Ever wondered how those stunning textured metal surfaces in modern buildings are created? Embossed metal sheets represent one of the most versatile innovations in architectural and industrial materials. These engineered surfaces combine aesthetic appeal with enhanced functionality, offering up to 40% greater strength than standard metal sheets while providing superior slip resistance and visual interest.

From sleek building facades to industrial flooring, embossed metal sheets have revolutionized how we approach both form and function in construction. This comprehensive guide explores everything you need to know about these remarkable materials – their types, benefits, applications, and manufacturing process.

What Are Embossed Metal Sheets?

Metal embossing transforms plain metal surfaces into patterned sheets through pressure-based techniques. It creates raised or depressed designs enhancing both functionality and aesthetics.

Core Process:

Historical Evolution:

Originally a manual craft centuries ago, metal embossing evolved from hand-hammered decorative pieces to modern industrial processes. Technology advancement brought precision and mass production capabilities.

Key Differences vs Regular Sheets:

| Feature | Regular Sheets | Embossed Sheets |

| Surface | Flat | Textured |

| Strength | Standard | Enhanced |

| Grip | Basic | Anti-slip |

| Uses | General | Specialized |

Modern Applications:

️ Construction materials

Automotive components

Industrial equipment

Architectural elements

Benefits of Using Embossed Metal Sheets

Structural Enhancement:

Metal embossing transforms plain sheets into stronger surfaces through strategic pattern placement. The patterns act like tiny support beams, distributing weight and pressure across the entire surface. This modification increases the material's load-bearing capacity by up to 30%, creating:

Deformation resistance

Impact absorption

Stress distribution

Wear reduction

Durability Boost:

Embossed patterns create a protective layer against everyday wear. The raised textures absorb impacts, prevent surface damage, and extend product life. Most embossed sheets last 40% longer than plain counterparts, ensuring:

Superior impact resistance

Better load distribution

Enhanced stress handling

Reduced wear patterns

Visual Impact:

Embossing adds dimensionality to flat metal surfaces. The process creates eye-catching patterns, ranging from subtle textures to bold designs. These patterns reflect light differently, adding depth and character through:

Safety Features:

The textured surface dramatically improves grip and traction. This enhancement reduces slip accidents by up to 60% compared to smooth surfaces, providing:

Non-slip performance

Grip enhancement in wet conditions

Traffic safety improvements

Accident prevention capabilities

Cost Efficiency:

While initial costs run 15-20% higher than plain sheets, embossed metals offer superior value:

| Feature | Benefit | Improvement |

| Initial Investment | Higher quality | Better ROI |

| Maintenance Cost | Minimal upkeep | -40% |

| Replacement Rate | Reduced frequency | -50% |

| Product Lifespan | Extended durability | +40% |

Environmental Impact:

Embossed sheets support sustainability through:

100% recyclable materials

40% longer service life

Reduced replacement waste

Lower resource consumption

Maintenance Ease:

Textured surfaces hide minor scratches and dents. They require only basic cleaning and minimal repairs, cutting maintenance time by half through:

Performance Quality:

These sheets maintain their properties under various conditions:

Weather resistant up to 20 years

Temperature tolerance: -40°F to 180°F

Chemical resistance to common substances

Impact resistance: 30% higher than standard sheets

Popular Types of Embossed Metal Sheets

Stucco Embossed Metal Sheets

Surface Pattern: Stucco embossing creates a distinctive orange-peel texture on metal surfaces. This unique pattern mimics traditional stucco finishes, providing both aesthetic appeal and functional benefits.

