What if a material could combine the best features of plastic and rubber? That’s exactly what TPU Plastic offers. Known for its flexibility and durability, TPU Plastic plays a vital role across various industries, from automotive to electronics. Its unique properties make it a go-to choice for manufacturers. In this post, you’ll learn why TPU Plastic stands out and how its recyclability supports a more sustainable future.

What is TPU Plastic?

TPU, or Thermoplastic Polyurethane, is a versatile material that combines the best properties of both plastics and rubbers. It’s known for its durability, flexibility, and high tensile strength, making it useful in many demanding applications, from automotive to textiles.

TPU was first discovered in 1937 by Otto Bayer and his coworkers at I.G. Farben in Leverkusen, Germany. They found that when a polyaddition reaction occurs between a diisocyanate and one or more diols in a specific way, it produces TPU.

TPU bridges the gap between plastic and rubber. It has the rigidity and strength of plastic but retains the elasticity and flexibility of rubber. This unique composition allows TPU to be both moldable and stretchable, which gives it an edge in applications requiring both toughness and flexibility.

The Chemistry Behind TPU Plastic

TPU, or Thermoplastic Polyurethane, is a unique polymer with a fascinating chemical structure. It's this structure that gives TPU its remarkable properties.

Chemical Composition of TPU

TPU is created through a polyaddition reaction. This involves three key components:

A polyol (long-chain diol)

A chain extender (short-chain diol)

A diisocyanate

These components combine to form a linear segmented block copolymer. It's this copolymer structure that makes TPU so special.

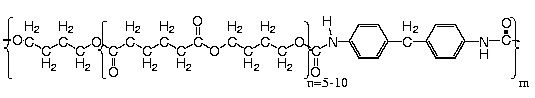

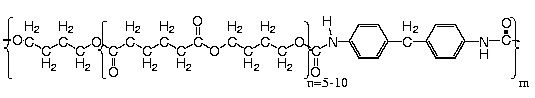

Molecular Structure of Thermoplastic Polyurethanes

Hard and Soft Segments in TPU Structure

The hard segments in TPU are created by the interaction between the diisocyanate and chain extender. These segments provide rigidity and mechanical strength. The soft segments are formed from the long-chain diol, giving TPU its elasticity and flexibility.

The balance between these hard and soft segments allows TPU to offer a wide range of properties, from rigid to flexible, depending on the application.

| Property | Hard Segments | Soft Segments |

| Structure | Rigid, crystalline | Flexible, amorphous |

| Function | Provides strength and toughness | Gives elasticity and flexibility |

The ratio of these segments determines TPU's properties. More hard segments increase rigidity, while more soft segments enhance flexibility.

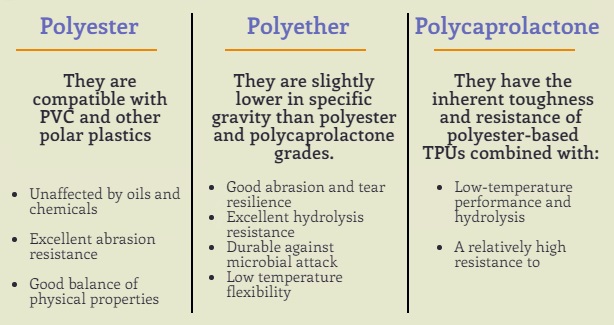

Types of TPU: Polyester-based, Polyether-based, and Polycaprolactone-based

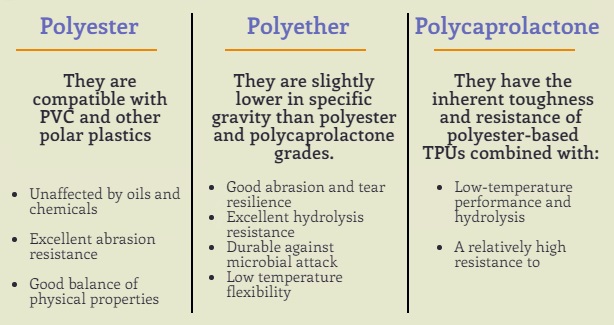

There are three main types of TPU, each offering distinct properties:

Polyester-based TPU: Known for its mechanical strength and chemical resistance, it performs well in applications exposed to oils and hydrocarbons. It’s ideal for industrial uses.

