Have you ever puzzled over the reason why some makers are obsessed with cast iron while others go gaga over cast aluminium? This choice can determine the direction and the future of a project in the highly dynamic world of manufacturing that we live in now. Whether it is that a person is engaged in designing aircraft components or creating machinery for the industries, it is important to know these metals and how they differ from each other.

Welcome to metal casting. We are going to examine these two material manufacturing and learn more about metal castings. For example, we are going to compare such factors as strength, wear resistance, cost and environmental friendliness and you are going to make the best sawn depending on the application of each of you.

Let's explore what makes each material unique and discover which one is right for you.

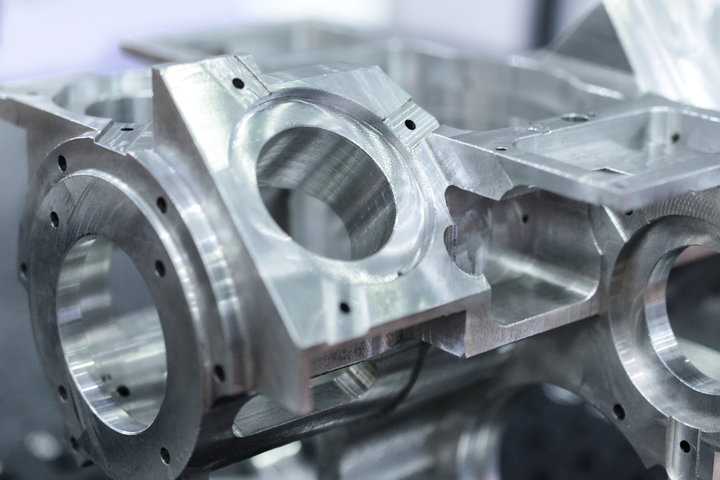

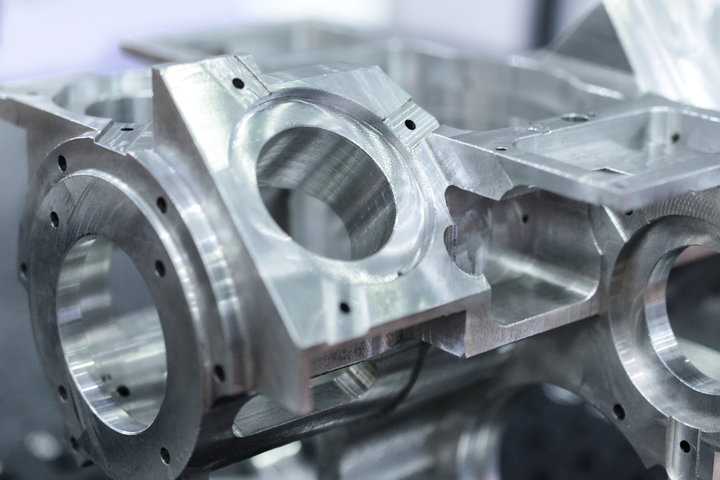

Understanding Cast Aluminium

Description and Definition

In contemporary mass production schemes, cast aluminum is an extraordinary technological innovation. It is a material of choice merging the lightness of pure aluminum and the strength of its elements. It comes as a result of the combination of the basic aluminum and some additional alloying materials including silicon, copper, and magnesium. Each of the components contributes some useful decay resistance and casting ability to the castings. The enhanced mechanical and physical properties yielded make it such that it is considered one of the most soluble ones for a variety of different practical cases in industry. Besides this, its high–light weight value can also help lower production costs of various structures since additional materials other than aluminum are not required.

