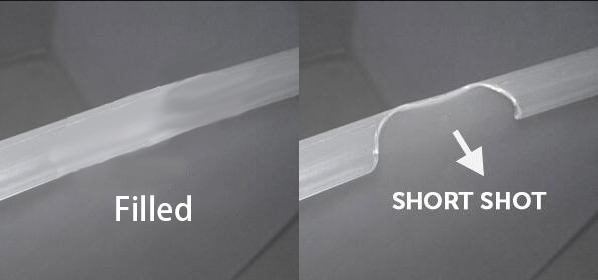

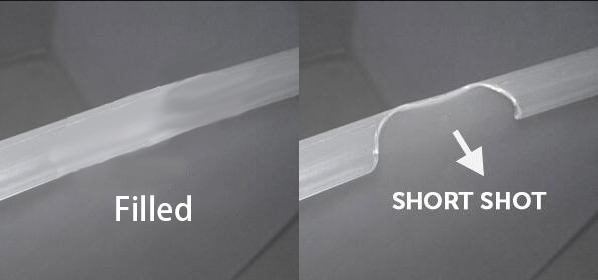

Have you ever encountered incomplete or defective plastic parts from your injection molding process? This issue, known as a "short shot," can significantly impact product quality and production efficiency. In injection molding, a short shot occurs when the molten plastic fails to fill the entire mold cavity, resulting in incomplete or missing features on the final part.

Addressing short shot issues is crucial for maintaining high-quality output and minimizing waste in your injection molding operations. In this post, we'll dive into the causes of short shots, how to identify them, and explore effective solutions to prevent and troubleshoot this common problem.

What is a Short Shot in Injection Molding?

A short shot is a common defect in injection molding. It happens when the molten plastic doesn't completely fill the mold cavity. This leaves the final product with missing or incomplete features.

Short shots can appear in various forms on molded parts:

Incomplete filling of thin sections or edges

Missing features or details

Visible voids or gaps on the surface

Inconsistent wall thickness or part dimensions

The impact of short shots can be significant:

Reduced product quality and functionality

Increased scrap rates and material waste

Lower production efficiency and throughput

Potential delays in order fulfillment

Higher overall manufacturing costs

Causes of Short Shots in Injection Molding

Several factors can contribute to short shots in injection molding. Let's explore the common causes related to materials, mold design, and machine settings.

Material-related causes

High viscosity materials or those with poor flow properties may not fill the mold cavity completely. This can lead to short shots.

Inconsistencies in material properties, such as variations in moisture content or contamination, can also cause flow issues and result in short shots.

Mold design-related causes

Inadequate venting or air traps in the mold can prevent proper filling. If air can't escape, it restricts the flow of molten plastic.

Improper gate size, location, or design can hinder material flow. Gates that are too small or poorly placed may cause short shots.

Thin walls or complex geometries in the product design can make it difficult for the material to fill all areas of the mold.

Machine settings and process-related causes

Low injection pressure or speed may not provide enough force to fill the mold cavity completely. This can result in short shots.

Insufficient melt or mold temperatures can cause the material to solidify too quickly, preventing complete filling.

Improper shot size or cushion settings can lead to insufficient material being injected into the mold.

Inconsistent cycle times or interruptions in production can disrupt the flow of material and cause short shots.

| Cause Category | Examples |

| Material | - High viscosity

- Poor flow properties

- Inconsistent properties |

| Mold Design | - Inadequate venting

- Improper gate design

- Thin walls or complex geometries |

| Machine Settings | - Low injection pressure/speed

- Insufficient temperatures

- Improper shot size/cushion |

By identifying the specific causes of short shots in your injection molding process, you can take targeted steps to address them and improve your production quality.

How to Identify Short Shots in Injection Molded Parts

Identifying short shots is crucial for maintaining quality control in injection molding. Here are some methods you can use to detect short shots in your molded parts.

Visual inspection methods

Incomplete filling or missing features are telltale signs of short shots. Inspect your parts visually for any areas that appear unfinished or lack detail.

Surface defects or irregularities, such as sink marks or voids, can also indicate short shots. Look closely at the part surface for any inconsistencies.

Dimensional analysis techniques

Measuring part dimensions against specifications can reveal short shots. Use calipers or other measuring tools to check if the part meets the required dimensions.

Variations in wall thickness or shrinkage can also signify short shots. Compare the thickness of different sections of the part to identify any discrepancies.

Other diagnostic tools and methods

Process monitoring software or sensors can help detect short shots in real-time. These tools monitor injection pressure, speed, and other parameters to identify potential issues.