Polyether-based TPU: This type excels in low-temperature flexibility and has excellent hydrolysis resistance, making it suitable for medical devices and outdoor equipment.

Polycaprolactone-based TPU: Combining the strengths of the other types, Polycaprolactone-based TPU provides durability, hydrolysis resistance, and low-temperature performance. It’s used in seals and hydraulic applications.

| TPU Type | Key Properties | Applications |

| Polyester-based | High mechanical strength, chemical resistance | Automotive, industrial parts |

| Polyether-based | Hydrolysis resistance, flexibility at low temperatures | Medical devices, outdoor equipment |

| Polycaprolactone-based | Durability, hydrolysis resistance, low-temp performance | Seals, hydraulic and pneumatic systems |

Properties of TPU

| Property | Performance | Examples of Applications |

| Flexibility and Elasticity | High across wide hardness range | Shoe soles, medical devices, automotive parts |

| Abrasion Resistance | Excellent | Conveyor belts, sports equipment, industrial components |

| Chemical Resistance | Good, especially to non-polar chemicals | Hydraulic seals, protective coatings |

| Transparency | Available in crystal-clear grades | Transparent films, tubing, injection molded parts |

| UV Resistance | Superior in aliphatic grades | Outdoor applications, automotive exterior parts |

| Low-Temperature Performance | Maintains flexibility in cold | Winter sports equipment, outdoor industrial applications |

| Breathability | Up to 10,000 g/m2/day in some grades | Sportswear, building materials |

| Strength and Toughness | High tensile strength and elongation at break | Industrial parts, protective gear |

| Oil and Grease Resistance | Excellent, especially in polyester-based | Automotive components, industrial seals |

| Mechanical Properties | High impact strength, good load-bearing capacity | Technical parts, automotive interior components |

| Durability | High resistance to wear and tear | Footwear, industrial belts, cable jacketing |

| Resilience | Good recovery from repeated stress | Shock absorbers, vibration dampers |

| Hydrolysis Resistance | Good in polyether-based TPUs | Medical tubing, underwater applications |

| Microbial Resistance | Good in polyether-based TPUs | Medical devices, food processing equipment |

| Melt Processability | Can be processed using conventional thermoplastic equipment | Various molded and extruded products |

| Recyclability | Can be melted and reprocessed multiple times | Eco-friendly product designs |

Applications of TPU Plastic Across Industries

TPU's versatility makes it a go-to material in various sectors. Let's explore how different industries leverage its unique properties.

Automotive Industry

The automotive sector extensively uses TPU for its durability and flexibility.

Seals and gaskets: TPU provides robust, flexible seals resistant to temperature variations and chemicals. It's ideal for door seals, window seals, and trunk seals.

Interior components: TPU offers a soft-touch feel, perfect for dashboards and armrests. It enhances the aesthetic and tactile experience of car interiors.

Airbag covers: The material's flexibility and strength ensure safe and effective airbag deployment. TPU airbag covers can withstand the sudden force of inflation.

Consumer Products

TPU's durability and versatility shine in everyday consumer goods.

Phone cases and electronic device protection: Its impact resistance and flexibility make TPU ideal for protective cases. These cases absorb shocks and prevent damage to devices.

Sporting goods and equipment: TPU is used in various sports gear. From helmet padding to swimming fins, it provides durability and flexibility.

Footwear components: Many shoe soles use TPU for its flexibility, durability, and slip resistance. It enhances comfort and safety in footwear.

Medical Industry

In healthcare, TPU's biocompatibility and flexibility are crucial.

Medical tubing and devices: TPU's flexibility and ability to withstand sterilization make it perfect for medical tubing. It's also used in various medical devices.

Prosthetics and orthotics: The material's durability and comfort make it suitable for prosthetic limbs and orthotic devices. TPU enhances the quality of life for many patients.

Industrial Applications

TPU's strength and resistance to wear are valuable in industrial settings.

Conveyor belts and industrial seals: Its durability and flexibility make TPU ideal for these applications. It can withstand constant use and harsh conditions.

Hydraulic and pneumatic hoses: TPU's resistance to oils and chemicals makes it perfect for these hoses. It ensures long-lasting performance in demanding environments.

Textile and Apparel

TPU's breathability and waterproof properties are assets in the textile industry.

Breathable membranes for sportswear: TPU allows moisture vapor to escape while blocking water. This keeps athletes dry and comfortable during intense activities.

