CNC wood router machines are a state-of-the-art technology in wood working, which alters the approach towards making wooden elements. These are computer controlled routing systems – ranging from small CNC router tables to large wood routing machines where precision surgical cutting is coupled with manufacturing centres.

Whether it is furniture making employing CNC router bits or undertaking architectural trim work, these wood CNC routing solutions have become a necessity in improving efficiency in production and even in design for woodworkers and wood manufacturing companies alike.

In this blog, we will inform you of definition, applications, features and maintaining tips on CNC wood routers, providing you professional suggestions on choosing best cnc wood router machines for manufacturing.

What is CNC Wood Router?

Understanding CNC Wood Router

The CNC (Computer Numerical Control) wood routing technology employs computerized digital processes to develop various cut wooden parts from simple to complex designs. The router machine is used to read CAD/CAM files or programming codes, which direct cutting tools onto the surfaces of chosen materials in accurate designs.

Contemporary wood router systems are based on the principles of three-axis control and the movements are made in X, Y and Z coordinates to create a 3D effect cutting pattern. The term does not only refer to wood working but also to integration of computer control and machines in achieving unbelievably accurate wood working processes even to repeatability of thousands of an inch.

Components of CNC Wood Router

Gantry System: A robust framework with an overhead beam, supporting the spindle's movement while stabilizing it even during aggressive routing speeds.

Spindle Unit: An assembly driven by a spindle motor with 13000 to 24,000 revolutions per minute, which is used to drive the cutting tools for the effective removal of materials.

Router Table: A large sized worktable whose surface has inbuilt vacuum channels and can support work pieces of about 5’ by 10’ and even larger.

Tool Holders: Quick changeable, operative bit shank fastening for ISO-30 or HSK – 63 interfaces.

Dust Collection: Dust extraction system installed with sizes ranging between 6-10 inches to eliminate wood chips and other wastes during the cutting process.

Control System: The interface which allows the user to operate a computer attached to a NC machine in order to cut to scale according to a design on a CAD.

Mechanism of CNC Wood Router

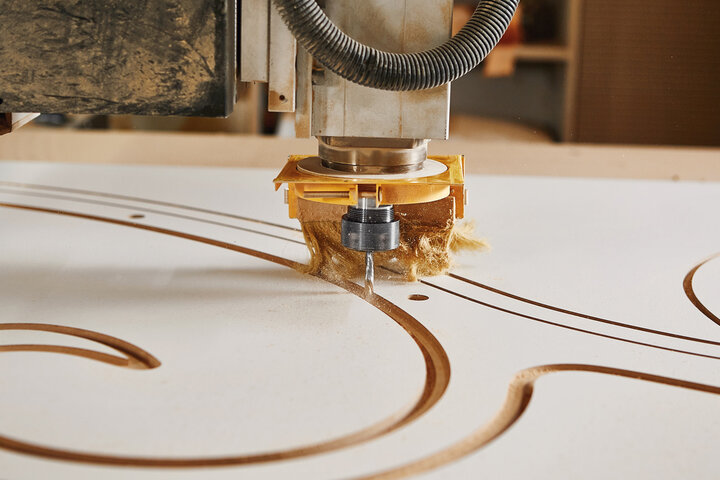

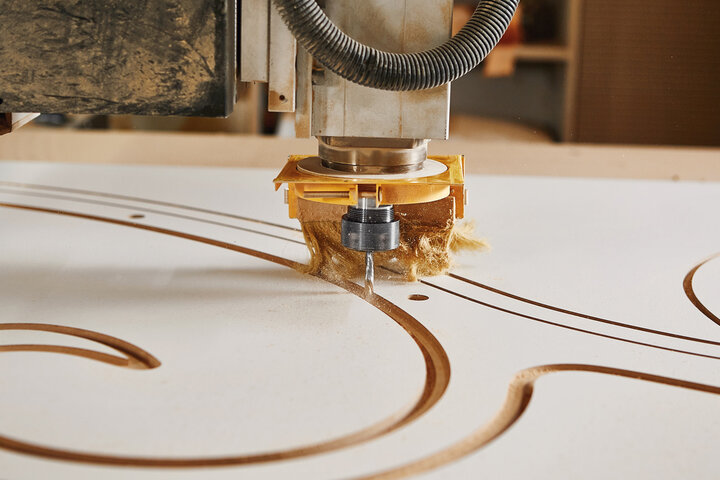

While executing any cutting task, a wood router machine combines together the rotation of the spindle and the movement of the tool on the workpiece surface. The routing process employs router bits that cut into the material at fixed feed rates, and maintains appropriate cutting speeds for different types of wood.