Core Features:

Uniform texture distribution

Light-diffusing properties

Scratch concealment ability

Fingerprint resistance

Application Range:

Building exteriors: Cladding, roofing

Appliance panels: Refrigerators, dishwashers

Industrial equipment: Machine covers, panels

Interior walls: High-traffic areas

Cost Analysis:

| Factor | Impact |

| Material Cost | Mid-range |

| Installation | Standard |

| Maintenance | Low |

| Lifespan | 15-20 years |

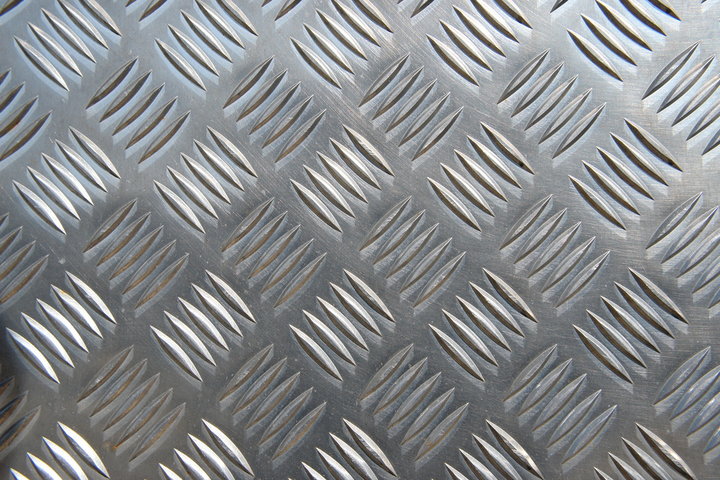

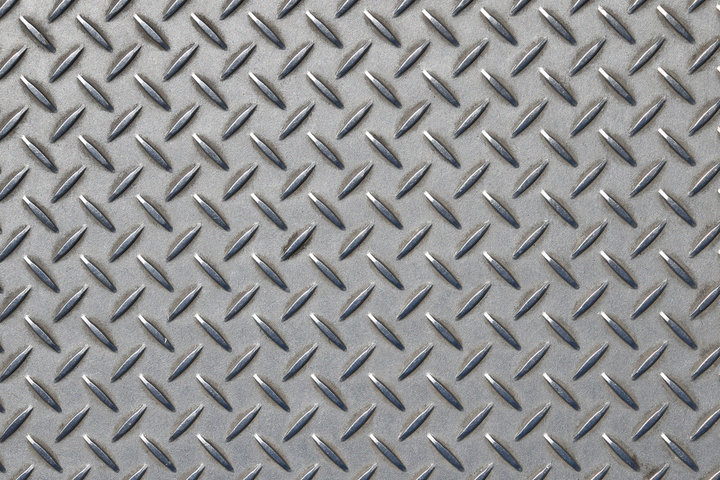

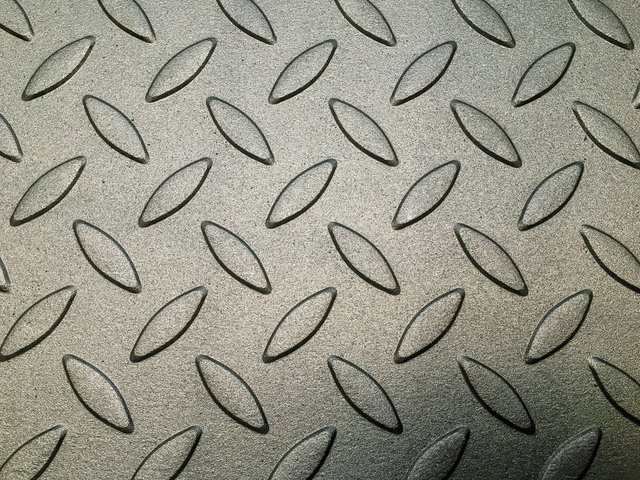

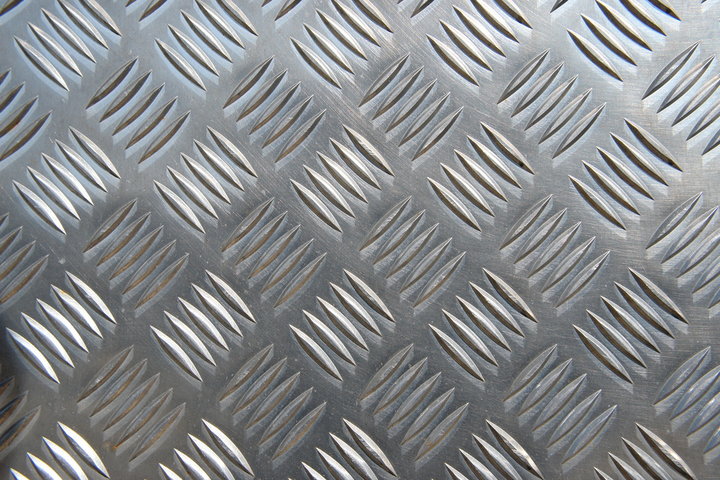

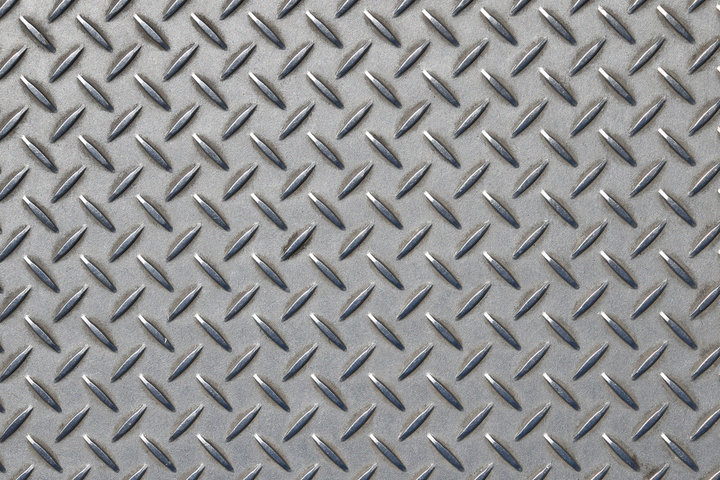

Diamond Plate Embossed Sheets

Pattern Design: Diamond plate features raised diamond patterns across the surface. These geometric shapes create a distinctive industrial look while providing crucial safety benefits.

Safety Characteristics:

Slip resistance rating: R12-R13

Load bearing capacity: +40%

Impact resistance: High

Traction enhancement: 60%

Industrial Applications:

Loading docks

Industrial flooring

Vehicle ramps

Stair treads

Installation Requirements:

Proper substrate preparation

Correct fastener spacing

Edge treatment

Expansion allowance

Leather Grain Embossed Sheets

Aesthetic Design: Leather grain embossing replicates natural leather textures on metal surfaces. This premium finish combines industrial durability with luxury appearance.

Design Applications:

Executive offices

High-end retail spaces

Luxury elevators

Designer furniture

Durability Specs:

Wear resistance: Excellent

UV stability: 10+ years

