Flanges are an essential component in various industries, acting as the connecting elements that hold pipes, pumps, valves, and other equipment together. Their role in ensuring the safe and efficient flow of fluids or gases under varying pressure and temperature conditions makes flange selection critical to the integrity of the system. With many types, sizes, and materials available, understanding the right flange for the right application is crucial.

This article dives deep into the types of flanges, their components, materials, and applications to help you make informed decisions.

Key Components of Flanges

Flanges, though varying in types, share certain key components that define their performance

and application. These components contribute to the overall functionality of flanges in piping systems.

Flange Face: The area of contact between the flange and the gasket used to create a tight seal. Common types of flange faces include:

| Flange Face Type | Features | Appearance | Applications | Advantages | Disadvantages |

| Flat Face (FF) | For low-pressure; full-face gasket required. | Flat, smooth surface. | Low-pressure water systems, non-critical services. | Easy alignment, prevents warping. | Not suited for high-pressure. |

| Raised Face (RF) | Stronger sealing for medium to high pressure. | Small raised area around bore. | Refineries, chemical plants, process piping. | Enhanced sealing for various pressures. | Requires precise alignment. |

| Ring-Type Joint (RTJ) | Metal-to-metal sealing for extreme conditions. | Deep groove for metal ring gasket. | Oil & gas, power generation. | Excellent sealing, resists vibration and expansion. | Higher cost, requires precise installation. |

| Tongue and Groove (T&G) | Interlocking flanges resist bending forces. | Raised tongue and matching groove. | High-pressure steam, pump covers. | Self-aligning, strong seal. | Requires matched pairs. |

| Male and Female (M&F) | Precise alignment with raised/recessed surfaces. | Male raised face, female recessed face. | Heat exchangers, precision applications. | Prevents misalignment, improves sealing. | Needs paired installation, precise machining. |

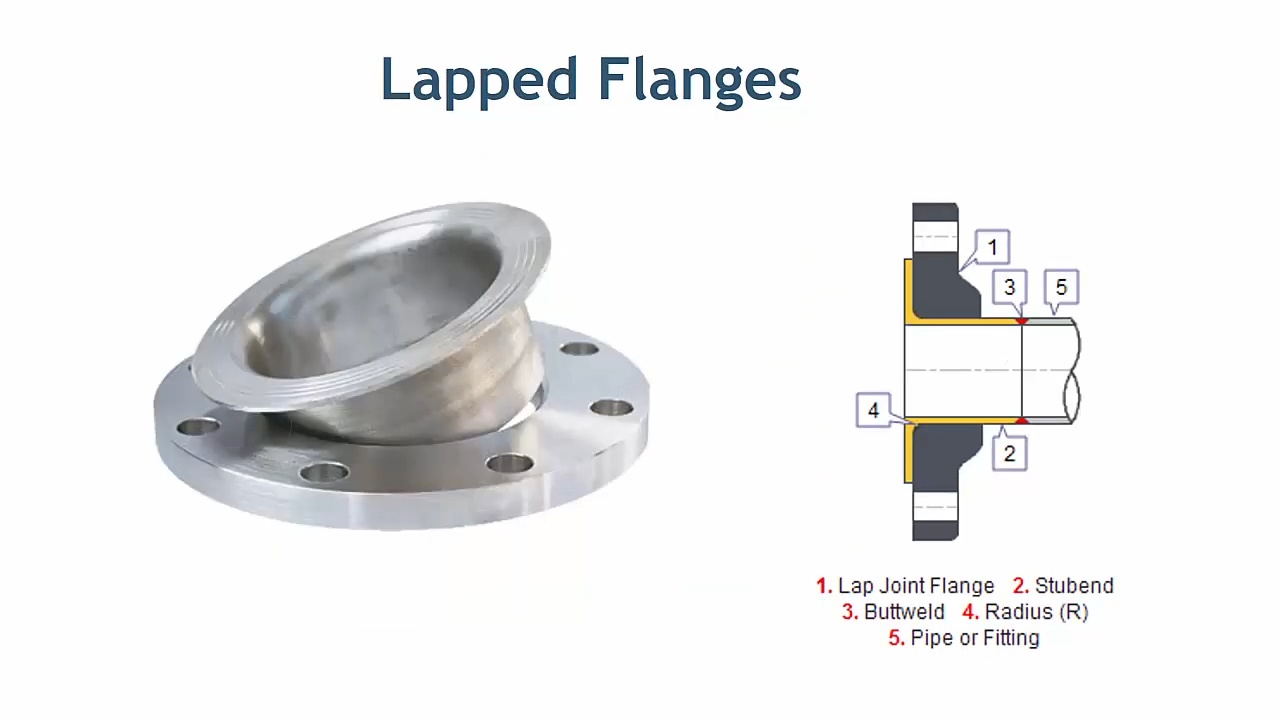

| Lap Joint | Flexible, easy disassembly; flange is loose. | Two-piece, free-rotating flange. | Food processing, plumbing systems. | Easy alignment, cost-effective. | Lower strength, not for high pressure. |

Flange Hub: This portion connects the pipe to the flange, providing reinforcement and helping to distribute pressure evenly.

Bore: The central hole where the pipe passes through. Bore size is important as it directly impacts fluid flow and pressure.

Neck (for Weld Neck Flanges): The neck provides reinforcement and helps align pipes during installation, especially in high-pressure systems.

| Component | Description |

| Flange Face | Area where gasket sits to form a seal |

| Flange Hub | Provides reinforcement for the connection |

| Bore | Central hole for pipe connection |

| Neck | For added strength and pipe alignment, particularly in weld necks |

Common Types of Flanges

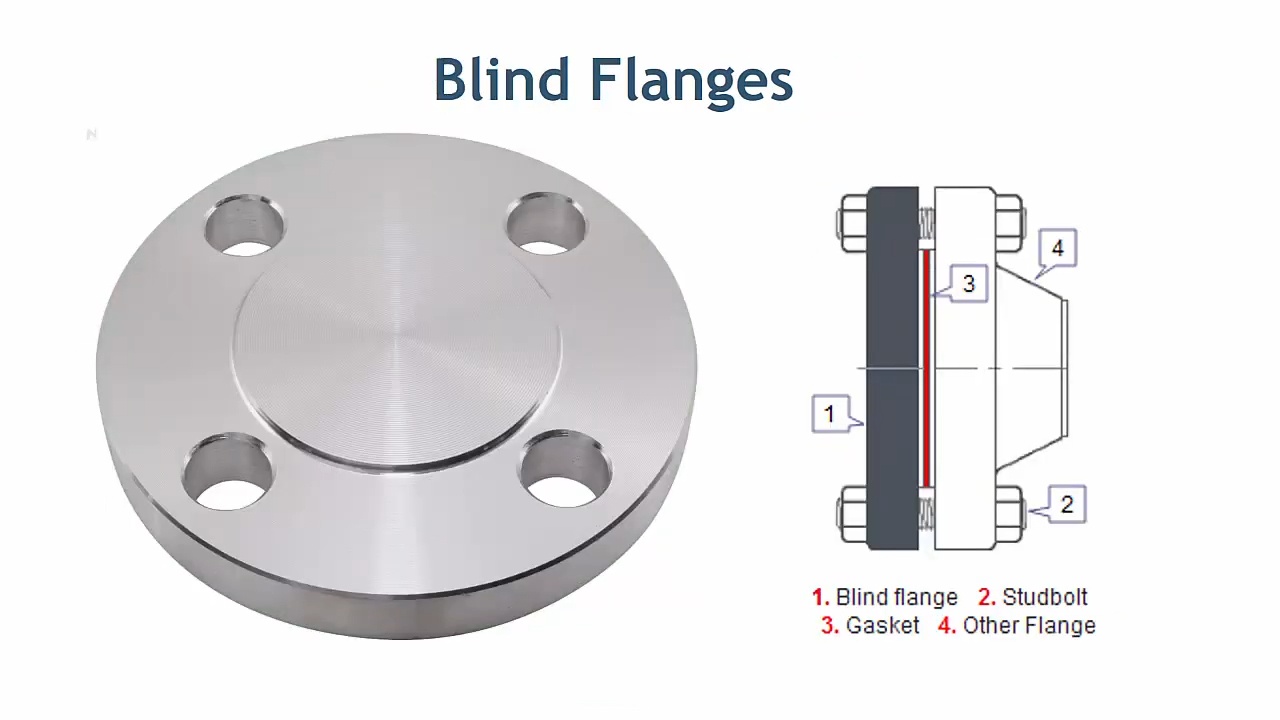

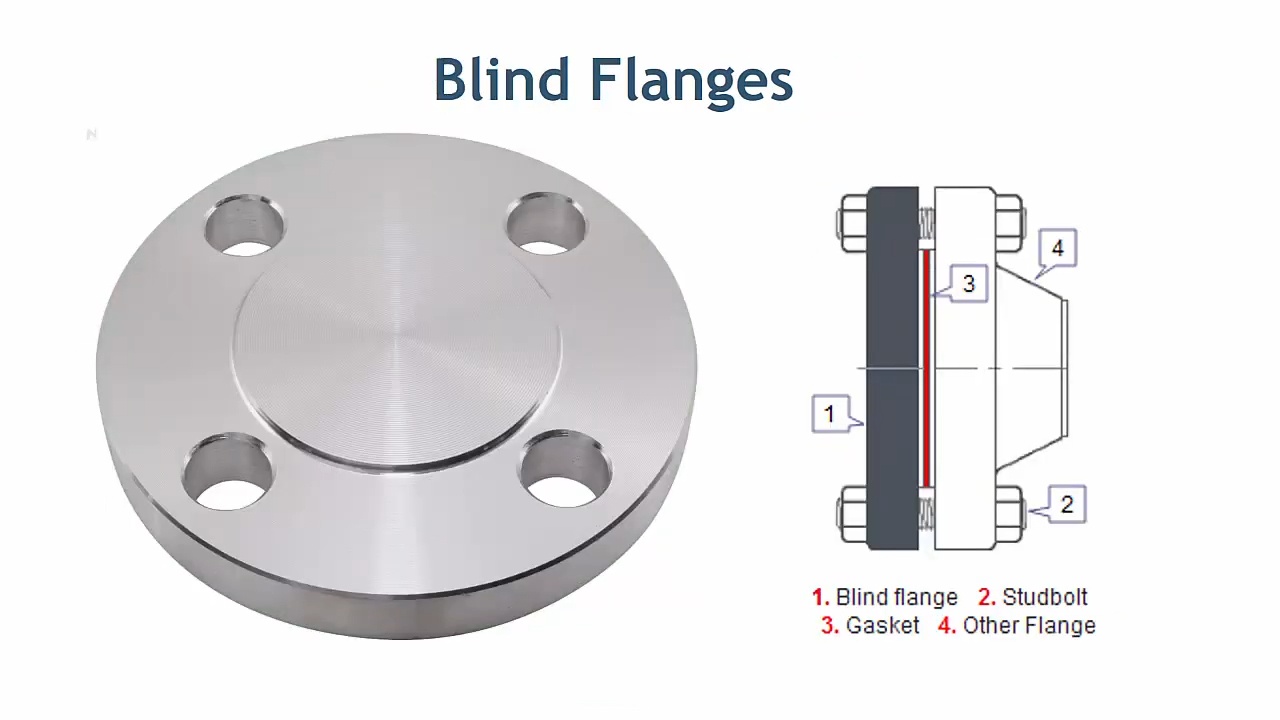

1. Blind Flange

A blind flange is designed to seal off the end of a pipe, valve, or pressure vessel, functioning much like a cap. It has no bore, meaning there’s no opening in the center, making it ideal for systems that may require future expansion, inspection, or maintenance. Blind flanges are particularly useful in high-pressure environments, as they withstand stress from both internal pressure and the forces exerted by bolting. They are commonly found in industries like oil & gas and chemical processing, where portions of pipelines are often isolated for maintenance or upgrades.

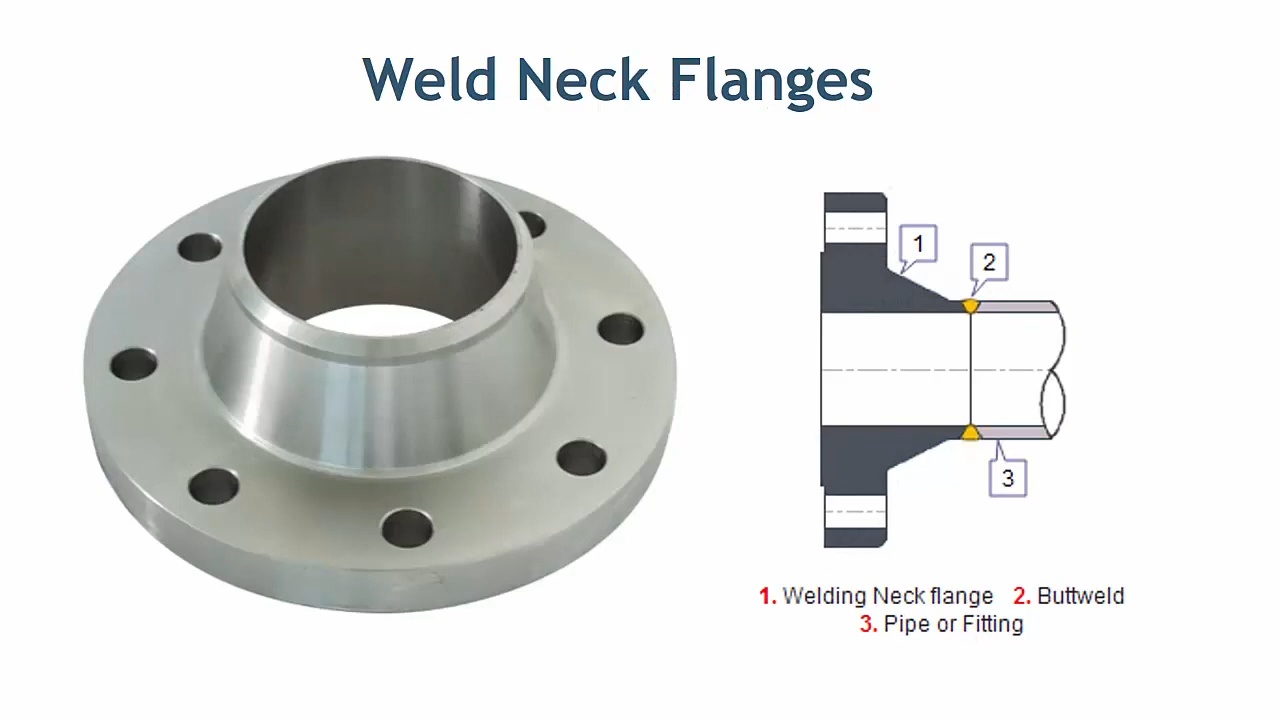

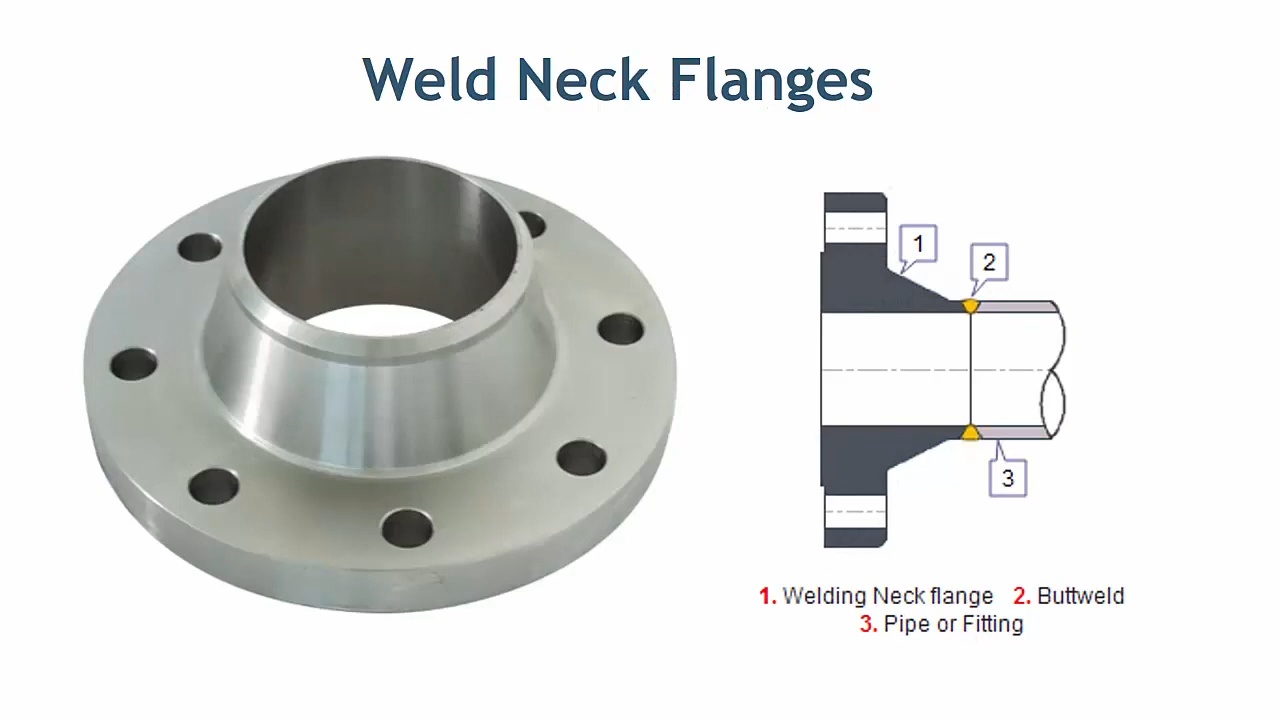

2. Weld Neck Flange

A weld neck flange is recognizable by its long tapered neck, which gradually joins the pipe. This design minimizes stress concentrations, making it ideal for high-pressure and high-temperature systems. The neck aligns with the pipe, ensuring smooth fluid flow and reducing erosion. This type of flange is primarily used in critical applications like petroleum refineries, power plants, and pipelines transporting corrosive or toxic substances. The full-penetration weld between the pipe and the flange ensures high structural integrity, which is vital for systems dealing with extreme conditions.

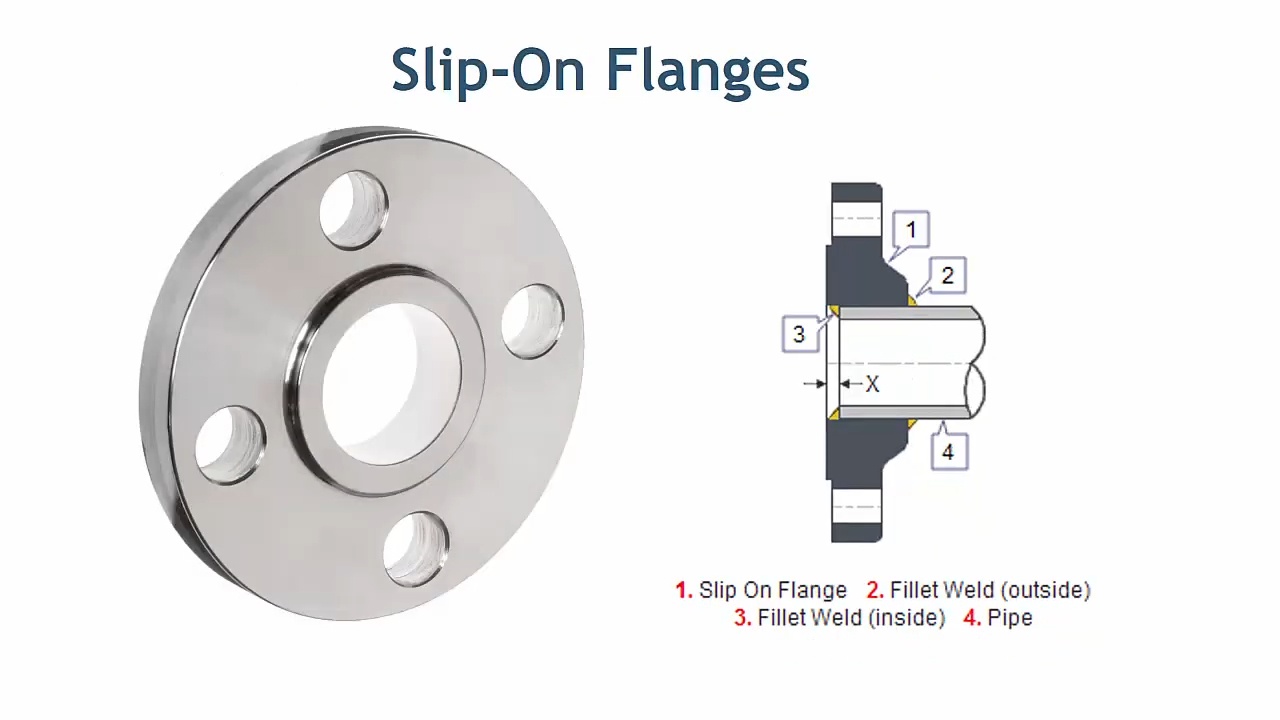

3. Slip-On Flange

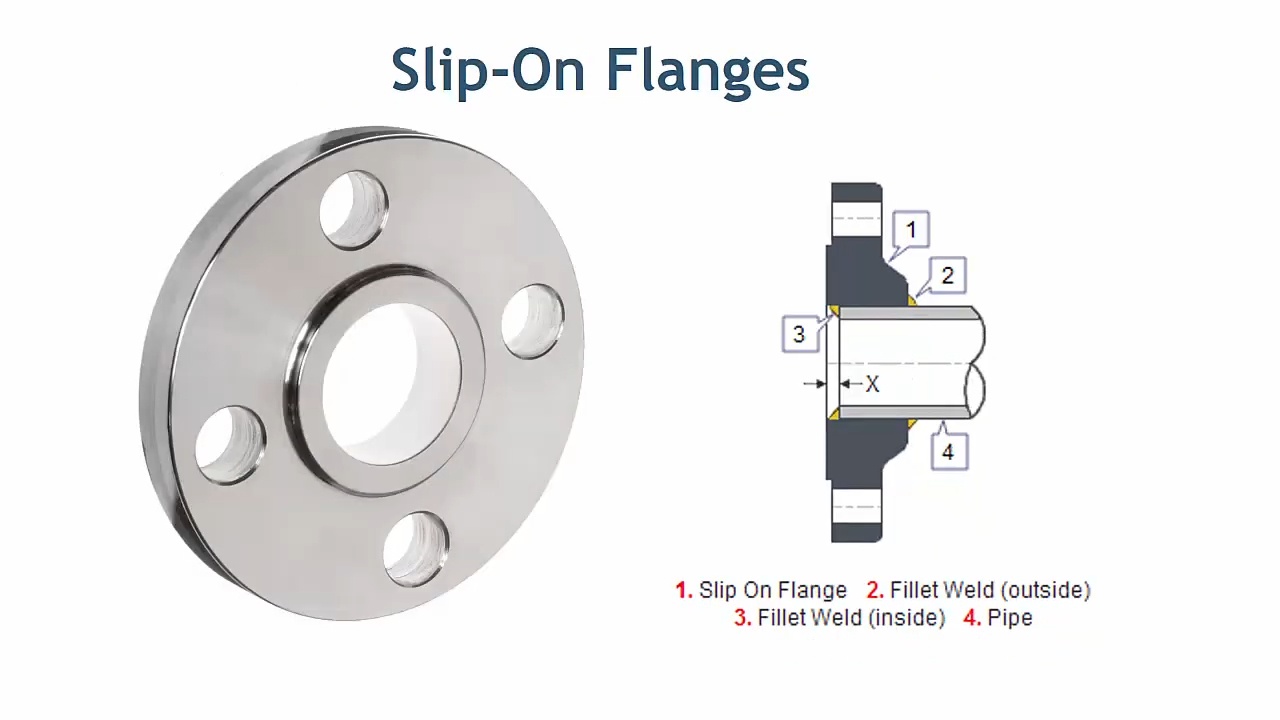

The slip-on flange is a simple, easy-to-install type that slips over the pipe and is welded both inside and outside to secure the connection. Its straightforward design makes it popular in low-pressure, non-critical applications where installation speed is important. Common uses include water treatment systems, air pipelines, and cooling water circuits. Although not as strong as a weld neck flange, it is cost-effective and ideal for situations where high-pressure performance is not required.

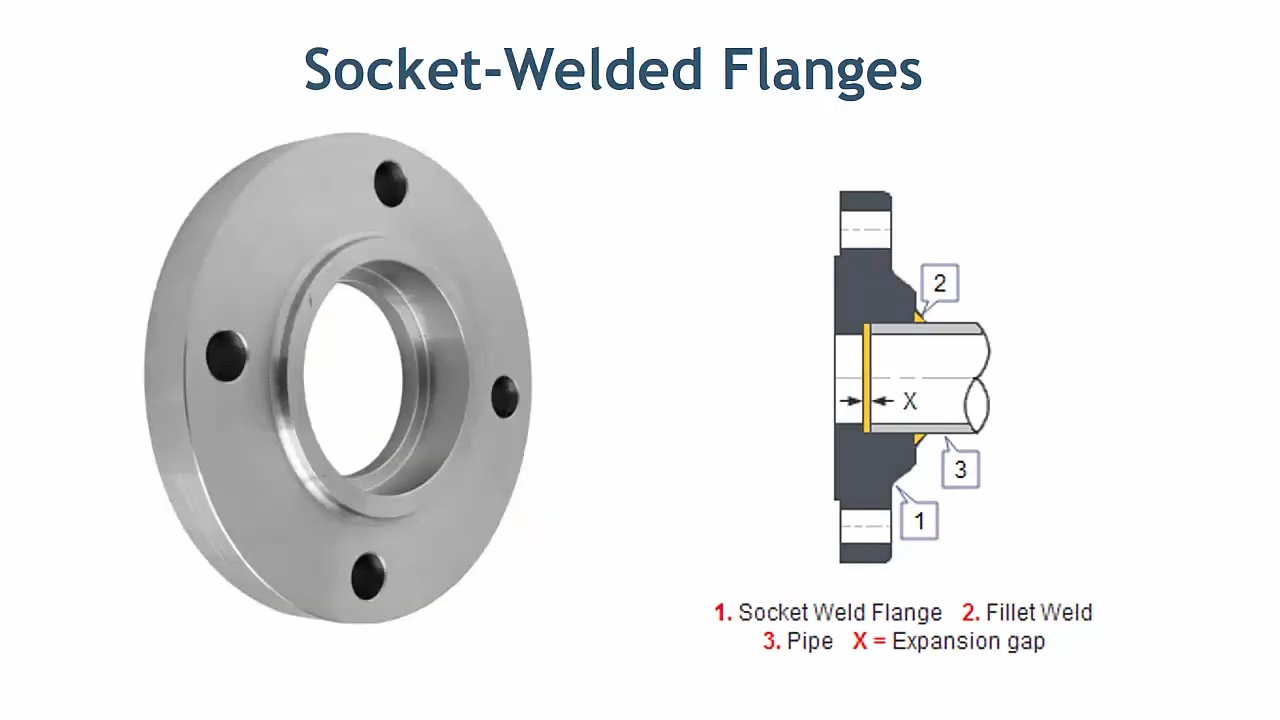

4. Socket Weld Flange

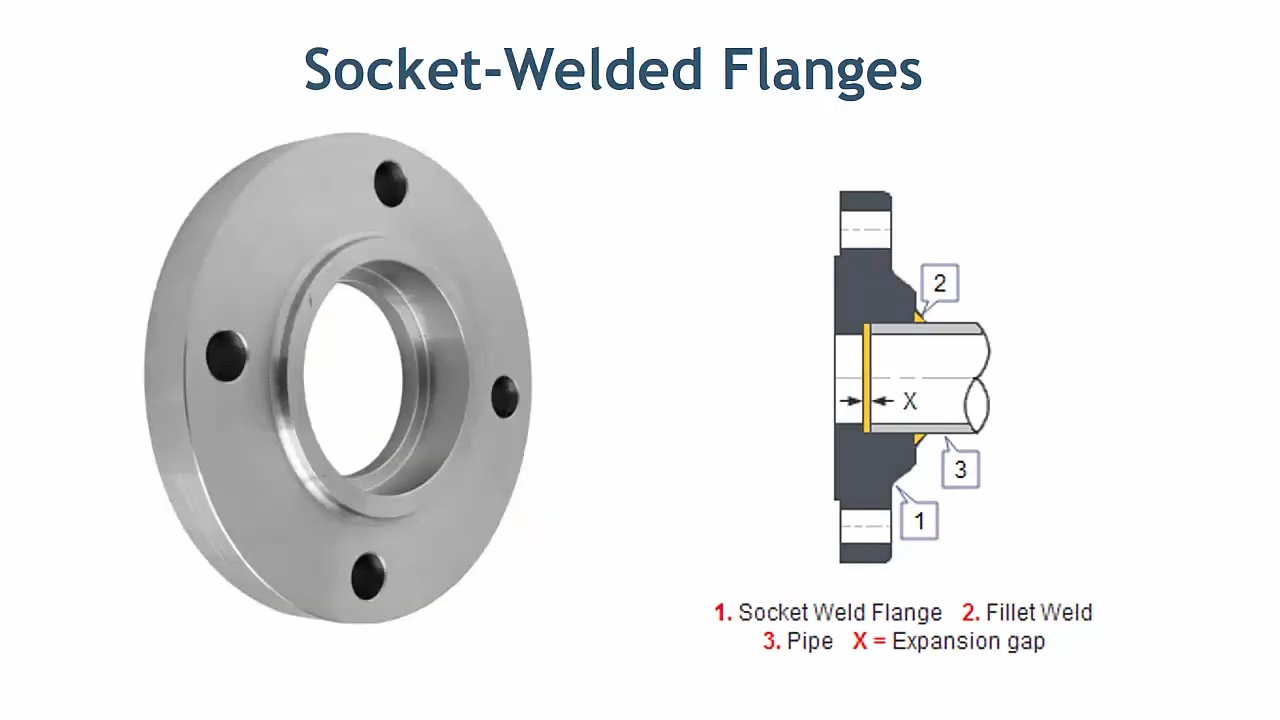

A socket weld flange has a socket where the pipe fits, and it is welded on the outside to form a strong connection. This type of flange is known for its ease of alignment and installation, making it ideal for smaller-diameter, high-pressure systems. It’s commonly used in hydraulic and steam lines, particularly where space is limited. However, it’s not recommended for critical service applications due to its lower fatigue resistance compared to weld neck flanges.

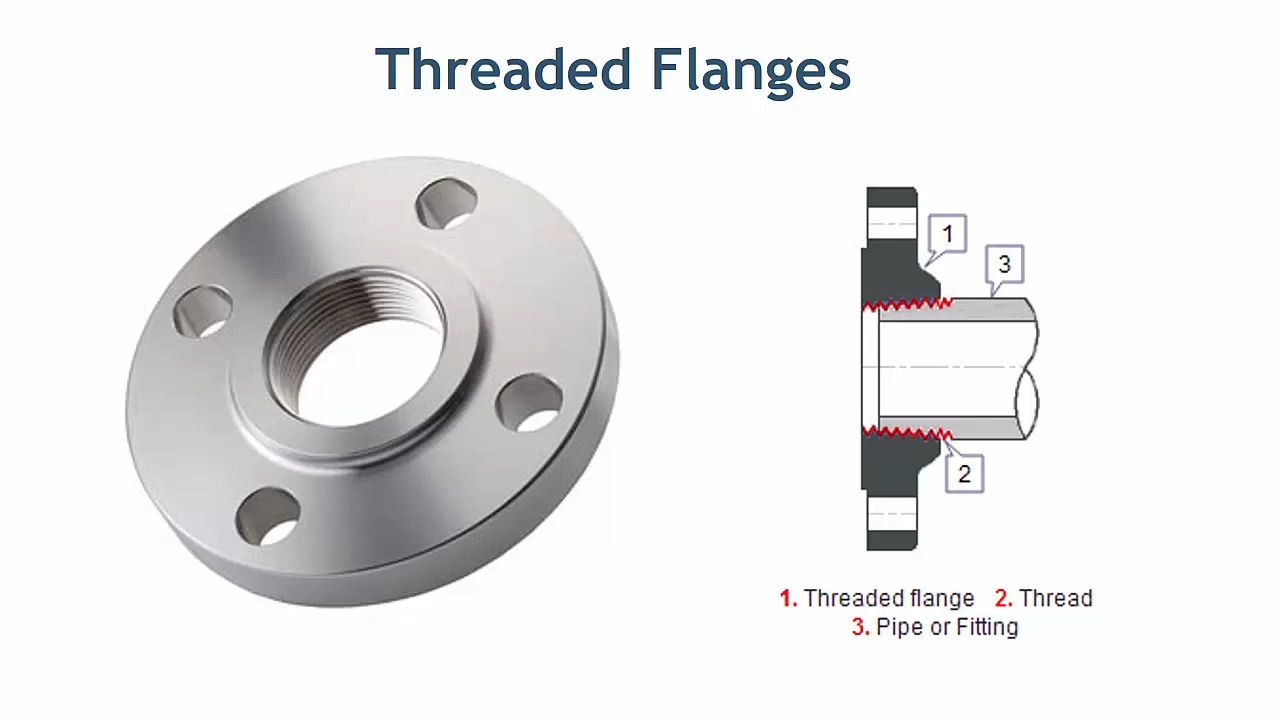

5. Threaded Flange

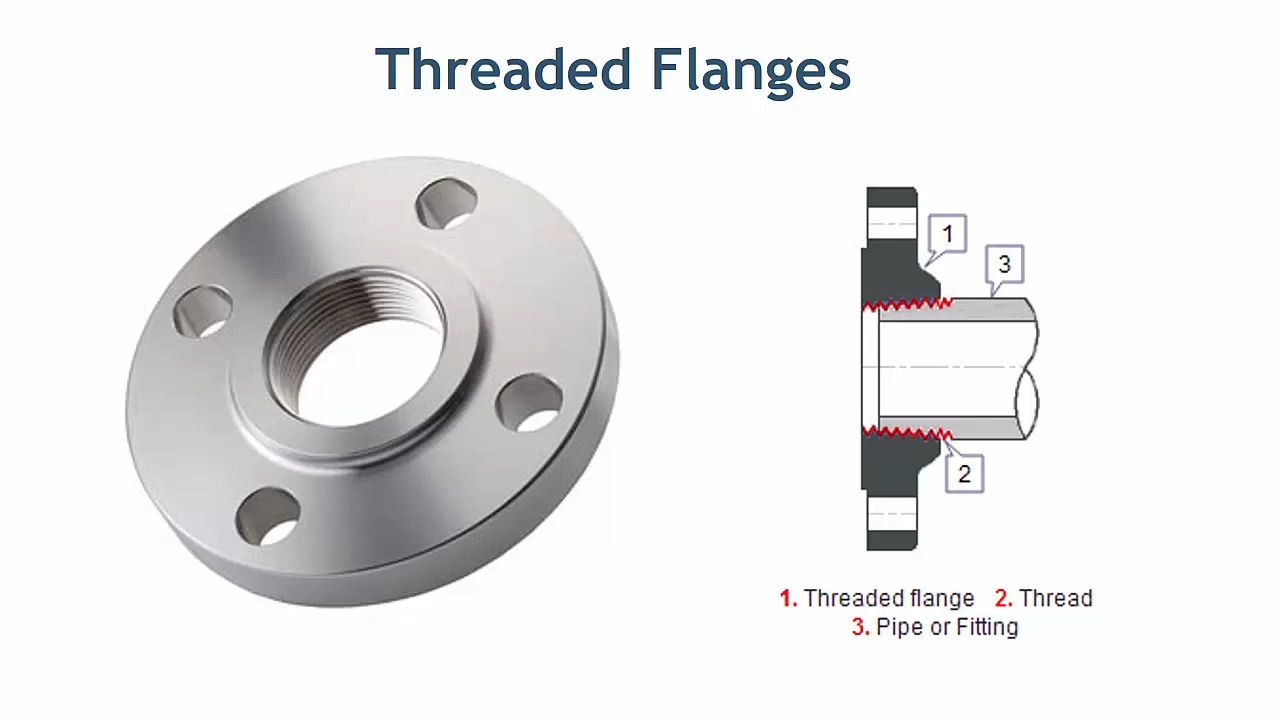

A threaded flange has internal threads that allow it to screw onto the pipe without the need for welding. This makes it particularly useful in applications where welding is not feasible, such as in systems carrying flammable substances where the risk of sparks must be minimized. Threaded flanges are typically used in low-pressure, low-temperature systems like water or air lines. They’re ideal for small-diameter pipes in non-corrosive environments.

6. Lap Joint Flange

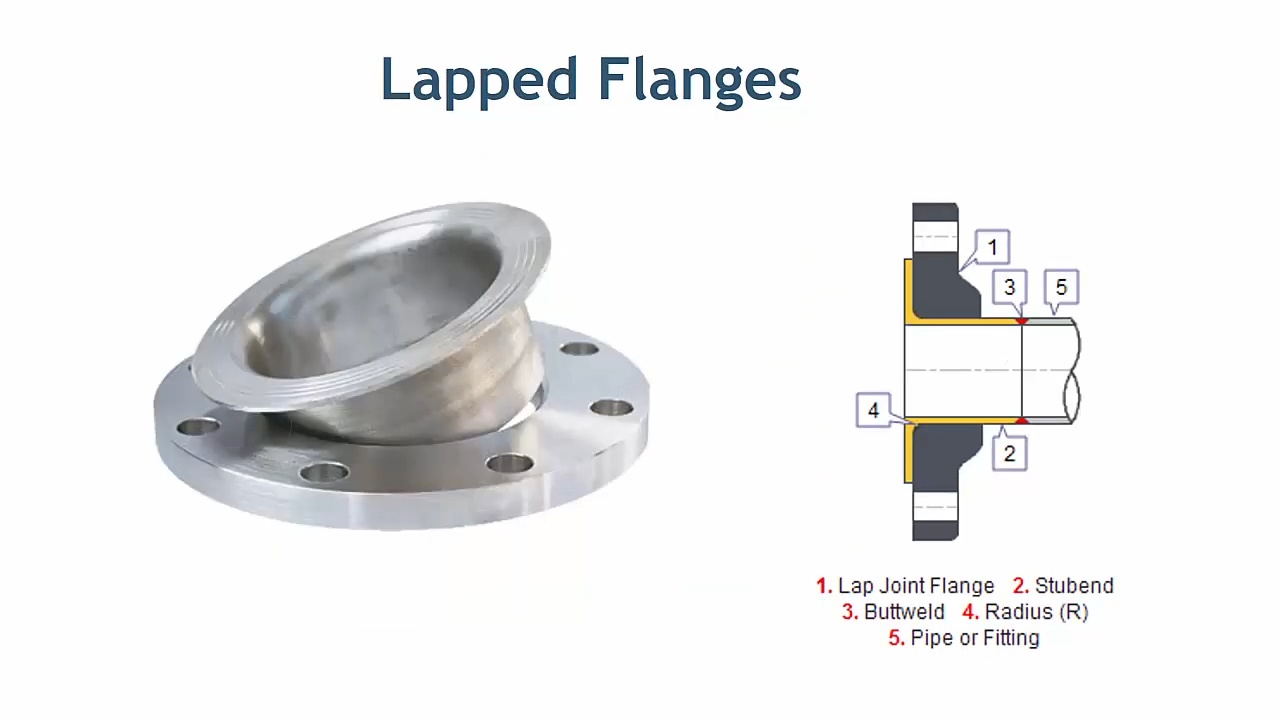

The lap joint flange is a two-part assembly consisting of a stub end and a loose backing flange. The loose flange allows for easy alignment of bolt holes, making it highly flexible and ideal for systems requiring frequent disassembly for maintenance or inspection. One of its key advantages is that it can be paired with an inexpensive carbon steel flange for use with expensive, corrosion-resistant piping materials like stainless steel. It’s often used in food processing, chemical plants, and other industries where cleanliness and corrosion resistance are critical.

7. Orifice Flange

An orifice flange includes an orifice plate, which is used to measure the flow rate of liquids, steam, or gases within a piping system. This flange type is commonly used in conjunction with pressure taps to monitor flow rates by creating a pressure differential. Orifice flanges are frequently found in chemical processing, oil refining, and water treatment systems where precise flow monitoring is essential for maintaining process efficiency.

8. Long Welding Neck Flange

A long welding neck flange is similar to a weld neck flange but with an extended neck, providing additional reinforcement for applications where high pressure is a concern. This flange type is used in high-pressure pipelines, often in the oil and gas industry, to ensure secure and reliable connections over long distances. Its elongated neck allows for better stress distribution in pipelines with large diameters.

9. Special Types of Flanges

Nipoflange: A combination of a welding neck flange and a Nipolet, this type is used to branch a pipeline at a 90-degree angle, offering a compact and sturdy connection.

Weldo Flange: This flange is designed to provide an outlet connection, typically used for branch pipelines. It is welded directly to the main pipe, offering a reliable and leak-proof connection.

Elbo Flange: Combining the functionality of an elbow and a flange, this flange type allows pipes to connect at an angle, reducing the need for separate elbow and flange components.

Swivel Flange: A swivel flange features a rotating outer ring, which simplifies bolt hole alignment, especially useful in subsea and offshore applications where precise alignment can be challenging.

Reducing Flange: Used to reduce the bore size of a pipeline, a reducing flange connects pipes of different diameters without the need for an additional reducer, often employed in systems where space is limited.

Expanding Flange: Opposite to a reducing flange, the expanding flange increases the bore size, allowing a pipeline to connect to equipment like valves and pumps that have larger inlets.

These flange types each have specific features and benefits that make them suitable for different industrial applications. Selecting the correct flange type for a particular environment depends on the system’s pressure, temperature, and material compatibility.

| Type of Flange | Main Use | Ideal Applications |

| Blind Flange | Sealing off pipes or systems | Oil refineries, pressure vessels |

| Weld Neck Flange | High-pressure, high-temperature pipelines | Chemical plants, petrochemical systems |

| Slip-On Flange | Low-pressure systems, easy alignment | Water lines, compressed air systems |

| Socket Weld Flange | High-pressure pipelines requiring secure joints | Hydraulic systems |

| Threaded Flange | Low-pressure, low-temperature systems | Water systems, where welding isn't possible |

| Lap Joint Flange | Systems requiring frequent disassembly | Corrosive environments |

| Orifice Flange | Flow measurement | Chemical processing, refineries |

Material Choices for Flanges

Selecting the right material for a flange is crucial for both performance and longevity, depending on the operating conditions. Here are the common materials used:

Carbon Steel: The most commonly used material for flanges due to its strength, durability, and affordability. It is ideal for general-purpose applications but may not perform well in corrosive environments.

Alloy Steel: Contains elements like chromium, nickel, or molybdenum, making it suitable for high-temperature and high-pressure conditions, commonly used in refineries and power plants.

Stainless Steel: Known for its excellent corrosion resistance, stainless steel flanges are ideal for environments with high humidity or exposure to corrosive chemicals.

Cast Iron: Often used in applications where strength and machinability are important, though it is less common in modern industrial settings due to its brittleness.

Aluminum: A lightweight, corrosion-resistant option often used in systems where reducing weight is important, such as in aerospace applications.

Brass: Excellent for high-temperature applications where conductivity and ductility are important, often found in marine and plumbing systems.

| Material | Characteristics | Typical Applications |

| Carbon Steel | High strength, affordable | General-purpose pipelines |

| Alloy Steel | High-pressure, high-temperature resistant | Power plants, refineries |

| Stainless Steel | Corrosion-resistant, durable | Chemical processing, food and beverage |

| Cast Iron | Strong but brittle | Historical use, lower-pressure applications |

| Aluminum | Lightweight, corrosion-resistant | Aerospace, transportation systems |

| Brass | High conductivity and ductility | Marine, high-temperature systems |

Factors to Consider When Selecting a Flange

Flange Type

Selecting the correct flange type is essential to ensure compatibility with the piping system and operating conditions. For example, weld neck flanges are better suited for high-pressure systems, while slip-on flanges are easier to install but less durable.

Face Type

The flange face must provide a reliable seal. Raised faces are preferred for higher pressure applications, while flat faces are suitable for lower-pressure systems.

Material Considerations

Flanges should be made of materials compatible with the fluids or gases being transported and the environment they’re operating in. Stainless steel may be required for corrosive environments, while carbon steel suffices in general applications.

Dimensions and Sizes

Flange dimensions, including the outer diameter and bore size, should match the piping system to ensure a proper fit and avoid leaks.

Pressure and Temperature Ratings

Always select flanges that meet or exceed the system's maximum pressure and temperature requirements to prevent failures.

Cost and Availability

High-quality flanges may have a higher initial cost but can save money over time by reducing downtime and repairs. Additionally, ensure that the selected flange type and material are readily available to avoid project delays.

Manufacturing Methods

The manufacturing process impacts the flange's strength and durability. Forged flanges are stronger, while cast flanges offer more precision and are easier to produce.

Manufacturing Methods for Flanges

There are two primary manufacturing methods for flanges:

Forging: Flanges are formed by heating and shaping the material under pressure. Forged flanges are stronger and more durable, making them ideal for high-pressure applications.

Casting: Molten metal is poured into a mold to form the flange. Casting allows for more complex designs, but cast flanges are generally less strong than forged flanges. They are suitable for low-pressure applications where precision is important.

Applications and Uses of Flanges

Flanges are used across various industries, each with specific requirements:

Manufacturing Industries: In factories, flanges are used to connect equipment like hydraulic and pneumatic systems. They ensure precise alignment and secure connections in molding machines.

Power Generation: In hydroelectric and thermal power plants, flanges connect turbines, pumps, and other equipment, ensuring strong, leak-proof joints that withstand extreme conditions.

Water and Wastewater Treatment: Flanges are critical in connecting pipes, valves, and pumps in sewer systems and treatment plants, where leaks would result in contamination.

Petrochemical Industry: High-pressure pipelines in chemical plants rely on durable flanges to withstand extreme temperatures and corrosive substances.

Marine Industry: Flanges are vital in shipbuilding, providing secure connections between fuel systems, cooling systems, and other components.

Conclusion

Flanges are a vital part of many industrial systems, providing secure, reliable connections that withstand pressure, temperature, and environmental conditions. Selecting the right flange based on type, material, and application ensures system integrity and reduces downtime. By understanding the different types of flanges and their respective uses, industries can make informed decisions that lead to more efficient, safe, and durable operations.

For expert guidance on your manufacturing project, contact us. Our experienced engineers will help you navigate the design, material selection, and manufacturing process to ensure optimal results. Partner with TEAM FMG for success. We will take your production to the next level.

FAQs About Flanges

1. What is a flange used for in piping systems?

A flange is used to connect pipes, valves, pumps, and other equipment in piping systems. It allows for easy assembly, disassembly, and maintenance of the system, while providing a tight, leak-proof connection through bolting and gasket sealing. Flanges are critical in high-pressure or high-temperature environments where a secure connection is essential.

2. What are the most common types of flanges?

The most common types of flanges include:

Weld Neck Flange: Known for high strength and used in high-pressure systems.

Slip-On Flange: Simple to install and used in low-pressure applications.

Blind Flange: Used to close the end of a piping system.

Socket Weld Flange: Often used for small-diameter, high-pressure pipelines.

Threaded Flange: Screwed onto pipes without welding, used in low-pressure systems.

3. What is the purpose of a raised face flange?

A Raised Face (RF) flange has a small raised section around the bore to concentrate the sealing force on a smaller area, improving gasket compression. This design allows it to handle higher pressures and makes it the most common flange face used in industrial applications, such as refineries and chemical plants.

4. How do I choose the right flange material?

Choosing the right material depends on factors like the type of fluid being transported, pressure, temperature, and corrosion resistance. Common materials include:

Carbon Steel: Ideal for general-purpose applications.

Stainless Steel: Provides corrosion resistance, often used in chemical or food processing.

Alloy Steel: Best for high-pressure and high-temperature environments.

5. What is the difference between a slip-on flange and a weld neck flange?

Slip-On Flange: Slips over the pipe and is welded on both the inside and outside. Easier to install but less durable, making it suitable for low-pressure systems.

Weld Neck Flange: Features a long neck that is butt-welded to the pipe, providing better alignment and stress distribution. It is ideal for high-pressure, high-temperature applications.

6. What is the function of the bore in a flange?

The bore is the central hole in the flange where the pipe passes through. It must match the pipe's diameter to ensure proper alignment and efficient fluid flow. For weld neck flanges, the bore is often tapered to distribute stress evenly and reduce the risk of leaks or structural failure.

7. How do flanges ensure a leak-proof connection?

Flanges achieve a leak-proof connection through a combination of bolting and the use of gaskets. The bolts secure two flange faces together, while the gasket provides a compressible material that fills any gaps between the flange faces, ensuring a tight seal. In high-pressure systems, metal-to-metal seals, such as Ring-Type Joint (RTJ) gaskets, are often used for extra security.