Welding joints play a crucial role in the success of any fabrication or construction project. These connections, formed by joining two or more pieces of metal, determine the strength, durability, and overall quality of the welded structure.

In this comprehensive guide, we'll dive into the five primary types of welding joints: butt, tee, corner, lap, and edge. By understanding the unique characteristics and applications of each joint type, you'll be better equipped to select the most suitable option for your specific needs. So, whether you're a seasoned welder or just starting out, join us as we explore the world of welding joints and unlock the secrets to creating strong, reliable welds every time!

What Are Welding Joints and Why Are They Important?

Welding joints are the connections formed when two or more pieces of metal are joined together through the welding process. These joints are essential in determining the strength, quality, and overall integrity of the welded structure. Let's take a closer look at why welding joints are so crucial:

1. Strength: The type of welding joint used directly impacts the strength of the welded connection. Selecting the appropriate joint design ensures that the welded structure can withstand the forces and loads it will be subjected to in its intended application.

2. Quality: Proper joint design and execution contribute to the overall quality of the weld. A well-designed and properly welded joint will have fewer defects, better fusion, and improved aesthetics compared to a poorly designed or executed joint.

3. Durability: The choice of welding joint influences the long-term durability of the welded structure. By selecting a joint type that is suitable for the specific application and material, you can ensure that the welded connection will remain strong and reliable over time.

When selecting a welding joint type for your project, there are several key factors to consider:

lMaterial thickness: The thickness of the materials being joined will influence the choice of joint type. Thicker materials may require groove welds or full penetration joints, while thinner materials can often be successfully joined with fillet welds or lap joints.

lApplication: Consider the intended use and load requirements of the welded structure. Some joint types are better suited for certain applications, such as butt joints for pressure vessels or tee joints for structural steel fabrication.

lAccessibility: The accessibility of the joint area can impact joint selection. If the joint is difficult to reach or has limited space for welding, certain joint types, such as corner or edge joints, may be more practical than others.

lCost and efficiency: Joint design can affect the overall cost and efficiency of the welding process. Some joint types require more preparation, consume more filler material, or take longer to weld than others. Consider these factors when selecting a joint type to optimize productivity and cost-effectiveness.

