ABS Plastic Injection Molding

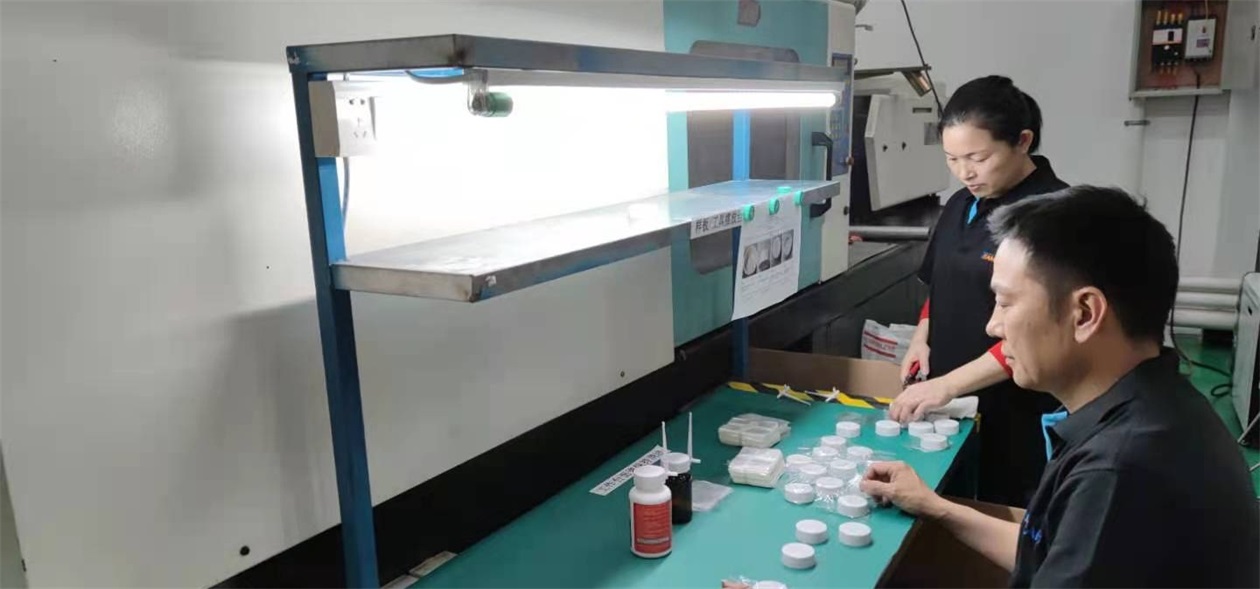

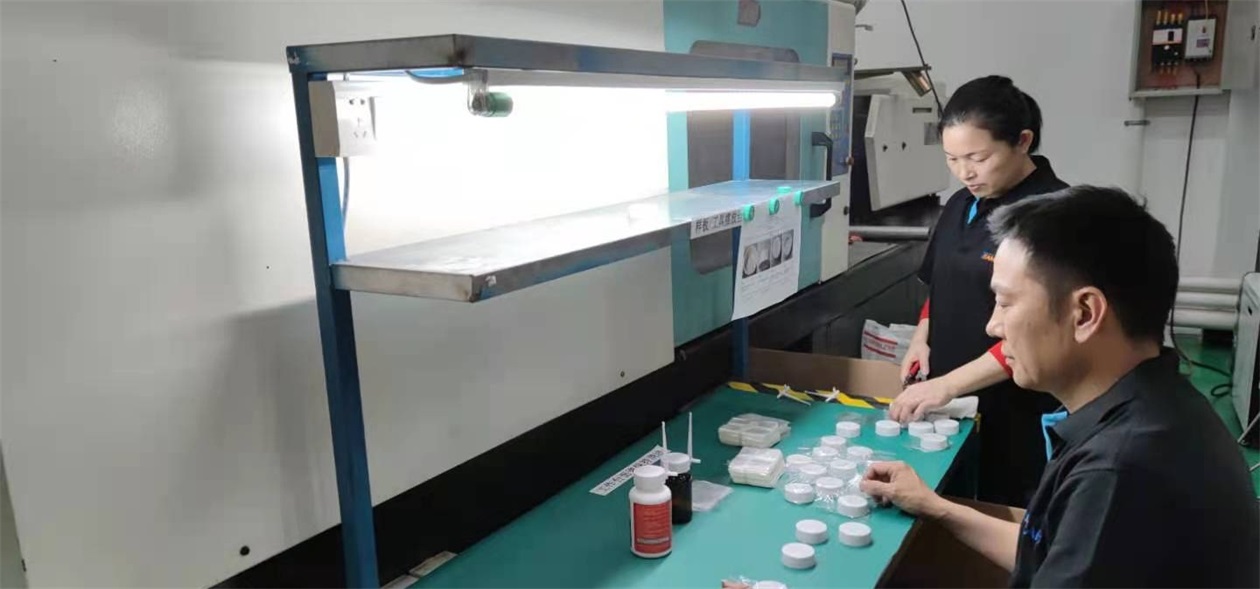

TEAM MFG offers a series of injection molding services to help with your molding project requirements. Our ABS plastic injection molding are widely used for a range of projects such as overmolding, insert molding, micromolding, ultrasonic bonding, pad printing and assembly.

Contact us for more information regarding our ABS plastic injection molding service, we are happy to assist you with your questions about tooling and molding. TEAM MFG is your preferred source in China for high quality ABS plastic injection molding parts.

Acrylonitrile butadiene styrene, short name as ABS, which is a common thermoplastic polymer widely used in injection molding. Styrene content imparts a shiny, impervious surface, while the polybutadiene it contains provides excellent toughness even at low temperatures. ABS’s excellent chemical characteristics allows it to have high performance, it is widely used in our daily life products.

Why ABS is Used So Commonly?

The ABS plastic is strongly resistant not only to the chemical corrosion but also the physical impacts. It is very easy machining as it features a very low melting point, which making it a perfect fit for plastic injection molding process via injection molding machine. In the meanwhile, ABS is inexpensive, of which the cost usually falls between those of Polypropylene (PP) and Polycarbonate (PC). Because of its low melting temperature, the ABS material made products are usually not applied in high heat conditions. By virtue of these properties, ABS can be widely used in a great number of project applications across an extensive range of trades.

What Are the Advantages of the ABS Plastic?

ABS has many good properties such as extreme versatility, good machinability, and moderate heat performance, which making it a popular material for numerous industries. ABS is commonly used in a wide range of industrial applications, as well as for sports equipment and medical devices. The products made in ABS by injection molding, medical molding, overmolding, insert molding, ultrasonic bonding and micro molding are common in our life.

Why ABS Plastic Injection Molding for My Products?