The computer has the ability to control these systems, and depending on the time of the cutting process, the system changes the parameters of the cutting process according to the wear of the tools or others materials. A sophisticated depth/finish control system has been implemented between the spindle and work piece to enable such control during every cut cycle.

How Does CNC Wood Routing Work?

Programming CNC Wood Patterns

In other words, CNC router machines turn the digital layout of a design into its corresponding wood cutting instructions. A CAD-CAM system laden with powerful wood router software imports CAD drawings and develops optimized tool paths, while the CNC wood routing program also investigates how to best use materials in complex wood router works.

Operating Router Machinery

CNC Wood Router Bits: Range consists of straight shank cutters, v-cut bits, profile bit and others for routing purposes.

Speed of wood Router: Adjustable precision from thirteen thousand to twenty four thousand revolutions per minute eases cuts made for varying wood router jobs.

Feed Rate of a CNC Router: Self adjustment of the feed rate of the router ensures clean cuts with varying wood router composites.

Cutting Depth of the Router: Multi-pass programming allows intricate designs made with a 3D wood router.

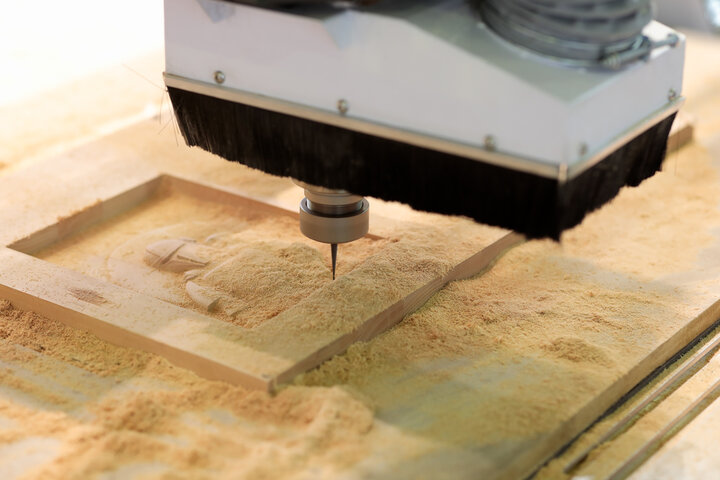

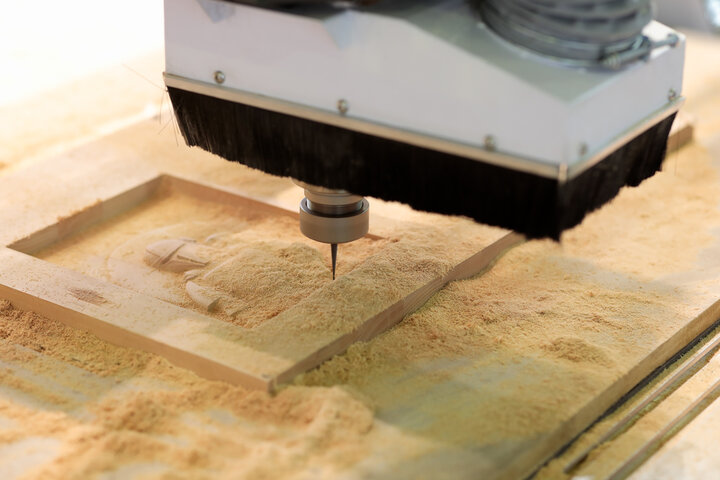

Wood Router Work Table: Vacuum based workholding allows for the fixing of workpieces while routing by CNC machine.