The 5 Primary Types of Welding Joints

Butt Joint

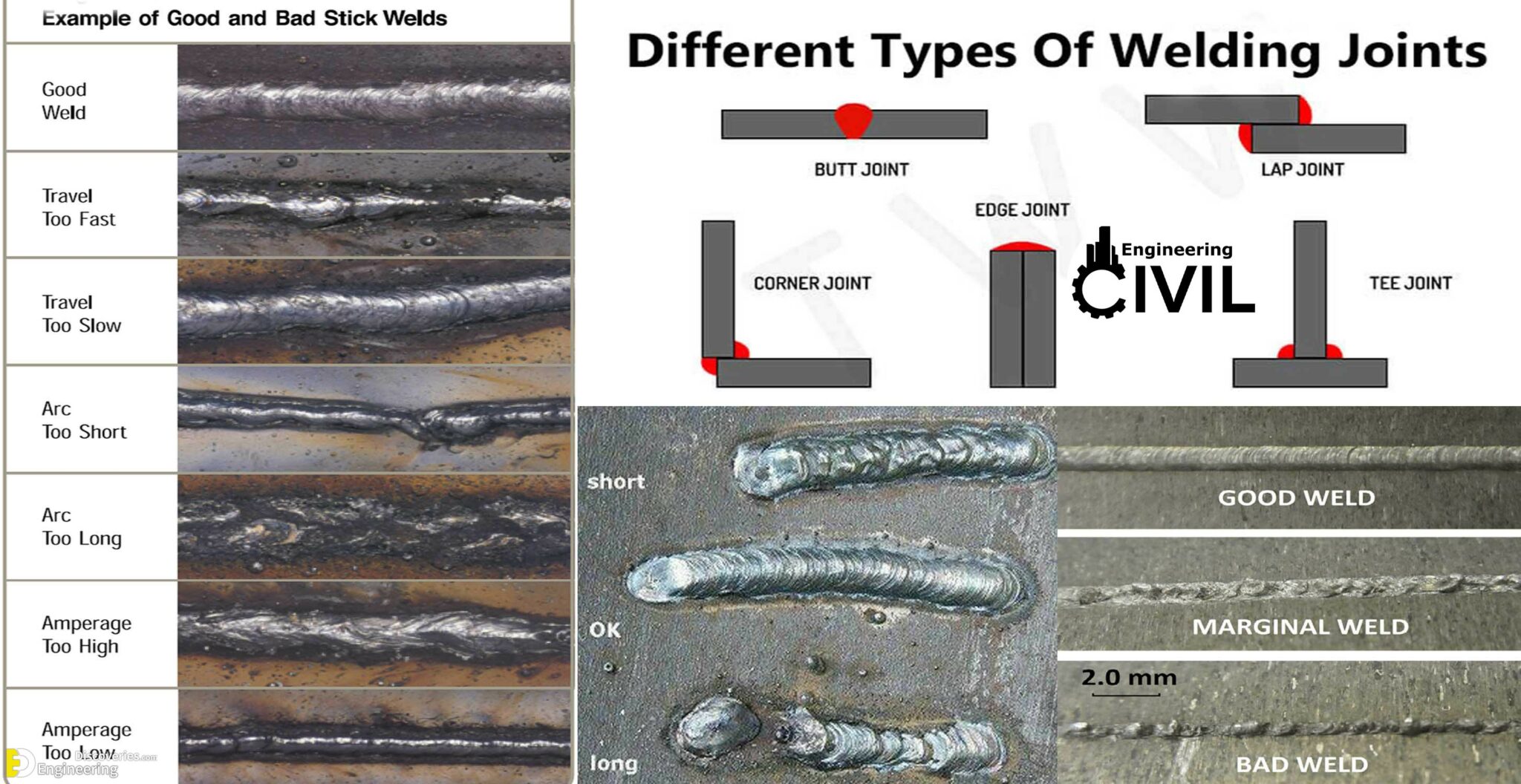

A butt joint is one of the most common and simplest types of welding joints. It is formed when two pieces of metal are placed edge-to-edge and welded together, creating a seamless and flat connection. Butt joints are widely used in various applications, including:

lPipe and tube welding

lStructural steel fabrication

lSheet metal fabrication

lPressure vessel construction

Butt joints can be created using several different groove configurations, depending on the thickness of the materials being joined and the desired weld strength. The most common variations include:

1. Square groove

2. V-groove

3. Bevel groove

4. U-groove

5. J-groove

To achieve high-quality butt welds, consider the following tips:

lEnsure proper alignment and fit-up of the joint edges to minimize gaps and misalignment.

lSelect the appropriate groove configuration based on material thickness and strength requirements.

lUse a backing strip or consumable insert when necessary to achieve full penetration and prevent burn-through.

lMaintain consistent welding parameters, such as amperage, voltage, and travel speed, throughout the welding process.

lClean the joint area thoroughly before welding to remove any contaminants that could affect weld quality.