Waterproof coatings: TPU can be applied as a coating to fabrics. It provides water resistance without compromising breathability.

Wire and Cable

The electrical industry benefits from TPU's insulating properties.

Construction and Building Materials

TPU's durability and flexibility are valuable in construction.

Waterproofing membranes: TPU membranes provide effective water resistance in roofing and other applications. They help protect structures from water damage.

Elastic joint materials: TPU's elasticity makes it suitable for expansion joints. It allows for building movement while maintaining a seal.

| Industry | Application | Key TPU Properties Utilized |

| Automotive | Seals, interior parts, airbag covers | Durability, flexibility, chemical resistance |

| Consumer Products | Phone cases, sporting goods, footwear | Impact resistance, flexibility, durability |

| Medical | Tubing, prosthetics | Biocompatibility, flexibility, sterilization resistance |

| Industrial | Conveyor belts, hoses | Wear resistance, chemical resistance, durability |

| Textile | Sportswear membranes, waterproof coatings | Breathability, water resistance |

| Wire and Cable | Cable insulation | Electrical insulation, flexibility |

| Construction | Waterproofing, joint materials | Water resistance, elasticity |

Processing Methods for TPU Plastic

TPU's versatility extends to its processing methods. Let's explore the various ways to shape this remarkable material.

Injection Molding

Injection molding is a popular method for producing complex TPU parts.

Key points:

Molten TPU is injected into a mold cavity

Ideal for complex shapes with tight tolerances

Commonly used for grips, gaskets, and caps

Drying requirements: Ensure residual moisture content is ≤ 0.05% before processing. This prevents brittleness in molded parts.

Extrusion

Extrusion is perfect for creating continuous TPU shapes.

Process overview:

TPU is melted and forced through a die

The extruded material takes the shape of the die opening

It's then cooled and cut to desired lengths

Applications:

Drying tip: Aim for residual moisture content ≤ 0.02% before extrusion.

Compression Molding

Compression molding is ideal for large, thick-walled TPU parts.

Steps:

Place TPU material in a heated mold

Apply pressure to form the desired shape

Cool and remove the finished part

This method is great for producing durable, impact-resistant components.

3D Printing with TPU Filaments

3D printing opens up new possibilities for TPU manufacturing.

Advantages:

Allows for complex geometries

Ideal for prototyping and small-scale production

Compatible with FDM (Fused Deposition Modeling) and SLS (Selective Laser Sintering) techniques

Tips for FDM printing:

Use a direct drive extruder for better control

Set heated bed temperature to 50 ±10°C

Print at speeds between 15-20 mm/s

Blow Molding

Blow molding is perfect for creating hollow TPU parts.

Process:

Extrude a TPU parison (hollow tube)

Clamp it in a mold

Inflate it with air to take the mold's shape

Common applications:

Solvent Processing

Solvent processing is used for TPU coatings and adhesives.

Key points:

TPU is dissolved in organic solvents

The solution is applied to surfaces

As the solvent evaporates, it leaves a TPU coating or adhesive layer

Applications:

Laminated textiles

Protective coatings

Functional adhesives

| Processing Method | Key Advantages | Common Applications |

| Injection Molding | Complex shapes, tight tolerances | Grips, gaskets, caps |

| Extrusion | Continuous shapes | Tubes, sheets, profiles |

| Compression Molding | Large, thick-walled parts | Durable components |

| 3D Printing | Complex geometries, prototyping | Custom parts, small batches |

| Blow Molding | Hollow parts | Bottles, containers |

| Solvent Processing | Coatings and adhesives | Textiles, protective layers |

Regardless of the method, proper drying of TPU before processing is crucial. It ensures optimal performance and prevents brittleness in the final product.

TPU vs. TPE: Understanding the Difference

When choosing materials for your project, you might encounter both TPU and TPE. Let's break down their differences.

Comparison Table: TPU vs. TPE

| Feature | TPU (Thermoplastic Polyurethane) | TPE (Thermoplastic Elastomers) |

| Chemical Composition | Polyurethane-based | Blend of thermoplastic and elastomer |

| Flexibility | High | Varies (generally high) |

| Hardness | Wide range, typically harder | Wide range, typically softer |

| Abrasion Resistance | Excellent | Good to excellent |

| Oil and Grease Resistance | Excellent | Varies (usually good) |

| Transparency | Can be transparent | Generally opaque |

| Elasticity | Excellent | Excellent |

| Processing | Injection molding, extrusion, blow molding | Injection molding, extrusion, blow molding |

| Temperature Resistance | Good (varies by grade) | Moderate (varies by type) |

| Durability | High | Moderate to high |

| Cost | Generally higher | Generally lower |

Key Advantages of TPU

TPU stands out in several areas. Let's explore its unique benefits.

