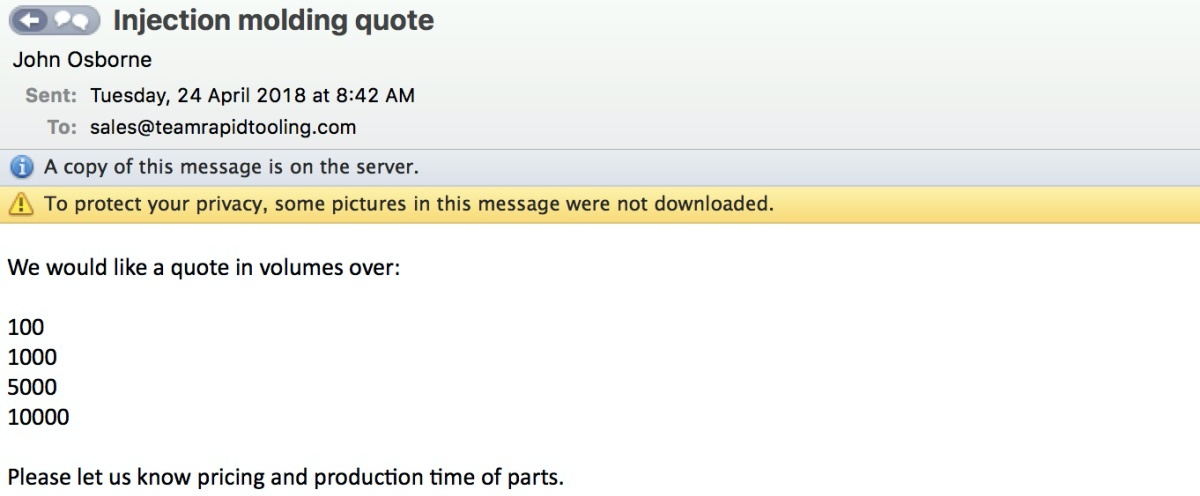

Job Specification:

Job Specification:

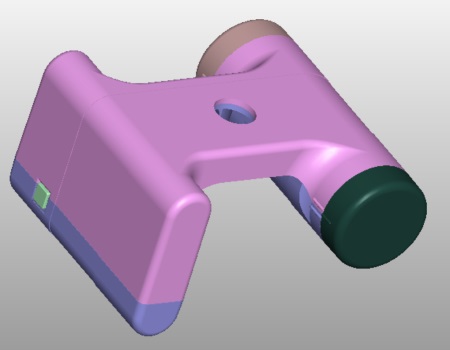

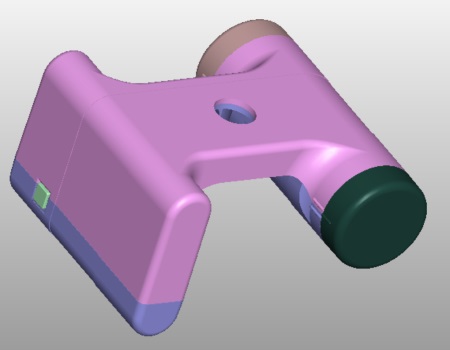

Project: I-Tap Battery Powdered Device

Process Involved: Rapid Tooling/Injection Mold, Rapid Injection Molding, Silk-Printing

Part Quantity: 4 Plastic Part total (3 parts in ABS, 1 part in TPE)

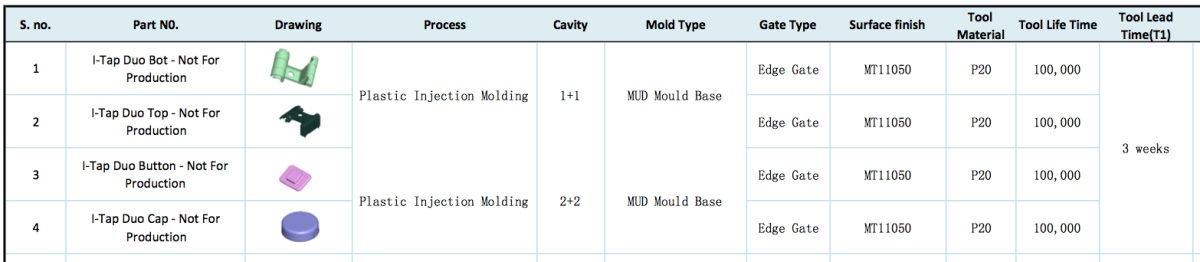

Mold Quantity: 2 Family Molds

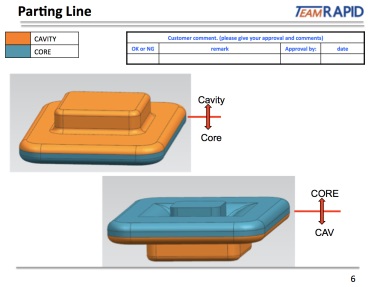

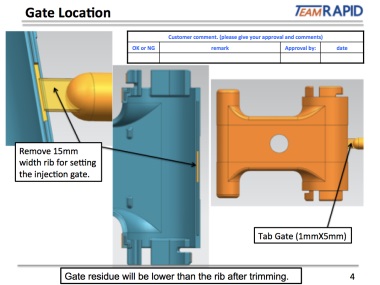

Mold Structure: MUD mold base, Switch Gate

Mold Steel: Chinese P20

Injection Material: ABS for the front, rear cover and cap, TPE for the button

Sample Order: 100 units

Mold and molding lead-Time: 22 Calendar Days

About the Product:

I-Tap is a intelligent, battery-powdered device designed to dramatically upgrade the efficiency of manual beer taps at locations everywhere- while providing vital data and making it possible for stadium & arenas to save up 2 million us in lost revenues annually .