Process of Aluminium Casting

Completing the task is the procedure of transforming raw aluminium into meticulously crafted articles or products through a complex series of production stages during which some particular technical and environmental requirements must be followed with precision. Primarily, this would involve the base aluminium and the other added components being subjected to an even and controlled heating process which usually rises and falls from around 650 to 750 degrees Celsius and a viscosity point is usually achieved wceyln;casting is then followed by one of the following methods:

Die casting utilizes high-pressure injection into permanent steel molds, ensuring dimensional accuracy and smooth surface finishes

Sand casting employs temporary molds created from special sand mixtures, offering flexibility for larger components

Permanent mold casting combines the durability of metal molds with gravity-fed pouring techniques

Lost wax casting enables the production of intricate designs with exceptional detail and precision

Temperature control is most precise and involves slow change in cooling rate and temperature; in this context, giving special care on the heat transfer process of the metallic materials to avoid soil fissures is also crucial as it is beneficial in the form of ensuring optimal material of forms on the workpiece, that is, helping to prevent distortions as much as it is possible.

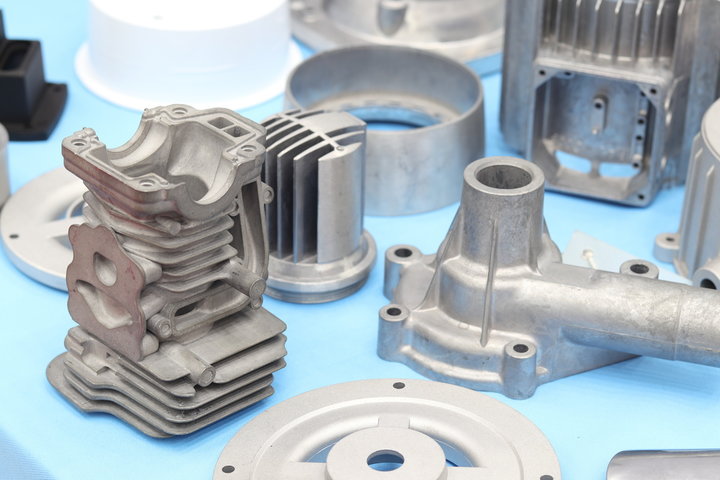

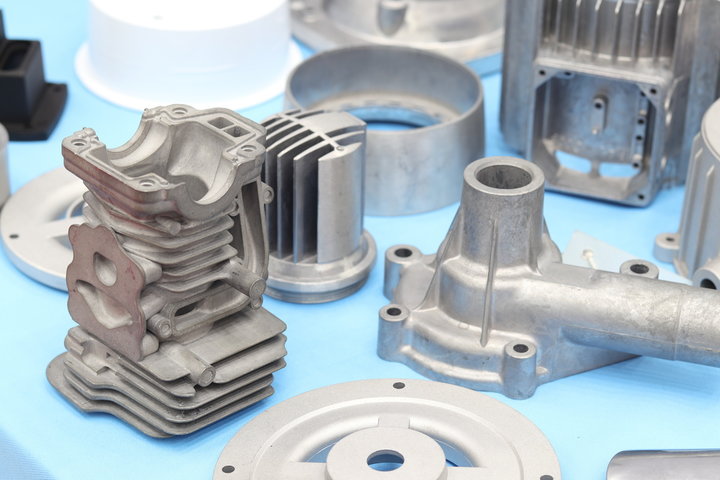

Understanding Cast Iron

Description and Definition

Cast iron is a ferrous alloy containing more than 2% of carbon and it is combined with iron to mold compounds such as silicon, manganese and occasionally chromium or nickel. This, in turn, bursts with unbelievable tensile strength and wear comfort, while the qualities of the iron are greatly reduced by the presence of graphite in the form of greys or spherulitic flake .Vibrational auto-mechanical analysis of cast iron".

The properties of cast iron are also controlled by its internal microstructure.Errors may occur in the formation of graphite and a type for a given application is formed due to the cooling rate and alloy composition. This structure also ensures that cast iron has excellent thermal conductivities as well as superior impact resistance properties. Cast iron finds use in a variety of applications as a result of these properties.