Chemical resistance: Moderate

Impact tolerance: Medium-high

Maintenance Protocol:

Regular dusting

Mild cleaner use

Annual inspection

Touch-up as needed

Each type serves specific purposes combining functional requirements with aesthetic preferences. Property owners should consider their specific needs when selecting the appropriate pattern.

Manufacturing Processes for Embossed Metal Sheets

Roller Embossing Technique

Process Mechanism: Roller embossing employs continuous rotation of patterned cylinders. Metal sheets pass between these rollers under precise pressure, creating consistent patterns across long surfaces.

Equipment Components:

Patterned roller pairs

Pressure control system

Feed mechanism

Collection system

Performance Metrics:

| Feature | Specification |

| Production Speed | Up to 50m/min |

| Pattern Depth | 0.1-2.0mm |

| Sheet Width | Up to 2000mm |

| Material Thickness | 0.3-3.0mm |

Application Strengths:

Large-scale production

Continuous operation

Pattern consistency

Cost efficiency

Stamping Press Embossing

Operating Principle: Stamping press uses matched die sets. High pressure creates detailed patterns through direct force application.

Optimal Usage:

Complex patterns

Deep impressions

Small batch production

Precision requirements

Technical Benefits:

Quality Assurance:

Pattern depth monitoring

Surface inspection

Dimensional checking

Material stress testing

Hydraulic Embossing Process

Technical Operation: Hydraulic systems generate controlled pressure through fluid dynamics. This method enables precise force distribution across complex patterns.