Controlling Material Movement

Movement of the workpieces is accurately controlled using a numerical control frame and a motion control software which utilizes an axis system placed on the surface of the wood router table. All of the axes are driven by industrial servo motors which are capable of holding specific positions even during complex carving processes of the wood routing machine.

With these advanced wood CNC router machines, there are systems that enable performance measurement in real-time and adjustments of the router parameters depending on the type of material being used. The control unit also guarantees the control of the quality of cutting in various ranges of wood routers, including those used for creating furniture parts and architectural details.

What Are CNC Wood Router's Advantages and Disadvantages?

Advantages of Router Wood CNC

Accuracy & Uniformity

CNC wood routers achieve extraordinary levels of accuracy and operate within tolerances of up to 0.001 inches or even lesser. This mechanical accuracy is beneficial in that it ensures uniformity in the results over a range of pieces thus eliminating human influence when productions runs have to be done. Be it intricate pieces of art or furniture elements, it goes without saying that each and every carving is executed with the same level of precision.

Automated Timeliness

These machines could be run without break, completing full-scale vision into the final product at a significantly lower time than the time consumed by hands. A single machine is capable of working on several jobs at the same time, provided that the quality remains the same. This type of workflow does away with excessive time and costs that would have been incurred in carrying out the same tasks manually within professional workshops.

Design Adaptability

The latest CNC technologies comfortably interpret an image digitally and produce the same; ranging from a straight forward cut to a detailed 3D sculpture. With modern engineering tools, a designer is not confined to creating only the best designs since changes can be made up to the last minute without incurring any material costs. This means that overly complicated shapes, designs and customizations can be done without the limitations of hand rendering.

Low-Cost Manufacturing

The considerable expense upfront can be justified by CNC routers by delivering positive returns after some time due to less labor force and less material waste . The mechanized process of production has its advantages as it brings down the costly mistakes and avoidable production work. The operational rate in turn helps to maximize the capacity of the workshop.

Disadvantages of Router Wood CNC

High Initial Investment

The setup of a CNC routing system calls for a considerable amount of money, which includes the purchase of machines, and procuring the software licenses and plus installation costs. Other costs include training of operators and buying necessary equipment such as dust collection system. Such a financial commitment can be very difficult for small organizations as they embark on their automation journey.

Specialist Skills Required

One needs to be skilled in both woodworking and computer technologies to operate the CNC machines. The operators have to be familiar with CAD/CAM systems and how to program them, and to work with different kinds of equipment. Such a requirement of technical knowledge implies that there is a high level skill that woodworkers who cannot work automated systems easily face when learning to use them.

What Are the Industrial Applications of CNC Wood Router?

Custom Furniture Manufacturing

The use of Wood CNC router machines can change the furniture production processes for better and more systematic ways. Modern router wood systems ensure that complicated joints and patterns can be cut accurately. The CNC router for wood kept a fair level of precision across all the furniture router jobs, while standard wood router bits implemented in all projects brought about decorative features.

Cabinet Making and Kitchen Installations

Modern wood cutting CNC routers have introduced automation in processes such as drilling, easing the processing of cabin panels. The wood routing machine accurately positions the system holes of 32mm while mobilizing the 32mm routing system of other tools. Industrial-grade CNC routers facilitate the manufacturing of cabinet faces and the inner parts in a more organized manner.

Architectural Millwork

CNC wood router systems with high power have the capacity to produce architectural details. The router machine for wood molding produces moldings and panels of high complexity. Highly advanced designs of CNC wood router involve furnishings like trim work and embellishments made on the wood using custom-made router bits.

Musical Instrument Production

Precision CNC routers for wood are made for crafting different wood parts of the instruments. The wood router machine provides superior performance in control of dimensions for acoustic purposes. In addition, complex router wood tooling technologies employ special wood CNC routing strategies to generate surfaces with complicated curves.

Exhibition and Display Manufacturing

Custom displays for retail purposes are fabricated using commercial wood router machines. The use of CNC routing technology allows for fast modelling of display parts. Examples of professional router projects in woodworks include interlocking framing systems and display boards made on vertical CNC wood router tables.