Tee Joint

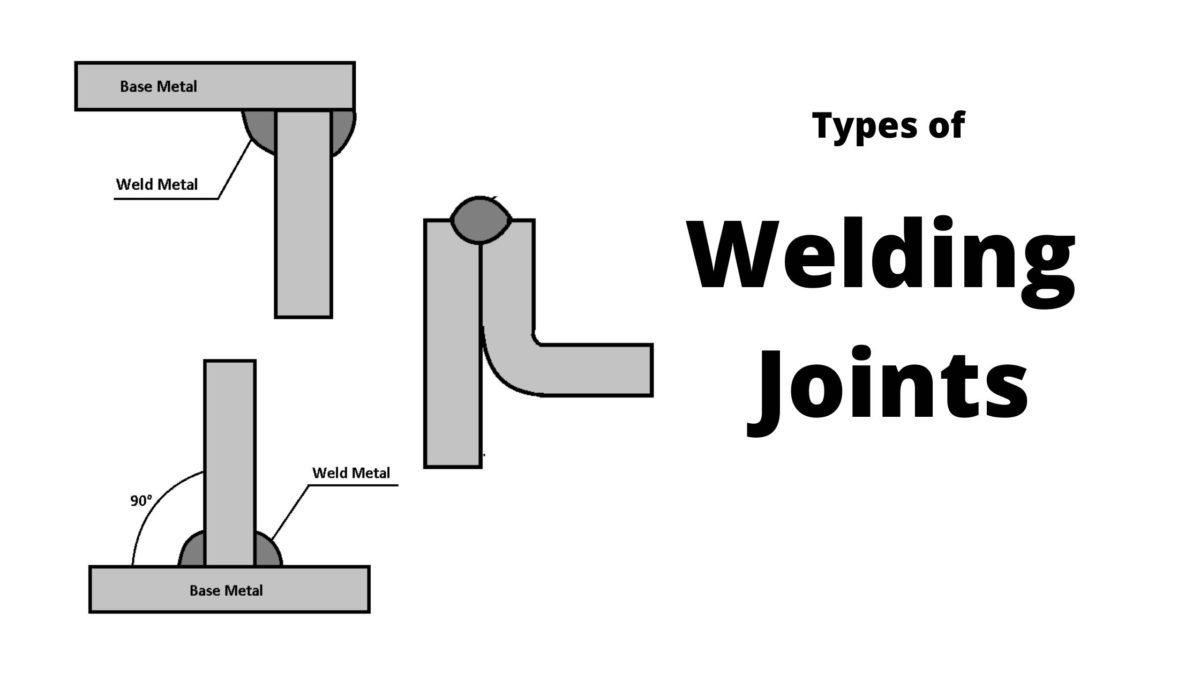

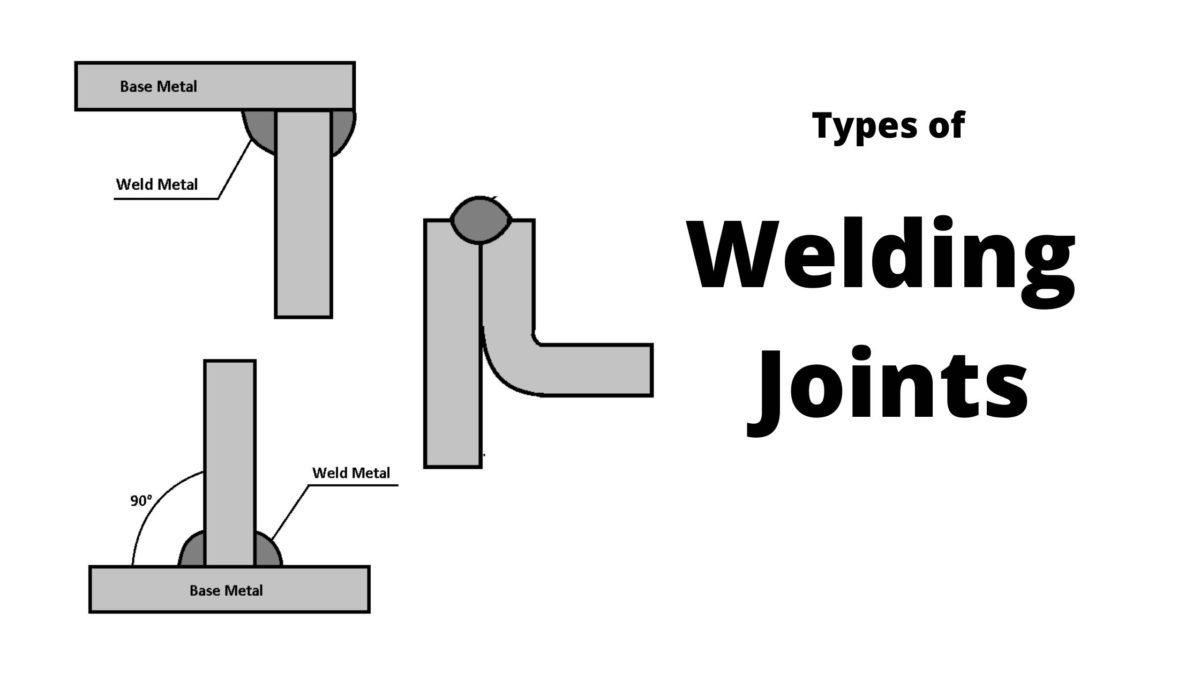

A tee joint, or T-joint, is created when one metal piece is perpendicular to another, forming a "T" shape. The edge of one workpiece is welded to the flat surface of the other. Tee joints are known for their good mechanical strength, especially when welded from both sides. They are widely used in various applications, including:

lStructural steel fabrication

lEquipment manufacturing

lPipe and tube welding

Tee joints generally require minimal joint preparation and are relatively easy to weld when the proper techniques and parameters are used. The edges of the joint can be left unaltered, or they can be prepared by cutting, machining, or grinding. Design considerations for tee joints include:

1. Work angle: When welding a 90-degree tee joint, it's best to use a 45-degree work angle to ensure adequate penetration on both workpieces.

2. Material thickness: If welding dissimilar metal thicknesses, focus more of the weld on the thicker piece for better fusion.

Several weld types and subvariations can be used for tee joints, such as:

lFillet welds

lBevel groove welds

lJ-groove welds

lPlug and slot welds

lFlare-bevel-groove welds

lMelt-through welds

When welding a tee joint, it is crucial to place the weld on the same side that will be subject to stress or load. Welding both sides of the joint can provide maximum strength and help prevent failure. Tee joints are versatile and can be welded in various positions, including flat, horizontal, vertical, and overhead.

One potential issue with tee joints is lamellar tearing, which can occur due to joint restraint. This can be mitigated by using proper welding techniques, preheating, or post-weld heat treatment as necessary.

Lap Joint

A lap joint is formed when two pieces of metal overlap each other, creating a joint where the welded area is situated between the two surfaces. This type of joint is particularly beneficial when joining materials of different thicknesses, as the overlapping configuration allows for a strong connection without the need for extensive joint preparation.

Key characteristics and benefits of lap joints include:

lOverlapping design allows for joining dissimilar thicknesses

lRequires minimal joint preparation, saving time and resources

lProvides a relatively large surface area for welding, enhancing joint strength

lOffers flexibility in welding position and technique

Lap joints are commonly used in various industries, such as:

1. Sheet metal fabrication

2. Automotive body panel assembly

3. Repair and maintenance applications

4. Trailer and container manufacturing

To create a lap joint, the two pieces of metal are positioned so that they overlap by a specific amount, which is determined by the thickness of the materials being joined. The overlapping surfaces should be clean and free from contaminants to ensure proper weld fusion.

Several welding styles can be employed to create lap joints, depending on the specific application and desired joint characteristics:

lFillet welds

lPlug welds

lSpot welds

lBevel groove welds

When preparing and welding lap joints, it is crucial to ensure that the overlapping surfaces are properly aligned and tightly fitted to minimize gaps and potential weld defects. The amount of overlap should be carefully considered, as insufficient overlap can lead to a weak joint, while excessive overlap can result in added weight and material costs.

Corner Joint

Corner joints are formed when two pieces of metal are joined at a 90-degree angle, creating an L-shaped configuration. These joints are similar to tee joints but differ in the positioning of the workpieces. Corner joints are commonly used in the fabrication of frames, boxes, and various sheet metal applications.

There are two main types of corner joints:

1. Open corner joint: In this type of joint, the edges of the two workpieces are brought together at their corners, forming a V-shaped groove. This allows for better accessibility and easier welding, especially when working with thicker materials.

2. Closed corner joint: A closed corner joint is created when the edge of one workpiece is brought flush against the face of the other, forming a tight, closed corner. This type of joint is more suitable for thinner materials and provides a cleaner, more aesthetically pleasing appearance.

The choice between an open and closed corner joint depends on several factors, such as the thickness of the materials, the desired strength of the joint, and the specific application requirements.

Corner joints are widely used in the following industries:

lSheet metal fabrication

lHVAC ductwork

lAutomotive body panels

lFrame construction

Several types of welds can be used to create corner joints, depending on the joint configuration and the desired strength:

lFillet welds

lV-groove welds

lEdge welds

lSpot welds

lCorner-flange welds

lJ-groove welds

lU-groove welds

lBevel-groove welds

lFlare-V-groove welds

lSquare-groove welds

When welding corner joints, it is essential to ensure proper fit-up and alignment of the workpieces to minimize distortion and maintain the desired angle. Preheating, post-weld heat treatment, and proper welding techniques can also help prevent issues such as cracking or warping.