ABS is an opaque thermoplastic and amorphous polymer, which is an ideal choice for applications that require an inexpensive, strong, stiff plastic that holds up well to external impacts. The chemical structure of ABS also allows it to be modified to improve certain characteristics to meet the special needs. Additional ABS plastic injection molding also benefits:

Excellent tensile strength and stiffness

Very high impact strength and toughness

Very good dimensional stability

Good machinability

Good heat resistance

High stability under load

Good dielectric properties

Maintains characteristics and performance in extreme temperatures

Very good resistance to most oils, acids, and alkalis

Excellent ductility

Easily alloyed with other polymers

Creep resistant

Recyclable

On the other hand, as the good properties of ABS, it allows you to have secondary operations such as ultrasonic welding and decorated moldings, which follows the hot stamping, pad printing or laser marking processes.

ABS Plastic Injection Molding Applications

Since ABS has so many excellent properties such as impact resistance, strength, and stiffness etc, it is often used as an injection molding material for numerous products from different industries:

Sports equipment

Automotive

Appliances

Electronics

Fittings

Consumer goods

Recreational products

What Are the Injection Molding Conditions of ABS Plastic?

1. Dry ABS under 80-90 degrees Celsius conditions at least for 2 hours, the moisture content of the material should be less than 0.1% after drying.

2. Melting Point temperature from 200 to 280 degrees Celsius, typically at 230 degrees Celsius.

3. Plastic Injection Molding Pressure from 50 to 100 MPa.

4. Depending on products’ strength and requirements, the regrind material should be less than 30%, or even no any recycled material.

5. Gate typically should be at 3mm width and 1mm length, and vent at 4to 6mm width at thickness between 0.025-0.05mm.

6. Typically slow injection molding speed should be applied for abs plastic injection molding.

7. The back pressure should be minimized as much as possible, usually 5 bar to avoid wear.

Contact TEAM MFG China for Your Custom ABS Injection Molded Parts

Contact us for more information about ABS plastic injection molding for your project and parts application requirements. TEAM MFG is your trusted source for ABS plastic injection molded products, send us a inquiry to request a quote today.