Process of Iron Casting

When it comes to cast iron, maximum control on a range of issues is compulsory with the very first one being the choice of original materials. Carbon and Alloy elements, according to their specified proportions, are added to the charge which is then melted in an appropriate furnace at 1,150-1,4000C. During the technological process, qualified metallurgists keep an eye on the specified composition to achieve desirable structure.

Sand casting represents the most common foundry practice and is the method where the cavities of a primed sand casting are filled with metal. After the industrialization of the sand mold and core production process, metal can be cast directly into the pre-prepared molds as provisional molds are used. Close surveillance is maintained also during the cooling and solidification stage to achieve the desirable characteristics of the material produced and avoid defects.

This procedure features the application of metallic mold made of mold steel which is in turn given specialized treatment known as heat control that helps achieve the desired surface and inner quality of the machinery. An advanced technology which is a great advantage for this foundry is cooling, applied during the manufacture to achieve the same characteristics and tolerances of mass production as in the sample.

Key Differences Between Cast Aluminium and Cast Iron

Weight and Density of Cast Aluminium and Cast Iron

At 2.7 g/cm³, for instance, its density compares favourably to that of cast iron, which is around 7.8 g/cm³. This distinction is why uses of this material becomes highly recommended in instances where the removal of matter lessens the effort and provides better useful machine performance. The aluminum components are known to be easier to carry as they have less weight hence reducing the cost of transportation and the easiness in handling during the installation and in case of repair which is an improvement that has become a phenomenon in the weight reducing paradigms in the modern manufacturing environment.

Strength and Durability of Cast Aluminium and Cast Iron

Varying as they are, the top allowance sg materials, cast iron especially, which is favored cover others on the subject of the compressing energy, the general and sustained loading and other conditions that are unbearable. Forged aluminium, however, surpasses cast iron in tensile properties and impact force strengths. But for aluminium strength, candybar phones can be preferred in space, especially this is ata's indication in newengland region.

Cast iron stands out by its most effective wear resistance that makes it highly applicable where there is frictions with very high forces, but in terms of these applications, the element’s low impact strength limits its use. This material in distinction to the craft of alloy ferrous encourtes less brittleness and heat control, such that it becomes abundant in light, shock resistant and fatigue free design applications. For example, it is possible to take advantage of this particular fact, in components with high cycle fatigue in the-intonation or even in the-linguistic context such is tremor.

Corrosion and Weather Resistance of Cast Aluminium and Cast Iron

Aluminum casting has innate potential of creating oxide coats which are very effective at resisting corrosion in even harsh conditions. This inbuilt advantage is beneficial because it relieves the users from the agony of maintenance coats throughout the service life. The material retains its initial characteristics and strength regardless of the changes in weather conditions over time.

Even though it is generally the more robust material, there are caveats attached to its use due to the need of iron. Corrosion damages the iron and therefore especialy in the presence of water the plates need to be carefully maintained or painted to prevent surface rust. The oxidation in Iron rods often is not counteracted by stopping the one layer because it continues through 20 layers more. But when taken care of, there is an ability for Iron to last for several more decades in harsh conditions.

Thermal Properties and Heat Resistance of Cast Aluminium and Cast Iron

Cast iron has solid heat holding abilities and working at any given temperature is easier to do given adequate knowledge. Cast iron is not ideal for every circumstance. In cases that need even heat distribution or temperature control, the simple properties of very low heat contain within the iron becomes very useful. The use of this material’s resistance to distortion even at temperatures of up to 1000°C has historically placed cast iron as the preferred material for cooking utensils and even furnaces for industry that heats.

Low thermal conductivity of cast aluminum allows heat to remain in the product long time enough to get to the user. Cast aluminum has the quality of being extremely heat-conductive and most especially in cases where the user requires efficient cooling. This applies mainly to industries such as automotive and electronics, where the proficiency and lifespan of products is determined by heat regulation closely. Lower specific heat in the material allows a faster change in temperature but it may cause the material not to be as effective in maintaining a steady-state temperature as cast iron.