Edge Joint

An edge joint is a type of welding joint formed when the edges of two metal pieces are aligned and welded together. This joint type is characterized by the side-by-side placement of the workpieces, with their edges either touching or slightly separated, depending on the specific application and welding process used.

Edge joints are commonly used in the fabrication of various structures and components, such as:

1. Thin sheet metal parts

2. Plate girders and beams

3. Frame structures

4. Tank and vessel seams

The versatility of edge joints lies in their ability to be adapted to different material thicknesses and welding requirements through the use of various edge preparations. These preparations involve shaping the edges of the workpieces to create a specific groove profile, which can influence the strength, penetration, and overall quality of the weld.

Common edge preparations for edge joints include:

lSquare edges: The simplest form of edge joint, where the edges of the workpieces are left flat and square. This preparation is often used for thin materials or when a backing strip is employed.

lV-groove: A V-shaped groove is created by chamfering the edges of both workpieces, allowing for deeper weld penetration and increased joint strength.

lBevel groove: Similar to a V-groove, but only one of the workpiece edges is chamfered, creating an asymmetrical groove profile.

lJ-groove: A J-shaped groove is formed by combining a square edge on one workpiece with a curved or radius edge on the other. This preparation is used in specific applications or when a backing bar is required.

lU-groove: A U-shaped groove is created by chamfering both workpiece edges with a curved or radius profile, providing excellent weld penetration and strength.

The choice of edge preparation depends on factors such as material thickness, desired weld strength, and the specific welding process being used.

Several welding techniques can be employed to create edge joints, each with its own advantages and considerations:

1. Groove welds: The most common technique for edge joints, groove welds involve depositing filler metal into the prepared groove between the workpieces. The specific type of groove weld (e.g., V-groove, bevel groove, or U-groove) depends on the edge preparation used.

2. Corner flange welds: These welds are used when one or both workpieces have a flanged or bent edge, creating a corner-like configuration. Corner flange welds provide additional strength and rigidity to the joint.

3. Edge flange welds: Similar to corner flange welds, edge flange welds are used when the edges of the workpieces are flanged or bent, but the flanges are oriented in the same direction, creating a flush or continuous surface.

When welding edge joints, it is essential to ensure proper alignment and fit-up of the workpieces to minimize gaps and prevent weld defects. The use of tack welds, clamping, or specialized fixtures can help maintain the desired alignment throughout the welding process.

Tips for Selecting the Right Welding Joint Design

Choosing the right welding joint design is crucial for ensuring the strength, durability, and overall success of your welding project. With so many factors to consider, it can be overwhelming to determine the best joint type for your specific application.

To help simplify the decision-making process, here are some essential tips to keep in mind when selecting a welding joint design:

1. Evaluate material thickness and joint accessibility:

a. The thickness of the materials being joined plays a significant role in determining the most suitable joint type.

b. Thicker materials may require groove welds or full penetration joints, while thinner materials can often be successfully welded using fillet welds or lap joints.

c. Additionally, consider the accessibility of the joint area – some joint types, such as corner or edge joints, may be easier to weld in tight spaces or hard-to-reach areas.

2. Understand strength requirements and load-bearing needs:

a. Assess the intended purpose and load-bearing requirements of your welded structure.

b. Will the joint be subjected to high stress, impact, or fatigue?

c. Some joint types, like full-penetration butt welds, offer superior strength compared to others.

d. Make sure to select a joint design that can withstand the expected loads and stresses over the life of the structure.

3. Consider desired final appearance and aesthetics:

a. In some applications, the appearance of the welded joint is just as important as its strength.

b. If a clean, seamless look is desired, you may opt for a butt joint with proper edge preparation and finishing techniques.

c. On the other hand, if the joint will be hidden or the appearance is not a primary concern, a lap or tee joint might be more practical.

4. Follow relevant welding codes, standards, and best practices:

a. When selecting a welding joint design, it is essential to adhere to any applicable welding codes, standards, or specifications for your industry or project.

b. These guidelines often provide detailed requirements for joint design, preparation, and welding procedures to ensure the safety and integrity of the welded structure.

c. Familiarize yourself with the relevant standards and follow them closely to avoid potential issues or rework.

