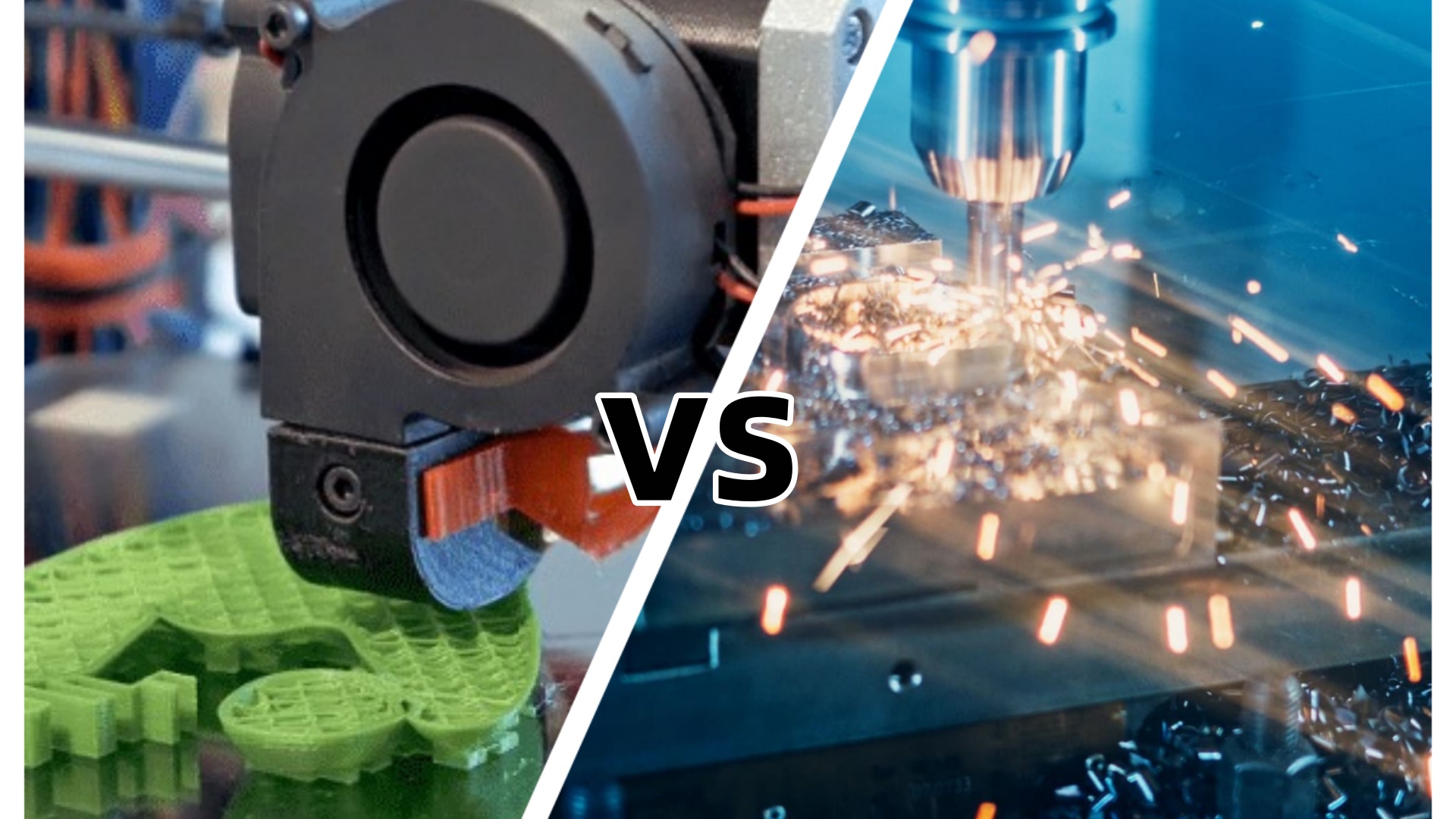

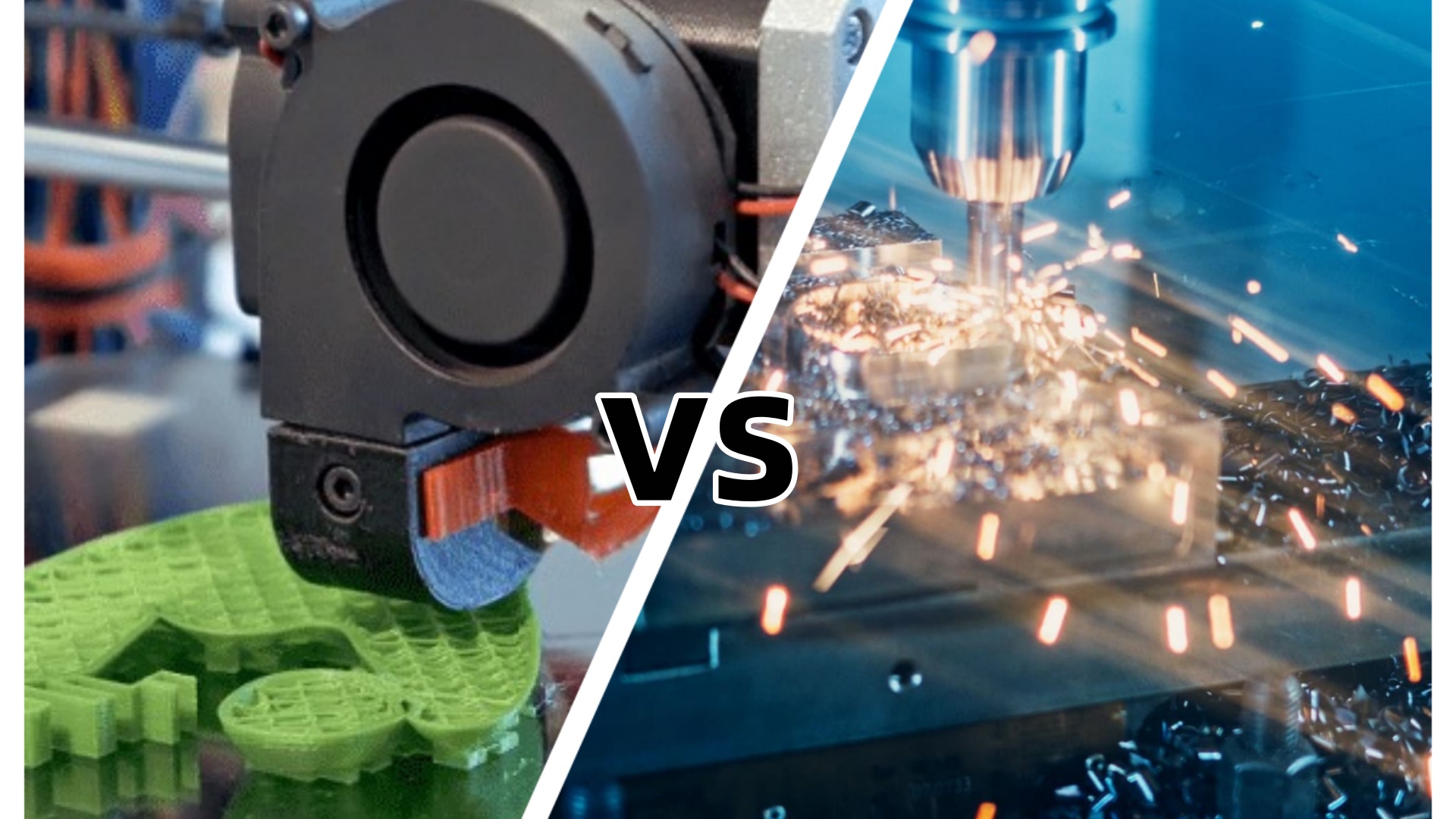

Which manufacturing process is better—adding layers or removing material? Additive and subtractive manufacturing differ in significant ways. Understanding these differences is key to choosing the right method.