Environmental Impact of Cast Aluminium and Cast Iron

There are several reasons why cast iron can be considered to be a sustainable material, however the most important one is the fact that the material, if maintained properly, can serve for quite a long time, which in turn would offset the higher carbon footprint in it's initial installation. Its production will normally incorporate more energy intensive steps, although the possibility of using some recycled materials will help reduce its negative impact on the environment. Subsequently portability of the machines poses disadvantages to the equivalent, the more or less heavier material to be transported, but the ability of being recycled used in building sustains its advantageous exploitation.

The environmental comparison with those materials includes factors such as maintenance and management during operations as well as disposal of worn out materials at the end of their useful life. The most notable environmental improvement as far as cast aluminium is concerned is in it being less maintenance intensive limiting that usage of the chemicals. Where Cast iron would be expected to be more frequently maintained and re-coated, and although because of its robustness and ability to be aged thus reducing the need to replace and hence reducing associated environmental costs.

Pros and Cons of Cast Aluminium and Cast Iron

Advantages and Disadvantages of Cast Aluminium

There are many reasons why manufacturers in different sectors have found the use of cast aluminium attractive. The lightweight characteristics allow for rapid mill which in turns reduces the lead-time of production. The weight reduction also helps in adding fuel efficiency, significantly lowering the overall operating costs of the fancy vehicles. As a result, a lightweight material, such as cast aluminum alloys, has to be used whenever possible to reduce the cost of operation of an automobile.

Protection against corrosion and the ease of application as well as the advantages of protection performance properties and the useful life of the service system server, are some of the other reasons why cast aluminum, is preferred over other materials for certain application locations.

The beneficial properties of cast aluminum also mean that it has other advantages in the application the heat transfer is maximized or at least is a target where the conductivity of materials is essential. Another advantage that cast aluminum presents is ease of application. There are a number of factors contributing to this. For example, cast aluminum can be coated, painted and finished in the manner available on the prints. These considerations allow for good aesthetic and functional fixing and finish in the design of cast aluminum products.

Finally, cast aluminum allows for some objective useful thickness in the design of given products since cast aluminum is quite a strong material for its unit mass, i.e. provides high strength with less material.

However, cast aluminum does not have disadvantages that allow for impulsive adoption. There are aspects which are specific to this kind of materials and which need special treatment. The ultimate mechanical strength in tension of cast aluminum among others is lower in comparison to some other materials. Therefore, high stresses constraints some of the applications of this material. True, the cost of the casting process is usually prohibitively high especially at the initial stages of the project development and completion. Nevertheless, the results are no transportation charges are incurred. This has the effect of reducing the overall costs since transportation costs over long distances are also avoided. Furthermore, in view of the conditions of use in some instances requires that caution is employed in the design of components.

Advantages and Disadvantages of Cast Iron

The consistent popularity of cast iron is due to the many good sides on it that are of great value to people. This has been proven applicable in almost any process where cast iron has yet to be replaced. It is known for its extreme ability to support forces and is used in frame based applications where forces would just be unmanageable. The reason why cast iron is popular in machinery is that it sucks off excess vibration and noise from the environment. This also helps the equipment stay off the ground and reduce the noise infecting the vicinity. These additional qualities of being heavy also make cast iron the material to use to where heat needs to be held together for example cooking.

Quite the opposite, cast iron’s production is reasonably economical, this holds well in larger production systems. It also has a high machinability that allows for existence of precise dimensions and finishing that are to be done on the surface of any material and high wear resistance that enhances service life in the presence of high friction. Furthermore, in higher temperature applications there is no creep on the material. This means that the material will not change shape at high temperatures.

In certain foundries and shops that make castings, cast iron will always be welcomed due to the preceding reasons. But it is also a limiting factor when selecting the material for a particular application. For example, its large weight necessitates additional expenses for transport and complicates the procedure of installation. Cast iron corrosion requires setting up a maintenance cycle in the areas where the material is used and also anti-corrosion coating in case of high humidity levels. The presence of cast iron in systems also brings an issue of fragility through which the constant applicability in situations where the impact load is present can disrupt the elementary structure and result in collapse before the engineering design has reached all the required geometric dimensions.