Door and Window Manufacturing

Nesting cnc systems for wood allow for fully automated door and window frame fabrication lines. The moulder machine accurately cuts mortise and tenon timber joints. Sophisticated CNC timber routing systems also allow for the multi-directional processing of timber router parts.

Pattern Making and Prototyping

With advanced tommorow's technology, CNC wood routers enable the manufacture of patterns for industrial use. The wood routing technology allows for simple change of designs within a short time. Production wood router machines equipped with special router bits, can create compact and complex patterns with sharp accuracy.

How to Maintain CNC Wood Router Systems?

Performing Regular Maintenance

A consistent check-up schedule on the router bits observes that their cutting edges remain sharp, while a periodic cleaning of the wood router table surface ensures that no debris builds up. Spindle bearings of the wood routing system should be lubricated at intervals as per the manufacturer's recommendation.

Taking care of the collection system as intended ensures that the CNC router for wood is in perfect operating condition. Vacuum seals on router wood tables should be checked on a regular basis by the operators, all contamination control elements should be cleaned, and the levels of suction checked to ensure the work-piece does not displace during wood CNC routing processes.

Solutions for Common Issues

High-end wooden router machines can also run out of alignment and would have to be calibrated after a certain period. The CNC router operator should check for any indication of axis movement wear and the tension of belts on the router wood systems, as well as the tool offset accuracy. Periodic assessment of the wiring and connections of the wood routing machine also helps in averting electrical system malfunctions.

In CNC woodworks, the quality of cutting is influenced by the state of the router bit. Therefore, Staggered tool replacement schemes for wood router bits help in managing the usage of cuttingtools. In order to assure the optimal cutting quality, it is fundamental to periodically check the spindle run out and the collet condition of a wood router machine.

Standards for System Calibration

Calibration methods for wood CNC routers guarantee uniform machining precision. The system for routing wood necessitates periodical checks of the perpendicularity of axes and the adjustments of motion control settings. Suitable for industrial use CNC router devices must undergo tests for positioning accuracy every now and then with the aid of laser measuring tools.

Sophisticated woodworking equipment undergoes periodic updates on the features installed and their validation. The control software of a CNC wood cutting machine should not forget to back up the machine parameters including the tools employed. NJ router machine’s operators are required to keep proper and updated records of all calibrations done for adherence to quality control standards.

Key Differences Between CNC Wood Router and Metal CNC Mill

Speed and Power Characteristics

CNC routers for wood work allow the use of higher spindle speeds, ranging between 13,000 up to 24,000 RPM on average. These routing operations performed at high speeds help enhance the quality of cuts in wooden materials. On the other hand, metal milling machines operate at lower speeds that average from 2000 to 10,000 rpm in order to provide the metal cutting torque needed.

Commercial grade routers use spindle power in the range of between 5 and 15 hp where surface speed is favored than cutting force. On the other hand, Metal CNC milling machines are equipped with much more powerful spindle motors, usually more than 20 horsepower, for the spindle to cut through hard metals.

Tooling and Holding Systems

Metals cranking out machines employ more rigid toolholding systems, such as BT40 or CAT40 taper equipment, which can endure considerable cutting forces. The wood routing machine usually makes use of less heavy-duty holders such as ISO-30 or HSK-63 that are suitable for fast wood processing operations.

CNC router bits for wood are not the same as metal cutting cutters since they possess a different geometry, having their own rakes and flutes for chip removal. In metal mills, custom made carbide tools are used with coating techniques that withstand heat and prolong life in cutting steel.

Work Area and Construction

CNC routers which are built for wood processing usually come with higher working envelopes which are mostly 4’ by 8’ or 5’ by 10’. This is to enable working on sheet goods. Metal milling machines are similar in that they also have work envelopes that are smaller in dimensions of the actual machine. However such machines are made much heavier so as to avoid any vibrations that would affect the cutting process.

Woodworking routers incorporate some work-holding systems that work on vacuum principles, while metal cutting routers mostly use mechanical clamping in T –slots and vises. The frame structure of the wood router machine is designed to take in overly large format workpieces. But metal mill design incorporates constructed barriers for cutting processes with much accuracy.