5. Consult with experienced professionals when unsure:

a. If you are unsure about the best joint design for your specific application, don't hesitate to seek advice from experienced welding professionals, such as certified welding inspectors (CWIs), welding engineers, or seasoned fabricators.

b. They can provide valuable insights and recommendations based on their knowledge and experience, helping you make an informed decision and avoid costly mistakes.

By following these tips and carefully considering the unique requirements of your welding project, you can select the optimal joint design that balances strength, accessibility, aesthetics, and compliance with relevant standards. Remember, taking the time to choose the right joint type upfront can save you significant time, effort, and resources in the long run, ensuring the success and longevity of your welded structure.

Techniques for Improving Weld Joint Quality

To achieve strong, reliable, and high-quality welded joints, it is essential to employ proper techniques throughout the welding process. By focusing on key aspects such as surface preparation, fit-up, welding parameters, and post-weld treatments, you can significantly enhance the overall quality and performance of your weld joints. Here are some crucial techniques to keep in mind:

1. Proper cleaning and surface preparation before welding:

a. Ensure that the surfaces to be welded are free from contaminants such as rust, oil, grease, or paint.

b. Use appropriate cleaning methods, such as wire brushing, grinding, or chemical cleaning, to remove any impurities that could affect weld quality.

c. Proper surface preparation promotes better fusion and minimizes the risk of weld defects like porosity or lack of fusion.

2. Maintaining tight fit-up and precise alignment of workpieces:

a. Ensure that the workpieces to be joined are properly aligned and fitted together with minimal gaps.

b. Use clamps, fixtures, or tack welds to maintain the desired alignment throughout the welding process.

c. Proper fit-up and alignment help ensure uniform weld penetration, reduce stress concentrations, and minimize distortion.