Superior Abrasion Resistance

Excellent Chemical Resistance

TPU resists oils, greases, and many solvents.

This makes it perfect for industrial and automotive uses.

Transparency Options

Unlike most TPEs, TPU can be made crystal clear.

It's great for applications requiring visibility, like medical tubing.

Wide Hardness Range

High Tensile Strength

Excellent Low-Temperature Performance

UV Resistance

Customizability

While TPE has its strengths, TPU often wins in demanding applications. Its unique combination of properties makes it a versatile choice.

Consider your specific needs when choosing between TPU and TPE. TPU might cost more, but its performance often justifies the investment.

Modifying TPU Plastic for Enhanced Performance

TPU is already a versatile material, but we can further enhance its properties.

Blending with Other Materials

Mixing TPU with other polymers can create unique property combinations.

Common blends:

These blends allow for tailored solutions in specific applications. They combine the strengths of different materials.

Adding Reinforcing Fibers

Reinforced TPU becomes a structural engineering polymer. It gains impressive new properties.

Benefits of fiber reinforcement:

Typical reinforcing materials:

Glass fibers

Carbon fibers

Mineral fillers

Reinforced TPU finds use in automotive parts and high-stress industrial components.

Incorporating Additives for Specific Properties

Additives can fine-tune TPU's performance. They enhance various characteristics to meet specific needs.

Common additives and their effects:

Antioxidants: Protect against thermal degradation

UV absorbers: Improve weatherability

Flame retardants: Enhance fire resistance

Plasticizers: Increase flexibility

Colorants: Provide custom colors

| Additive Type | Purpose | Common Applications |

| Antioxidants | Thermal stability | Automotive parts |

| UV absorbers | Outdoor durability | Exterior components |

| Flame retardants | Fire safety | Cable jacketing |

| Plasticizers | Increased flexibility | Soft-touch products |

| Colorants | Aesthetic appeal | Consumer goods |

These additives allow manufacturers to tailor TPU for specific environments and uses.

Use of Polycarbonate Diols (PCDs)

PCDs are a game-changer in TPU production. They create high-performance polyurethanes with exceptional properties.

Advantages of PCD-based TPUs:

Extreme durability

Superior chemical resistance

Improved hydrolytic stability

Greater thermal resistance

Enhanced abrasion resistance

Applications of PCD-based TPUs:

High-performance seals

Durable coatings

Advanced medical devices

PCDs allow for the creation of TPU grades that outperform standard formulations. They're ideal for demanding applications.

Designing TPU Parts for Manufacturing

When creating TPU parts, understanding the manufacturing process is crucial. Let's explore design considerations for two popular 3D printing methods.

Designing for Selective Laser Sintering (SLS)

SLS offers great freedom in TPU part design. It can produce complex geometries without support structures.

Minimum Wall Thickness and Feature Size

Wall thickness: Aim for at least 1.5 mm

Increase to 3 mm for enhanced rigidity

Minimum feature size: 0.5 mm

Engraved or embossed details: 1.5 mm in height and width

These guidelines ensure structural integrity and accurate reproduction of your design.

Design Complexity and Assembly Considerations

SLS allows for intricate, enclosed, and interlocking parts. You can design components that don't require separate assembly.

Tips:

This ensures successful printing and easy assembly or movement of parts.

Hollowing and Escape Holes

Hollowing parts can save material and reduce printing time.

Key points:

Escape holes facilitate powder removal after printing, ensuring a clean final product.

Designing for Fused Deposition Modeling (FDM)

FDM is widely used for prototyping and small-scale production of TPU parts.

Minimum Wall Thickness and Feature Size

Wall thickness: At least 1.5 mm

Minimum feature size: 0.5 mm

Embossed or engraved details: 1.5 mm in height and width

These dimensions prevent warping and ensure accurate printing of your design.

Design Complexity and Assembly Considerations

FDM has some limitations compared to SLS. Keep your designs relatively simple.