In this post, we’ll explore their advantages, limitations, and real-world applications. You’ll learn how to decide between these two approaches for your next project.

What is Additive Manufacturing?

Additive Manufacturing (AM) is a process that creates objects by adding material layer by layer, typically based on a 3D model. Unlike traditional methods, which remove material, AM constructs parts from scratch, allowing for intricate designs and material efficiency.

Brief History of Additive Manufacturing

The concept of AM dates back to the 1980s, when 3D printing technologies were first introduced. Early innovations were aimed at rapid prototyping, providing faster, more affordable ways to create product prototypes. Since then, AM has evolved into a wide array of industrial applications, including aerospace, automotive, and medical fields.

How Additive Manufacturing Works

Additive manufacturing begins with a CAD model. The model is sliced into thin layers using software. The AM machine then adds material, layer by layer, until the final object is formed. Materials used range from plastics to metals. Depending on the process, it may require post-processing, such as cleaning or curing, to complete the part.

Common Additive Manufacturing Techniques

Several techniques fall under the umbrella of AM, each offering unique advantages:

3D Printing

3D printing is the most recognized AM method. It builds objects by layering materials like plastic or metal. Ideal for custom parts and prototypes, it's widely accessible and cost-effective for smaller applications.

Selective Laser Sintering (SLS)

SLS uses a laser to sinter powdered material, typically plastic or metal, into solid parts. It’s known for creating durable, functional prototypes with complex geometries.

Fused Deposition Modeling (FDM)

FDM works by extruding thermoplastic filaments through a heated nozzle. It’s commonly used for prototyping and producing low-cost plastic parts.

Stereolithography (SLA)

SLA uses ultraviolet light to cure liquid resin layer by layer, creating highly accurate parts with smooth finishes. It’s suited for intricate designs and fine details.

Direct Metal Laser Sintering (DMLS)

DMLS builds metal parts by sintering fine metal powders using a laser. This technique is ideal for producing complex, strong metal components for industries like aerospace.

Additional Additive Manufacturing Techniques

In addition to the commonly known methods, several other advanced techniques are available:

Binder Jetting: A bonding agent selectively deposits between powder layers, creating complex structures.

Directed Energy Deposition (DED): This technique uses focused thermal energy to fuse materials as they are deposited, often used for repairing or adding features to existing parts.

Material Extrusion: Material is selectively extruded through a nozzle to build layers, commonly used with thermoplastics.

Material Jetting: Droplets of material are deposited layer by layer to create precise parts, often using photopolymers.

Sheet Lamination: Sheets of material are bonded layer by layer, suitable for metals and composites.

Vat Photopolymerization: Liquid resin is selectively cured by light to form solid parts, with applications in both prototyping and production.

Advantages of Additive Manufacturing

Additive Manufacturing (AM) offers numerous benefits across industries. These advantages make it a game-changer in modern production.

Reduced Material Wastage

AM uses only the material needed for the final product. This approach significantly reduces waste compared to traditional methods.

Complex Geometries and Intricate Designs

AM excels in creating complex shapes. It can produce parts impossible to make with conventional techniques.

Internal channels

Lattice structures

Organic forms

Faster Prototyping and Shorter Lead Times

Rapid prototyping becomes reality with AM. It allows quick iterations and faster product development cycles.

| Traditional Prototyping | AM Prototyping |

| Weeks to months | Hours to days |

| Multiple steps | Single process |

| High tooling costs | No tooling |

Cost-Effective Small Batch Production

AM shines in producing small quantities. It eliminates the need for expensive molds or tooling.

Improved Sustainability

The reduction in waste translates to improved sustainability. AM conserves resources and energy.