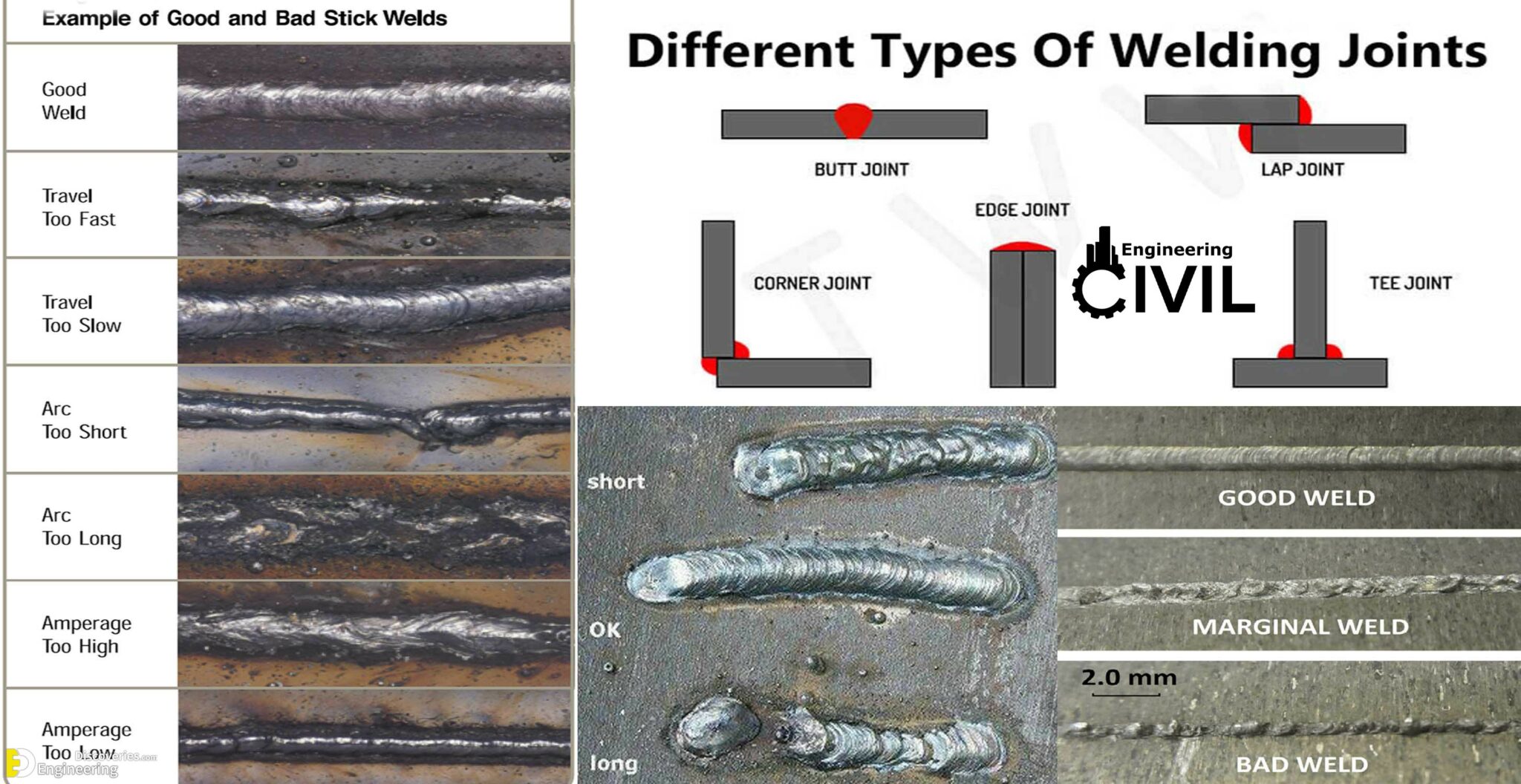

3. Selecting appropriate welding parameters and consumables:

a. Choose the right welding process, filler metal, and shielding gas for the specific material and application.

b. Adjust welding parameters such as amperage, voltage, and travel speed to achieve the desired weld penetration and bead profile.

c. Using the correct consumables and parameters minimizes the risk of weld defects, improves weld quality, and increases productivity.

4. Controlling heat input and implementing proper welding sequences:

a. Manage heat input by adjusting welding parameters and using appropriate welding techniques, such as stringer beads or weaving.

b. Implement proper welding sequences, such as backstepping or skip welding, to minimize distortion and residual stresses.

c. Controlling heat input and using proper welding sequences help maintain the desired mechanical properties of the base material and reduce the risk of weld-related issues.

5. Utilizing post-weld treatments and inspections as needed:

a. Perform necessary post-weld treatments, such as stress relief, heat treatment, or surface finishing, to improve the mechanical properties and appearance of the welded joint.

b. Conduct appropriate non-destructive testing (NDT) methods, such as visual inspection, penetrant testing, or radiographic testing, to detect any potential weld defects.

c. Utilizing post-weld treatments and inspections helps ensure the integrity and quality of the welded joint and identifies any issues that may require repair or rework.

By implementing these techniques consistently and paying close attention to detail, you can significantly improve the quality and performance of your welded joints. Remember, investing time and effort into proper welding practices upfront can save you significant time, resources, and potential headaches down the line, ultimately leading to a more successful and reliable welding project.

Conclusion

In this comprehensive guide, we've explored the five main types of welding joints: butt, tee, corner, lap, and edge. Each joint type has its unique characteristics, applications, and considerations for achieving optimal weld quality and strength.

Selecting the appropriate welding joint is crucial for ensuring the integrity and performance of your welded structure. By understanding the factors involved in joint selection, such as material thickness, load requirements, and accessibility, you can make informed decisions that lead to successful welding projects.

FAQs

Q: What are some common welding defects to watch out for with each joint type?

A: Common defects include incomplete fusion, porosity, and cracking. Proper joint preparation, welding technique, and parameter selection can help prevent these issues.

Q: Can multiple welding joint types be combined in a single project?

A: Yes, multiple joint types can be used in a single project. The choice depends on the specific requirements of each connection.

Q: What are the most important factors when choosing between different groove configurations?

A: Material thickness, desired weld strength, and welding process are crucial factors. Groove design affects penetration, fusion, and overall joint performance.

Q: How do I determine if I need complete or partial joint penetration?

A: Consider the load requirements and design specifications of the welded structure. Complete joint penetration provides maximum strength, while partial penetration may suffice for less critical applications.