The mechanical properties of the material depend strongly on the temperature hence the stress distribution in the structural configurations can be greatly affected by such heat up and cool down sequences. The tensile strength of cast iron is lower than in some other materials that offer compressive strength.

Applications of Cast Aluminium and Cast Iron

Key Industry Applications and Analysis

Cast Aluminium Industries:

Aerospace ManufacturingParts, engine casing, and furnishings of lightweight aircraft construction where fuel efficiency and energy production capacity can be advanced.

Automotive ProductionEngine block, transmission casing, and frame or other key structures of vehicles where fuel efficiency and energy production capacity could be victimizing whilst refurbishing.

ElectronicsScrew mounted semiconductor devices, fiber glass components, and backbones of lattice structures for thermal management of electrical components, and electronic enclosures where both thermal and electromagnetic properties need to be handled properly.

Modern ArchitectureAny efat elements ‘bricks/blocks’ including panels and masonry elements plall margins of the building excluding the partition and the glazing element.

Cast Iron Industries:

Heavy ManufacturingMachine tool bases, industrial equipment frames, and pump housings requiring superior vibration dampening and compressive strength.

InfrastructureManhole covers, drainage systems, and structural supports where durability and load-bearing capabilities are essential.

Power GenerationTurbine housings, valve bodies, and equipment bases requiring thermal stability and wear resistance.

Traditional ConstructionBuilding columns, radiators, and architectural elements where historical authenticity meets structural requirements.

Comparative Applications

| Industry Sector | Cast Aluminium Applications | Cast Iron Applications |

| Transportation | • High-speed vehicles

• Aircraft components | • Heavy equipment

• Railway components |

| Marine | • Above-water structures

• Speed boat components | • Engine blocks

• Ballast systems |

| Energy Sector | • Renewable energy components

• Solar mounting systems | • Traditional power plant equipment

• Pressure vessels |

| Consumer Products | • Outdoor furniture

• Sporting equipment | • Cooking equipment

• Decorative items |

Tips on Making the Right Choice Between Cast Aluminium and Cast Iron

Requirement for Material

Determine all the features, which are important in creating your product: its ability to bear loads, conformability to working conditions, targets relating to quality, durability, etc. Evaluate how well each of them fits to the material in question.

Assessment of Mass Effects

Question the requirement for mass minimisation in the design. The use of cast aluminum instead of cast iron will lead to a weight reduction of up to 65% thereby lessening the transportation and installation costs.

Climate Constraints

Consider the degree of hazard of the environment in which the structure is to operate. Alloy forms rapidly and naturally protects aluminum from corrosion and dissimilar metals attack ranking much better than iron which requires more than just the anodizing treatment of it.

Thermal Requirements

Find out the heat management requirements of the structure. Aluminum has high thermal conductivity and heat dissipation and conversely, cast iron demonstrates very high heat retention ability and thermal stability characteristics.

Budget Analyze

Discover all of the costs encompassing various life cycle expenses from the material purchase costs, delivery costs, erection costs, maintenance and operation periods and the functioning of the structures through.

Care for Technical Adjustments

Define what resources are available for care. Cast aluminum will provide a service without need for constant supervision while in case of cast iron, series of actions is necessary in order to protect surfaces against corrosion or the maintenance of protective layers.

Factory Production VolumeAlways think about production size before fabricating. For large quantities, cost considerations may favor the use of cast iron, whereas small scale productions can be cheaper with cast aluminum applications.

Component GeometryCheck the design difficulty of the component. The figures presented by the manufacturer's medium range materials do not compare with those of cast iron including the factors of beams and columns. Cast iron components are simple in shape and do not have digressions.