Less raw material consumption

Reduced transportation needs

Lower energy usage in production

Potential for Mass Customization

AM enables tailoring products to individual needs. This opens new possibilities in various fields:

Disadvantages of Additive Manufacturing

While Additive Manufacturing (AM) offers many benefits, it also has limitations. Understanding these drawbacks is crucial for its effective application.

Limited Material Options

AM uses fewer materials than subtractive methods. This restriction can limit its use in certain industries.

Common AM materials:

Thermoplastics

Some metals

Certain ceramics

Slower Large Volume Production

AM excels in small batches but lags in mass production. Traditional methods often outpace it for large volumes.

| Production Volume | AM Speed | Traditional Speed |

| Small (1-100) | Fast | Slow |

| Medium (100-1000) | Moderate | Fast |

| Large (1000+) | Slow | Very Fast |

Higher Large-Scale Production Costs

For mass production, AM can be more expensive. The cost per unit doesn't decrease significantly with volume.

Lower Part Accuracy and Surface Finish

AM parts may have lower precision than machined ones. Their surface finish often requires improvement.

Tight Tolerance Challenges

Achieving tight tolerances is difficult with AM. This can be problematic for parts needing precise fits.

Post-Processing Requirements

Most AM parts need additional work after printing. This adds time and cost to the production process.

Common post-processing steps:

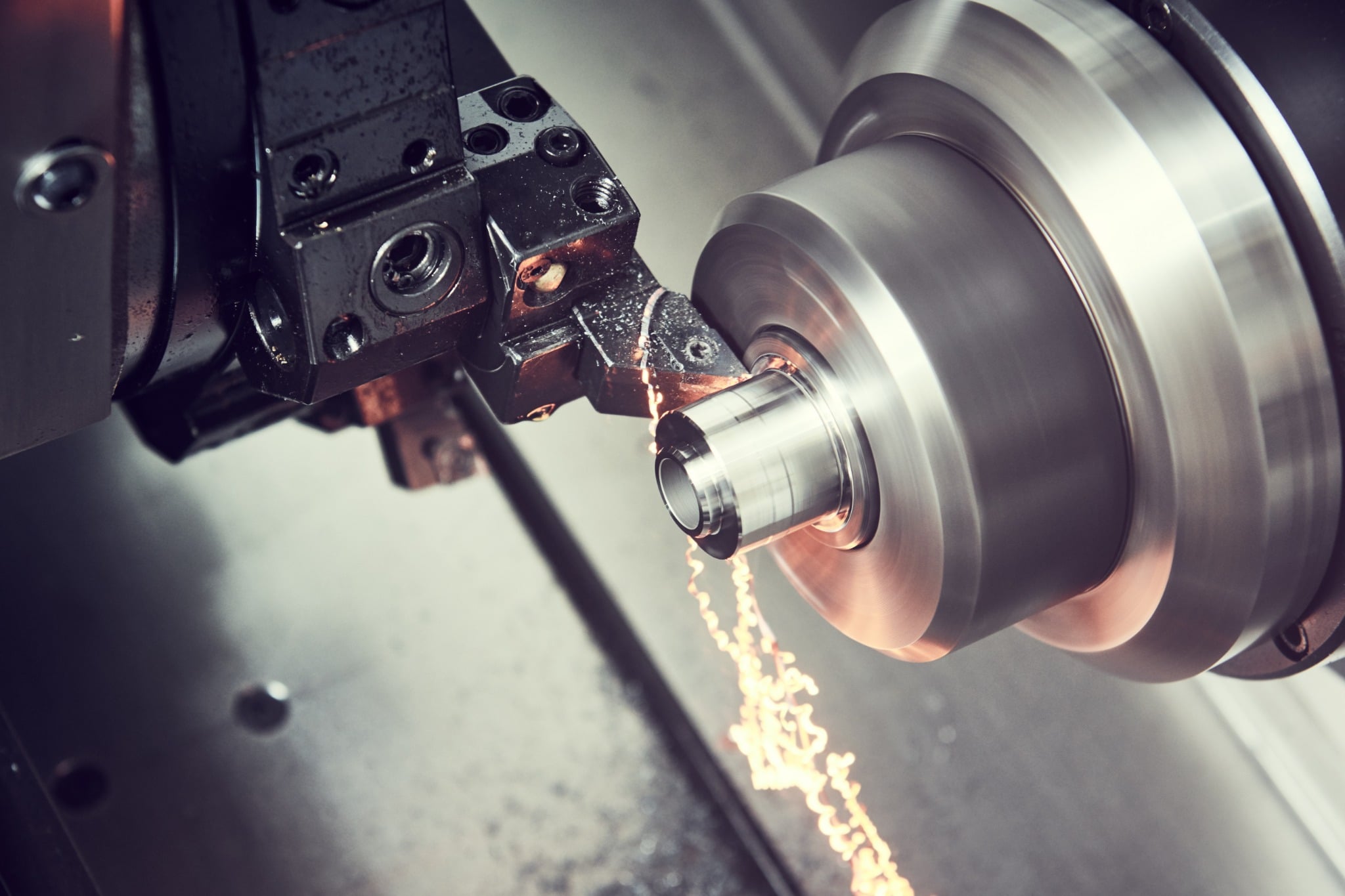

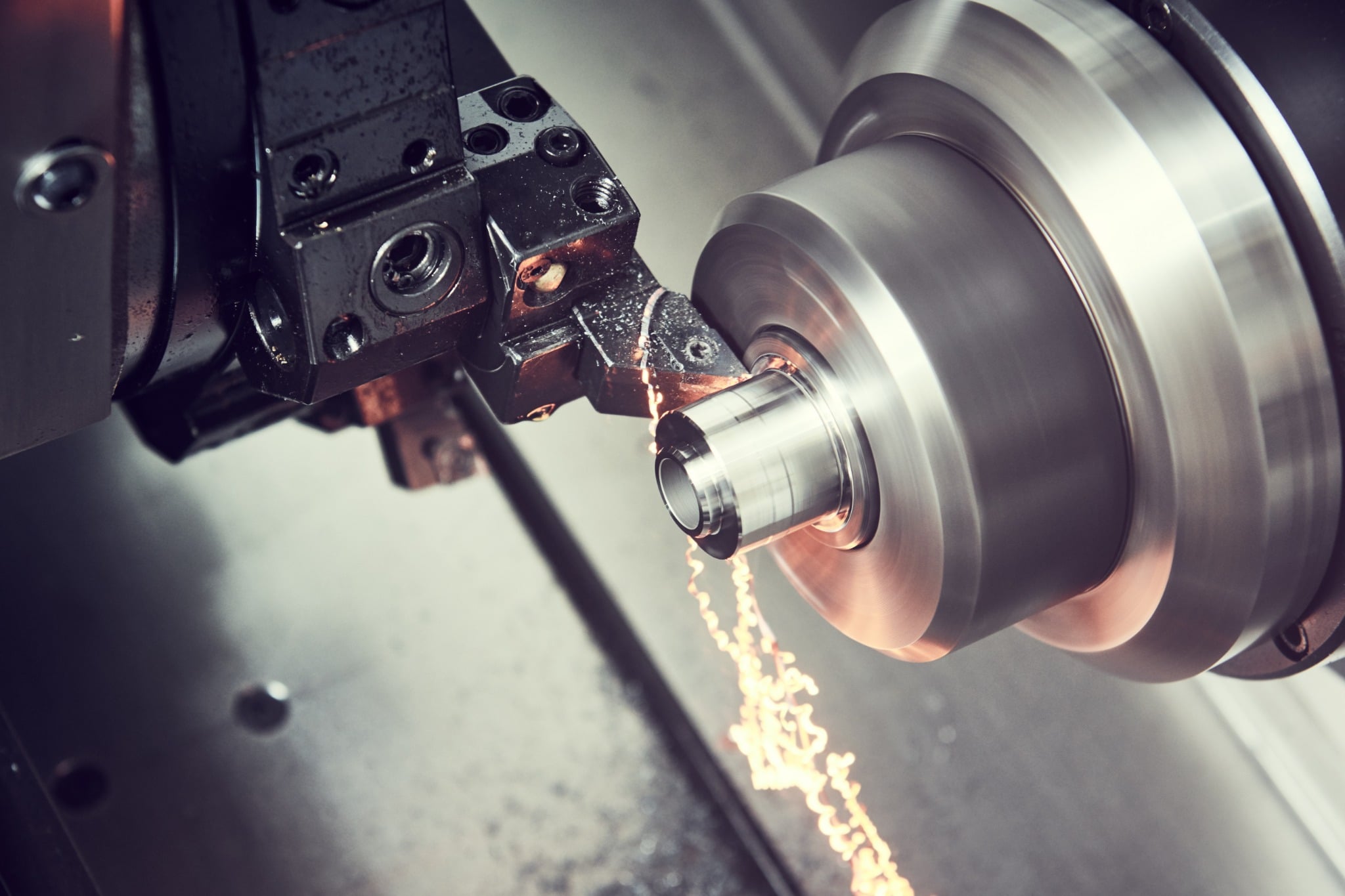

What is Subtractive Manufacturing?

Subtractive Manufacturing (SM) creates objects by removing material from a solid block. It's a traditional method used in various industries.

Brief History

SM dates back to ancient times. Early examples include stone carving and woodworking. Modern SM evolved with the Industrial Revolution, leading to precise machine tools.

How It Works

SM starts with a larger piece of material. Machines or tools then cut away excess material to create the desired shape.

Common Techniques

CNC Machining

Computer Numerical Control (CNC) machines use programmed instructions to remove material.

Milling: Cuts material using rotating tools

Turning: Shapes cylindrical parts by rotating the workpiece

Drilling: Creates holes in the material

Laser Cutting

This technique uses a high-powered laser to cut materials. It's precise and works on various materials.

Waterjet Cutting

Waterjet cutting uses high-pressure water, often mixed with abrasive particles, to cut materials.

Plasma Cutting

Plasma cutting melts material using an electrically conductive gas. It's effective for cutting metal.

Electrical Discharge Machining (EDM)

EDM uses electrical discharges to remove material. It's ideal for hard metals and complex shapes.

Additional Details

Machining Processes