Control Features:

Pressure range: 100-500 tons

Digital control interface

Real-time monitoring

Adjustable speed settings

Design Capabilities:

Multi-level patterns

Custom designs

Variable depths

Complex geometries

Cost Structure:

| Element | Impact Level |

| Equipment | High initial |

| Operation | Moderate |

| Maintenance | Low |

| Per-piece | Variable |

Production Parameters:

Cycle time: 15-45 seconds

Pattern accuracy: ±0.05mm

Size capacity: Up to 3000mm

Material range: Extensive

Materials Used in Metal Sheet Embossing

Aluminum Embossed Sheets

Material Properties: Aluminum offers exceptional lightness and corrosion resistance. Its density stands at 2.7 g/cm³, making it 70% lighter than steel while maintaining structural integrity.

Physical Characteristics:

Weight: Ultra-light

Strength-to-weight ratio: 3:1

Corrosion resistance: Excellent

Temperature range: -80°C to 300°C

Application Range:

Building facades

Interior panels

Ceiling systems

Transportation equipment

Cost-Benefit Analysis:

| Factor | Rating | Details |

| Initial Cost | Medium | $3-5/sq ft |

| Installation | Low | Easy handling |

| Maintenance | Minimal | Self-protecting oxide layer |

| Lifespan | 20+ years | Weather resistant |

Stainless Steel Embossed Sheets

Strength Metrics: Stainless steel delivers superior strength properties. Its tensile strength reaches 515-827 MPa, offering exceptional durability.

Resistance Properties:

Corrosion protection: Superior

Chemical resistance: High

Heat tolerance: Up to 800°C

Impact resistance: Excellent

Common Applications:

Market Positioning:

Premium grade: $8-12/sq ft

Commercial grade: $6-8/sq ft

Industrial grade: $5-7/sq ft

Custom specs: Variable

Brass and Copper Embossed Sheets

Aesthetic Features: These materials offer rich, warm metallic tones. They develop distinctive patinas over time, enhancing visual appeal.

Workability Factors:

Forming ease: Excellent

Pattern definition: Sharp

Detail retention: High

Surface finishing: Various options

Application Specifics:

Architectural accents

Decorative panels

Heritage restoration

Luxury interiors

Maintenance Protocol:

| Task | Frequency | Purpose |

| Cleaning | Monthly | Preserve shine |

| Polishing | Quarterly | Maintain luster |

| Protective coating | Yearly | Prevent oxidation |

| Inspection | Semi-annual | Check patina development |

Performance Metrics:

Tensile strength: 200-400 MPa

Thermal conductivity: High

Oxidation rate: Moderate

Pattern retention: Long-term

Applications of Embossed Metal Sheets

Architectural Applications

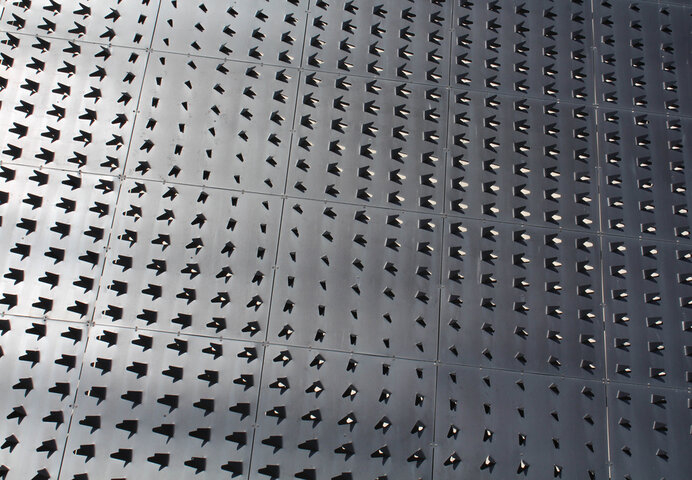

Building Facades: Embossed metal sheets transform exterior surfaces. These panels create dynamic visual effects through light reflection, adding depth to building designs while providing weather protection.