Mold flow analysis or simulations can predict the likelihood of short shots before production begins. These virtual tests can help optimize mold design and process settings.

To sum up, you can identify short shots through:

Visual inspection

Dimensional analysis

Process monitoring

Mold flow analysis

Throw using a combination of these methods, you can quickly detect and address short shot issues in your injection molding process.

Solutions for Preventing and Troubleshooting Short Shots

Preventing and troubleshooting short shots requires a multi-faceted approach. Let's explore solutions related to material selection, mold design, machine settings, and preventive maintenance.

Material selection and optimization

Choose materials with appropriate flow properties and viscosity for your application. This can help ensure proper filling of the mold cavity.

Additives or fillers can improve material flow and reduce the risk of short shots. Consider incorporating them into your material formulation.

Proper material handling, drying, and storage are crucial. Moisture or contamination can affect flow properties and lead to short shots.

Mold design improvements

Add or modify vents and ejector pins to facilitate better air evacuation. This allows the molten plastic to fill the cavity more easily.

Optimize gate size, location, and type for improved flow. Larger gates or multiple gates can help prevent short shots.

Adjust wall thickness and part geometry to promote easier filling. Uniform wall thickness and smooth transitions can reduce flow resistance.

Machine settings and process adjustments

Increase injection pressure, speed, or time as needed to ensure complete filling. Experiment with different settings to find the optimal balance.

Optimize melt and mold temperatures for the specific material. This can improve flow and prevent premature solidification.

Adjust shot size, cushion, and other machine parameters to provide sufficient material for filling the mold.

Implement process monitoring and control systems to detect and correct short shots in real-time.

Preventive maintenance and troubleshooting tips

Regularly clean and inspect the mold and machine components. This can prevent buildup or damage that may cause short shots.

Document and analyze process data and defect trends. This information can help identify patterns and root causes of short shots.

Conduct root cause analysis and implement corrective actions. Systematically address the underlying issues to prevent future short shots.

| Solution Category | Key Actions |

| Material Selection | - Choose appropriate materials

- Use additives or fillers

- Ensure proper handling and storage |

| Mold Design | - Improve venting and ejection

- Optimize gates and flow paths

- Adjust wall thickness and geometry |

| Machine Settings | - Adjust pressure, speed, and time

- Optimize temperatures

- Implement process monitoring and control |

| Preventive Maintenance | - Regular cleaning and inspection

- Document and analyze data

- Conduct root cause analysis |

Best Practices for Avoiding Short Shots in Injection Molding

To minimize the risk of short shots, it's essential to follow best practices throughout the injection molding process. Here are some key areas to focus on.

Design for manufacturability (DFM) principles

Incorporate DFM guidelines early in the product design stage. This can help ensure that your parts are optimized for injection molding.

Consider factors such as wall thickness, draft angles, and gate locations to promote better flow and reduce the likelihood of short shots.

Proper material selection and testing

Select materials that are well-suited for your application and have appropriate flow properties. Conduct thorough testing to validate material performance.

Work with your material supplier to ensure consistent quality and properties across batches. This can help prevent variations that may lead to short shots.

Mold design validation and optimization

Use mold flow analysis software to simulate the injection molding process. This can help identify potential short shot issues before mold fabrication.

Optimize the mold design based on simulation results and expert input. Make necessary adjustments to gates, vents, and other features to improve flow and reduce short shots.

Machine and process parameter settings based on scientific molding principles

Apply scientific molding principles to determine optimal machine and process settings. This involves systematic experimentation and data analysis.

Document and maintain a robust process window that consistently produces good parts. Monitor and adjust settings as needed to prevent short shots.

Quality control and continuous improvement initiatives

Implement a comprehensive quality control system to detect and address short shots promptly. This may include visual inspection, dimensional checks, and other testing methods.

Foster a culture of continuous improvement. Encourage team members to identify and solve problems collaboratively. Regularly review process data and defect trends to drive ongoing enhancements.

Throw adhering to these best practices, you can significantly reduce the occurrence of short shots in your injection molding operations. Remember, prevention is key – investing time and effort upfront can save you from costly quality issues down the line.

Conclusion

Short shots in injection molding can be caused by various factors, from material issues to machine settings. Identifying and addressing them requires a comprehensive approach. By implementing effective solutions and best practices, you can improve product quality, boost productivity, and enhance cost-efficiency in your injection molding operations.

Are you struggling with short shots in your injection molding process? Team Mfg's expert engineers can help. Contact us today to learn how our comprehensive solutions can improve your product quality and productivity. Let Team Mfg be your partner in injection molding success.