Grinding: Uses abrasive wheels for fine surface finishes

Reaming: Enlarges and finishes holes

Boring: Enlarges holes with single-point cutting tools

EDM Principles

EDM works by creating controlled electrical sparks between an electrode and the workpiece.

Laser Cutting Parameters

Power: Determines cutting depth

Speed: Affects cut quality

Focus: Influences precision

Waterjet Cutting Parameters

Pressure: Typically 60,000 PSI or higher

Abrasive flow rate: Affects cutting speed and quality

Nozzle diameter: Influences cut width and precision

Advantages of Subtractive Manufacturing

Subtractive Manufacturing (SM) offers numerous benefits across industries. These advantages make it a crucial method in modern production.

Wide Range of Compatible Materials

SM works with an extensive variety of materials:

Metals (steel, aluminum, titanium)

Plastics (ABS, PVC, acrylic)

Composites (carbon fiber, fiberglass)

Wood

Glass

Stone

This versatility allows SM to meet diverse manufacturing needs.

High Accuracy and Precision

SM excels in creating highly accurate parts. It achieves tight tolerances, often as small as 0.001 inches.

| Technique | Typical Tolerance |

| CNC Milling | ±0.0005" |

| EDM | ±0.0001" |

| Laser Cutting | ±0.003" |

Excellent Surface Finishes

SM produces parts with superior surface quality. This often eliminates the need for additional finishing processes.