Guidelines:

Simplifying designs helps ensure successful printing and sturdy final products.

Printing Considerations

Proper settings are crucial for successful FDM printing of TPU.

| Parameter | Recommended Setting |

| Printer Type | Direct drive extruder |

| Bed Temperature | 50 ±10°C |

| Printing Speed | 15-20 mm/s |

| Extrusion Temperature | 225-250°C |

| Cooling | Medium to high |

Additional tips:

Adjust extrusion multiplier for strong layer bonding

Use skirts instead of rafts

Disable retraction to prevent filament stretching

These settings help achieve optimal results when printing TPU with FDM.

Challenges and Limitations of TPU Plastic

While TPU offers numerous advantages, it's not without its challenges.

Processing Difficulties

TPU can be tricky to process, especially for those new to the material.

Common processing challenges:

To address these issues:

Thoroughly dry TPU before processing

Use precise temperature control

Apply mold release agents when necessary

Proper preparation and equipment setup are crucial for successful TPU processing.

Cost Considerations

TPU is often more expensive than alternative materials. This can impact project budgets and product pricing.

Factors affecting TPU cost:

Despite higher upfront costs, TPU's durability can offer long-term savings. Consider the total lifecycle cost when evaluating TPU for your project.

Performance Limitations in Certain Environments

While versatile, TPU has its limits. It may not be suitable for all conditions.

Potential limitations:

High-temperature environments (above 80°C)

Prolonged exposure to strong UV radiation

Certain aggressive chemicals

| Environment | TPU Performance |

| High Heat | Limited resistance |

| Strong UV | May degrade over time |

| Harsh Chemicals | Varies by TPU type |

Always test TPU in your specific application environment before full implementation.

Hydrolysis Sensitivity

Hydrolysis can be a significant issue, especially for polyester-based TPUs.

Key points:

Moisture can break down TPU molecular chains

This leads to loss of mechanical properties

Polyether-based TPUs are more resistant

To mitigate hydrolysis:

Choose polyether-based TPU for high-moisture environments

Use protective coatings when necessary

Implement proper drying procedures before processing

Future Trends in TPU Plastic Technology

Emerging Applications

TPU is finding new roles across industries. Its versatility opens doors to innovative uses.

Potential future applications:

Smart textiles with integrated TPU sensors

3D-printed customized medical implants

Advanced automotive components for electric vehicles

Biodegradable packaging materials

These applications leverage TPU's unique properties. They promise to revolutionize various sectors.

Advancements in TPU Formulations

Scientists are pushing TPU's capabilities further. New formulations are enhancing its already impressive properties.

Upcoming improvements:

Higher temperature resistance

Increased UV stability

Enhanced chemical resistance

Improved printability for additive manufacturing

These advancements will expand TPU's usability. They'll make it suitable for even more demanding applications.

Sustainable TPU Innovations

Sustainability is a key focus in TPU development. Researchers are exploring eco-friendly options.

Green TPU trends:

Recycled content TPU grades

Easily recyclable TPU formulations

TPU with reduced carbon footprint

Water-based TPU systems for coatings

These innovations aim to reduce TPU's environmental impact. They're making it a more sustainable choice for manufacturers.

Development of Bio-based TPUs

Bio-based TPUs are gaining traction. They offer a renewable alternative to traditional petroleum-based TPUs.

Key points:

Made from plant-based materials

Reduced reliance on fossil fuels

Potential for carbon neutrality

Comparable performance to traditional TPUs

| Source | Advantages | Challenges |

| Corn | Renewable, abundant | Land use concerns |

| Castor oil | Non-food crop, hardy plant | Limited supply |

| Algae | Fast-growing, high yield | Extraction difficulties |

Bio-TPUs are still evolving. They show promise for a more sustainable future in plastics.

The future of TPU technology looks bright. From new applications to greener formulations, TPU continues to adapt and improve.

These trends reflect growing demands for performance and sustainability. They're shaping the next generation of TPU materials.

Summary

In summary, TPU Plastic offers unmatched versatility with its blend of strength, flexibility, and durability. Understanding its properties and processing methods is essential to fully utilize its benefits across various industries. As innovation continues, TPU’s customization potential will drive new solutions in automotive, medical, and consumer products, making it an essential material for modern manufacturing.

Tips: You maybe interested to the all plastics