automotive industry heavily relies on tapped holes for assembling and mounting components. From engine blocks to body panels, tapped holes provide secure attachment points. They enable the fastening of parts like:

Mirrors

Brackets

License plates

Interior trim pieces

The use of tapped holes allows for easy installation, maintenance, and replacement of these components. They contribute to the overall structural integrity and functionality of vehicles.

Furniture Assembly

Tapped holes are commonly used in furniture assembly. They offer a convenient and reliable method for joining wooden or metal parts. Examples include:

Attaching legs to tables and chairs

Securing shelves to cabinets

Fastening drawer slides and hinges

Furniture that utilizes tapped holes can be easily assembled and disassembled for transport or storage. This feature enhances the versatility and practicality of furniture pieces.

Electronic Devices

In the electronics industry, tapped holes are used to secure components and assemblies within devices. They provide mounting points for:

Circuit boards

Heatsinks

Connectors

Enclosures

Tapped holes allow for precise positioning and stable attachment of these components. They ensure proper functionality and protect delicate electronic parts from damage due to vibration or movement.

Industrial Machinery

Industrial machinery heavily depends on tapped holes for assembly and maintenance. They are used to fasten components such as:

Gears

Bearings

Actuators

Sensors

Tapped holes facilitate the secure connection of moving parts and the mounting of equipment onto support structures. They play a vital role in ensuring the reliability and longevity of industrial machinery.

Conclusion

By providing secure and removable connections, tapped holes offer numerous advantages across these diverse applications.From automotive parts to furniture, electronic devices to industrial machinery, tapped holes are a fundamental fastening solution. Their versatility and reliability make them an essential aspect of design and manufacturing across industries.

FAQs

What is the difference between a tapped hole and a threaded hole?

A tapped hole is a hole drilled and then internally threaded using a tap. A threaded hole can refer to any hole with internal threads, regardless of how they were created (such as by tapping, thread milling, etc.). Essentially, all tapped holes are threaded holes, but not all threaded holes are tapped.

How do you determine the correct tap drill size?

To determine the correct tap drill size, identify the thread size and pitch using a thread gauge. Always select a drill size slightly smaller than the major diameter to allow proper thread engagement.

What materials are suitable for tapping?

Tapped holes can be created in a variety of materials, including metals (e.g., steel, aluminum, brass) and certain plastics. For harder materials like stainless steel, high-speed steel (HSS) or carbide taps are recommended, while softer materials may require special taps to avoid thread deformation.

What is the difference between a self-tapping screw and a tapped hole?

A self-tapping screw creates its own threads when driven into a material, eliminating the need for pre-drilled or tapped holes. Tapped holes, on the other hand, require a tap to cut threads beforehand. Self-tapping screws are often used in softer materials like wood or plastic, while tapped holes are better suited for metals and high-stress environments.

Why is lubrication important in tapping?

Lubrication reduces friction and heat, helping prevent tap breakage and ensuring cleaner, more precise threads. It also extends the life of the tap and improves the overall quality of the threaded hole.

How deep should a tapped hole be?

The depth of a tapped hole depends on the diameter of the fastener being used. A general rule is to make the thread depth at least 1.5 times the diameter of the fastener for optimal strength. For example, a 1/4-inch screw should have a hole at least 3/8 inches deep.