Material Property RequirementsMatch material toughness to locations of high stress. These contradictory requests are solved by the following: use cast iron with high compressive or loads and cast aluminium with better tensile strength and impact resistance.

Social and Environmental ResponsibilityTaking into account the environmental factors, the use of cast aluminium should be encouraged because such materials are easily recycled and have a lower carbon footprint.

Ready to Transform Your Manufacturing Project?

At TEAM MFG, we bring over two decades of expertise in both cast iron and cast aluminum manufacturing.

Custom Solutions for Every Need From prototype to mass production, our state-of-the-art facilities deliver precision-engineered components that meet your exact specifications.

Expert Material Selection Support Not sure whether cast iron or cast aluminum is right for your project? Our engineering team provides professional consultation to help you make the optimal choice.

Quality Guaranteed ISO 9001 certified, delivering world-class quality with competitive pricing.

Contact us today!Get your free quote within 24 hours

Reference Sources

Cast iron

Aluminum

Frequently Asked Questions about Cast Iron VS Cast Aluminum (FAQs)

Q: Please explain the fundamental differences between cast iron and cast aluminum

The major differences between them concern weight, strength and thermal characteristics induced in cast iron as opposed to cast aluminum. The level of weight that they have is different in the sense that cast aluminum has 2.7 with cast iron having 7.8, with other properties such as the compressive strength and heat retention being appealing in favor of cast iron.

Q: Which material is more cost-effective in the long run?

While the initial price of cast iron is often lower, over time, it is more economical to use cast aluminum in many applications because of reduced surface treatment costs, reduced transportation costs and high resistance to corrosion.

Q: How do environmental conditions affect the choice between cast aluminum and cast iron?

Cast aluminum is a better choice when used in conditions which have corrosive properties owing to the natural oxide layer it possesses. Cast iron on the other hand requires some other protecting which cause some cost, but they are best in high temperature applications.

Q: What are the key maintenance requirements for each material?

Natural durability capabilities in the air allow cast aluminum to have few issues when it comes to maintenance regimes. On the other hand, this is so far from the truth when we are talking of maintenance levels comprising of cast irons primarily, where their inspection should be regular, coatings and materials to prevent rust on them should be applied and even their protective coatings should be renewed.

Q: How do I decide which material is most suitable for my project?

Weight, operating environment, financial constraints, ease of maintenance and durability of materials, as well as the expectations of the application are evaluated. Both short and long term requirements have to be taken into consideration.

Q: What type of safety issues should I remember while operating with the deemed alloys?

Both materials are demanding while pouring and handling. There is less dust in machine operation of cast iron, which is however relieved by ventilation, when working on cast aluminium, the dust has to be controlled to avoid excessive thermal expansion during casting.

Q. Unlike iron, which applications are more suited to aluminum casting?

Applications that involve structures with lightweight construction, resistance to corrosion, and the ability of the material to absorb and dissipate heat, such as in aerospace components and electronic enclosures, are more suitable for cast aluminum.

Q: Are the waste recycling rates of cast aluminum and cast iron similar?

Cast aluminum is 100% recyclable and involves no degradation in quality with the process needing less energy for recycle. Cast iron can also be recycled but it may be resource-heavy increasing the cost of recycling.

Q: Which kind of structures more prone to failure when the considered materials are used?

While working with cast iron, it is generally the case that the material will fracture in a brittle mode in the vicinity of the region of interest even under low stresses, impacting loads for stress-concentrating areas. In the case of cast aluminum, on the other hand, fatigue and wear takes its toll in most cases of high-stress rather impact applications. The understanding of this assists in establishing contrary engineering determinations as well as parallel construction.

Q: How does the use of advanced techniques impact the preference for these system?

Novel constructive methods such as inclusion impregnation has allowed these two materials to increase their amounts with the formation of new compounds and the development of aluminum grades core in respect to tensile strengths while cast iron grades are worked on to reduce their weight by from material development considerations affecting the overall scheme of selection.