Faster Large-Volume Production

For high-volume production, SM outpaces additive methods:

Multi-axis CNC machines work quickly

Automated tool changing reduces downtime

Simultaneous operations on different parts

Cost-Effective High-Volume Production

SM becomes more economical as production volume increases. Initial setup costs are offset by faster production rates.

Large-Scale Part Creation

SM easily handles large components. It's ideal for industries requiring substantial parts:

Aerospace (aircraft components)

Automotive (engine blocks)

Construction (structural elements)

Disadvantages of Subtractive Manufacturing

While Subtractive Manufacturing (SM) offers many benefits, it also has limitations. Understanding these drawbacks is essential for effective application.

Higher Material Waste

SM removes material to create parts. This process generates significant waste:

Up to 90% of material can become scrap in some cases

Recycling options may be limited for certain materials

Increased environmental impact due to waste disposal

Limited Complex Geometry Creation

SM struggles with intricate designs:

Internal cavities are challenging to produce

Certain shapes may require multiple setups or specialized tools

Some complex features might be impossible to machine

Longer Set-up Times and Higher Tooling Costs

SM often requires extensive preparation:

| Aspect | Impact |

| Tool selection | Time-consuming |

| Machine programming | Requires expertise |

| Fixture creation | Additional cost |

Less Design Flexibility

Modifying designs in SM can be costly:

Changes may require new tooling

Reprogramming machines is often necessary

Existing setups might become obsolete

Higher Operator Skill Requirements

SM machines demand skilled operators:

Understanding of material properties

Knowledge of cutting speeds and feed rates

Ability to interpret complex technical drawings

Tool Wear and Replacement Costs

SM tools degrade over time:

Regular tool replacement is necessary

High-quality tools can be expensive

Worn tools can affect part quality

Comparison of Additive vs. Subtractive Manufacturing

| Aspect | Additive Manufacturing | Subtractive Manufacturing |

| Process | Builds objects by adding layers of material | Removes material from a larger piece to create objects |

| Material Waste | Minimal waste | High material waste |

| Compatible Materials | Limited (mainly plastics and some metals) | Wide range (metals, plastics, wood, glass, stone) |

| Complexity | Can produce highly complex and intricate geometries | Better suited for relatively simple geometries |

| Accuracy | Less accurate (tolerances as tight as 0.100 mm) | More accurate (tolerances as tight as 0.025 mm) |

| Production Volume | Suitable for small batches | Ideal for large production runs |

| Speed | Slower for large volumes | Faster for large volumes |

| Cost | More cost-effective for small quantities | More cost-effective for large quantities |

| Design Flexibility | High flexibility for design changes | Less flexible for design changes |

| Surface Finish | Often requires post-processing | Can produce smooth finishes directly |

| Operator Skill | Requires less skilled operators | Requires highly skilled operators |

| Equipment Cost | Lower initial equipment cost | Higher initial equipment cost |

| Tooling | Minimal tooling required | Extensive tooling often needed |

| Sustainability | More sustainable due to less waste | Less sustainable due to material waste |

| Internal Features | Can easily create internal features | Difficult to create internal features |

| Size Limitations | Generally limited to smaller parts | Can produce large-scale parts |

| Post-processing | Often requires multiple steps | Higher completion level after initial process |

Hybrid Manufacturing Processes

Hybrid manufacturing combines Additive Manufacturing (AM) and Subtractive Manufacturing (SM). This approach leverages the strengths of both methods, creating a powerful synergy in production.

Definition and Benefits

Hybrid processes integrate AM and SM techniques:

Benefits include:

Example process flow:

3D print a near-net shape

CNC machining for precise dimensions

Polish for superior surface finish

Common Applications

Hybrid manufacturing excels in various areas:

| Application | Benefit |

| Tooling | Complex designs with tight tolerances |

| Jigs and Fixtures | Custom shapes with durable finishes |

| High-tolerance Parts | Intricate geometries with precise features |

Industries utilizing hybrid processes:

Aerospace

Automotive

Medical devices

Custom manufacturing

Choosing Between Additive and Subtractive Manufacturing

Selecting the right manufacturing method depends on various factors. Each process offers distinct advantages, so it’s crucial to align your choice with project requirements.

Factors to Consider When Selecting a Manufacturing Method

Material Requirements

The choice of material plays a significant role. Additive manufacturing (AM) typically works best with plastics and some metals, whereas subtractive manufacturing (SM) can handle a wide range of materials, including metals, plastics, wood, and glass. If you need hard-to-machine materials or higher durability, SM is often the better option.

Part Complexity and Design

For intricate designs with complex geometries—such as internal cavities or articulating joints—AM excels, allowing for high customization. SM, while precise, may struggle with extremely complex designs. It's better suited for simpler or intermediate geometries where tight tolerances are necessary.

Production Volume and Scalability

AM is ideal for low to medium production volumes, such as rapid prototyping or small-batch production. For large-scale production, SM is far more efficient, especially when producing thousands of identical parts. As production volume increases, the cost-effectiveness of SM becomes clear.

Lead Time and Time-to-Market

Projects requiring a short lead time benefit from AM due to minimal setup and fast transition from design to product. For larger production runs, however, SM can offer quicker manufacturing times once the setup is complete, especially for metal parts.

Budget and Cost Constraints

AM is more cost-effective for small, complex parts, especially when prototyping. However, SM becomes more economical for larger parts or high production volumes. Setup costs and the cost per part typically decrease as volume increases in SM.

Sustainability Goals

AM generates less waste, making it a more sustainable option. SM, while faster for large runs, produces significant material waste in the form of chips or scraps. If sustainability is a key priority, AM might be the better fit.

Decision Matrix for Additive vs. Subtractive Manufacturing

The following decision matrix provides a quick comparison of factors to help you choose the right method:

| Factor | Additive Manufacturing (AM) | Subtractive Manufacturing (SM) |

| Material Range | Limited (mostly plastics, some metals) | Wide (metals, plastics, wood, glass) |

| Part Complexity | Handles complex, intricate designs | Best for simpler, precise geometries |

| Production Volume | Ideal for small-batch, prototyping | Efficient for mass production |

| Lead Time | Faster setup, quick turnaround | Slower setup, faster for large runs |

| Cost | More expensive for large parts or metals | More cost-effective at higher volumes |

| Sustainability | Less waste, more sustainable | Significant waste, less sustainable |

Use this matrix to align your project’s needs with the strengths of each manufacturing method.

Real-world Applications of Additive and Subtractive Manufacturing

Additive Manufacturing (AM) and Subtractive Manufacturing (SM) play crucial roles across various industries. Their applications continue to expand and evolve.

Aerospace and Aviation

AM: Lightweight components, complex geometries

SM: High-precision engine parts, structural elements

Automotive Industry

AM: Rapid prototyping, custom parts

SM: Engine blocks, transmission components

Medical and Dental

AM: Custom implants, prosthetics

SM: Surgical instruments, dental crowns

Consumer Goods and Electronics

AM: Personalized products, small-batch items

SM: Smartphone casings, laptop components

Industrial Machinery and Tooling

Architecture and Construction

AM: Scale models, decorative elements

SM: Structural components, facade elements

Conclusion

Additive and subtractive manufacturing each have unique strengths and weaknesses. AM excels in complex designs and customization. SM offers precision and material versatility.

Understanding these differences is crucial for making informed manufacturing decisions. Consider your project's specific needs when choosing a method.

Evaluate factors like material, complexity, volume, and cost. This will help you select the best approach for your manufacturing goals.