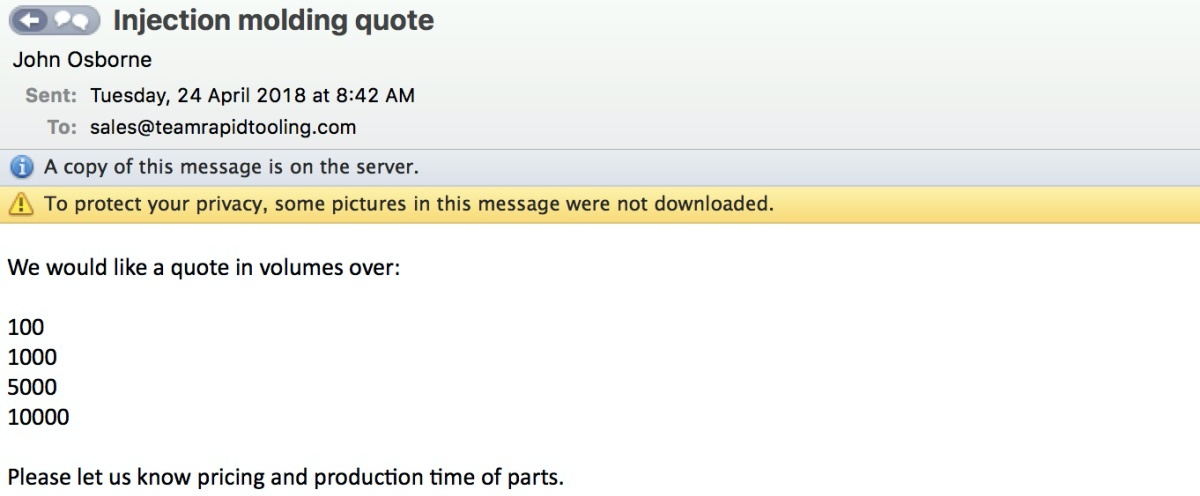

About the Customer:

A company in US contacted us to make some parts for their device, their president John Osborne sent us the email for enquiry:

Quotation

TEAM MFG suggested 2 family molds for all these 4 parts to cut down the cost. Applying with the switched gate method we can mold the cap in ABS, and button in TPE separately.

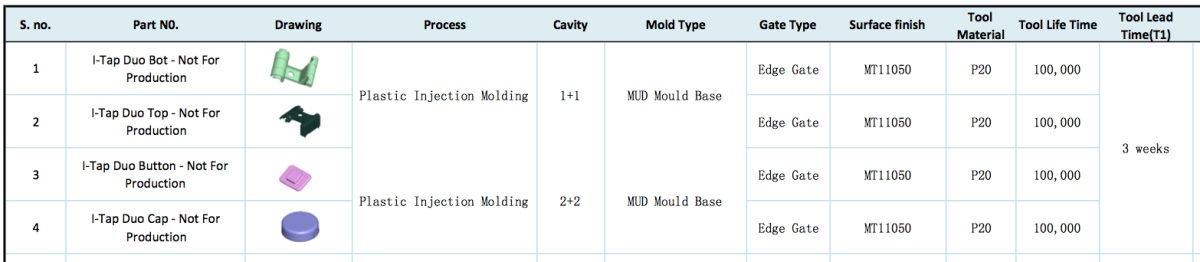

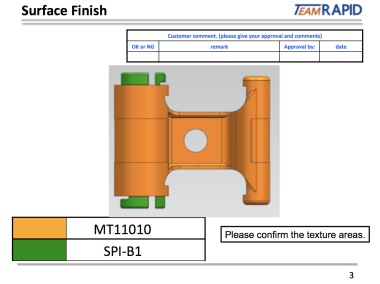

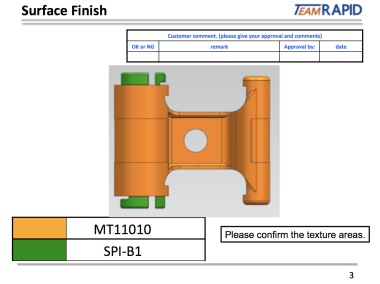

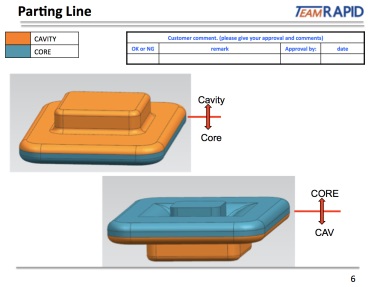

Design for Manufacturing

Customer approved our quotation proposal, we moved forward to design for manufacturing stage

Built the Mold

DFM Approval → Tool Design → Cavity & Electrode CNC Machining → Wire EDM → EDM → Mold Fitting → Polishing & Texture → Mold Trial

Ran the sample & Silk Printing

The customer was happy with the sample, and placed the larger order 1000 unit in the following weeks. And the color for the following production switched to RAL 3001(Red)

Are you working on your next injection molding project? Contact us at ericchen19872017@gmail.com to get strong supports now!

Job Specification:

Job Specification: