How can manufacturers produce high-quality plastic parts faster while saving costs? The secret lies in mastering injection molding cycle times. In today’s competitive market, every second counts, and optimizing this cycle can make a significant difference.

The injection molding process involves heating plastic material, injecting it into a mold, and cooling it to form a solid part. But how long does it take to complete one cycle, and what factors influence this time? Understanding and reducing cycle time can improve efficiency and lower production costs.

In this post, you’ll learn what influences cycle times in injection molding and discover techniques to optimize the process. From adjusting clamping forces to redesigning cooling channels, we’ll cover proven strategies to cut cycle times without sacrificing product quality.

What is Injection Molding Cycle Time?

Injection molding cycle time refers to the total time required to complete one full cycle of the injection molding process. It starts when the molten material is injected into the mold cavity and ends when the finished part is ejected from the mold.

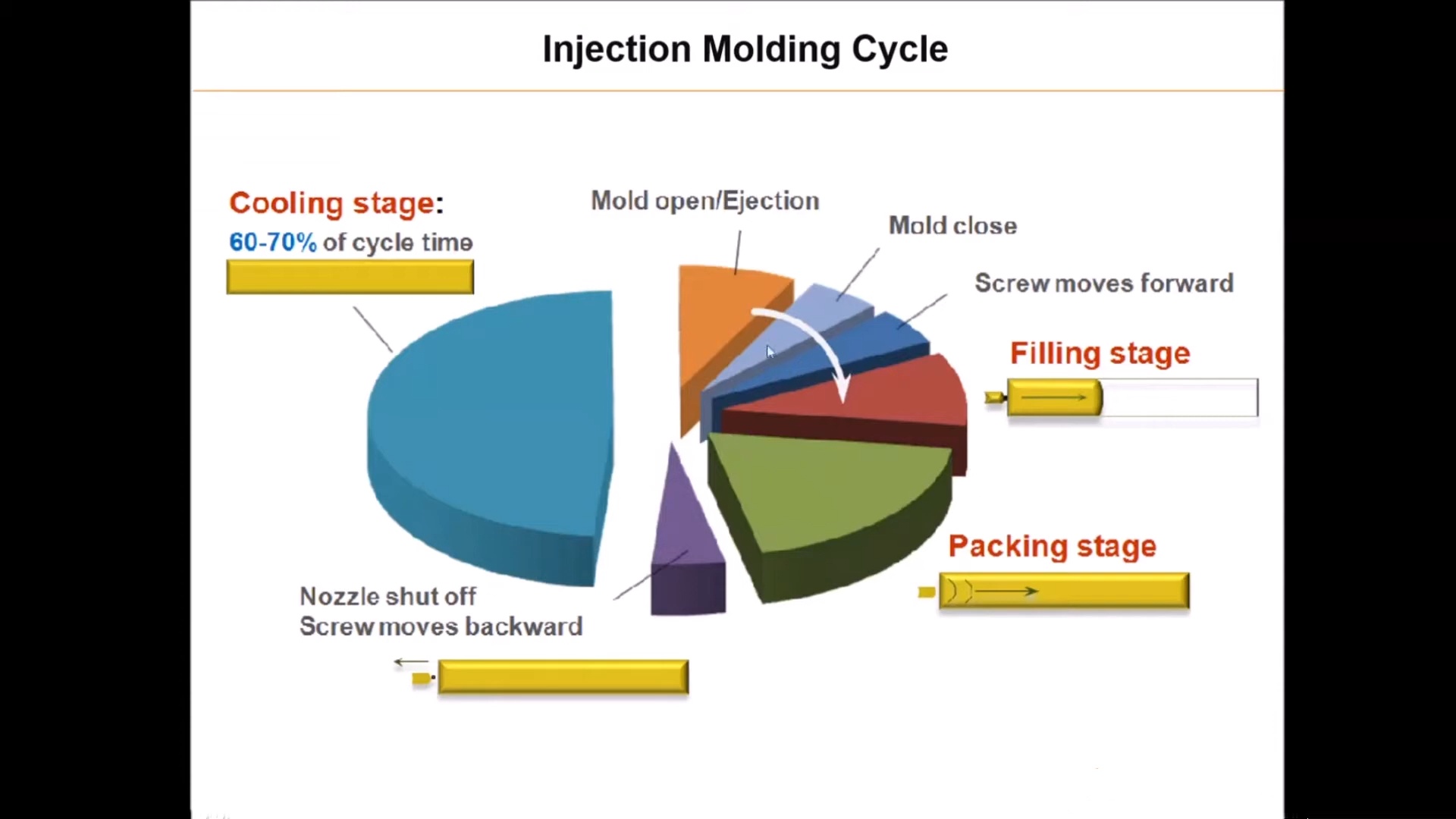

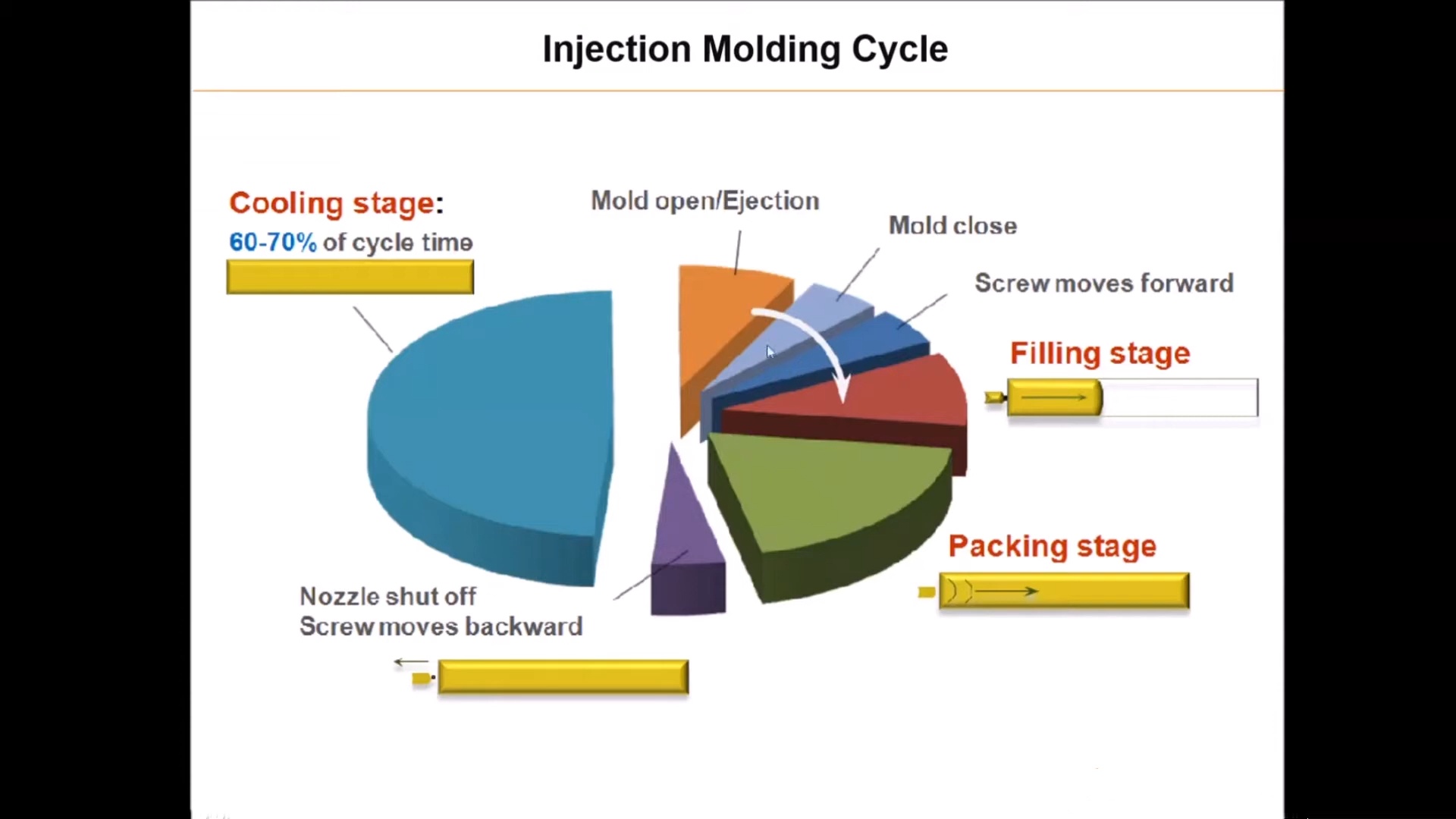

Components of the Injection Molding Cycle

The injection molding cycle consists of several stages. Each stage contributes to the overall cycle time. The key components of the injection molding cycle are:

Injection Time:

Duration it takes to inject the molten material into the mold cavity until it is completely filled

Influenced by factors such as material flow characteristics, injection speed, and part geometry

Cooling Time:

Period for the molten plastic to cool and solidify after the mold cavity is filled

Critical part of the cycle as it affects part dimensional stability and quality

Influenced by material type, part thickness, and mold cooling system efficiency

Dwelling Time:

Ejection Time:

Mold Opening/Closing Time:

Importance of Understanding and Optimizing Cycle Time

Understanding and optimizing the injection molding cycle time is crucial for several reasons:

Production Efficiency: Reducing cycle time leads to increased productivity and higher production output

Cost Savings: Shorter cycle times result in lower production costs and improved profitability

Product Quality: Optimizing cycle time helps achieve consistent part quality and reduces defects

Competitiveness: Efficient cycle times enable faster time-to-market and enhance competitiveness in the industry

Key Points:

Injection molding cycle time is the total time for one complete molding cycle

It includes injection time, cooling time, dwelling time, ejection time, and mold opening/closing time

Optimizing cycle time improves production efficiency, reduces costs, and enhances product quality

Understanding cycle time is crucial for staying competitive in the injection molding industry

How to Calculate Injection Molding Cycle Time

Understanding cycle time calculation is crucial for optimizing injection molding processes. This section provides a comprehensive guide to accurately determine cycle time.

Step-by-step Guide to Calculating Cycle Time

Measuring Injection Time

Record the duration required to fill the mold cavity

Use injection molding machine settings or production data

Consider material flow rate, injection speed, and cavity volume

Determining Cooling Time

Assess material type and part design

Evaluate mold cooling system efficiency

Utilize mold flow analysis software for accurate estimation

Estimating Dwelling Time

Determine additional time for complete solidification

Base it on material properties and part requirements

Typically shorter than cooling time

Calculating Ejection Time

Factors influencing ejection time:

Accounting for Mold Opening/Closing Time

Consider mold complexity and size

Evaluate molding machine capabilities

Measure actual time during production runs

Cycle Time Calculation Formula

Use this formula to calculate total cycle time:

Total Cycle Time = Injection Time + Cooling Time + Dwelling Time + Ejection Time + Mold Opening/Closing Time

Online Tools and Simulation Software for Estimating Cycle Time

Several resources are available for accurate cycle time estimation:

Online Calculators

Mold Flow Analysis Software

Simulate entire injection molding process

Provide detailed insights into each cycle stage

Examples: Autodesk Moldflow, Moldex3D

Machine-specific Tools

CAE Software

These tools help manufacturers optimize cycle times, improve efficiency, and reduce costs in injection molding operations.

Factors Affecting Injection Molding Cycle Time

Several factors influence the injection molding cycle time. They can be categorized into four main aspects: mold design parameters, product design parameters, material selection, and injection molding process parameters.

Mold Design Parameters

Cooling System Design:

Runner and Gate Design:

Number of Cavities:

Venting Design:

Product Design Parameters

Wall Thickness:

Part Geometry:

Material Selection

Melt and Cooling Characteristics:

Material Thickness and Its Impact on Cooling Time:

| Materials | Cooling Time (seconds) for Different Thicknesses |

|

|

|

|

|

| 1mm | 2mm | 3mm | 4mm | 5mm | 6mm |

| ABS | 1.8 | 7.0 | 15.8 | 28.2 | 44.0 | 63.4 |

| PA6 | 1.5 | 5.8 | 13.1 | 23.2 | 36.3 | 52.2 |

| PA66 | 1.6 | 6.4 | 14.4 | 25.6 | 40.0 | 57.6 |

| PC | 2.1 | 8.2 | 18.5 | 32.8 | 51.5 | 74.2 |

| HDPE | 2.9 | 11.6 | 26.1 | 46.4 | 72.5 | 104.4 |

| LDPE | 3.2 | 12.6 | 28.4 | 50.1 | 79.0 | 113.8 |

| PMMA | 2.3 | 9.0 | 20.3 | 36.2 | 56.5 | 81.4 |

| POM | 1.9 | 7.7 | 20.3 | 30.7 | 48.0 | 69.2 |

| PP | 2.5 | 9.9 | 22.3 | 39.5 | 61.8 | 88.9 |

| PS | 1.3 | 5.4 | 12.1 | 21.4 | 33.5 | 48.4 |

Table 1: Cooling times for different materials and thicknesses

Injection Molding Process Parameters

Injection Speed and Pressure:

Melt Temperature:

Mold Temperature:

Holding Time and Pressure:

Environment Conditions

Humidity:

Air Quality:

Temperature:

Strategies for Reducing Injection Molding Cycle Time

Reducing injection molding cycle time is crucial for improving production efficiency and cost-effectiveness. We can achieve shorter cycle times by optimizing various aspects of the molding process. Let's explore some key strategies.

Optimizing Mold Design

Improving Cooling System Efficiency:

Optimizing Runner and Gate Design:

Improving Venting:

Incorporate adequate venting in the mold design

Proper venting allows for efficient air and gas escape, reducing cycle time

Optimizing Product Design

Maintaining Uniform Wall Thickness:

Simplifying Part Geometry:

Selecting the Right Material

Choosing Materials with Faster Cooling Rates:

Considering Material Thickness:

Fine-Tuning Injection Molding Process Parameters

Using High-Speed Injection:

Optimizing Injection Pressure:

Controlling Mold Temperature:

Minimizing Holding Time and Pressure:

Investing in Advanced Equipment

Fast Clamping Systems:

Efficient Ejection Mechanisms:

Streamlining the Injection Molding Process

Developing a Consistent Process:

Maximizing Processing Window:

Implementing Scientific Molding Principles:

Setting Up Process Before Tool Changes:

Monitoring Tool Temperature and Venting:

Analyzing Tool Functionality During Sampling:

Benefits of Reducing Injection Molding Cycle Time

Optimizing injection molding cycle time offers numerous advantages for manufacturers. This section explores the key benefits of streamlining production processes.

Increased Production Output

Reducing cycle time directly impacts production capacity:

Higher parts-per-hour ratio

Increased machine utilization

Ability to meet larger order volumes

Example: A 10% reduction in cycle time can potentially increase annual output by 100,000 units for a high-volume production line.

Lower Production Costs

Shorter cycle times contribute to cost savings:

| Cost Factor | Impact of Reduced Cycle Time |

| Energy | 5-15% reduction per part |

| Labor | 10-20% decrease in man-hours |

| Overhead | 8-12% reduction in fixed costs |

Improved Product Quality

Optimized cycle times often lead to enhanced quality:

By minimizing exposure to heat and pressure, shorter cycles help maintain material integrity, resulting in superior end products.

Faster Time-to-Market

Efficient production cycles accelerate product launches:

Quicker prototype iterations

Rapid scaling of production

Flexibility to meet changing market demands

This agility allows manufacturers to capitalize on emerging opportunities and respond swiftly to consumer trends.

Enhanced Competitiveness

Streamlined processes provide a competitive edge:

Ability to offer shorter lead times

Improved pricing flexibility

Capacity to handle rush orders

These factors position manufacturers as preferred suppliers in a crowded market.

Energy Efficiency

Reduced cycle times contribute to sustainability efforts:

Lower energy consumption per unit

Decreased carbon footprint

Alignment with eco-friendly manufacturing practices

Energy Savings Example:

Annual Production: 1,000,000 units

Original Cycle Time: 30 seconds

Reduced Cycle Time: 25 seconds

Energy Consumption: 5 kWh per hour

Original Energy Usage: 41,667 kWh

Optimized Energy Usage: 34,722 kWh

Annual Energy Savings: 6,945 kWh

Conclusion

Optimizing injection molding cycle time is crucial for manufacturing efficiency and competitiveness. By implementing strategies like improving mold design, selecting appropriate materials, and fine-tuning process parameters, businesses can achieve significant benefits. These include increased output, lower costs, better quality, and faster market response.

Shorter cycle times lead to improved energy efficiency and enhanced flexibility in production schedules. This ongoing process of optimization positions companies for long-term success in the dynamic manufacturing landscape.

Manufacturers should prioritize cycle time reduction to streamline operations, boost profitability, and meet evolving market demands. Continuous monitoring and adjustment are key to maintaining peak performance in injection molding processes.