Interior Elements:

Wall cladding: Sound absorption, +30% noise reduction

Ceiling panels: Light diffusion, enhanced acoustics

Column covers: Impact resistance, decorative finish

Partition walls: Space division, aesthetic appeal

Application Performance:

| Feature | Benefit | Impact |

| Durability | 20+ years lifespan | Long-term value |

| Weather Resistance | All-climate suitable | Reduced maintenance |

| Installation | Modular system | Fast assembly |

| Aesthetics | Custom patterns | Design flexibility |

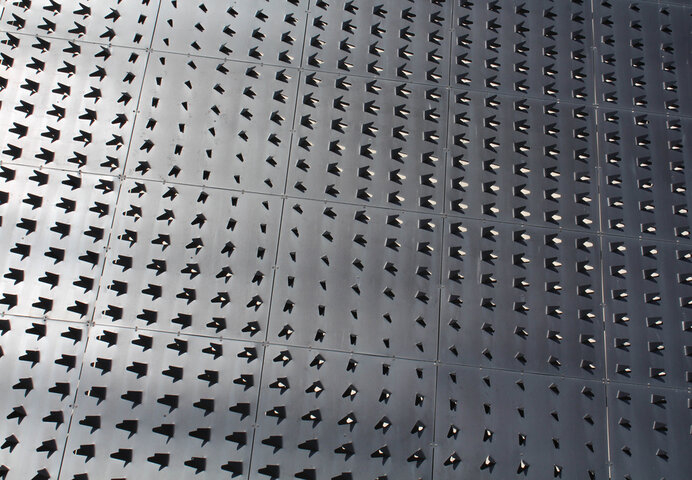

Industrial Uses

Safety Solutions: Industrial applications prioritize functionality. Embossed patterns provide crucial safety features in demanding environments.

Key Applications:

Platform flooring: 60% slip reduction

Equipment enclosures: IP65 protection rating

Machine guards: Impact resistance up to 50 joules

Storage systems: Load capacity 500kg/m²

Technical Specifications:

Grip pattern depth: 0.5-2.0mm

Load bearing: Enhanced by 40%

Temperature tolerance: -40°C to +120°C

Chemical resistance: Industrial grade

Commercial Settings

Retail Environments: Commercial spaces benefit from versatile applications. Embossed metals combine practicality with modern aesthetics.

Design Applications:• Display Systems

Load capacity: 100kg/m²

Customizable patterns

Modular design

Easy installation

• Interior Solutions

Sound rating: NRC 0.75

Fire rating: Class A

Light reflection: 65%

Maintenance: Minimal

Functional Features:

Anti-vandal properties

Easy cleaning protocols

Modular replacement

Design flexibility

Installation Metrics:

| Application | Installation Time | Maintenance Cycle |

| Wall Panels | 2-3 days/100m² | Annual |

| Flooring | 1-2 days/100m² | Semi-annual |

| Furniture | Custom | Quarterly |

| Signage | 1 day/unit | Monthly |

How to Choose the Right Embossed Metal Sheet

Purpose Assessment: Start by identifying your primary application needs. Consider load-bearing requirements, traffic intensity, and aesthetic goals. Industrial applications need focus on durability, handling loads up to 500kg/m². Decorative uses prioritize pattern consistency and visual appeal.