Material Removal Process

CNC wood routing allows for the removal of material at a relatively higher speed and with lesser cutting forces, more appropriate for the characteristics of wood fibers. However, this is not the case in metal milling operations where high cutting forces are used to cut metals at low speeds in order to control the heat generated and chips formed in metals.

The wood router machine is highly proficient in surface shear and cut-out pattern making in flat works as well as in complex three-dimensional forms. On the other hand, the metal mills are fitted with high-speed rotating cutting tools designed to remove material, contouring very accurately the material in several series of operations. Chip Coolant Systems are often available for these cutting units as on occasions cuts might be too deep and too hot to perform in one pass.

Table: CNC Wood Router vs Metal CNC Mill

| Feature Category | CNC Wood Router | Metal CNC Mill |

| Spindle Speed | 13,000-24,000 RPM | 2,000-10,000 RPM |

| Power Rating | 5-15 horsepower | 20+ horsepower |

| Tool Holders | ISO-30, HSK-63 | BT40, CAT40 |

| Table Size | 4'x8' to 5'x10' typical | 2'x4' typical |

| Workholding | Vacuum system | Mechanical clamps, T-slots |

| Frame Construction | Aluminum/Steel hybrid | Solid cast iron |

| Typical Applications | Sheet goods, panels, furniture | Parts, molds, dies |

| Cutting Strategy | High speed, light cuts | Low speed, heavy cuts |

| Material Removal | Surface profiling | Precise depth control |

| Coolant System | Dust collection | Liquid coolant |

| Movement Speed | 1000+ inches/minute | 100-400 inches/minute |

| Accuracy Range | ±0.005" typical | ±0.0005" typical |

| Common Materials | Wood, plastics, composites | Steel, aluminum, alloys |

| Tool Life Focus | Surface finish quality | Heat/wear resistance |

| Machine Cost Range | $20,000-100,000 | $50,000-500,000+ |

Ready to elevate your woodworking capabilities?

TEAM MFG brings you professional-grade CNC wood routing solutions backed by industry expertise. Our dedicated team of CNC specialists provides around-the-clock support, ensuring your production never stops. Contact us today to discover how our cutting-edge wood CNC machines can transform your manufacturing process.

24/7 Technical Support

Expert Consultation

️ Professional Installation

✅ Reliable After-sales Servic

Frequently Asked Questions (FAQs)

Q: How do I select appropriate router bits for various woods?

When choosing router bits, one should take into account the hardness of the wood as well as the direction of the grain. For instance, carbide tipped CNC wood router bits are more durable and can better serve professionals who work with harder woods. Moreover, the feed rate and RPM should vary with the diameter and number of flutes on the bit. It is advisable to use compression bits in plywood applications for a better finish.

Q: What are the operational and safety features should I have in CNC wood routers?

When it comes to the basic safety features, there are always e-stop buttons, the cutting chamber is always enclosed, and there are dust containment systems in place. In modern wood router machines, access panel safety interlocks and automatic brake systems for the spindle have become a requirement for the safety of the user.

Q: Why does my CNC router leave burn marks on hardwood?

Burns that occur during woodworking usually come from using the wrong feed rate or using a router with a worn out bit. During the wood routing process, heat is generated and should be controlled by appropriate cutting conditions. Such surface burning is avoided through regular sharpening of tools and proper adjustment of cutting speeds.

Q: How much 'effective' space do I need for placement of a CNC woodrouter system?

Commercial-grade CNC Router installations call for space that exceeds that of the machine's footprint. A standard 4’x8’ wood router table requires, on average 15’x12’, total area inclusive of dust collection and material storage areas.

Q: What machine upkeep schedule would I need to observe to ensure maximum efficiency of the machine?

The cleaning of router bits and dust collection checks are some of the everyday maintenance practices. Limbering the guide rails and checking belt tension are among the activities performed once every week. Inspection and re-calibration of the system in its entirety together with a tooling check is what is involved wood CNC router maintenance after every month.

Q: Is it possible for me to add further functions to my CNC router for even more complex wood projects?

Most woodworking router systems enable add-ons such as tool changers, bigger spindles and vacuum table zones extensions. The control system of the CNC routing device can also be enhanced with sophisticated software functionalities for advanced wood router design projects.