Pattern Selection:

Anti-slip needs: R9-R13 ratings available

Light reflection: 20-65% range

Sound control: NRC 0.15-0.75

Visual impact: Pattern depth 0.1-2.0mm

Environment Analysis: Evaluate the installation environment carefully. Temperature fluctuations, humidity levels, and chemical exposure significantly impact material choice. Consider:

| Environmental Factor | Impact on Selection |

| Temperature Range | -40°C to +120°C |

| Humidity Exposure | 0-100% RH |

| Chemical Contact | pH 2-13 resistance |

| UV Exposure | Rating needed |

Budget Planning: Calculate total ownership costs, not just purchase price:

Initial Investment

Installation Costs

Labor: $2-5/sq ft

Tools and equipment

Mounting systems

Installation Requirements: Understanding installation needs prevents future problems:

Maintenance Planning: Factor in long-term care requirements:

Quality Verification: Check essential specifications:

Material certification

Pattern consistency

Thickness tolerance

Surface finish quality

Installation Guide for Embossed Metal Sheets

Pre-Installation Requirements: Successful installation begins well before the first sheet goes up. The key lies in thorough preparation. Metal sheets must acclimate to room temperature for 24 hours before installation to prevent thermal expansion issues.

Surface Preparation: A properly prepared surface directly impacts installation quality and longevity.

Clean substrate: Remove all debris, oil, and rust. Even minor contaminants can compromise adhesion

Level surface: Ensure maximum deviation stays within 2mm/m. Uneven surfaces lead to visible distortions

Temperature control: Maintain 15-25°C during installation. Temperature affects metal expansion

Humidity management: Keep below 60% to prevent moisture-related issues

Essential Tools: Professional installation demands the right equipment. Each tool serves a specific purpose:

| Basic Tools | Purpose | Safety Equipment | Measuring Devices |

| Metal shears | Clean cuts | Safety glasses | Laser level |

| Power drill | Fastener holes | Cut-resistant gloves | Digital tape measure |

| Impact driver | Secure mounting | Steel-toe boots | Professional square |

| Level | Alignment check | Respirator | Marking tools |

Installation Process:

Layout Planning: Proper planning prevents costly mistakes and ensures aesthetic appeal.

Measure installation area twice for accuracy

Calculate sheet placement to minimize waste

Mark clear reference lines every 1 meter

Plan expansion gaps: 3-5mm prevents buckling

Sheet Preparation: Careful handling preserves sheet quality.

Verify dimensions against plan specifications

Cut sheets using appropriate tools for clean edges

Clean surfaces with manufacturer-approved products

Apply protective coating when specified

Mounting Sequence: Follow a systematic approach for best results.

Begin from room corners or designated starting points

Use laser level for perfect alignment

Install fasteners according to load requirements

Check pattern matching between sheets

Common Mistakes Prevention:

Incorrect spacing leads to pattern misalignment

Use manufactured spacer guides

Create installation templates for consistent results

Double-check measurements before securing

Over-tightening damages sheet integrity

Follow torque specifications exactly

Use calibrated tools for consistent pressure

Check each fastener during installation

Poor surface preparation causes long-term failures

Complete thorough surface assessment

Document preparation steps

Verify conditions before proceeding

Safety Protocol:

Personal Protection: Safety equipment isn't optional.

Impact-resistant eye protection prevents metal debris injuries

Cut-resistant gloves rated for metal handling

Steel-toe boots protect against dropping sheets

Proper respiratory protection during cutting operations

Work Area Safety: Create a secure installation environment.

Ensure proper ventilation for dust control

Use OSHA-approved work platforms

Maintain clear walkways

Keep first aid supplies accessible

Quality Checks:

Verify pattern alignment every 3-4 sheets

Test each fastener for proper seating

Inspect surface cleanliness before finishing

Check edge finishing for safety

Document final installation appearance

Remember: Professional installation might cost more initially but prevents expensive repairs and replacements later. Each step in this process contributes to a successful, long-lasting installation that meets both functional and aesthetic requirements.

Conclusion

Embossed metal sheets have undergone remarkable transformation since their inception. From humble beginnings as decorative elements, they've evolved into sophisticated solutions meeting diverse industrial, architectural, and commercial needs. Their ability to combine aesthetic appeal with functional benefits has established them as indispensable materials in modern construction and design.

The future of embossed metal sheets looks bright, offering enhanced solutions for tomorrow's challenges. Make informed decisions today by connecting with industry experts who can guide your project toward success. Your next innovative solution might just begin with embossed metal sheets.

Reference Sources

Sheet metal embossing

Sheet metal

Metal